Building formwork machining component, machining system and formwork machining method

A technology for building formwork and processing components, which is applied in metal processing equipment, manufacturing tools, auxiliary welding equipment, etc., can solve the problems of low formwork processing efficiency, achieve the effects of improving low processing efficiency, facilitating connection, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

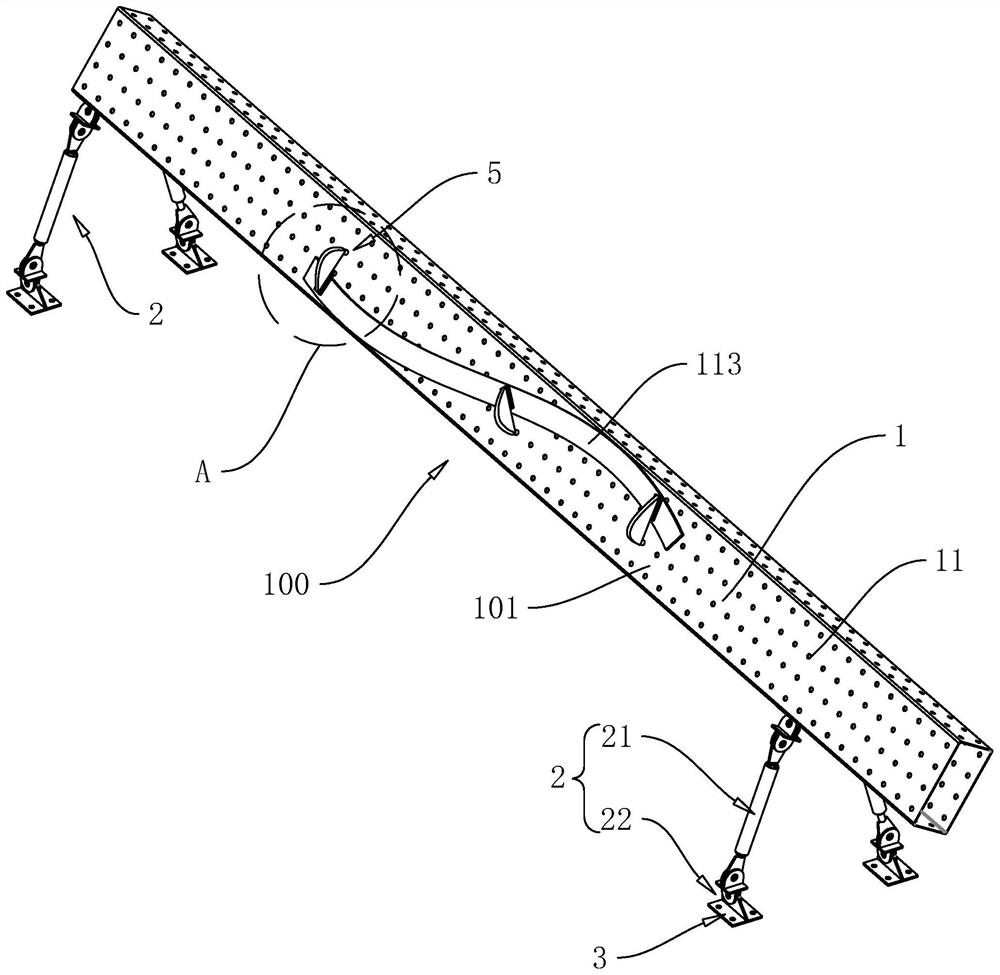

[0054] This embodiment discloses a building formwork processing component 100 . refer to figure 1 and figure 2 , the building formwork processing component 100 includes an installation base 3 , an adjustment device 2 , an installation top seat 4 and a beam 1 .

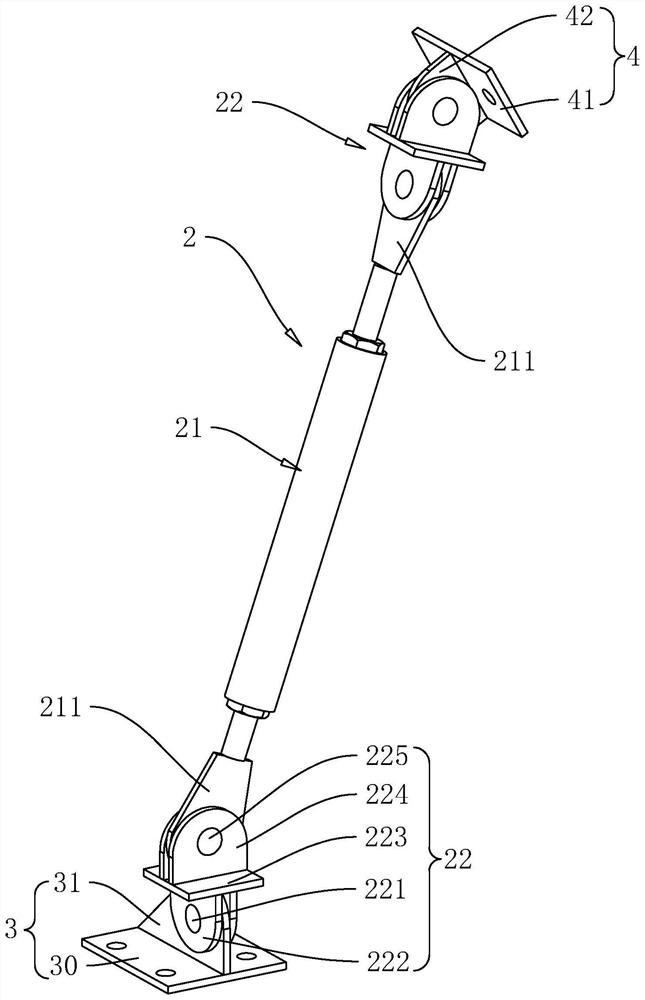

[0055] The installation base 3 includes a bottom plate 30 and a first convex plate 31 protruding from the bottom plate 30. The bottom plate 30 is fixedly connected to the flat plane by fasteners to realize the stable fixing of the building formwork processing member 100, and the first convex plate 31 is used for fixing. Adjustment device 2.

[0056]The adjusting device 2 includes a telescopic part 21 and at least one angle adjusting part 22 . In this embodiment, the opposite ends of the telescopic element 21 are respectively provided with angle adjustment elements 22 . The telescopic piece 21 is a hydraulic rod, a telescopic cylinder or a threaded screw, and the telescopic piece 21 can be self-locked after the tel...

Embodiment 2

[0065] refer to Figure 7 The difference between this embodiment and Embodiment 1 is that the number of adjustment devices 2 is three, two adjustment devices 2 are fixed to the same surface of the beam 1 , and the other adjustment device 2 is fixed to the other surface of the beam 1 . Three adjusting devices 2 can support the beam 1, which saves the use of materials.

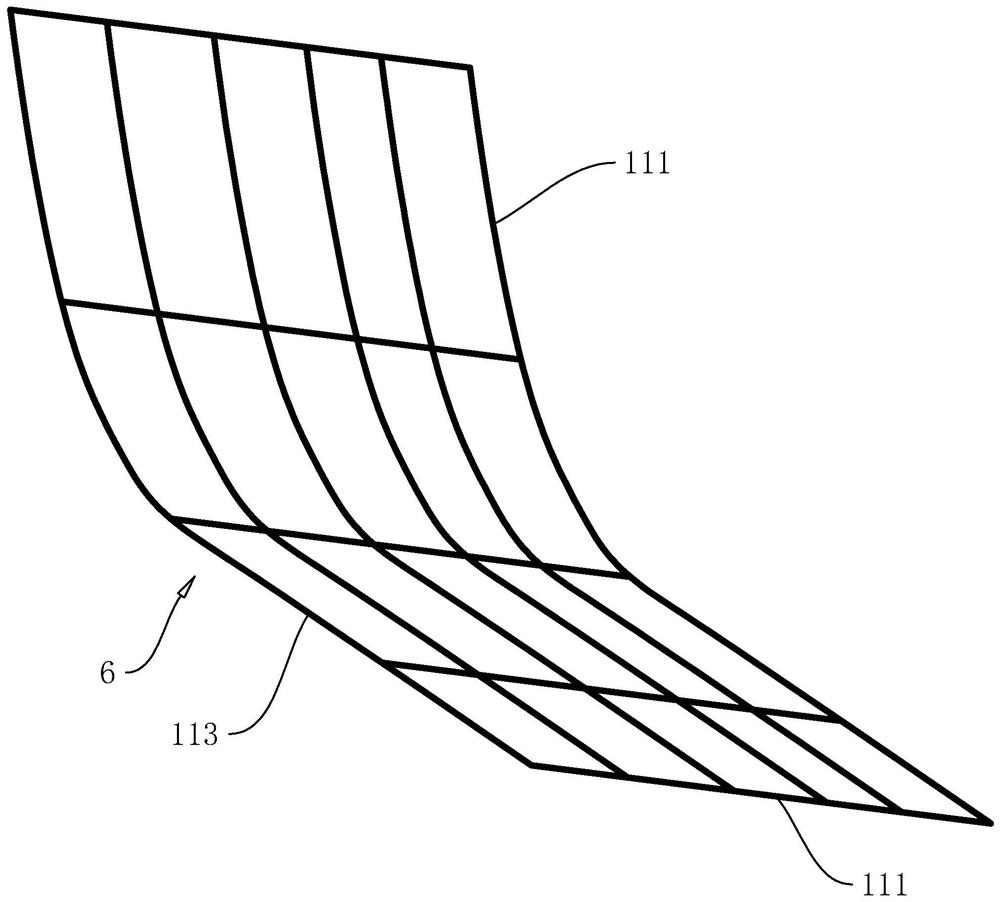

[0066] The embodiment of the present application also discloses a building formwork processing system 200 . refer to image 3 and Figure 8 , the building formwork processing system 200 is used for processing to form a building formwork 6 .

[0067] The building formwork processing system 200 includes a plurality of building formwork processing components 100; the beams 1 included in the plurality of building formwork processing components 100 can be enclosed to form a predetermined shape. This preset shape is determined according to the shape of the building template 6 to be processed, such as image 3 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com