Patents

Literature

33results about How to "Prevent over-pressurization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

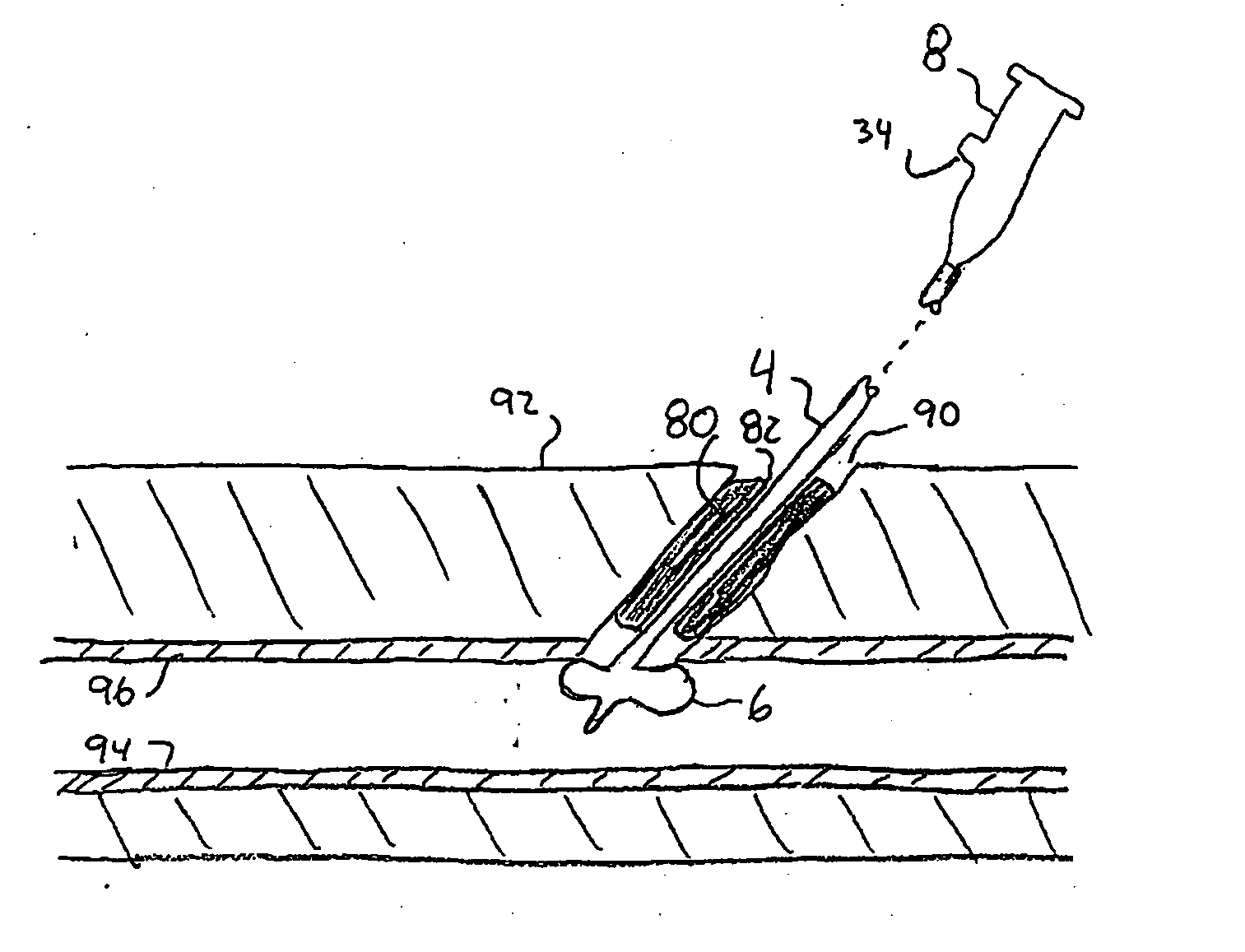

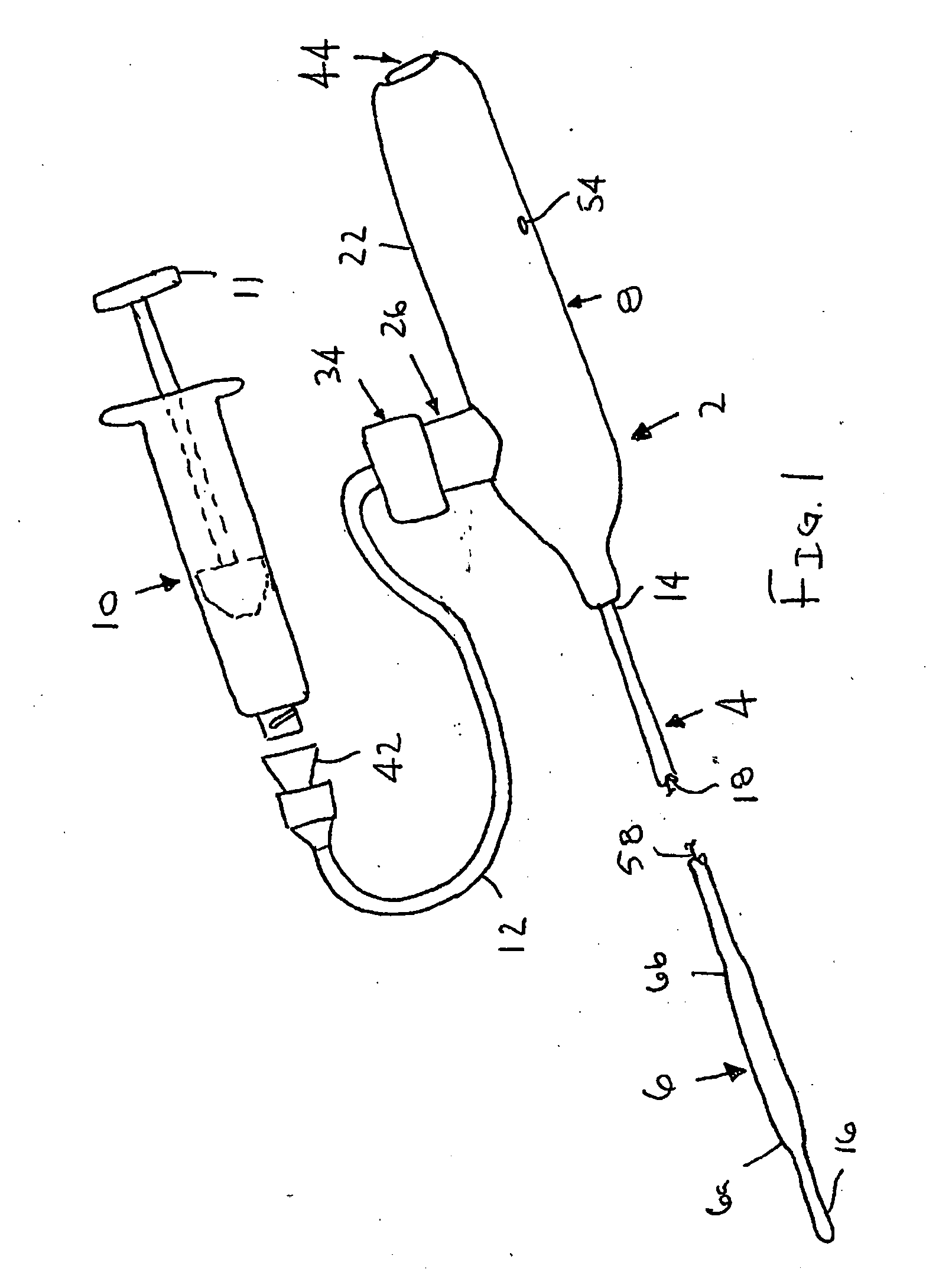

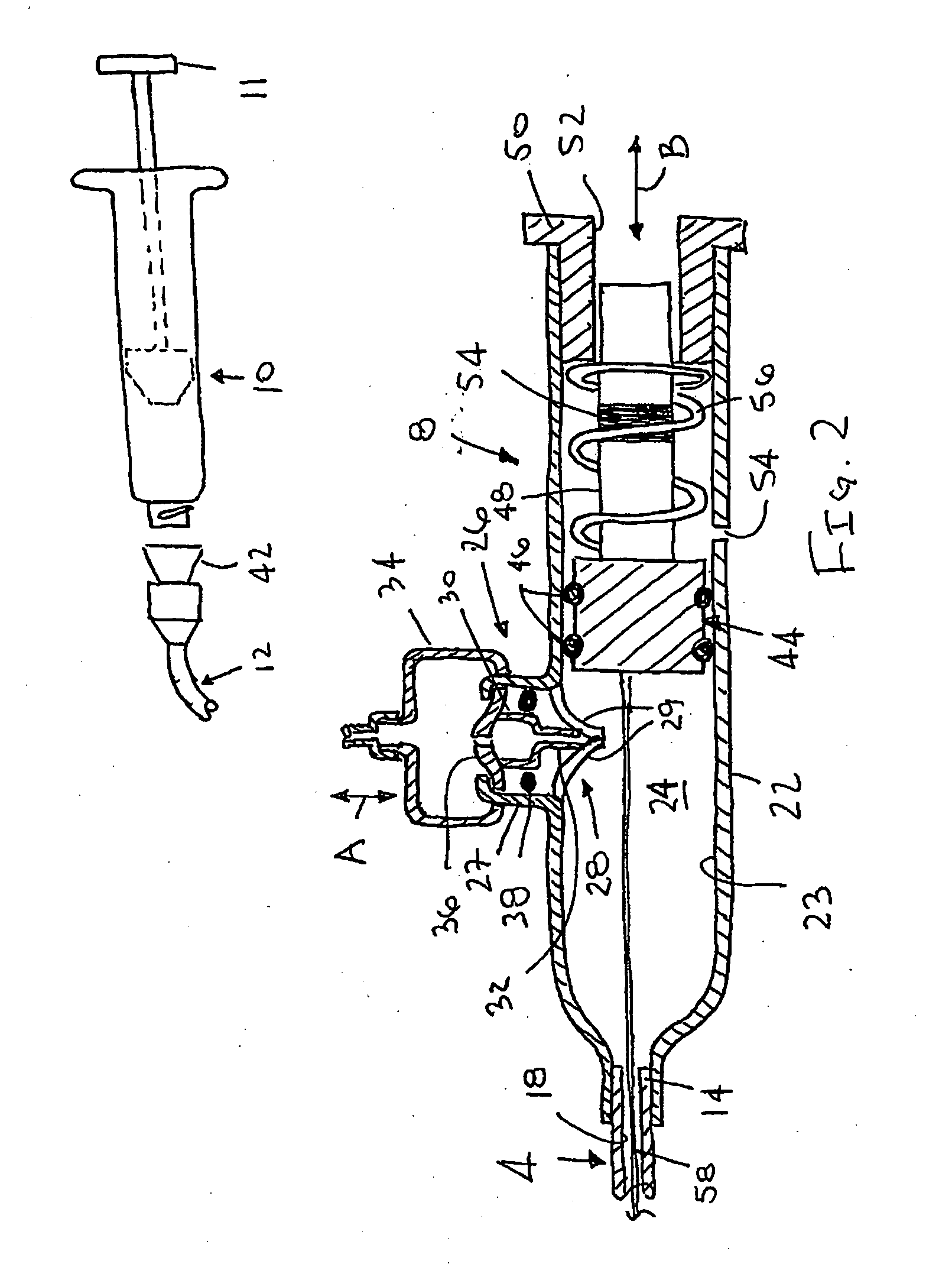

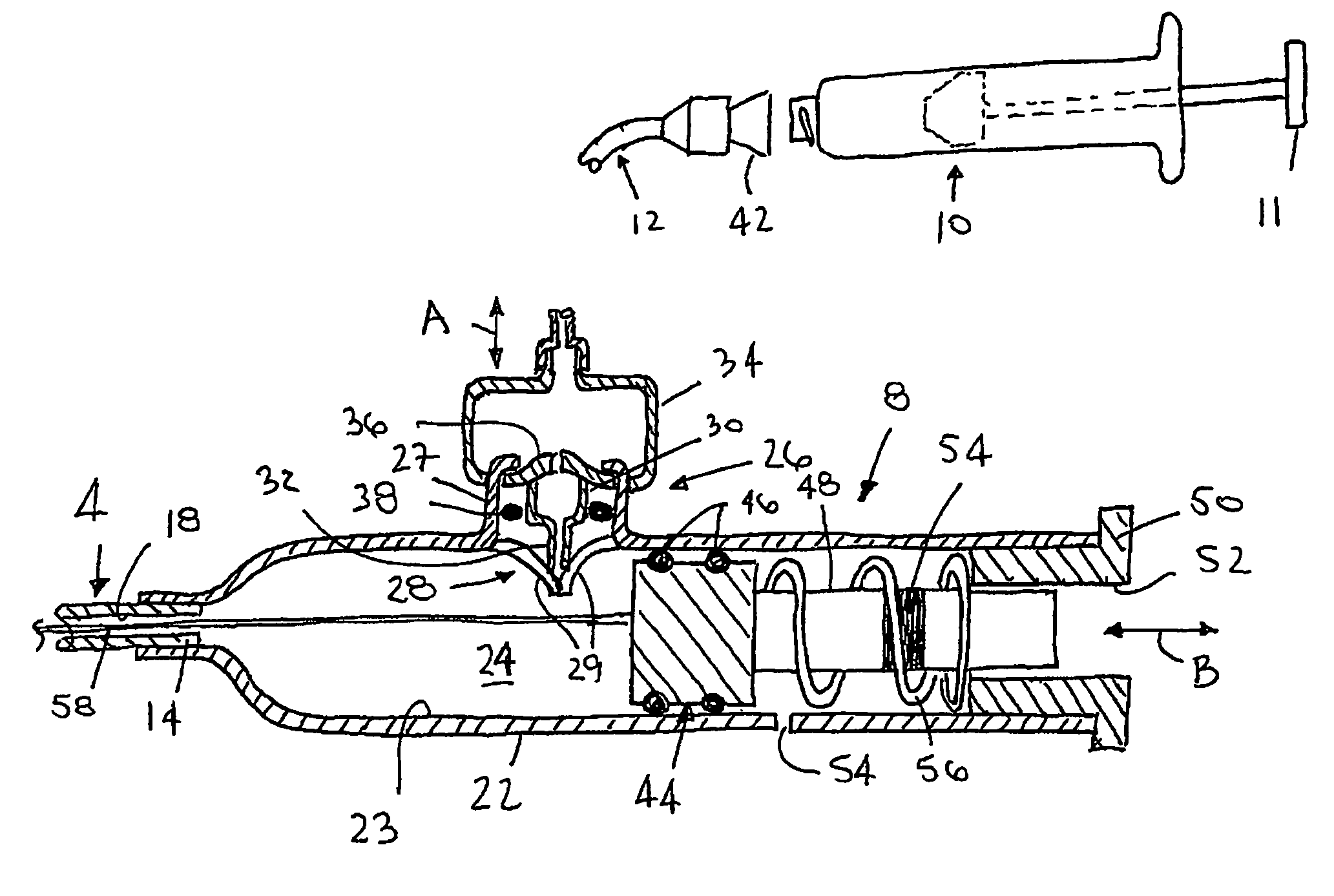

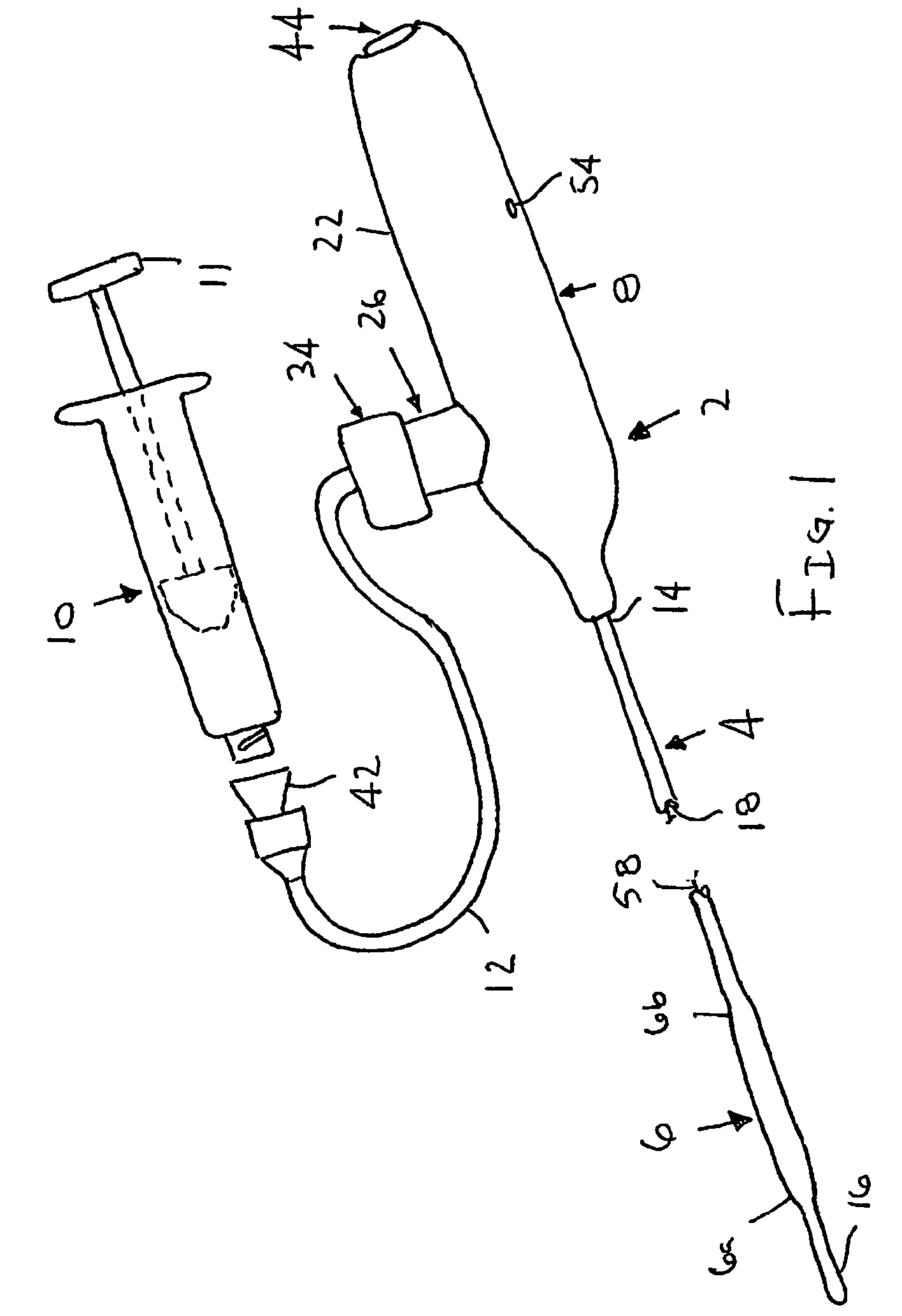

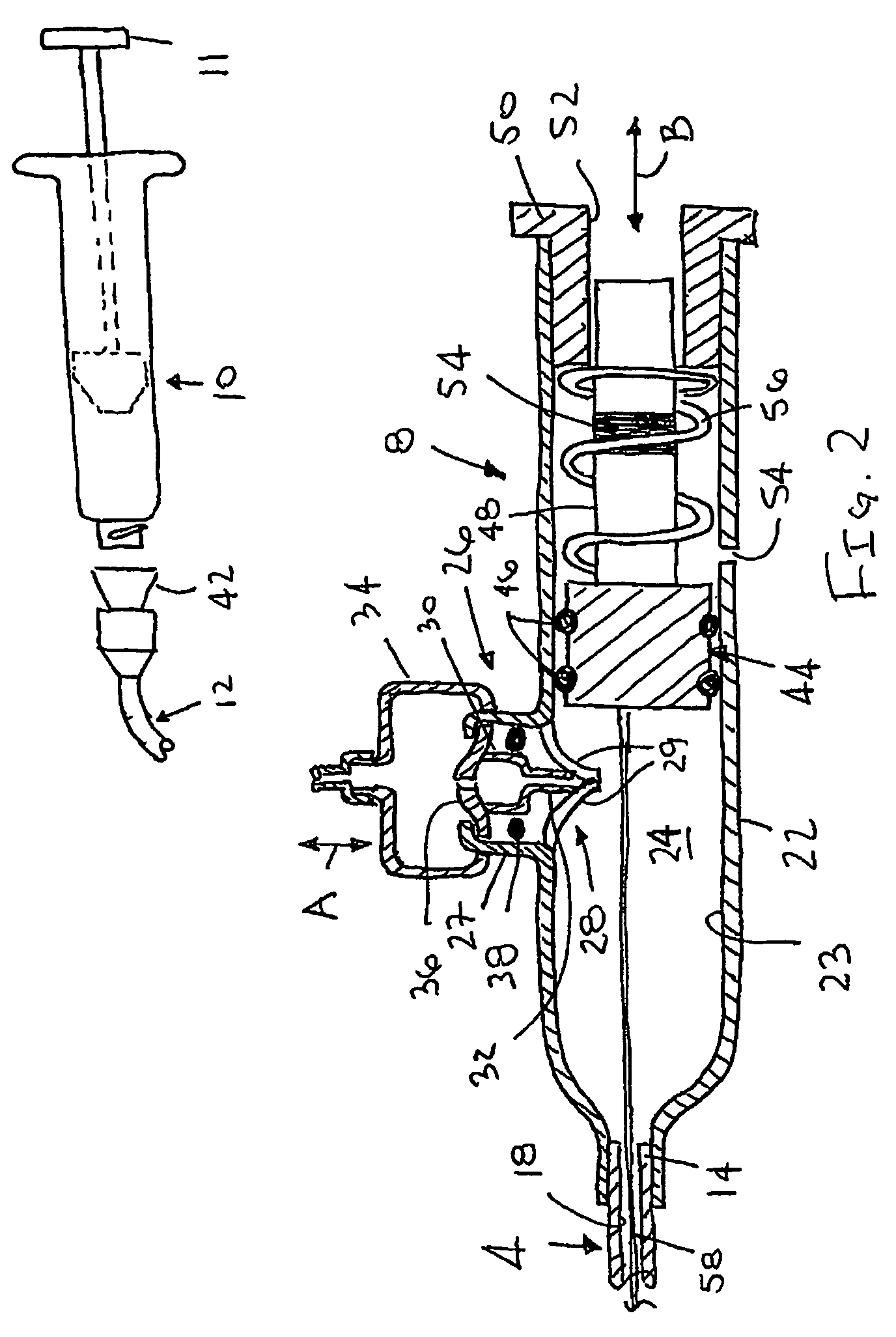

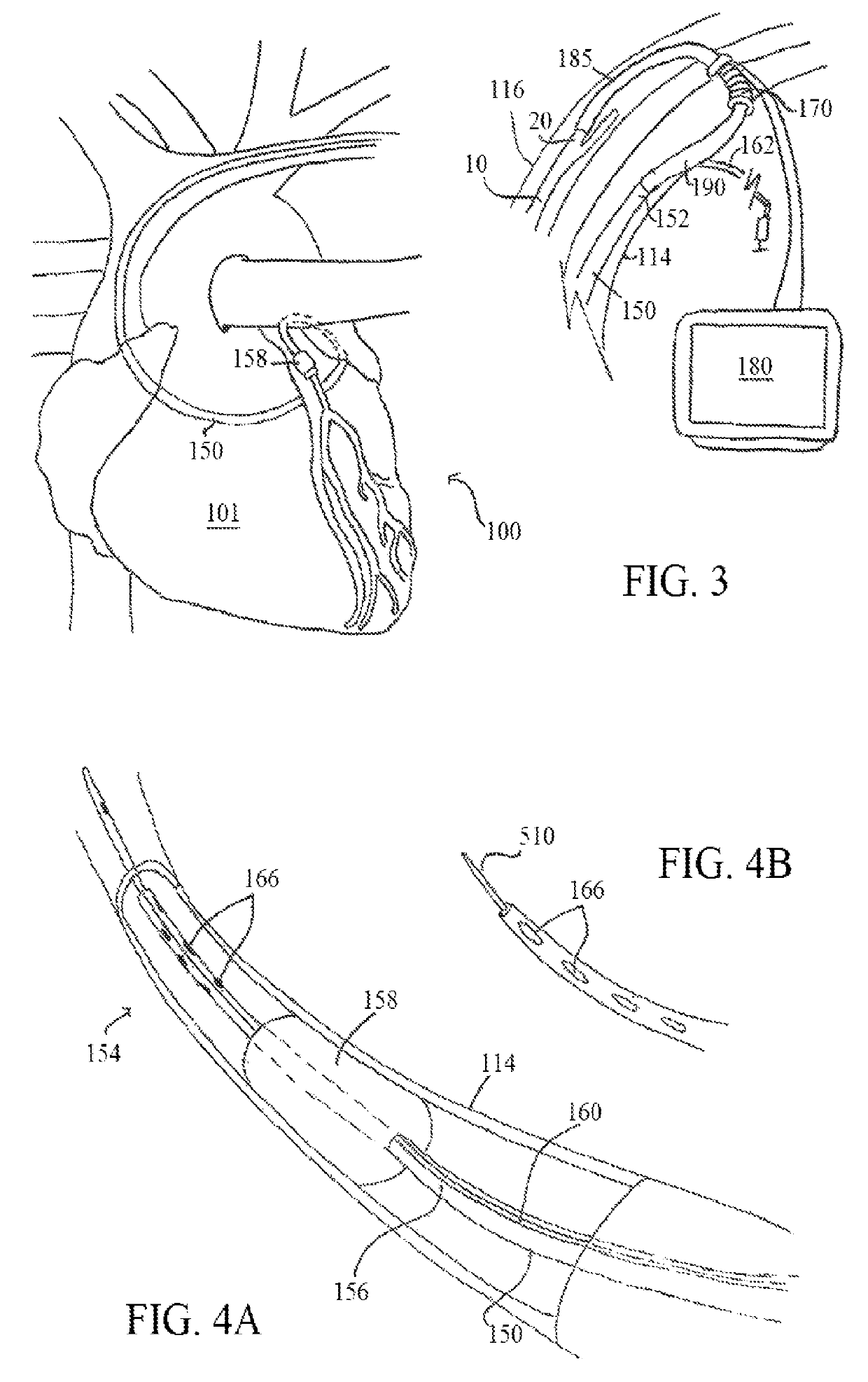

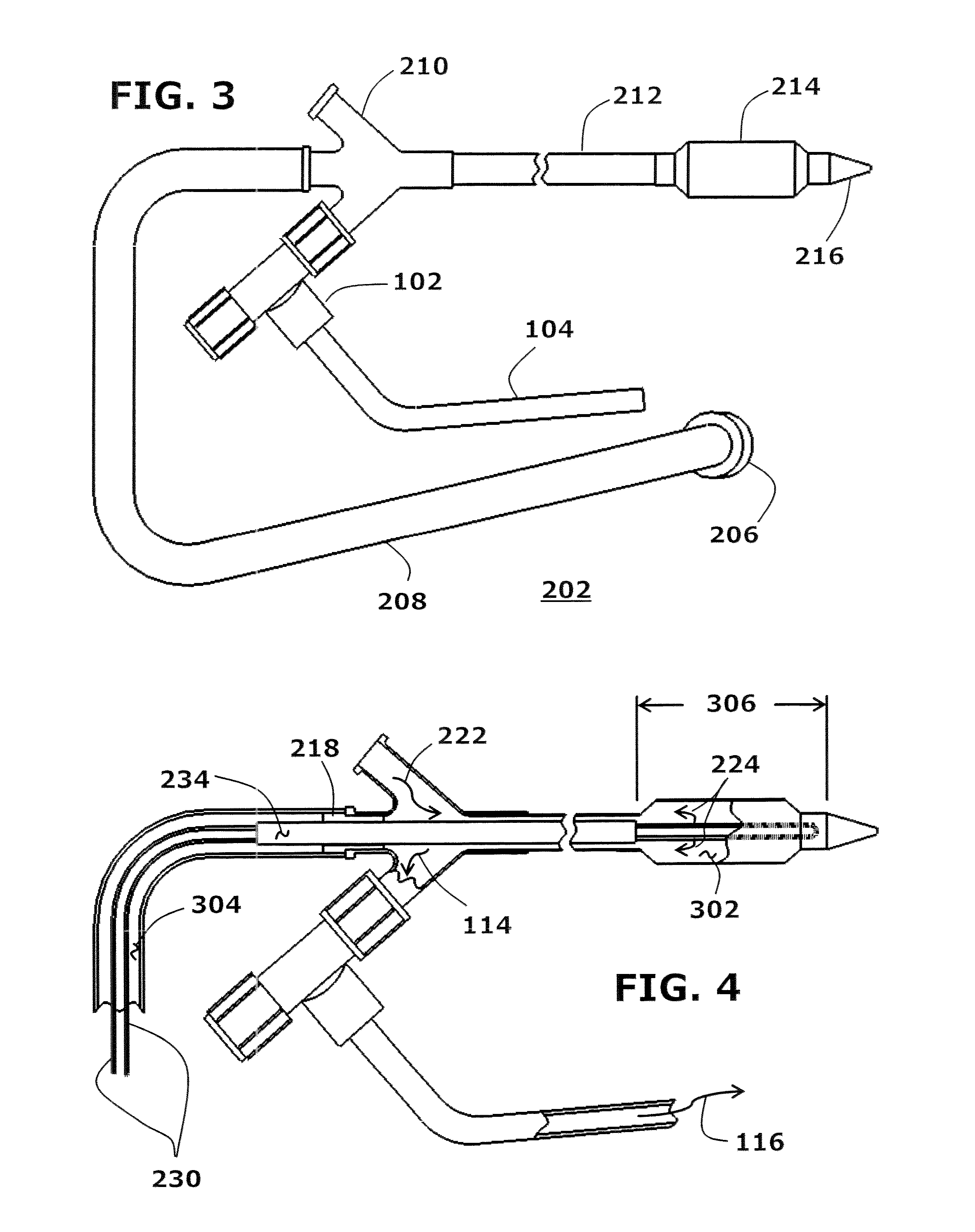

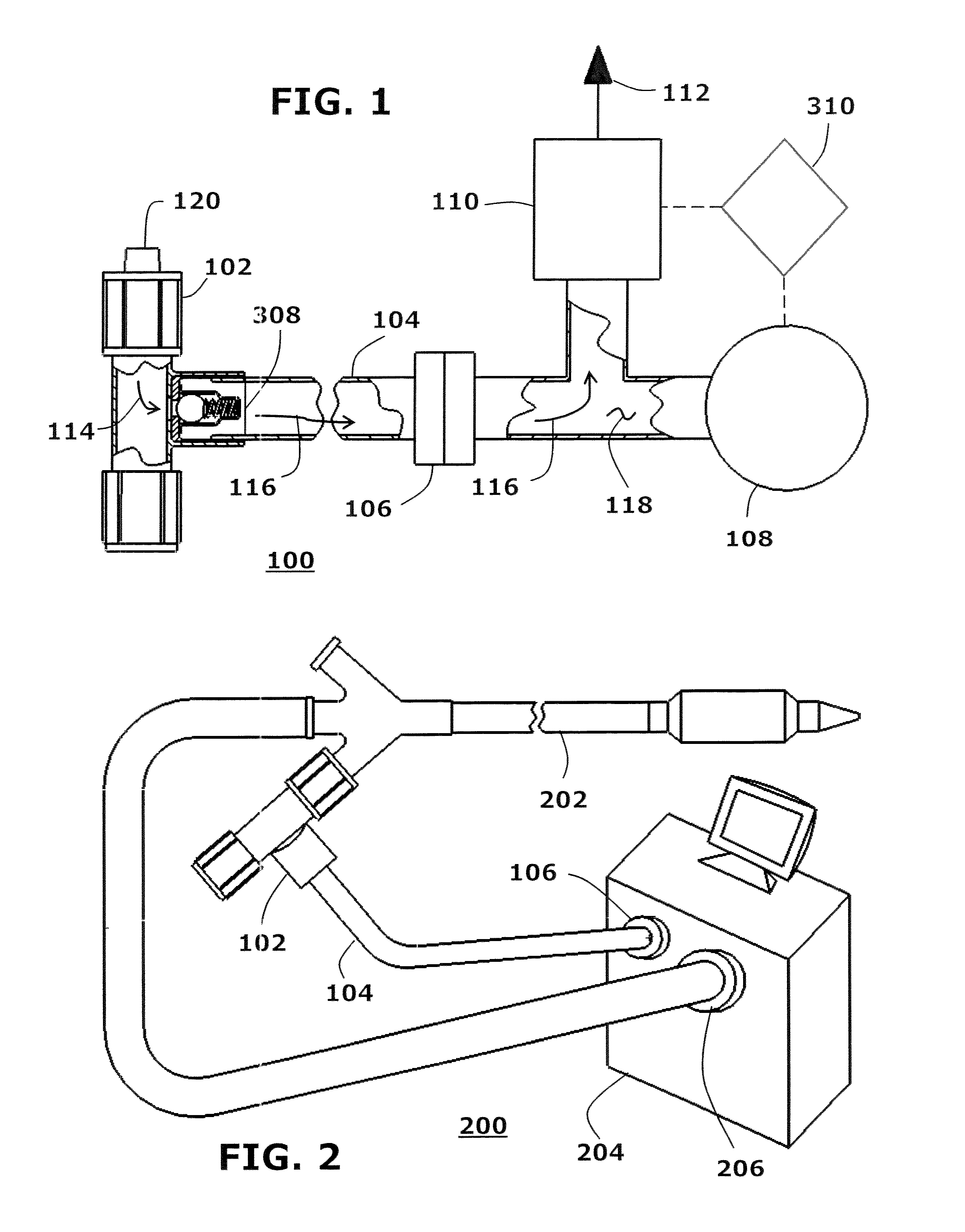

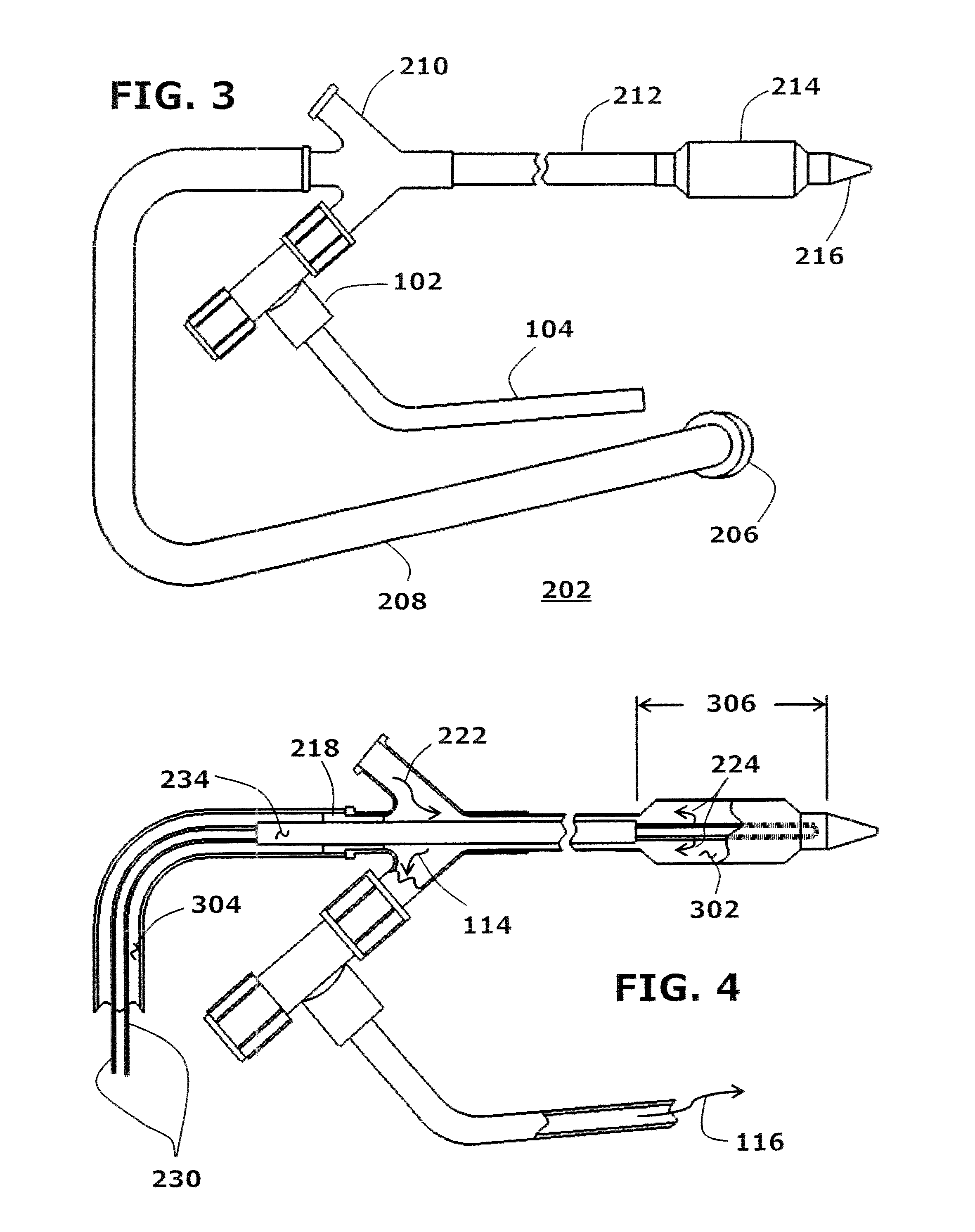

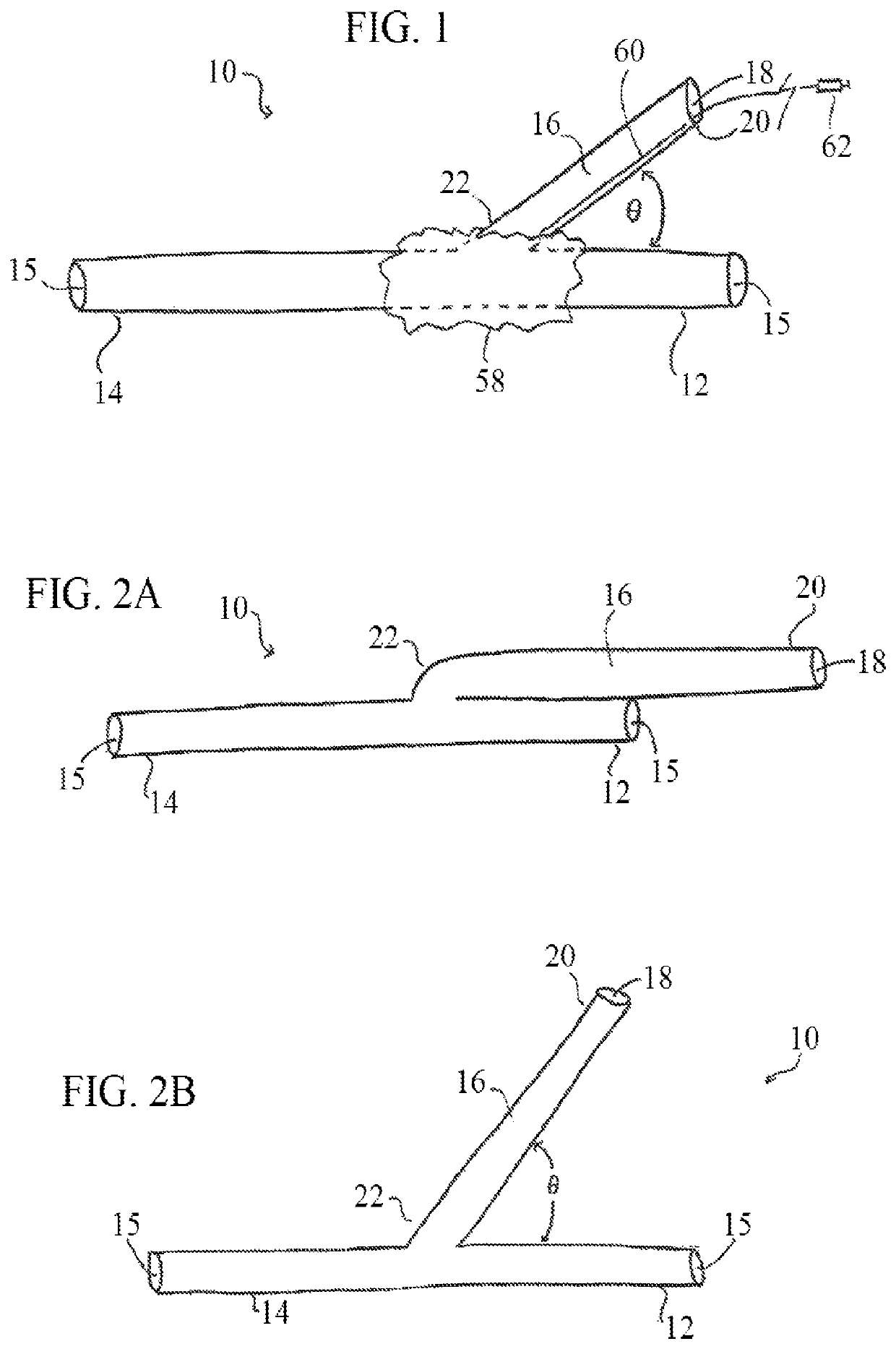

Apparatus and method for temporary hemostasis

ActiveUS20080009794A1Good hemostasisPrevent over-pressurizationBalloon catheterSurgeryVALVE PORTPlunger

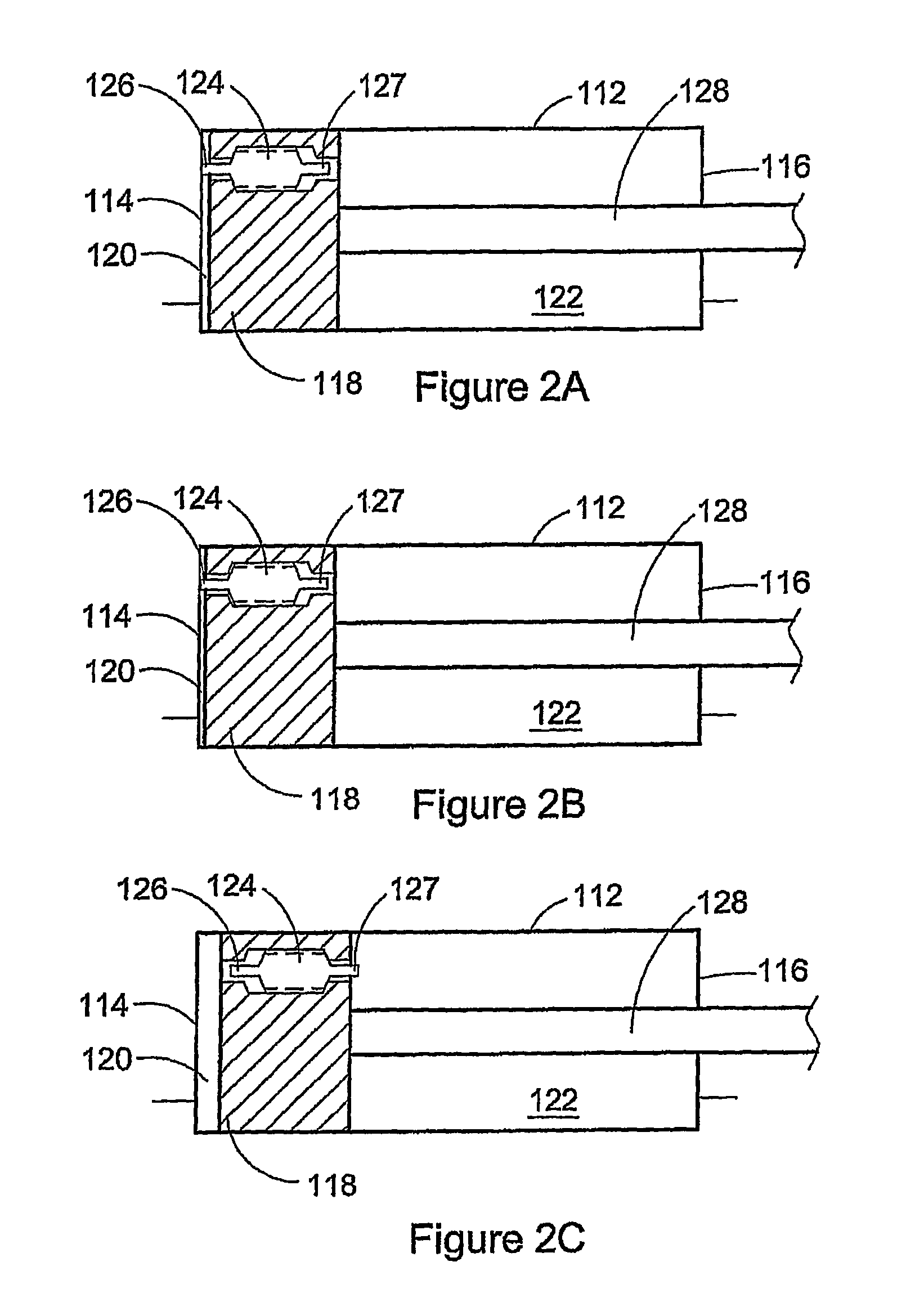

An apparatus for providing hemostasis within a puncture through tissue includes an elongate member having a lumen extending between proximal and distal ends thereof, an expandable member carried on the distal end and a housing on the proximal end, the housing including an interior communicating with the lumen, and further including a valve assembly with a one-way valve allowing access into the housing interior upon application of a pressure differential across the valve, and a movable plunger for overriding and opening the valve.

