Detection device for intelligent machining

A detection device and intelligent machinery technology, applied in the direction of sorting, etc., can solve the problems of heavy manual labor, inaccurate detection, etc., and achieve the effect of easy screening or reprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

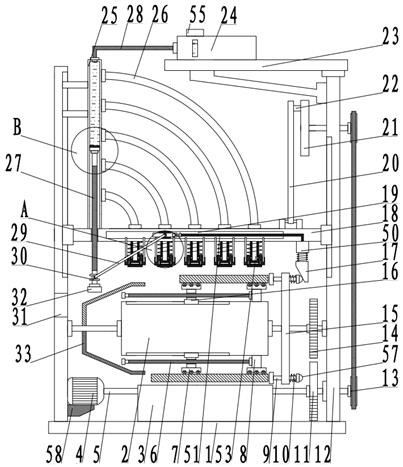

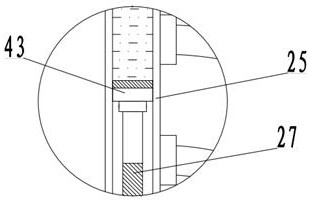

[0026] see Figure 1-6, a detection device for intelligent mechanical processing, comprising a base plate 1, and further comprising: a surrounding plate 12 fixedly arranged on both sides of the base plate 1, a feeding roller 2 is rotatably connected between the surrounding plates 12, and a movable plate 18 is arranged on one side of the feeding roller 2; Both sides of the movable plate 18 are slidably connected with the enclosure plate 12, and the detection mechanism 53 arranged on one side of the movable plate 18 includes a measuring cylinder 25, which is fixedly connected to the movable plate 18, and a sealing block 43 is slidably arranged in the measuring cylinder 25. , one side of the sealing block 43 is rotated and connected to the screw rod 27, one end of the screw rod 27 is threaded through the side wall of the measuring cylinder 25, and the end is fixedly connected to the mounting post 32, and one side of the movable plate 18 is fixedly set through the lower material cy...

Embodiment 2

[0030] see Figure 1-6 , the other content of this embodiment is the same as that of Embodiment 1, the difference is:

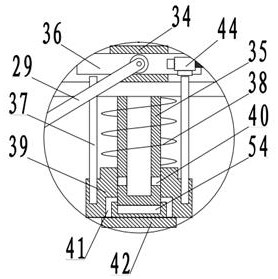

[0031] The transmission assembly includes an installation ring 30 that is rotatably sleeved and mounted on the installation post 32. One side of the installation ring 30 is hinged to the transmission arm 29, and one end of the transmission arm 29 is hingedly connected to the stop rod 36. A piston sleeve 39 at one end of the material cylinder 35, a material guide groove 41 is provided in the piston sleeve 39, a marking pad 42 is fixed at the end of the piston groove on one side of the material guide groove 41, and one end of the lower material cylinder 35 on the side of the piston sleeve 39 is sleeved A telescopic piece 38 is provided, and one side of the piston sleeve 39 is fixedly connected with the push rod 37 .

[0032] The feeding assembly 55 includes a top plate 23 fixed on the top of the enclosure plate 12, the top plate 23 is fixedly connected to the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap