Compression tool for fastening spring-back stop ring to piston rod of shock absorber of motor vehicle

A technology of limit ring and piston rod, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve problems such as difficult distinction, and achieve the effect of simplifying targeted control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

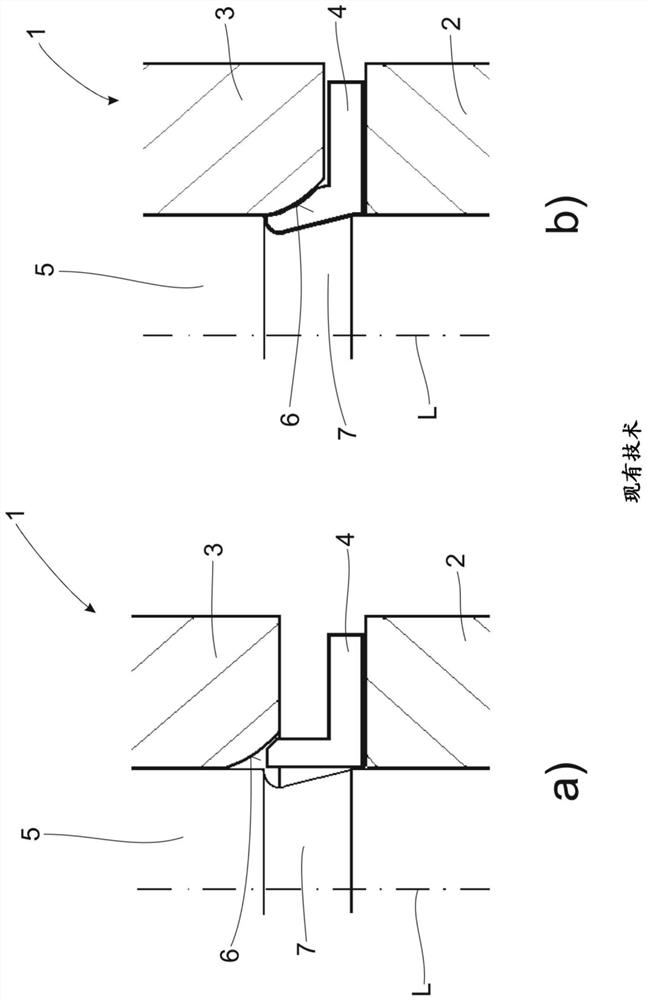

[0035] figure 1 The figures a) and b) show a pressing tool 1 implemented according to the prior art for fastening the rebound stop ring 4 on the piston rod 5 of the shock absorber. Here, illustration a) shows the initial position of the first workpiece 2 , the second workpiece 3 , the piston rod 5 and the rebound stop ring 4 shortly before the start of the tightening process. In this case, the press-in surface 6 of the second workpiece 3 is convex.

[0036] On the other hand, illustration b) shows the final state of the fastening process, after which the first workpiece 2 and the second workpiece 3 are moved coaxially to each other by fastening means not explicitly shown here to the extent that , the distance between the two workpieces 2, 3 is reduced to a final dimension defined by the system pressure of the fastening device. The rebound stop ring 4 is pressed in sections into a circumferential groove 7 formed on the piston rod 5 and surrounding the piston rod 5 , thereby f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com