Owner:ACCESSCLOSURE

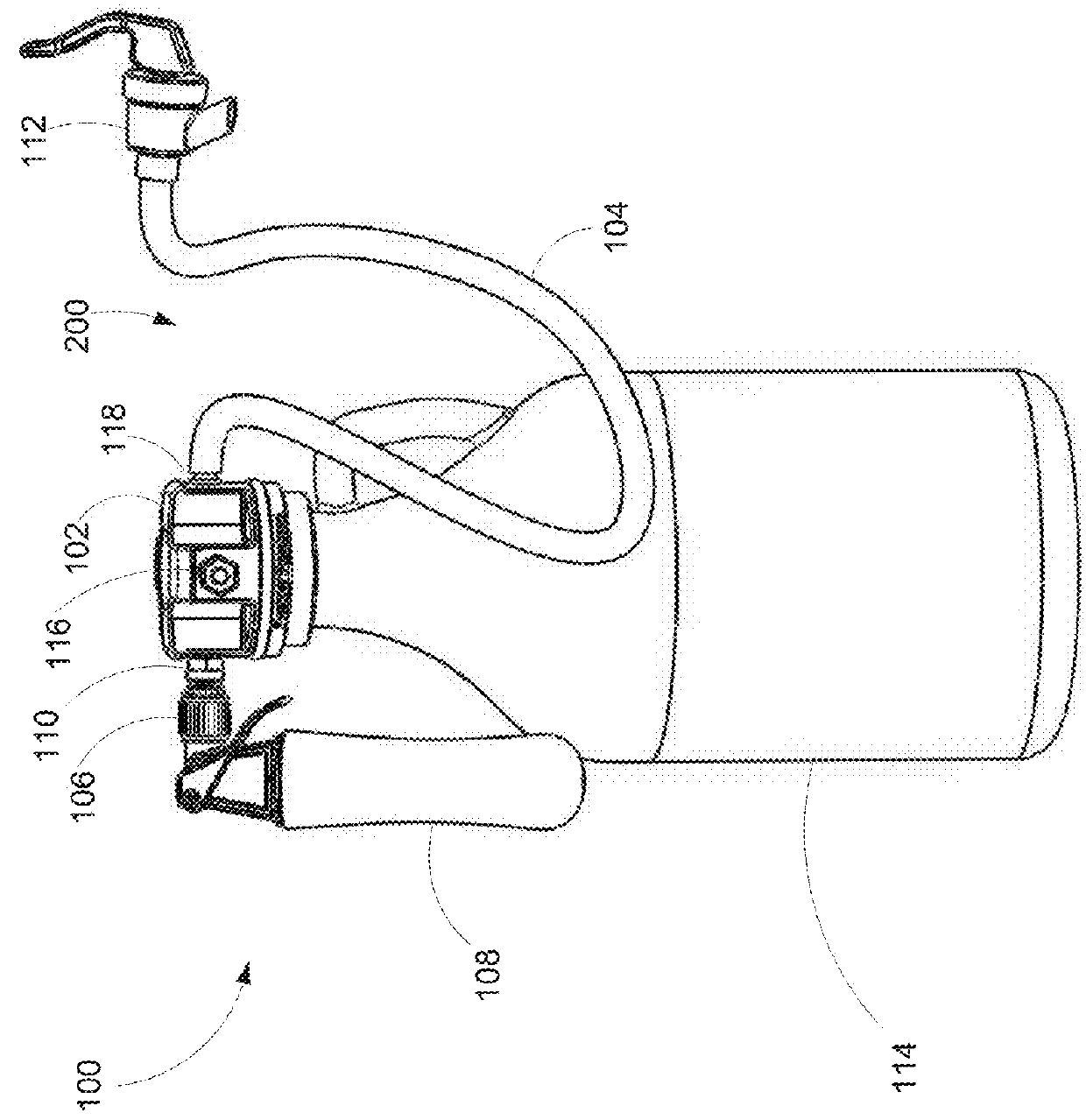

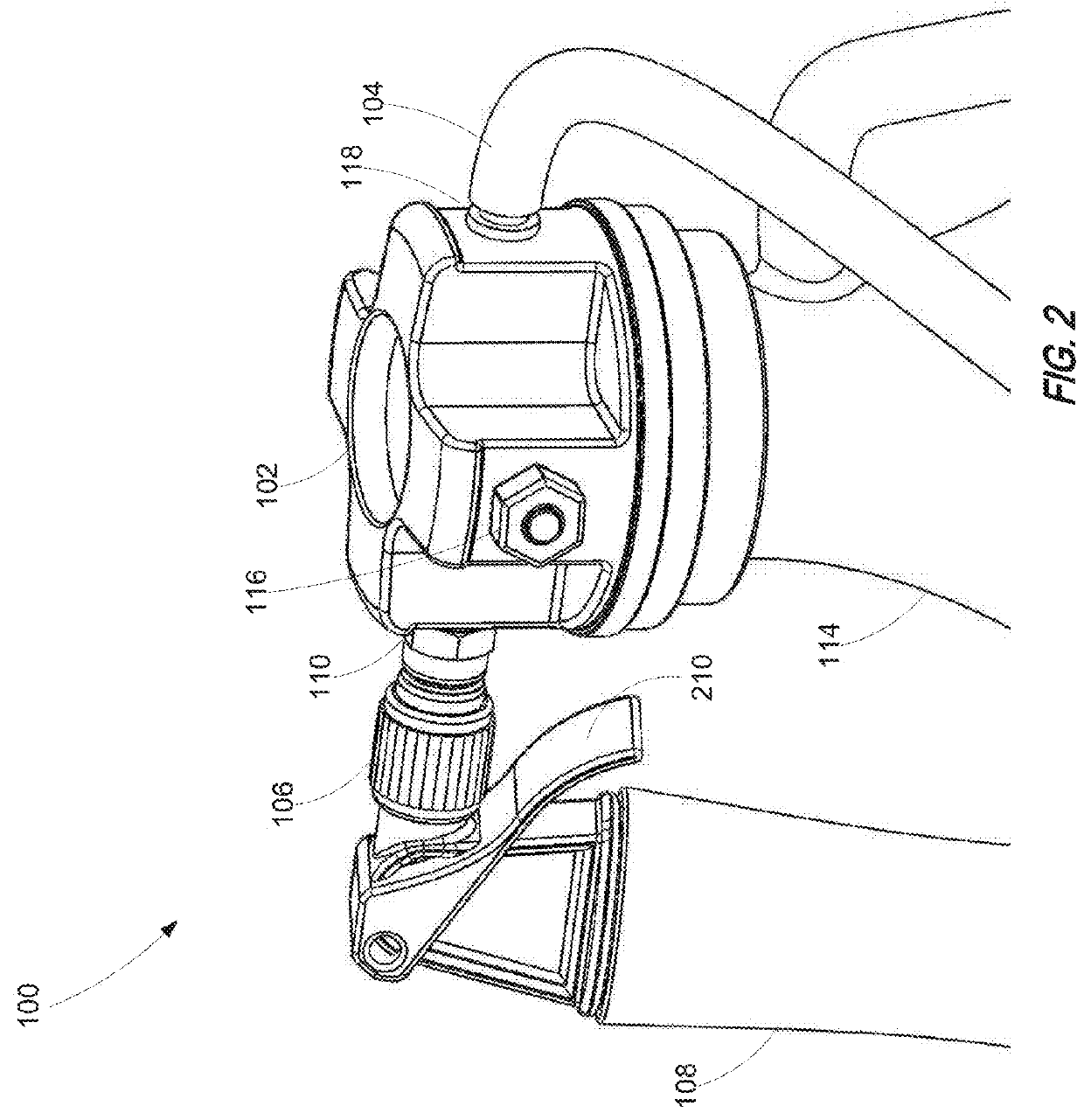

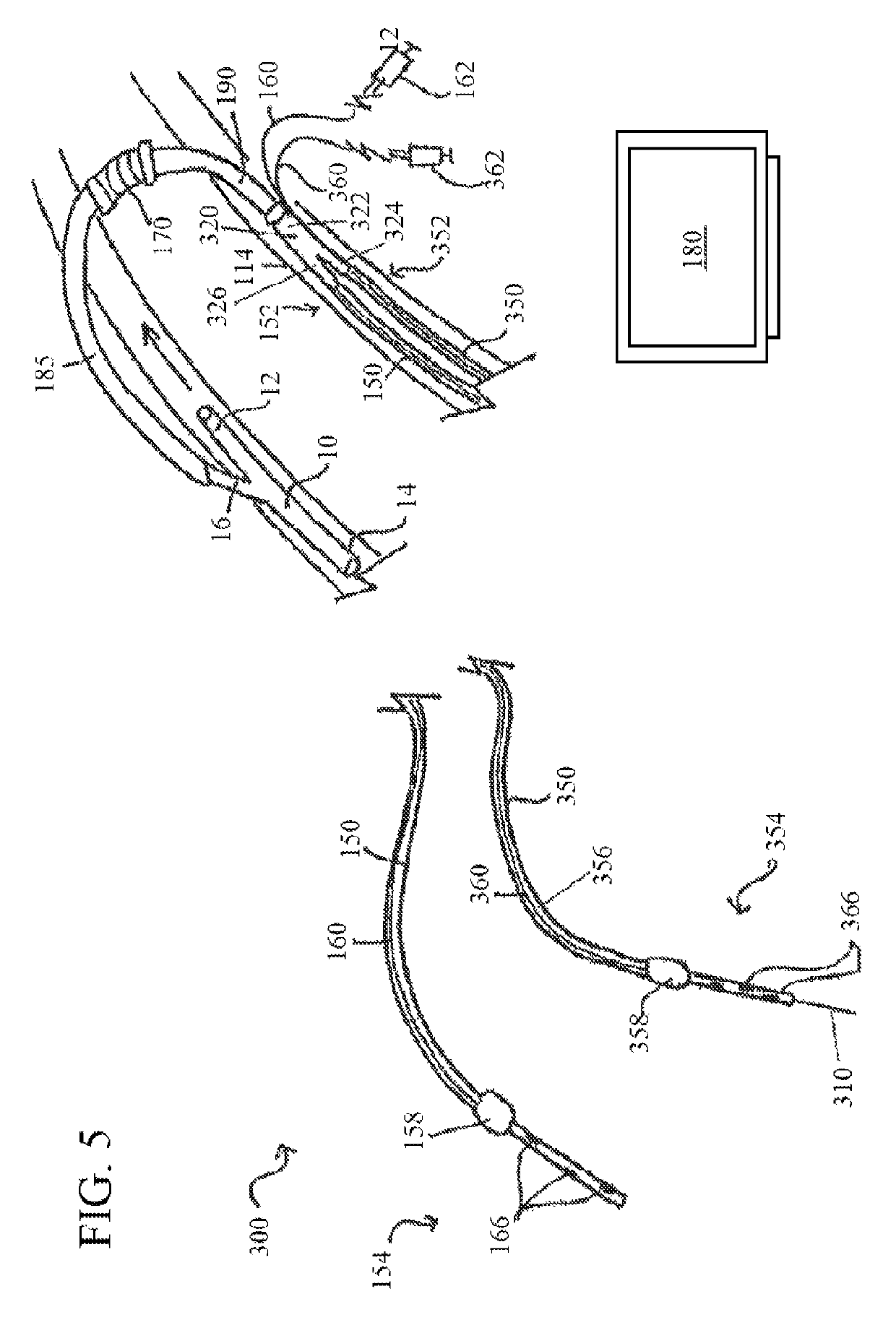

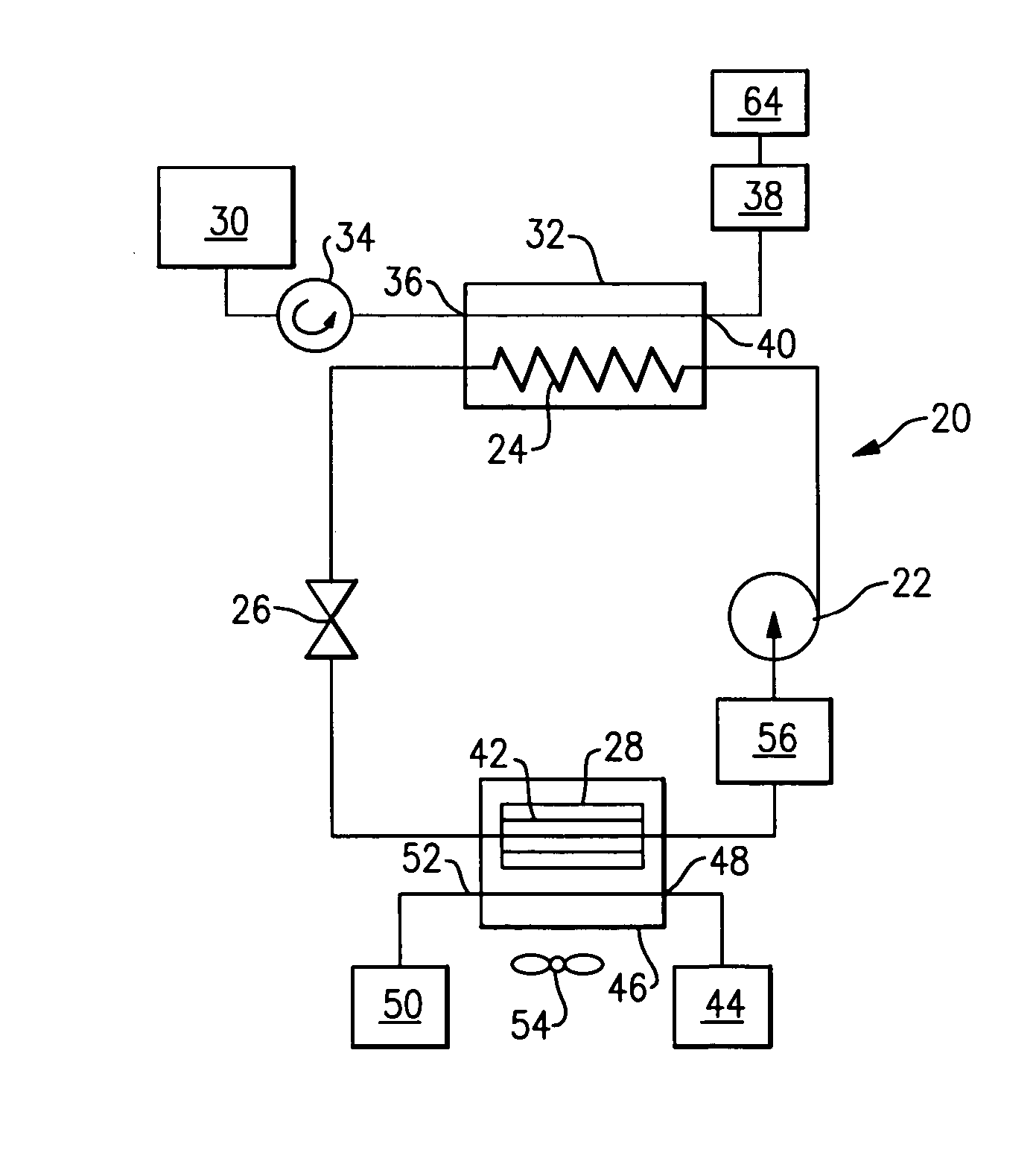

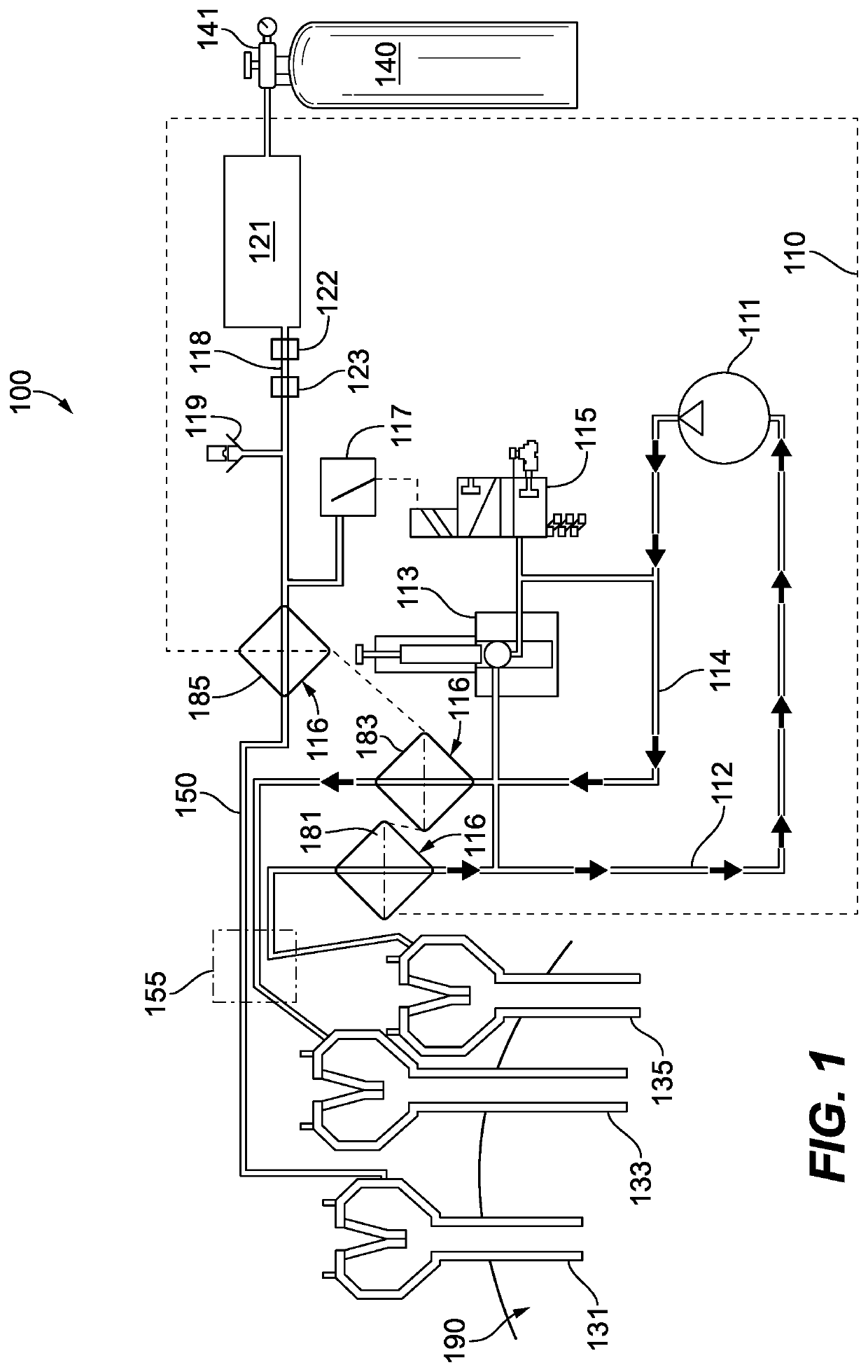

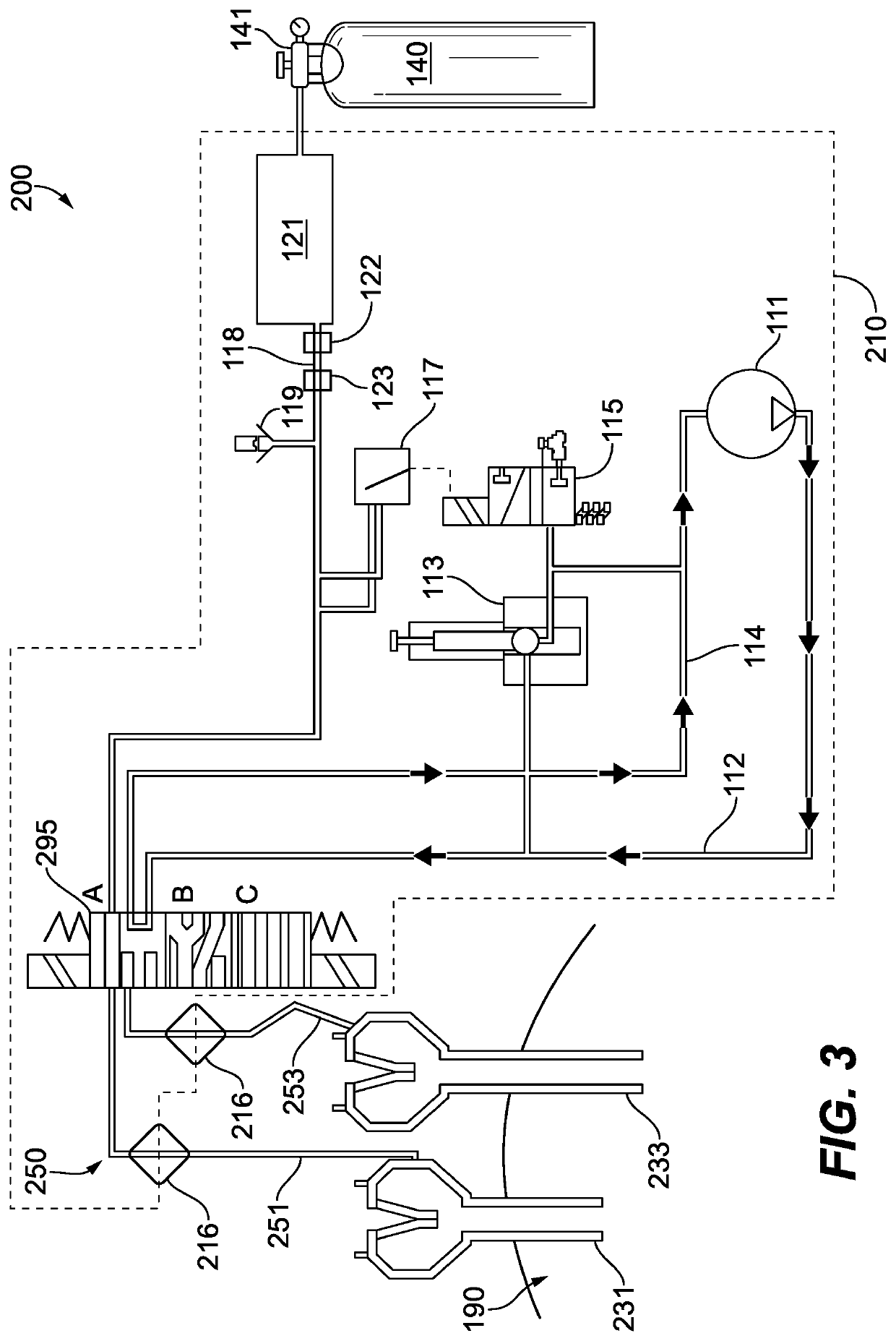

Smoke evacuation system for continuously removing gas from a body cavity

ActiveUS20180221598A1Prevent over-pressurizationEasy to adjustCannulasSurgical needlesProduct gasContinuous flow

An evacuation system for continuously removing gas from a body cavity of a patient during an endoscopic surgical procedure is disclosed, which includes an inlet flow path leading to a first trocar communicating with the body cavity through which an essentially continuous flow of gas is delivered to the body cavity, an outlet flow path leading from a second trocar communicating with the body cavity though which an essentially continuous flow of gas is removed from the body cavity, a pump communicating at least with the outlet flow path for removing an essentially continuous flow of gas from the surgical cavity, and a processor operatively associated with the pump for controlling at least the essentially continuous flow of gas from the body cavity.

Owner:CONMED CORP

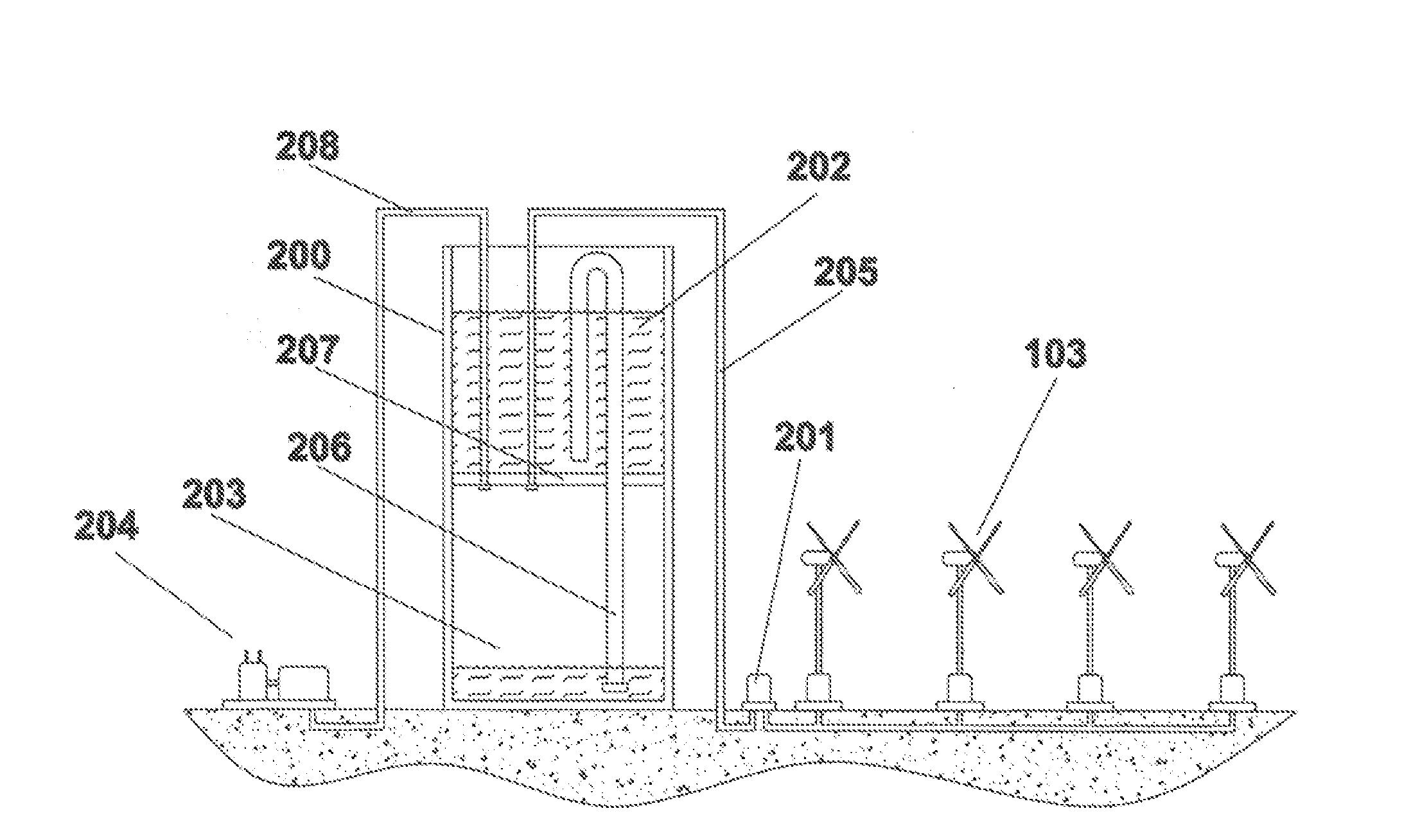

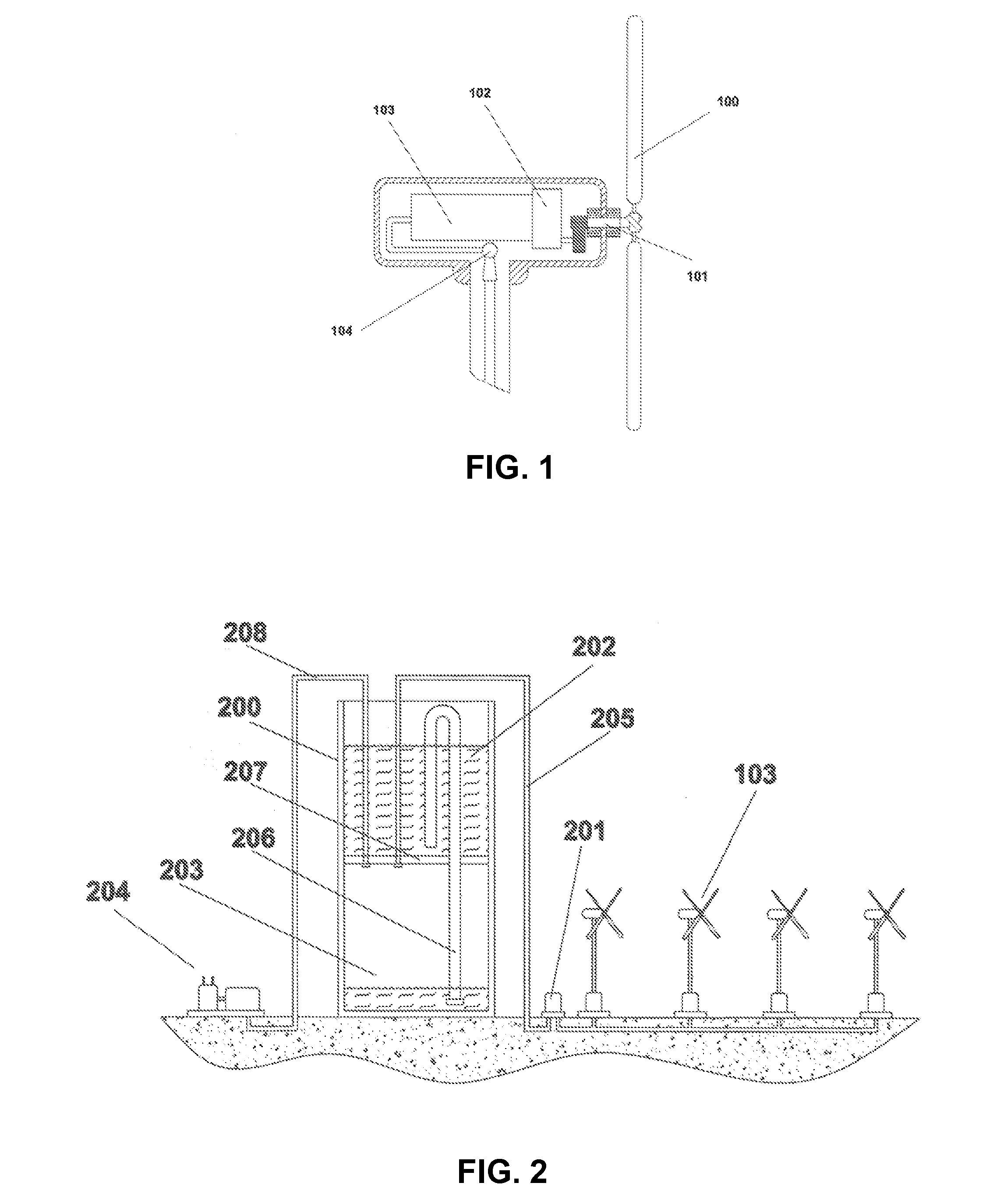

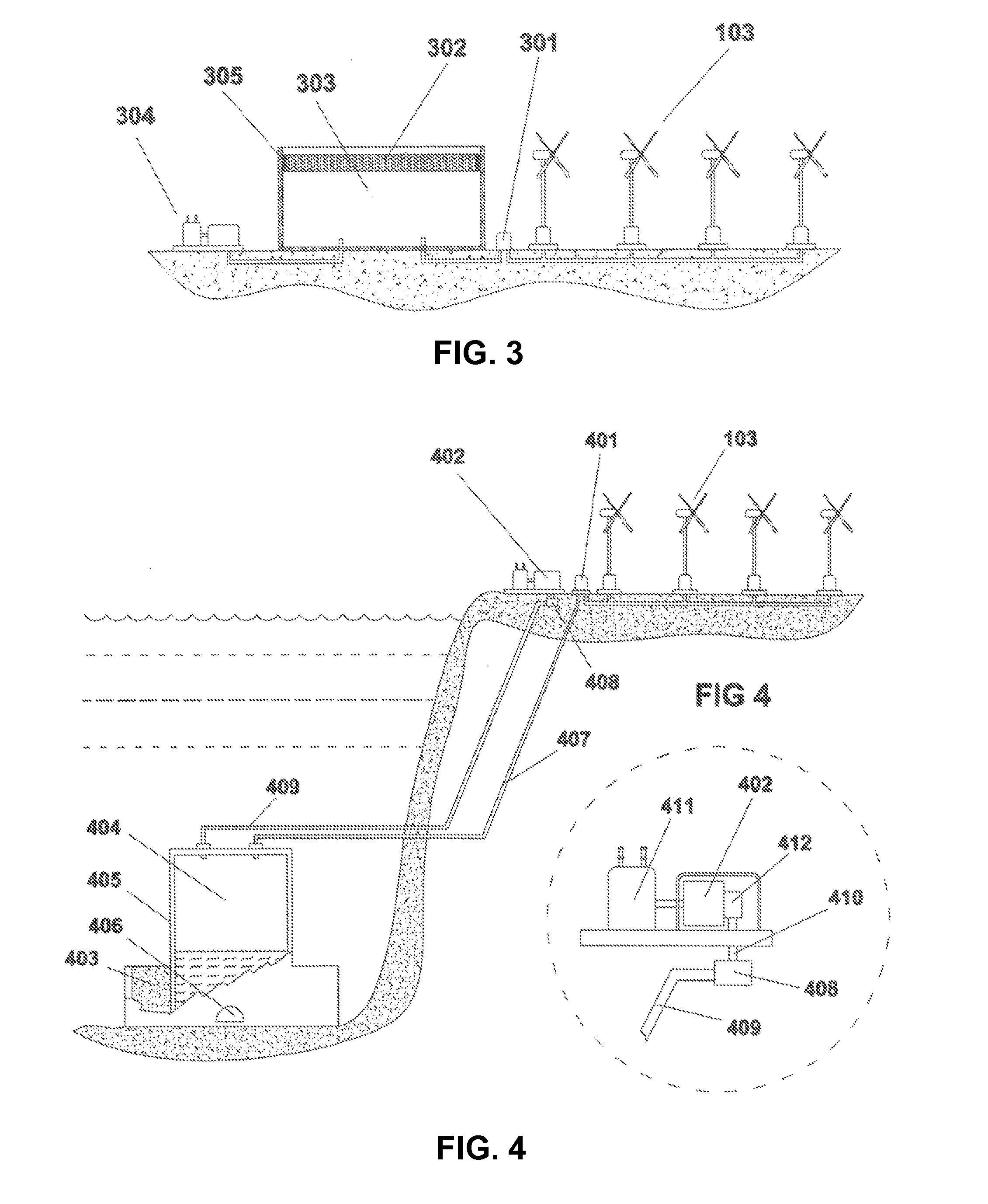

Integrated wind-power electrical generation and compressed air energy storage system

InactiveUS20090021012A1Prevent over-pressurization of the storage unitFrequency stabilityWind energy with garvitational potential energySteam accumulatorsThermal energy storageEngineering

The present invention relates to a method and apparatus for using wind energy to compress air or pressurize a fluid as a means of storing energy. Compressed air or pressurized fluid is generated directly by the wind turbines, thereby avoiding the energy losses that occur when wind power is used first to generate electricity to run an electrically powered air compressor. The compressed air or pressurized fluid is stored by means of expanding a volume at constant or nearly constant pressure. This method avoids energy losses that would otherwise result from compressional heating; while also allowing lower pressures to be employed, reducing the cost of the containment facility and avoiding the need to locate facilities in geographically favored locations where underground storage is available. The invention permits both large and small-scale storage at low cost per unit of energy stored, thereby avoiding the difficulty of using a highly variable and unreliable source of energy such as the wind for electrical power generation. The invention can be used for generation and storage on land, in shallow near-shore waters and in deep-water locations far from shore.

