Air conditioner outdoor unit assembling production line and axial flow fan blade grabbing device thereof

An axial flow fan blade and grasping device technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of high labor intensity, low production efficiency and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

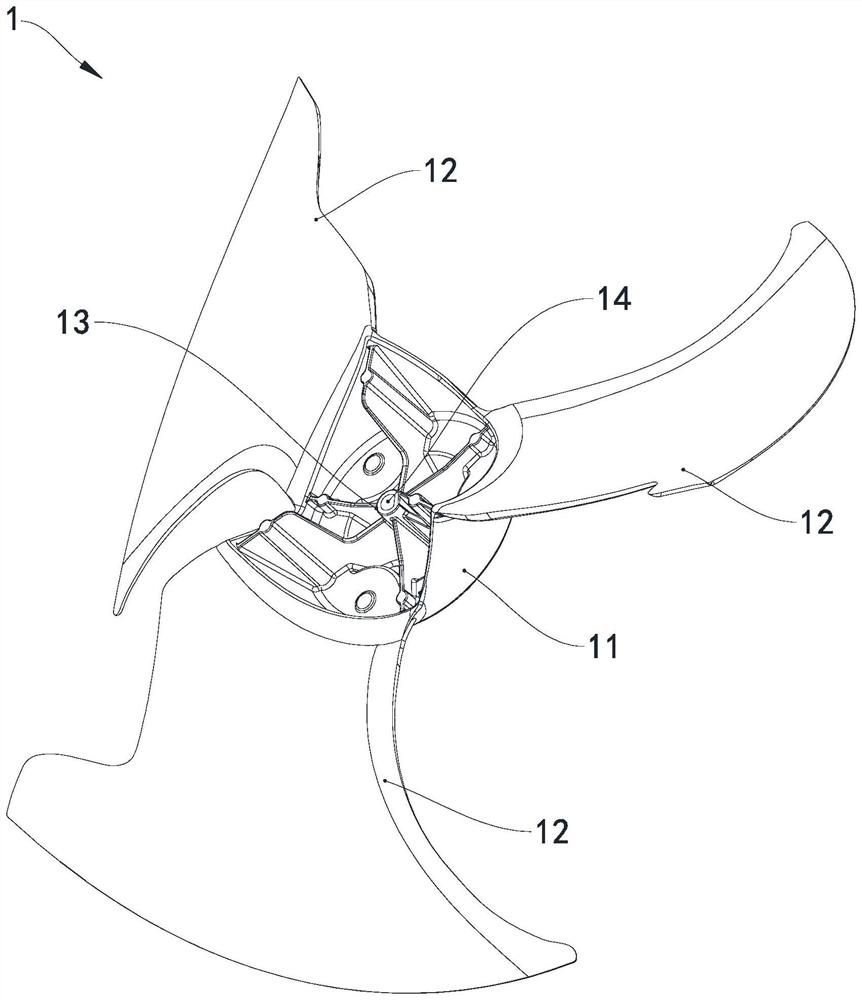

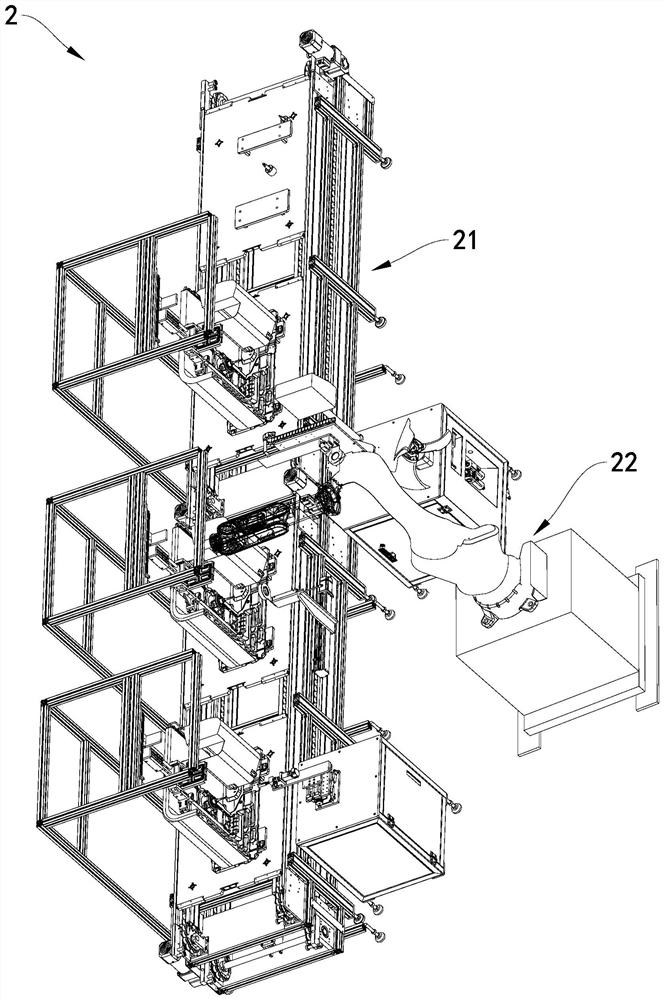

[0025] see figure 2 , the assembly production line 2 of the air conditioner outer unit in this embodiment includes a conveying line 21 and an axial flow fan blade grabbing device 22. The conveying line 21 is used for conveying the air conditioner outer unit assembly with a motor, and the axial flow fan blade grabbing device 22 is used for grabbing Axial flow fan blade 1 and press-fit axial flow fan blade 1 to the motor shaft of the motor.