Owner:STULL MARK A +1

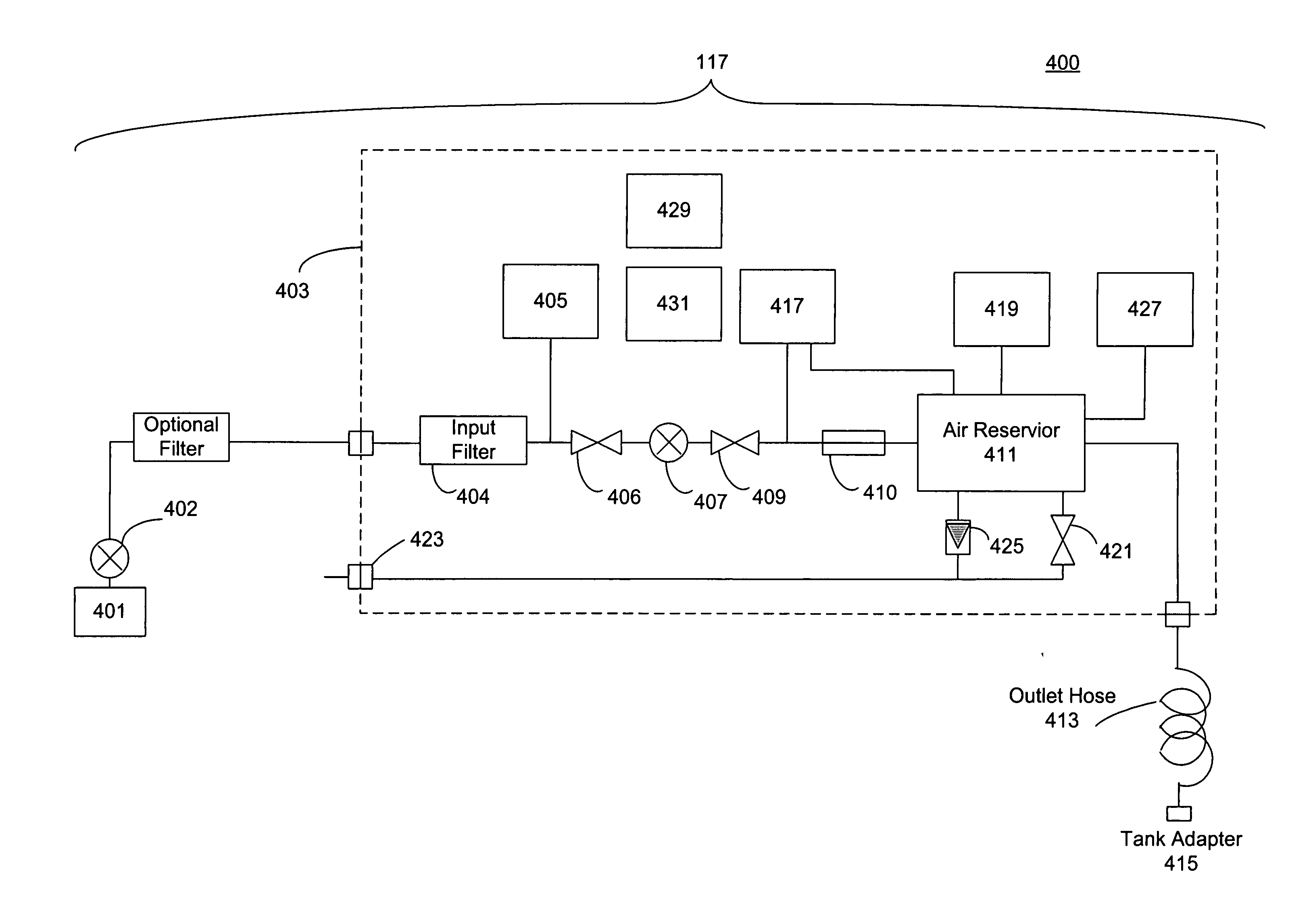

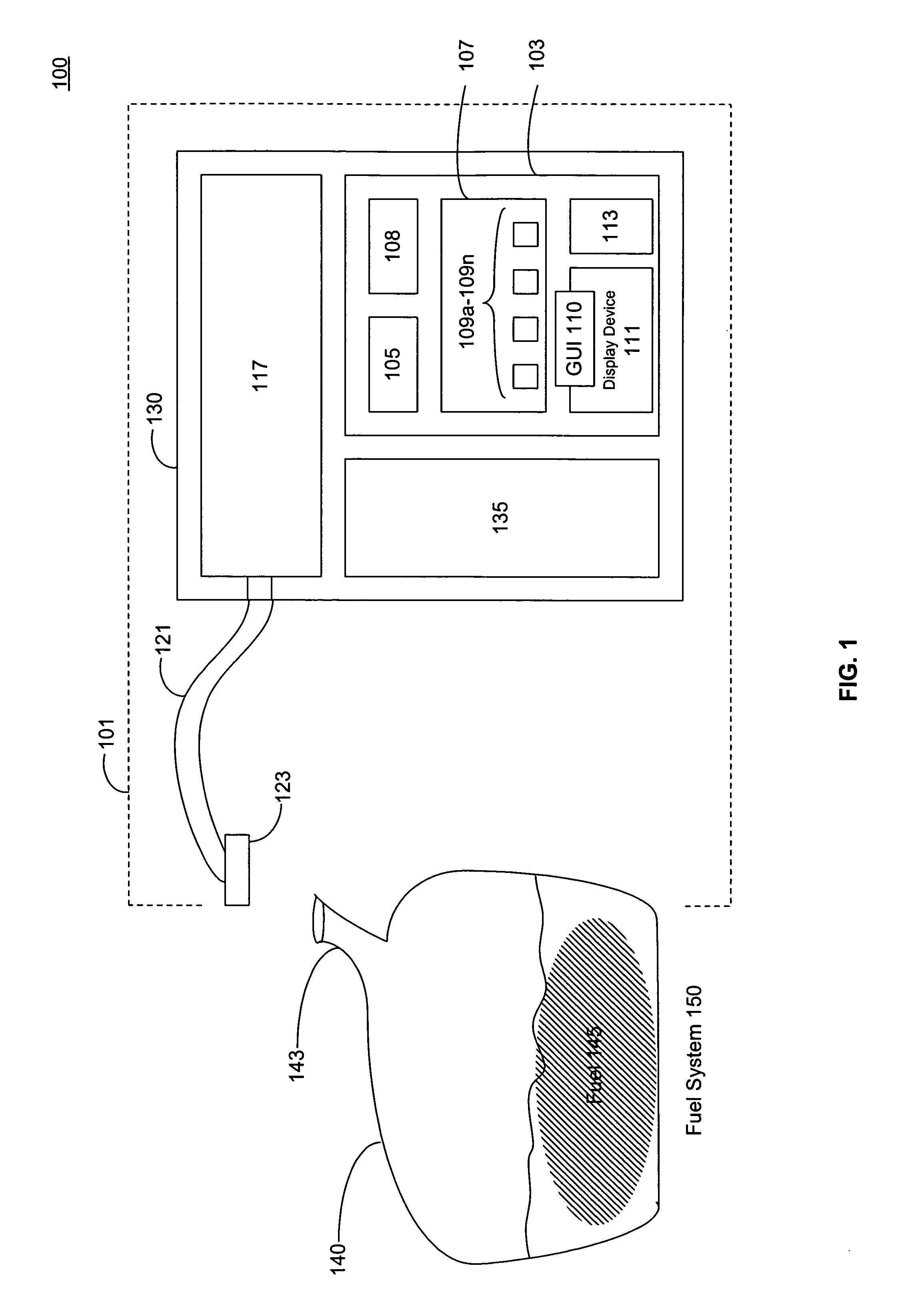

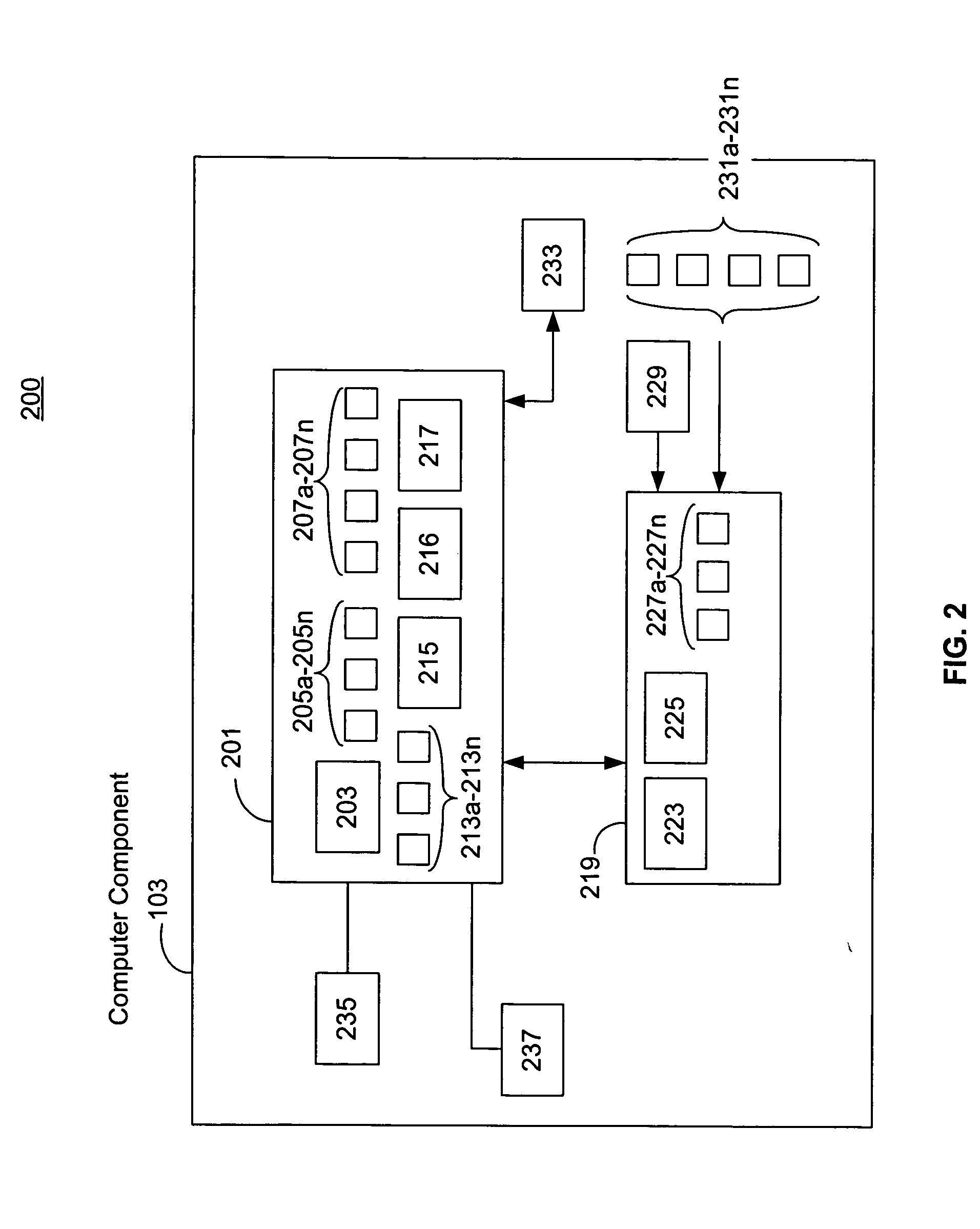

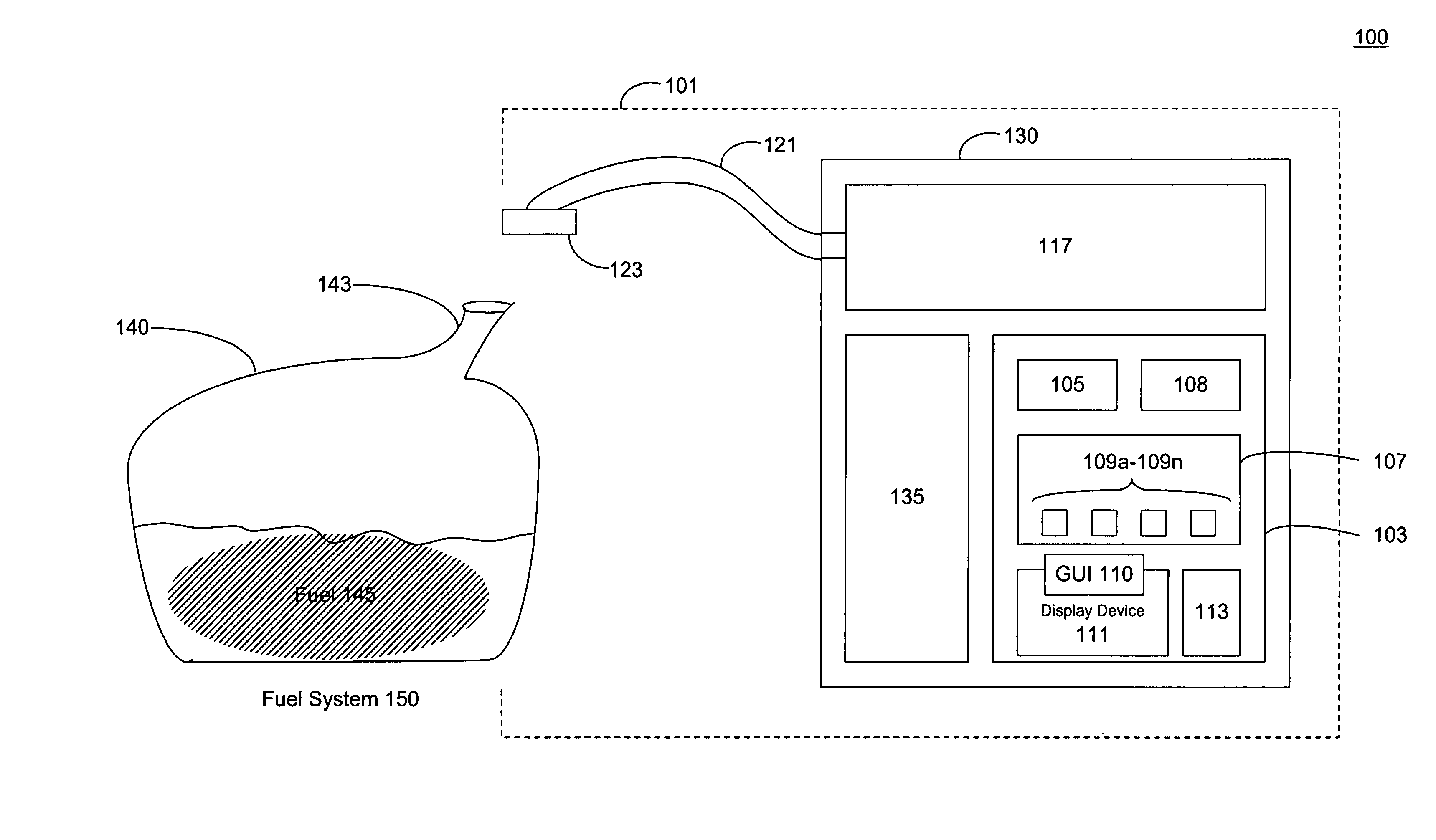

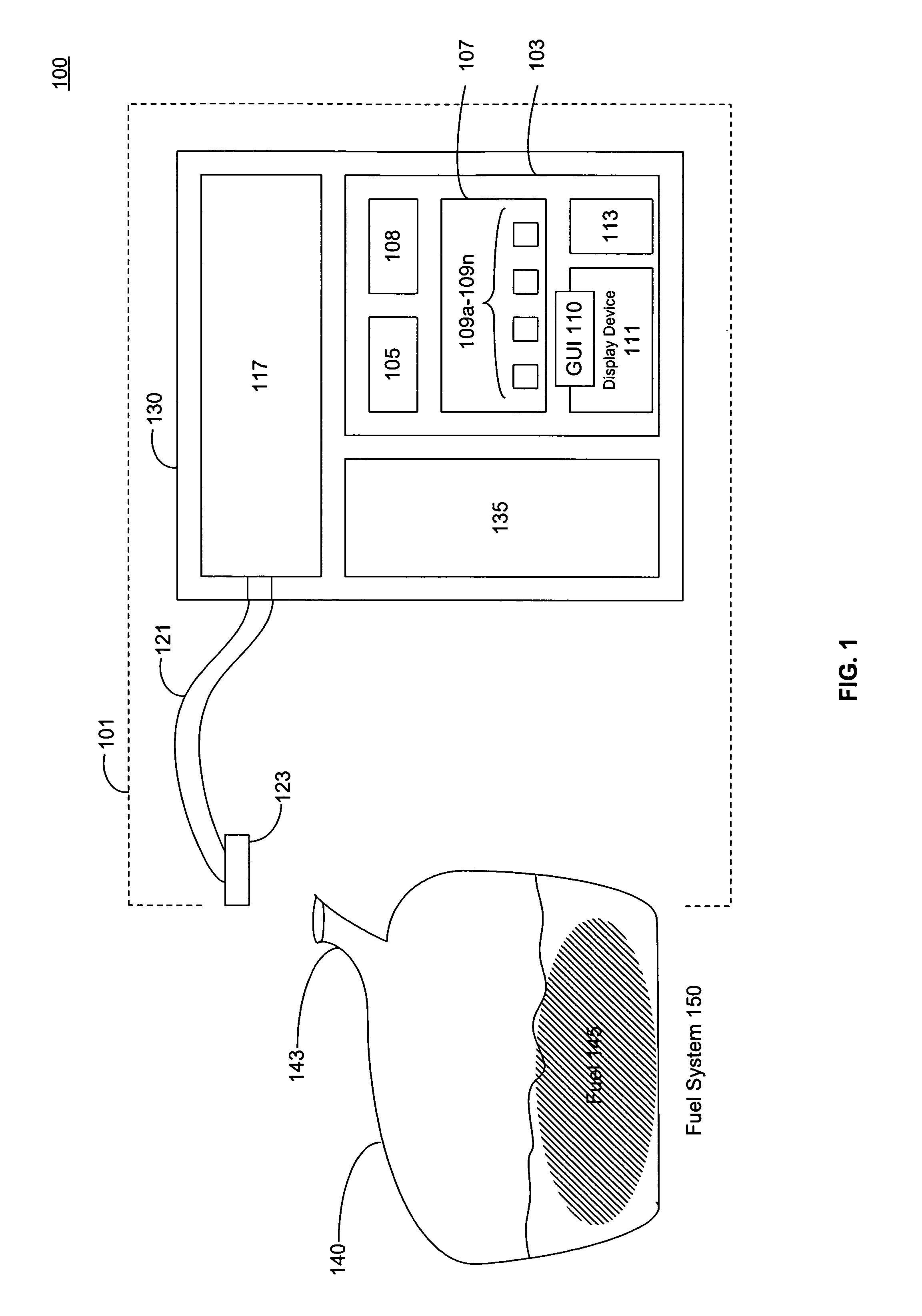

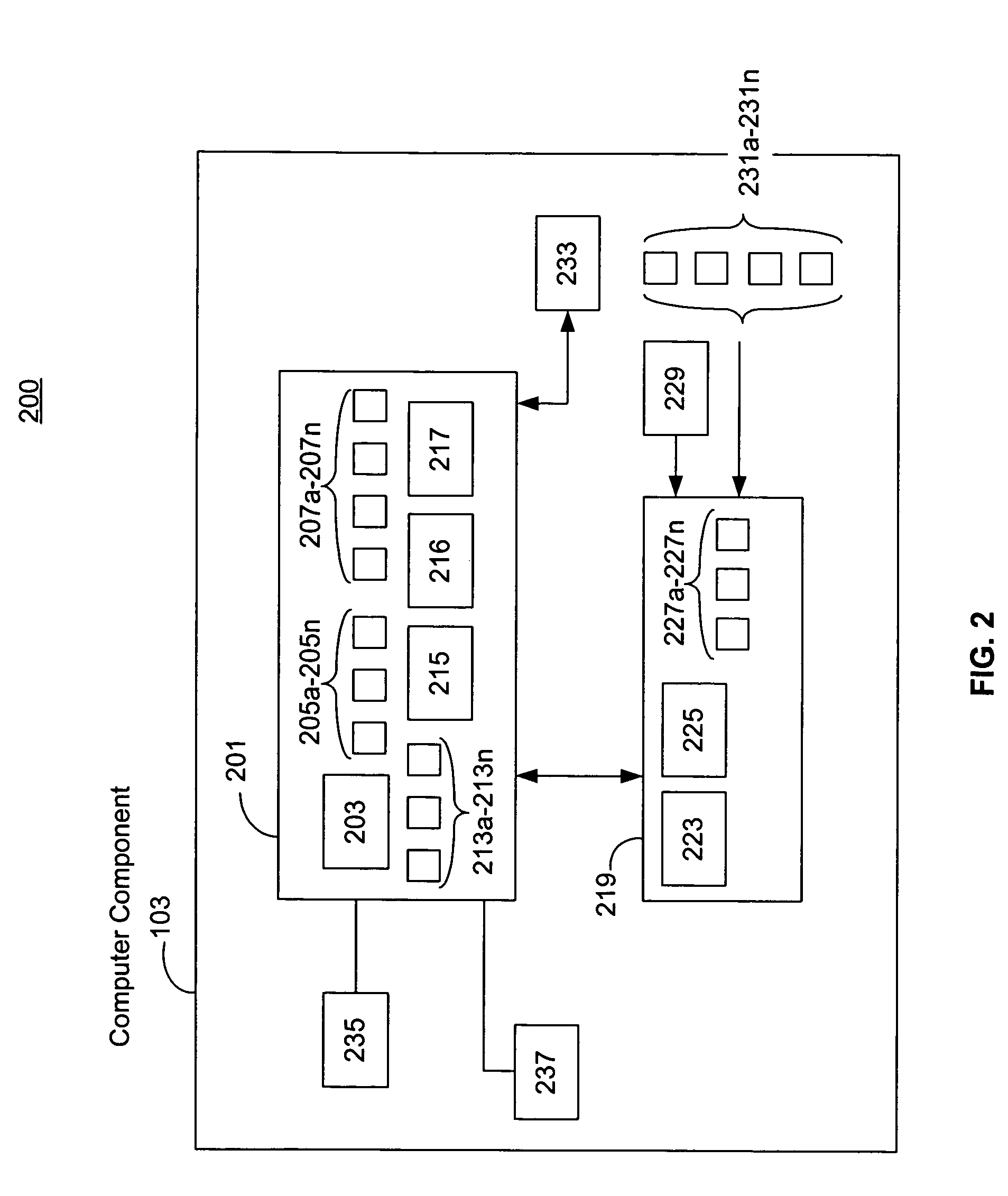

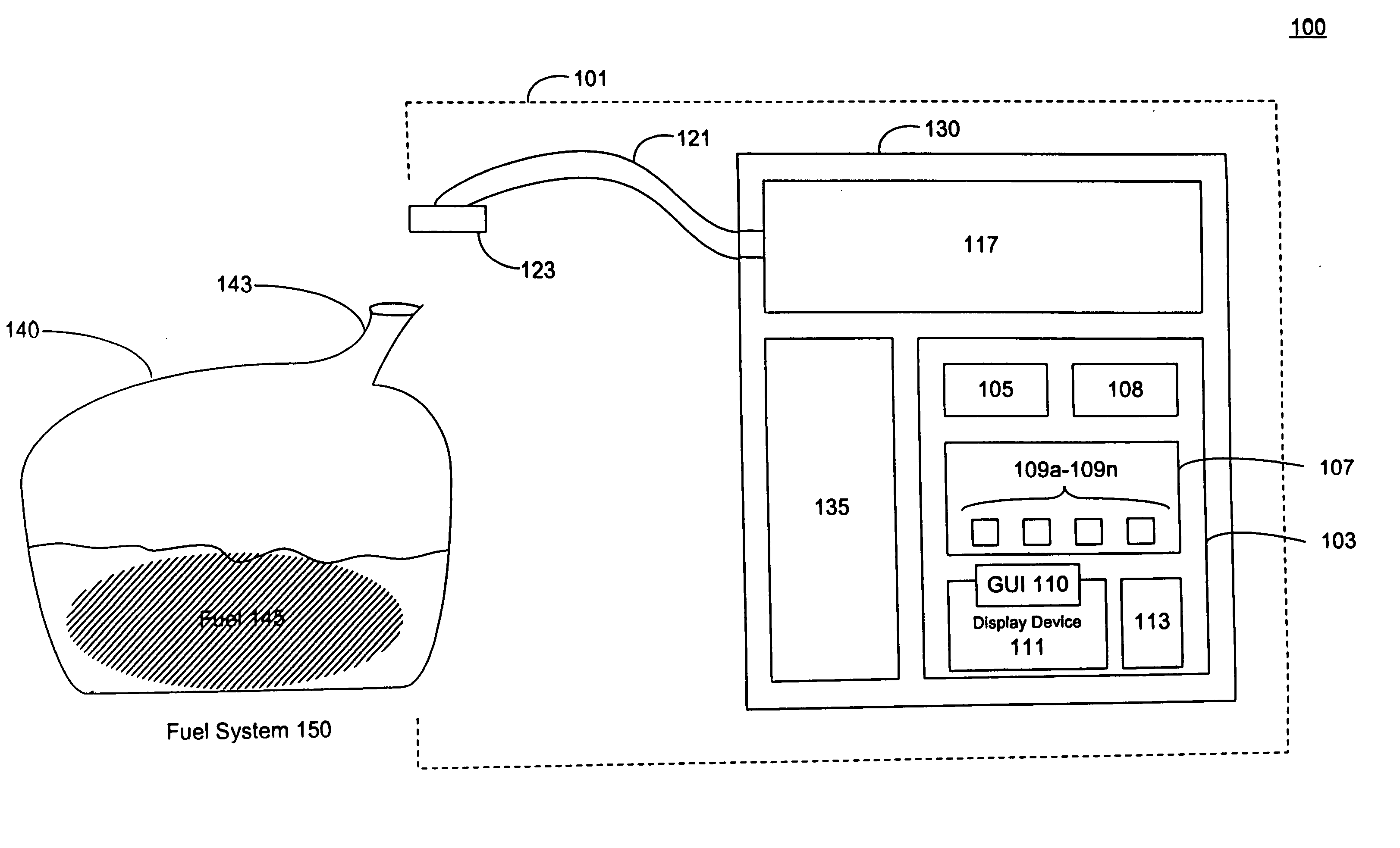

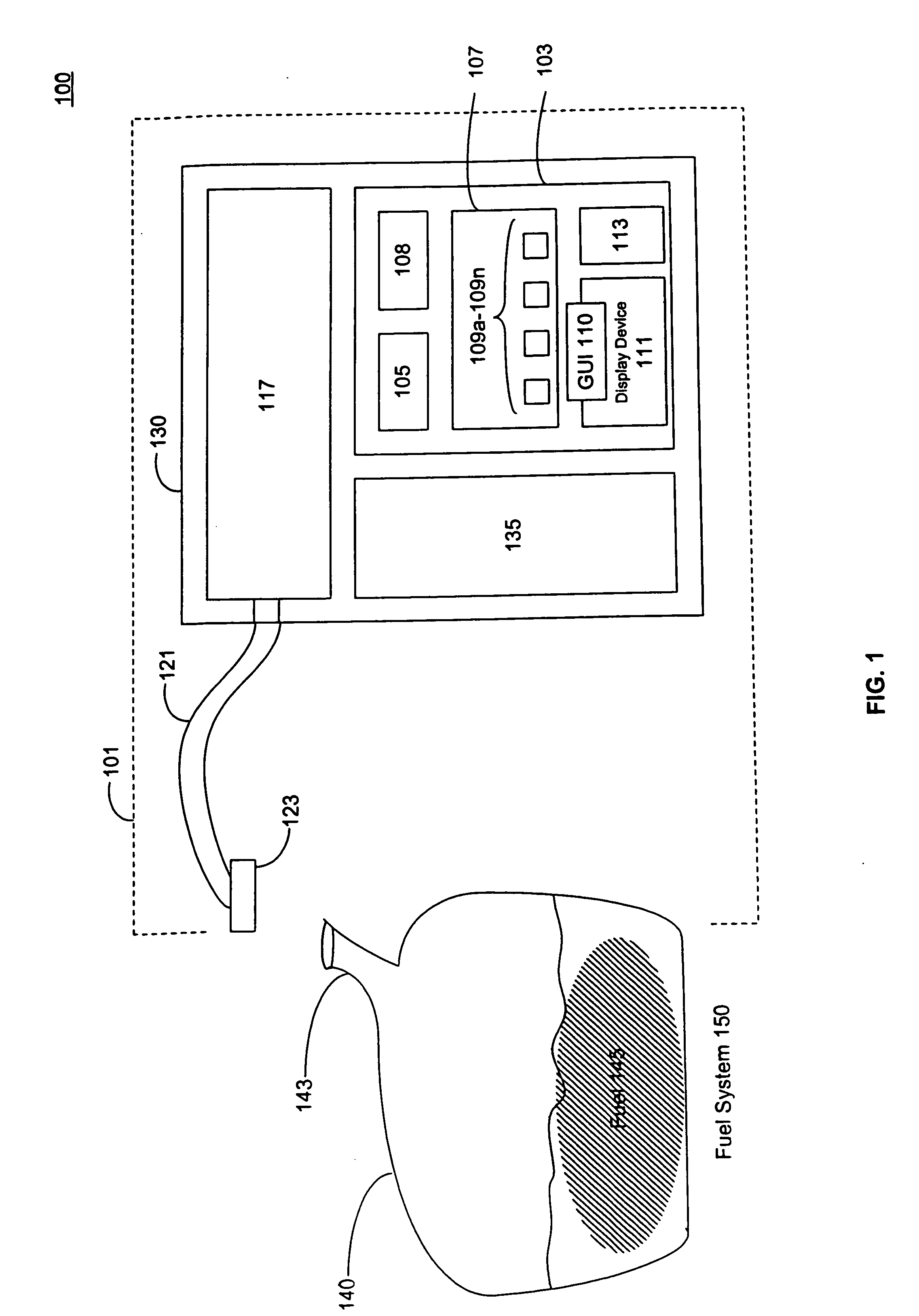

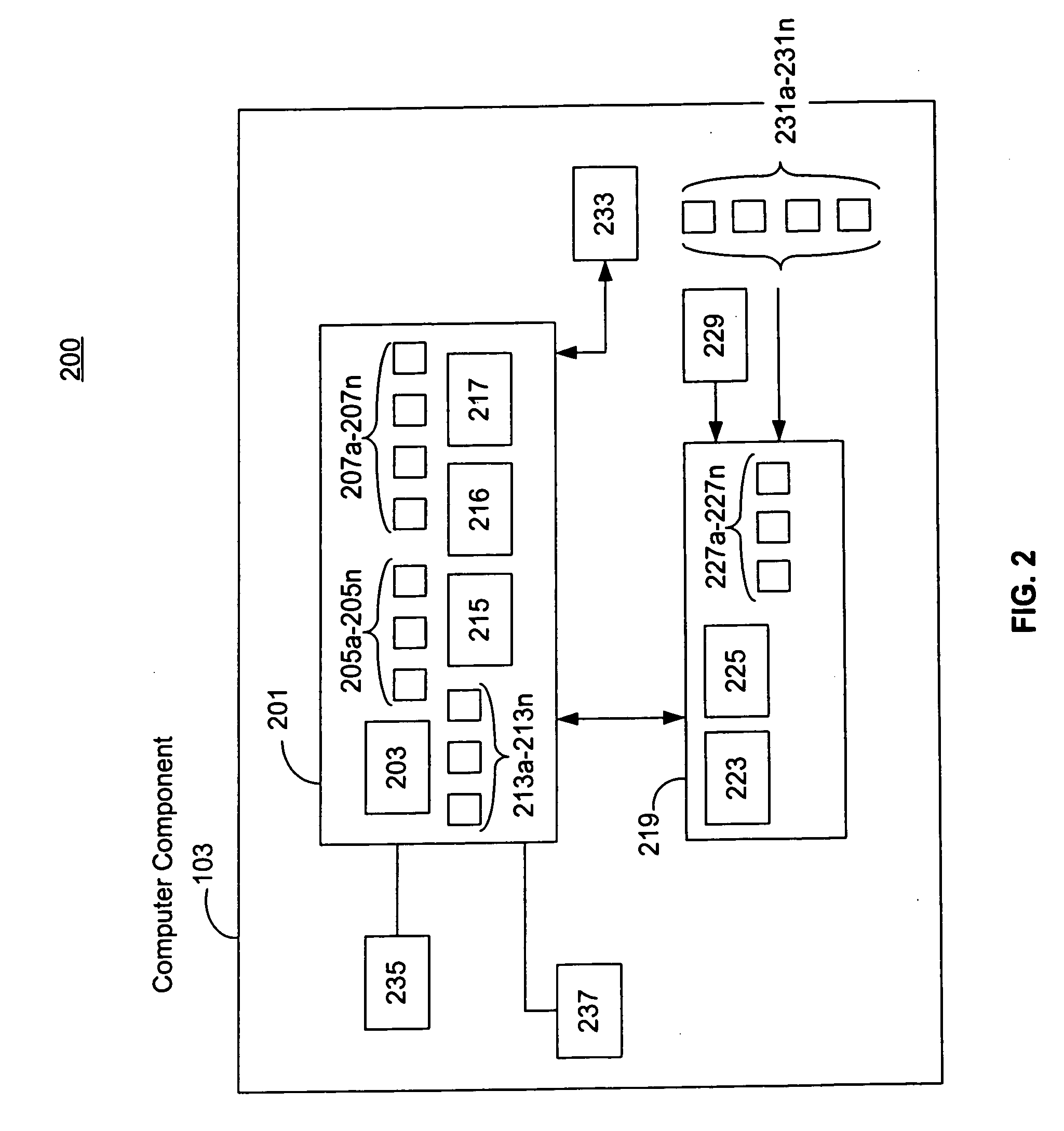

System and method for testing fuel tank integrity

ActiveUS20050126265A1Prevent pressurizationEasy and rapid connectionDetection of fluid at leakage pointMeasurement of fluid loss/gain rateFuel tankTester device

The invention relates generally to a system and method for testing fuel evaporative systems, and more particularly to a stand-alone tank tester system (and method) for testing vehicle fuel tank integrity. Furthermore, a self-contained calibration tank with switchable leak sizes for calibrating the tank tester to multiple leak sizes is provided. Constant flow and vacuum methods for testing fuel tank integrity are also provided.

Owner:OPUS INSPECTION

Apparatus and method for temporary hemostasis

ActiveUS7806856B2Prevent over-pressurizationReduce positioningBalloon catheterSurgeryPressure differenceVALVE PORT

An apparatus for providing hemostasis within a puncture through tissue includes an elongate member having a lumen extending between proximal and distal ends thereof, an expandable member carried on the distal end and a housing on the proximal end, the housing including an interior communicating with the lumen, and further including a valve assembly with a one-way valve allowing access into the housing interior upon application of a pressure differential across the valve, and a movable plunger for overriding and opening the valve.

Owner:ACCESS CLOSURE INC

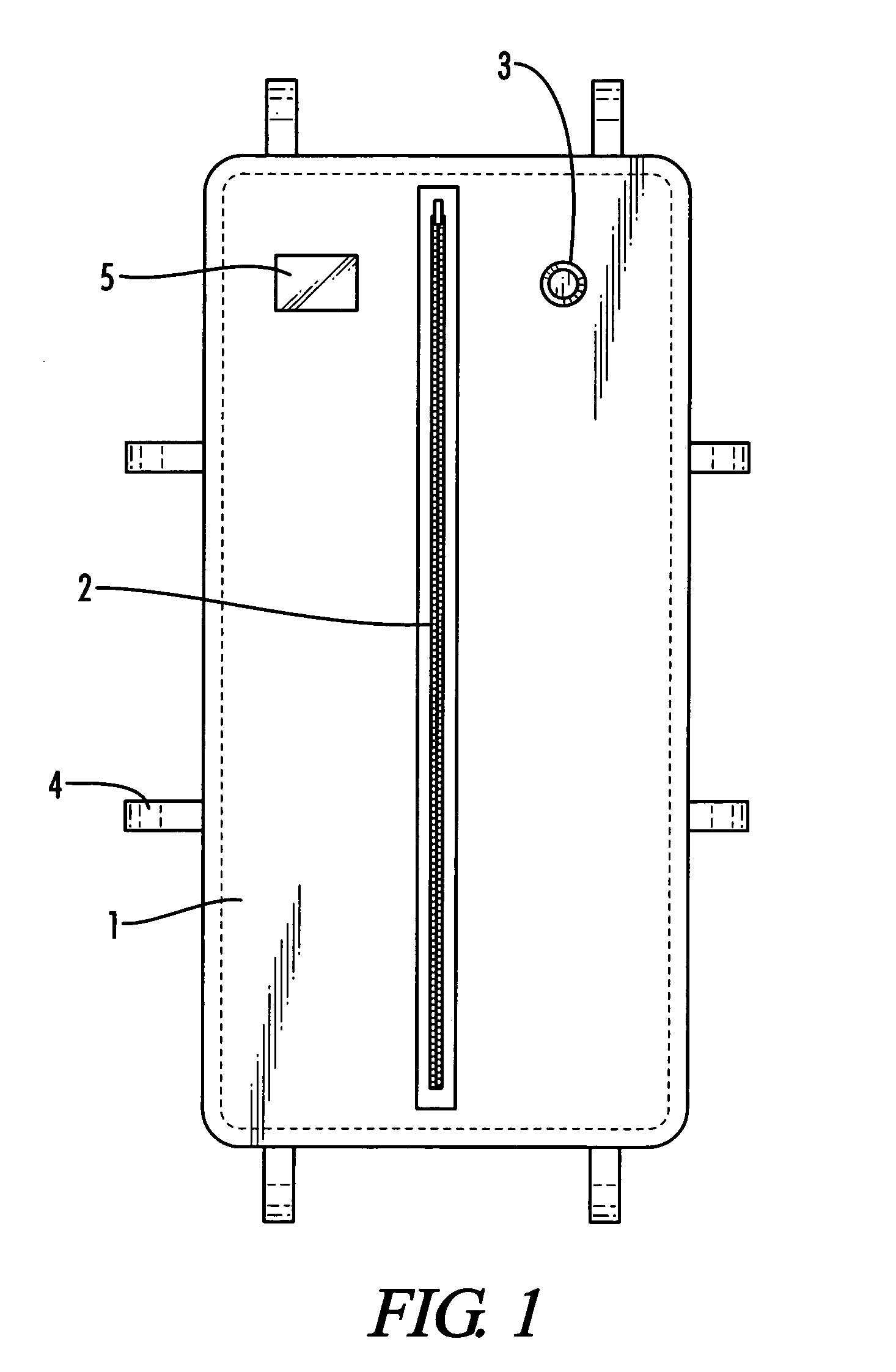

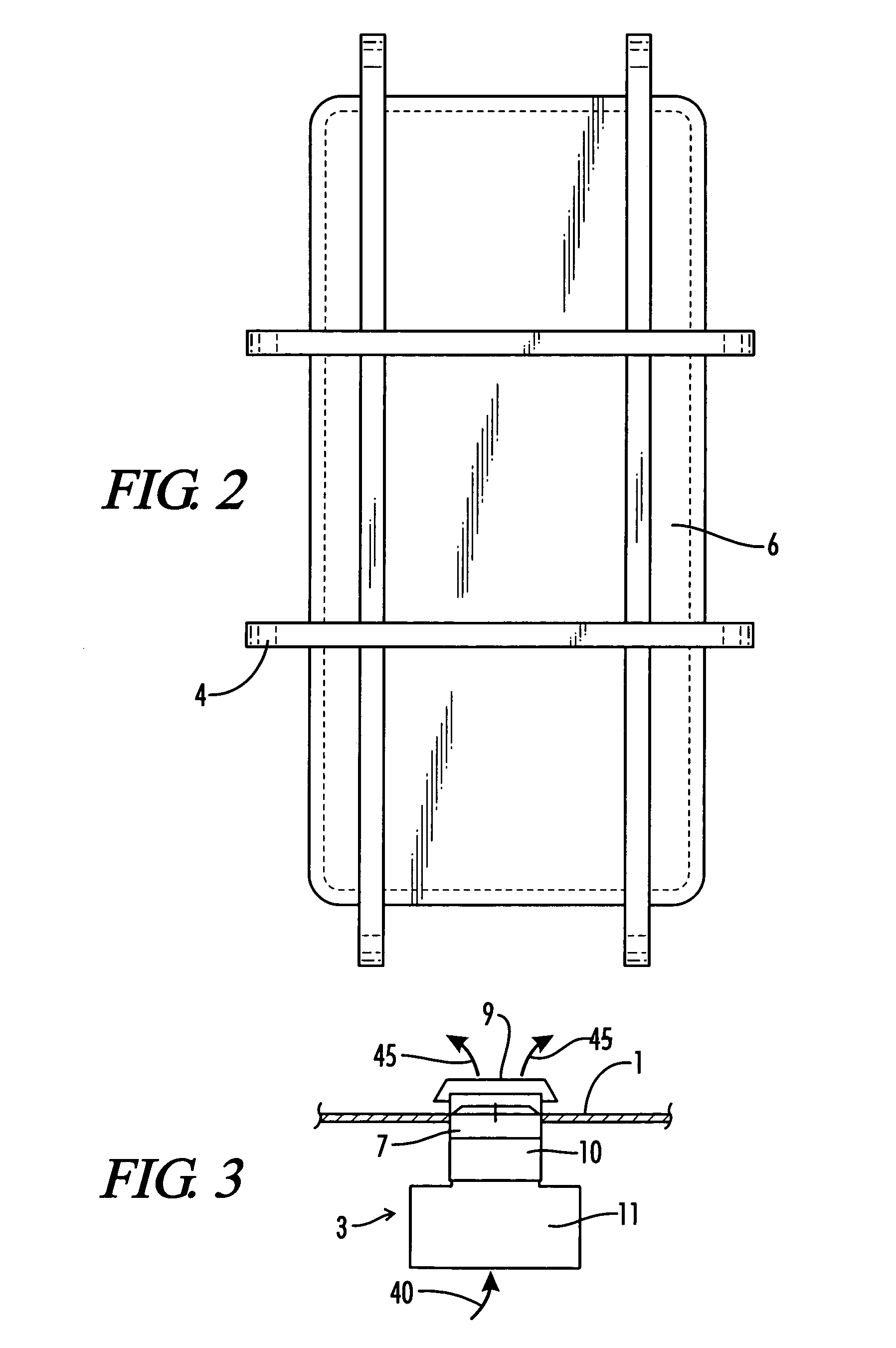

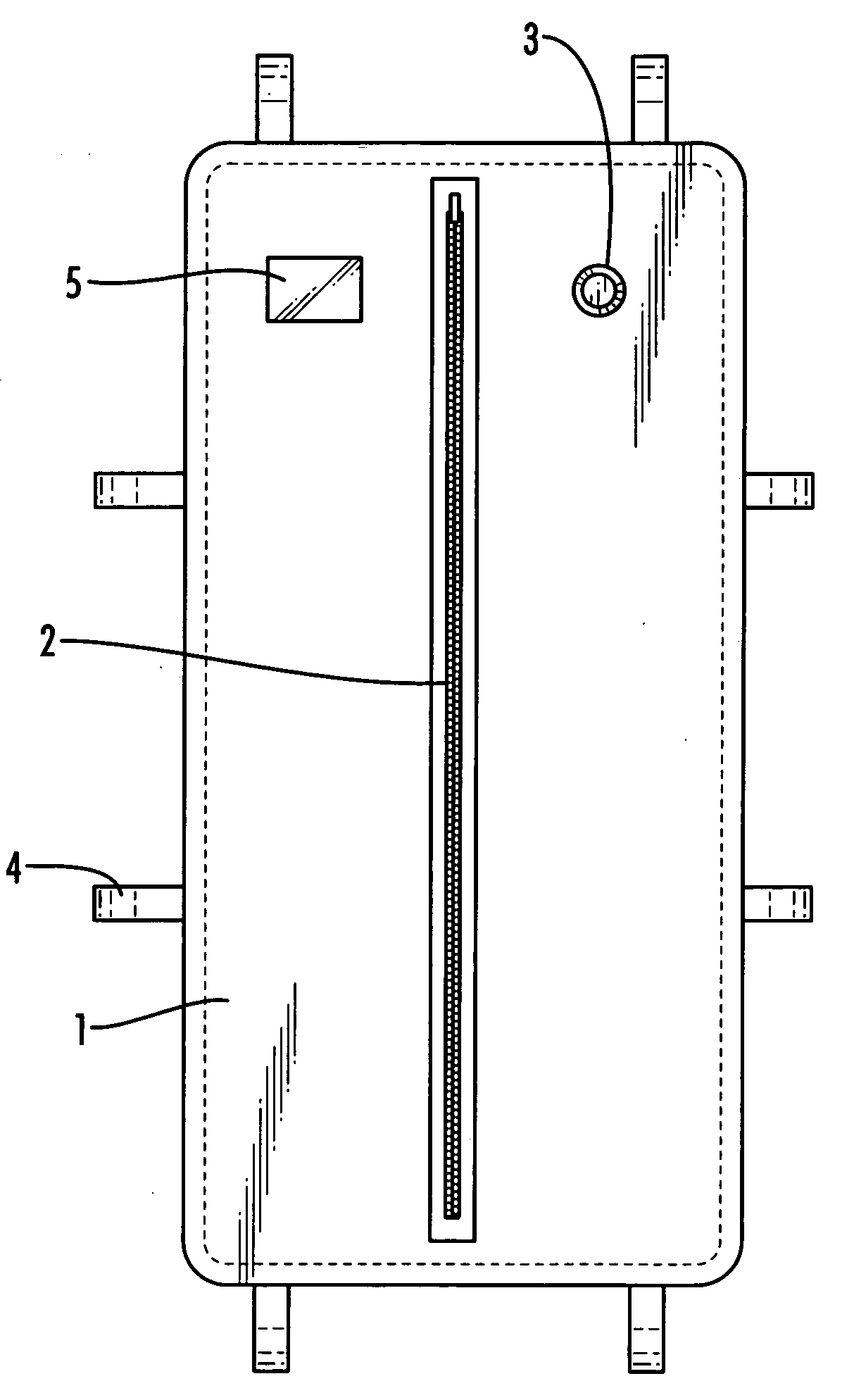

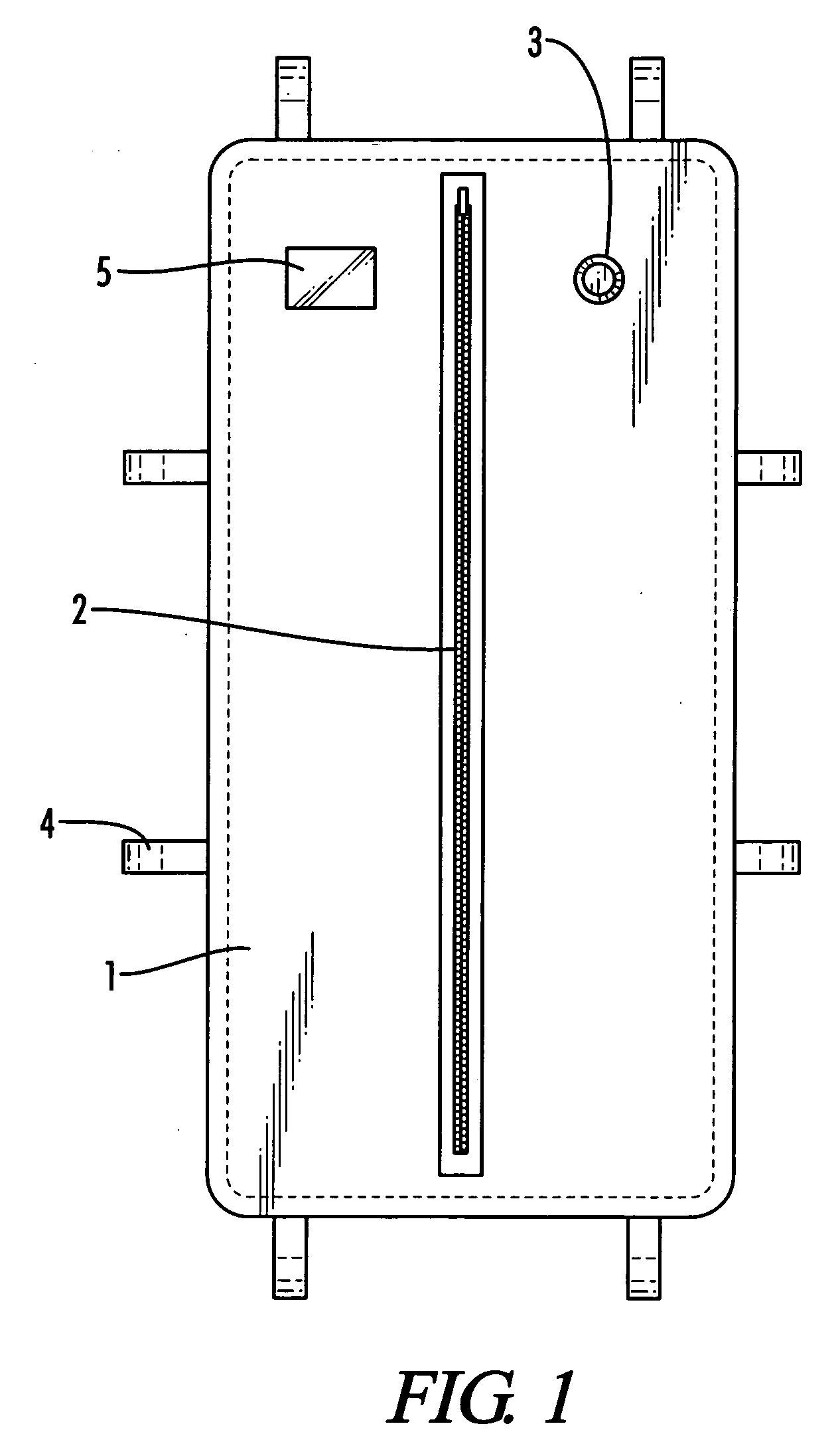

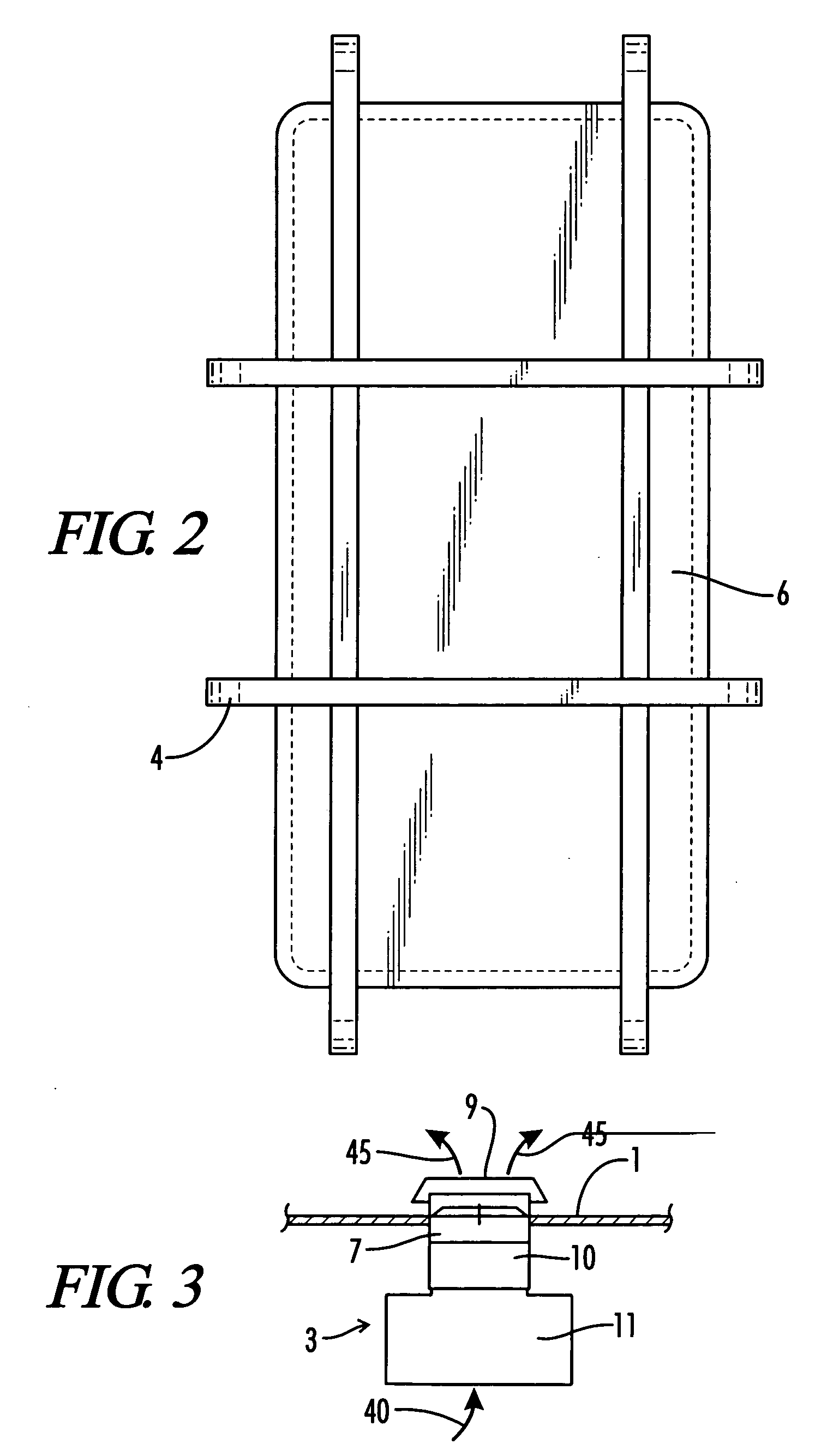

Transportable contaminated remains pouch

Owner:KAPPLER

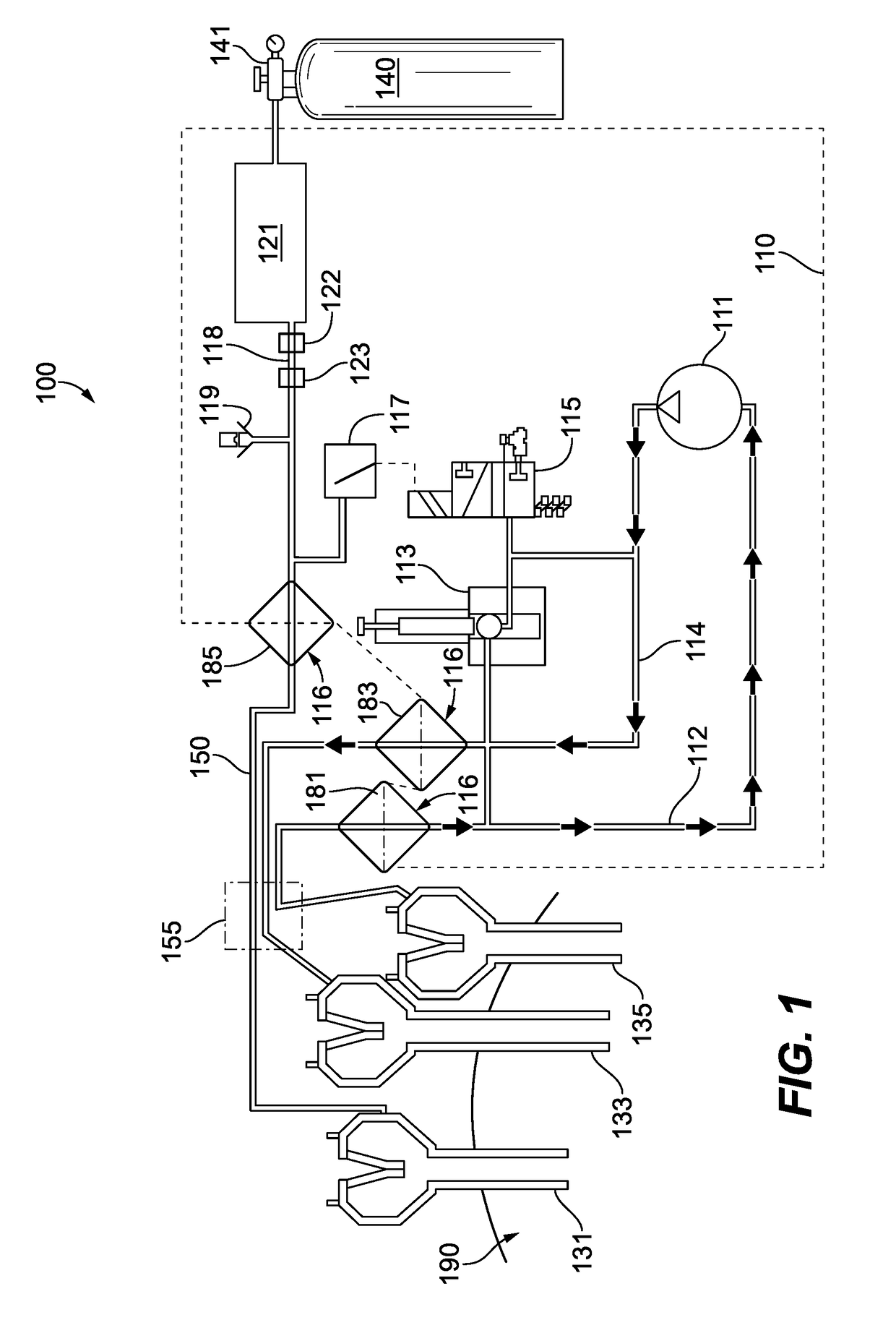

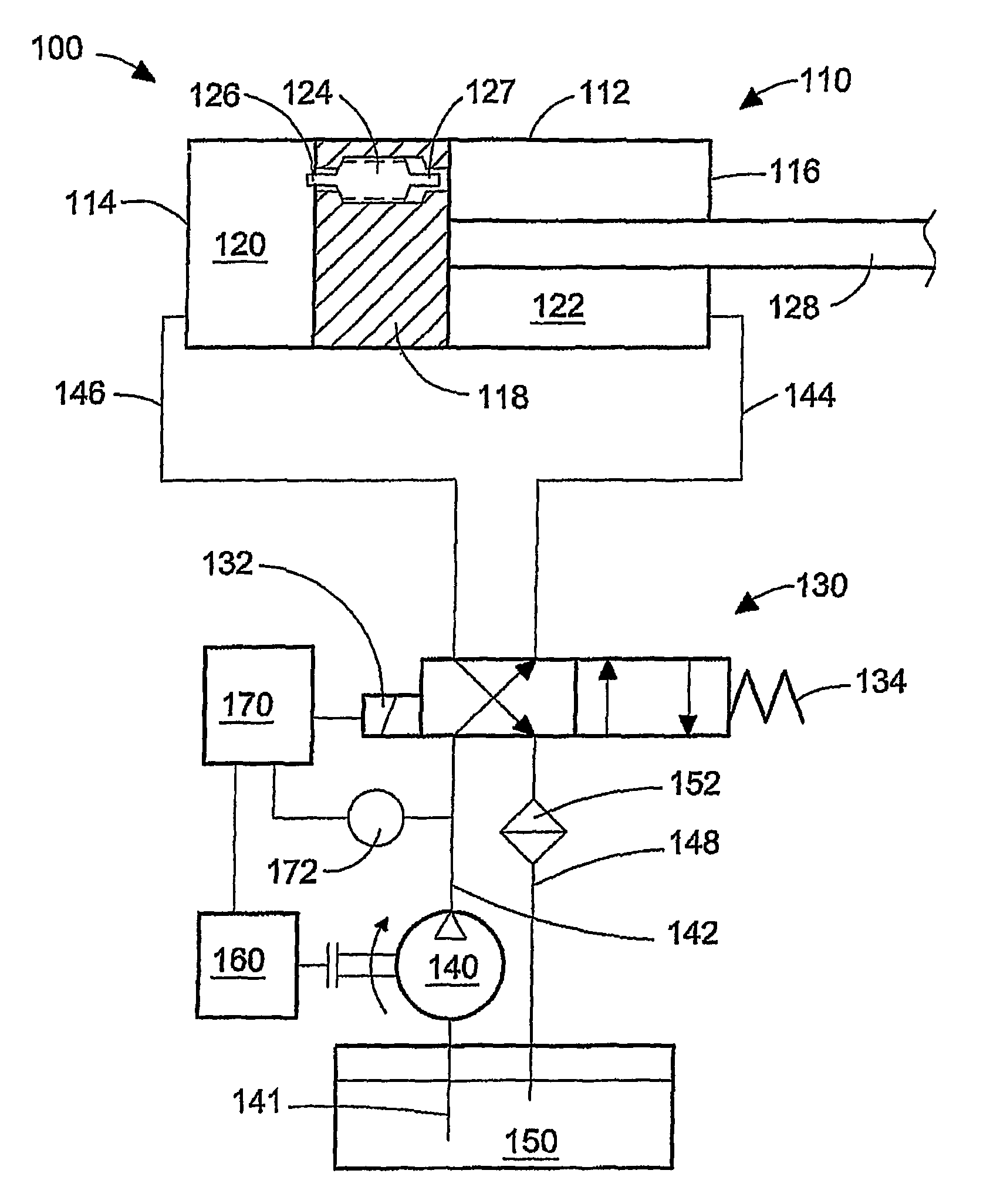

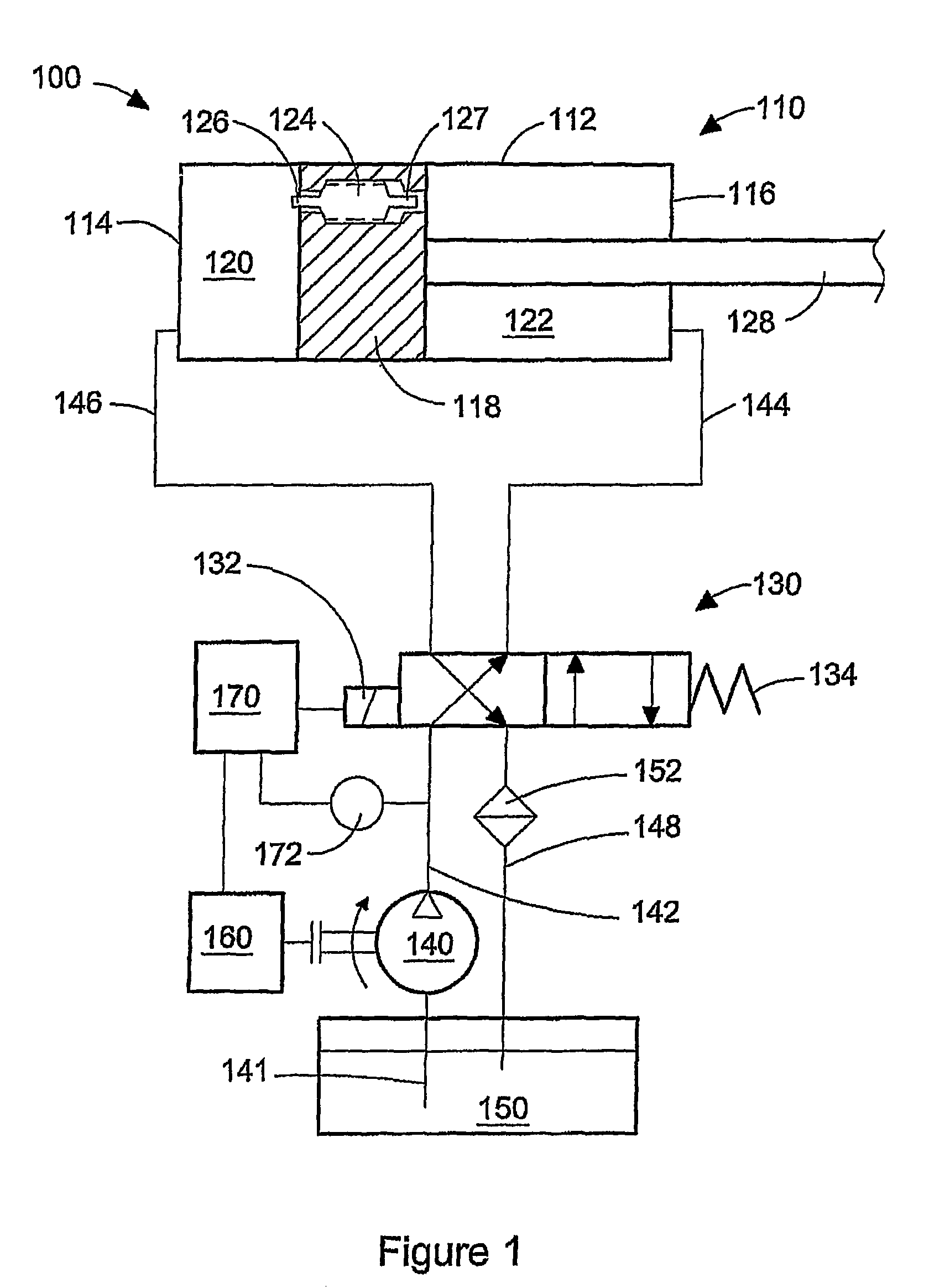

Hydraulic drive system and method of operating a hydraulic drive system

ActiveUS7739941B2Easy to operateEasy to driveFluid couplingsServomotorsCylinder headDifferential pressure

A hydraulic drive system comprises a hydraulic actuator comprising a piston reciprocable between two cylinder heads for actuating a machine. A flow switching device reverses the direction of hydraulic fluid flow to and from chambers on opposite sides of the piston. The piston stops at the end of each piston stroke when a shuttle valve associated with the piston opens to allow hydraulic fluid to flow between the chambers cancelling the differential pressure that acts on the piston to cause reciprocal movement. A controller is programmed to determine when the piston reaches the end of each stroke based upon at least one of hydraulic pump speed, hydraulic fluid pressure, or elapsed time, with each of these measured during each stroke. The controller then sends an electronic signal to command the flow switching device to reverse the direction of hydraulic fluid flow.