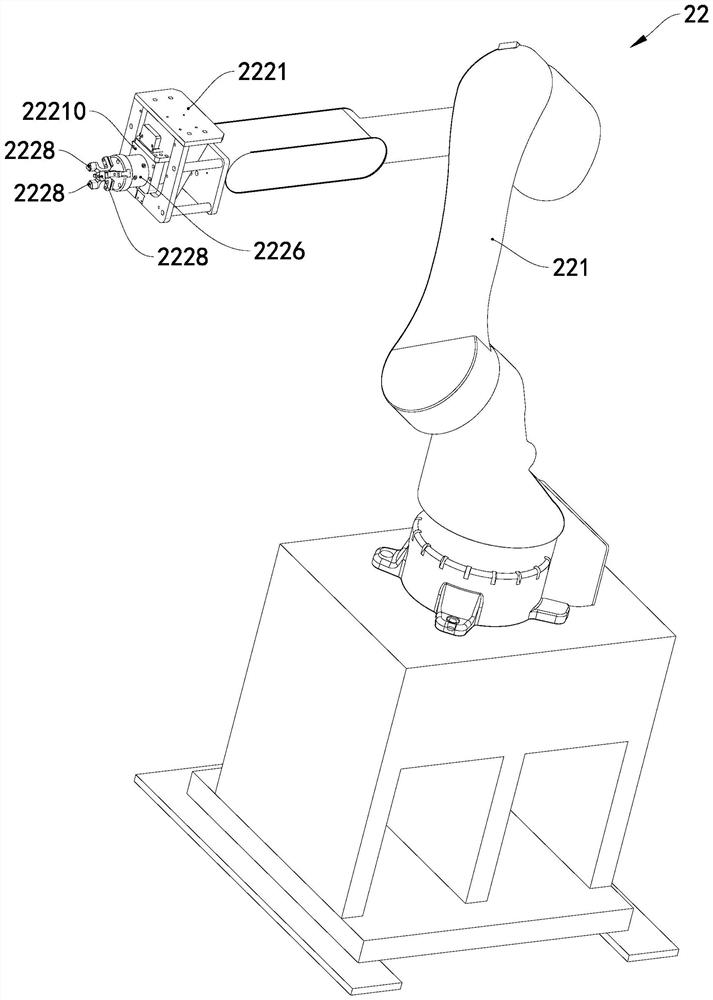

[0026] join Figure 3 to Figure 7 , the axial flow fan blade grasping device 22 in this embodiment includes an operation control mechanism, a support frame 2221, a positioning pin 2222, an elastic member, a drive control mechanism, a mounting plate 22210, a grasping control mechanism and at least two clamping jaws 2227. The operation control The mechanism can control the support frame 2221 to move and rotate in multiple degrees of freedom, and the drive control mechanism is disposed on the support frame 2221 and can control the mounting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com