Owner:WESTPORT FUEL SYST CANADA INC

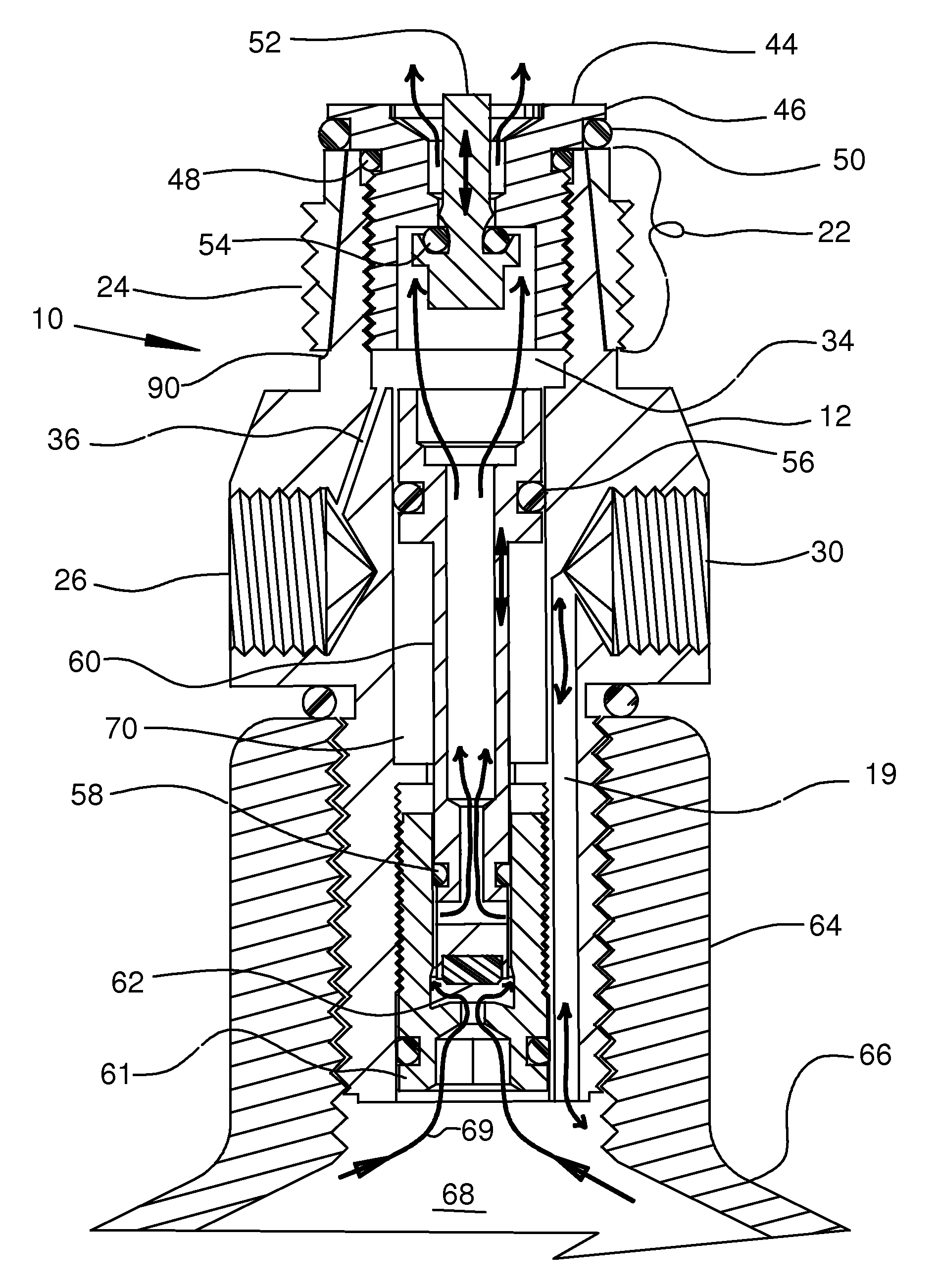

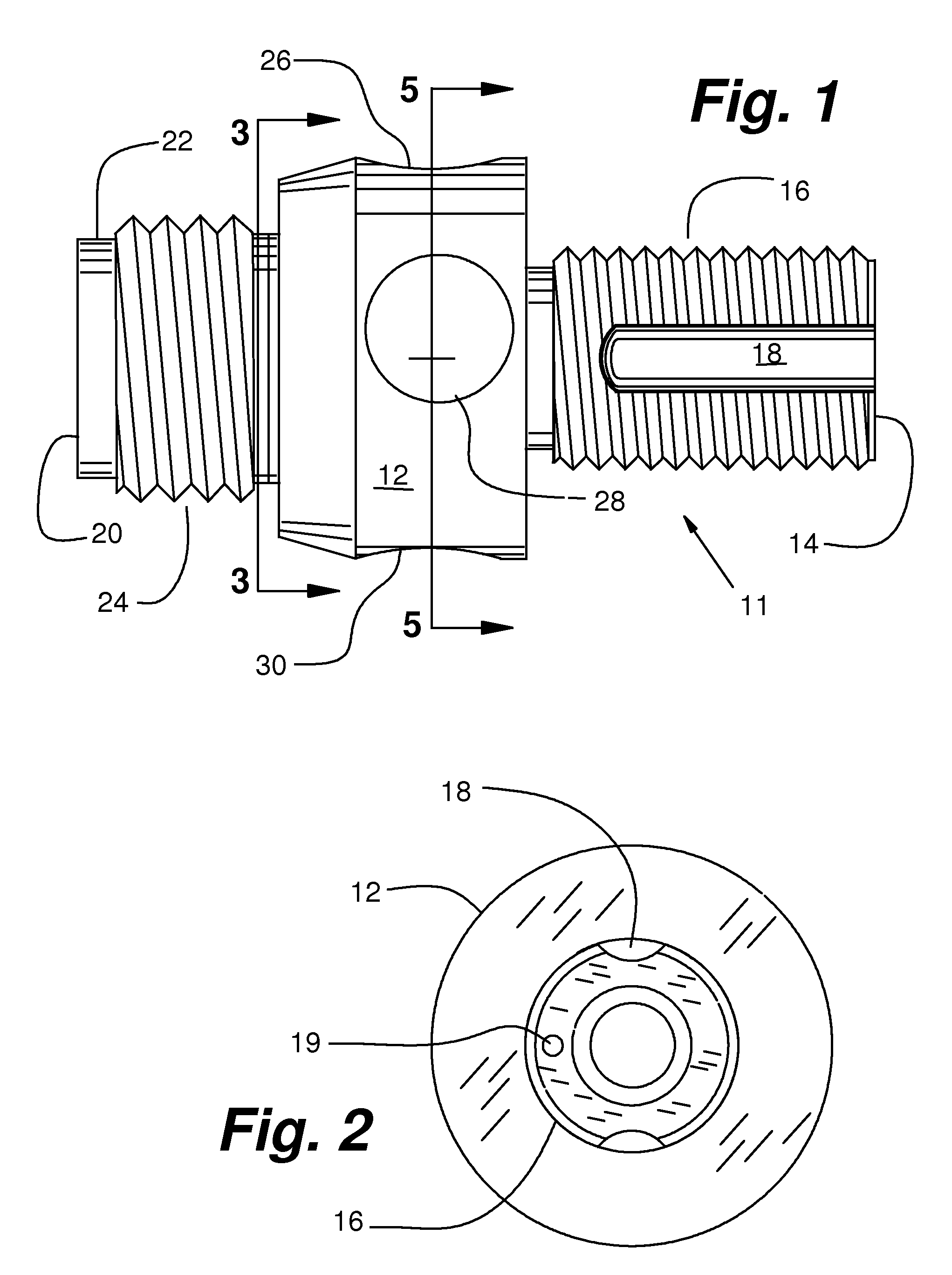

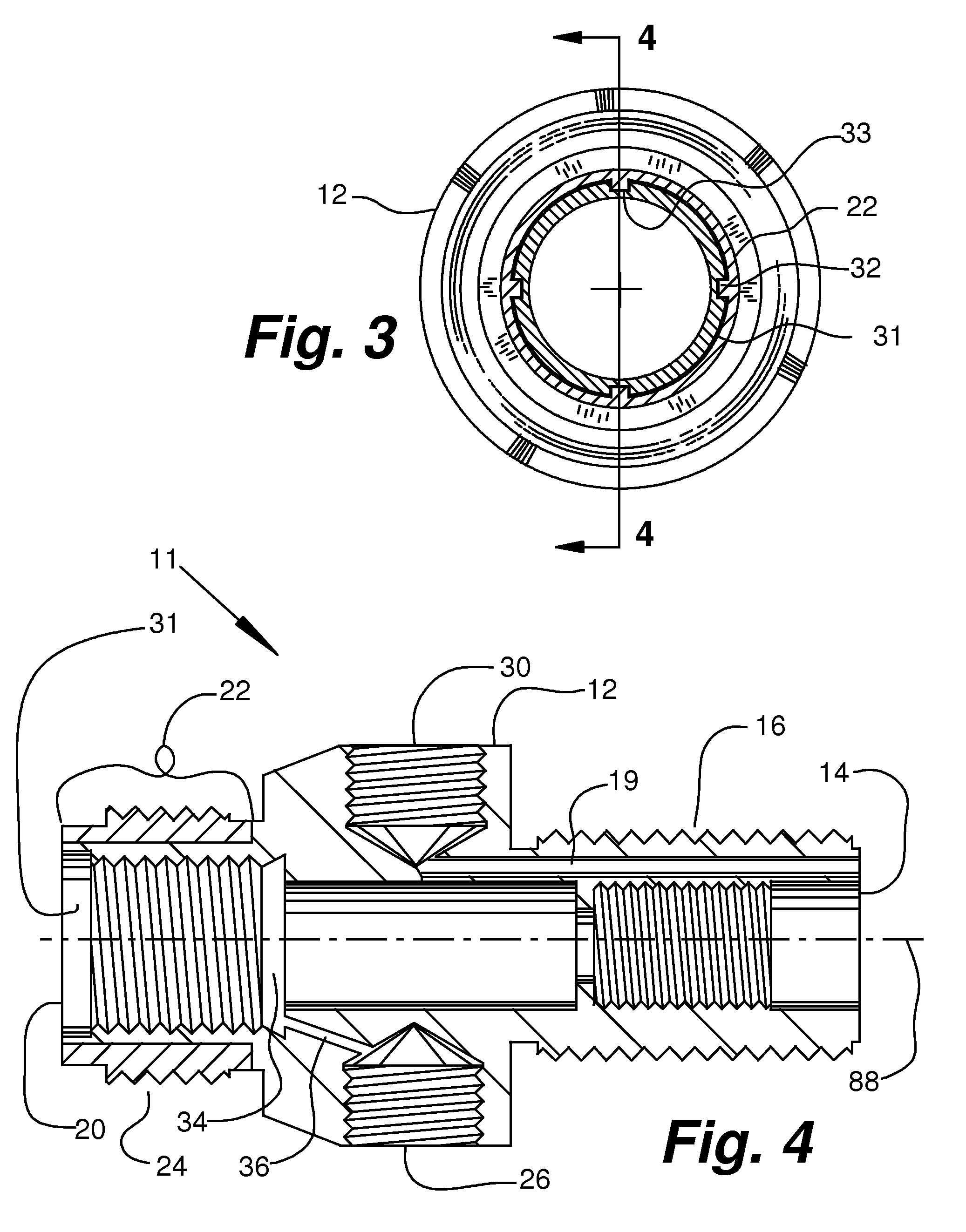

Liquid container pressurization and dispensing device

An apparatus may be utilized for sealing a vessel and for providing various mechanisms for preserving and maintaining freshness of the vessel's contents. In one embodiment, the apparatus prevents a premature oxidation process by enabling a vessel to be filled with contents without compromising the seal of the vessel. Further, the apparatus eliminates the necessity of opening the vessel during the dispensing process, thereby maintaining the vessel's seal while emptying the vessel's contents. The apparatus may be initially purged of ambient air and oxygen prior to filling the vessel with contents further reducing premature oxidation by reducing a substance's oxygen contact as substances initially enter the vessel. The apparatus enables venting of excess gas, thereby preventing over-pressurization of the vessel's structure and over-pressurization of the contents within the vessel. The apparatus regulates the flow of incoming gas, whereby gas is introduced at a consistent rate preventing disruption of the contents.

Owner:CROMULENT CONCEPTIONS

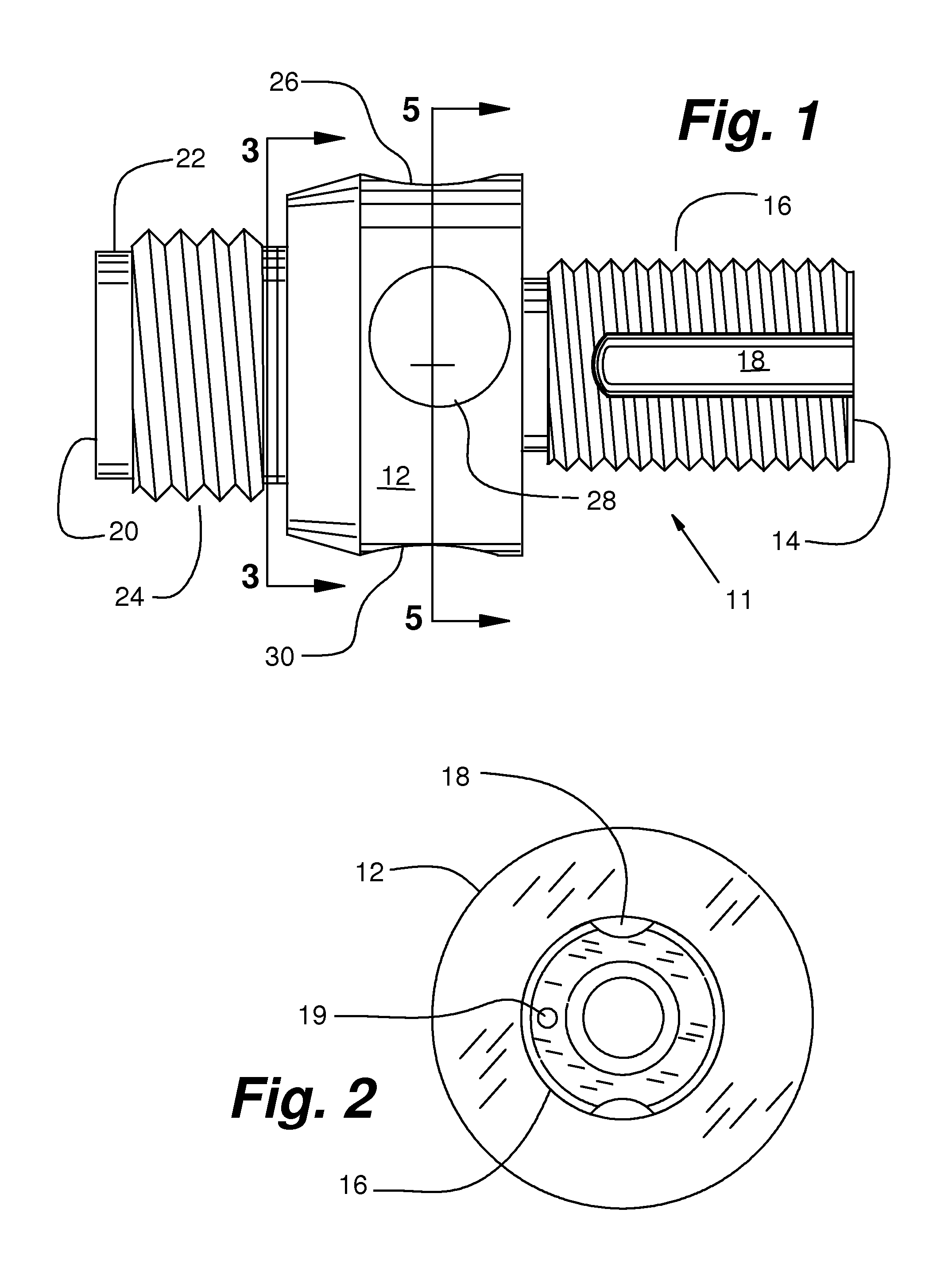

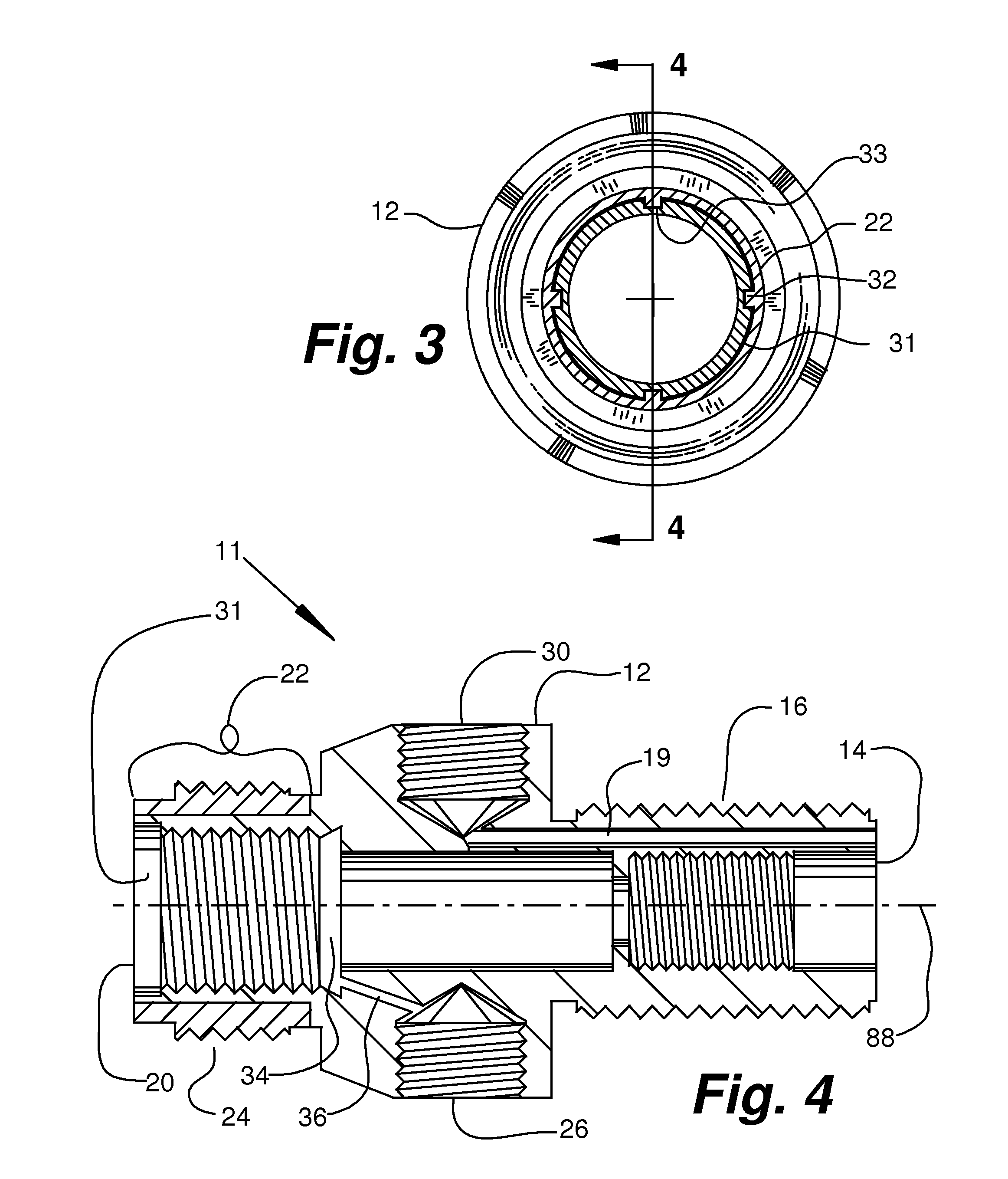

Compressed Gas Regulator Apparatus

InactiveUS20100175763A1Function increaseReduce complexityOperating means/releasing devices for valvesCompressed gas gunsPistonMovement control

Regulators for regulating gas that is delivered in discrete charges from a tank that contains compressed gas to a paintball gun, marker, or other application that utilizes or is activated by pressure controlled discrete charges of gas. The regulator has holding, discharge, and fill configurations, controlled by the movement of a piston member in a pressurized chamber, and the activation of a poppet valve on the discharge of the system. One or two low side pressure relief members are provided to prevent the over-pressurization of the pressurized chamber. An externally threaded sleeve member is non-rotatably, but axially slidably received on a distal portion of the body of the regulator so that the sleeve member and distal portion may be axially slidably disengaged, and the regulator can be rotationally positioned so that the pressure gauge is easily viewed by an operator.

Owner:LEHR IP LLC

System and method for testing fuel tank integrity

ActiveUS7168297B2Easy and rapid connectionPrevent over-pressurizationDetection of fluid at leakage pointMeasurement of fluid loss/gain rateFuel tankEngineering

The invention relates generally to a system and method for testing fuel evaporative systems, and more particularly to a stand-alone tank tester system (and method) for testing vehicle fuel tank integrity. Furthermore, a self-contained calibration tank with switchable leak sizes for calibrating the tank tester to multiple leak sizes is provided. Constant flow and vacuum methods for testing fuel tank integrity are also provided.

Owner:OPUS INSPECTION

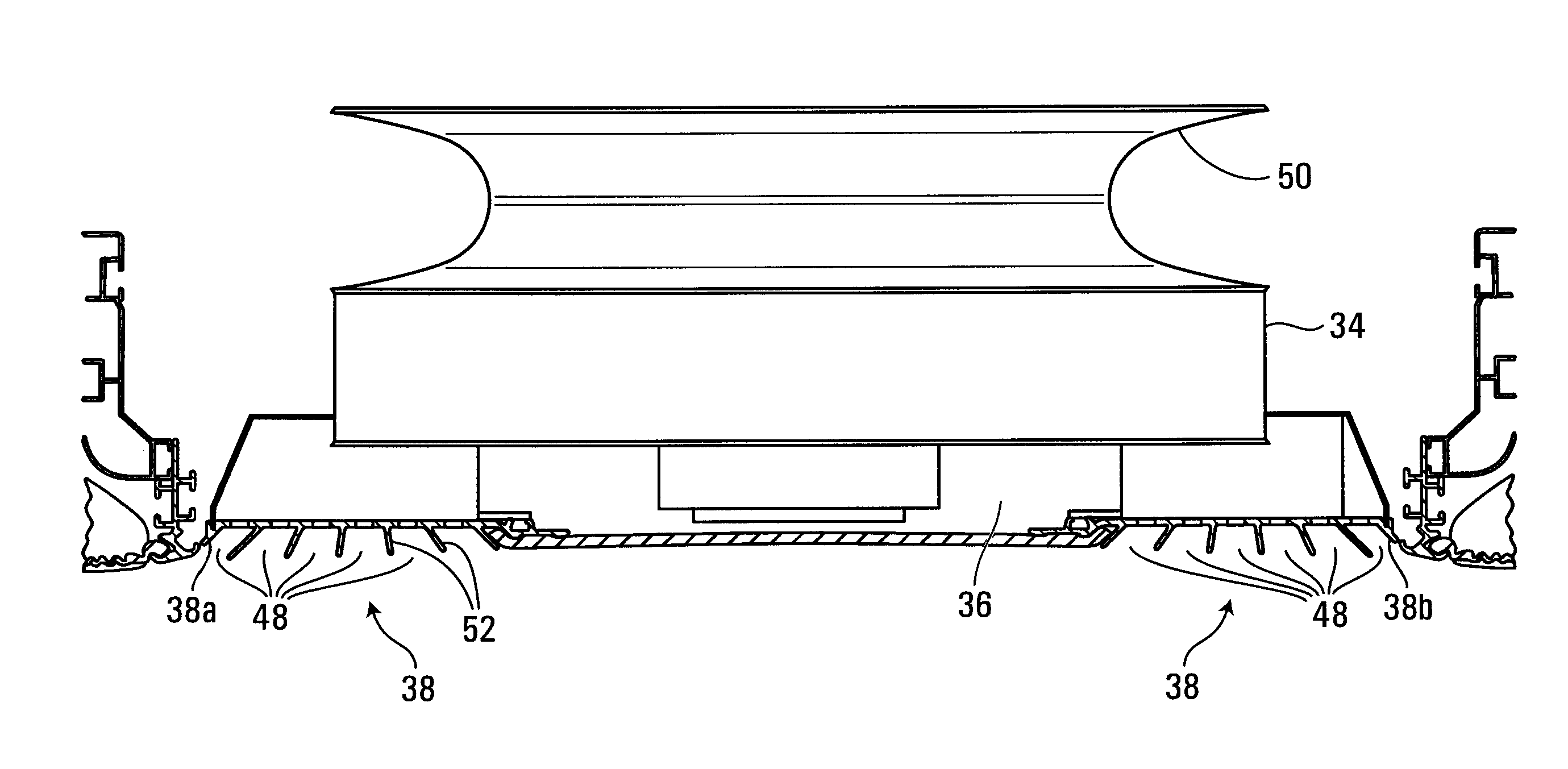

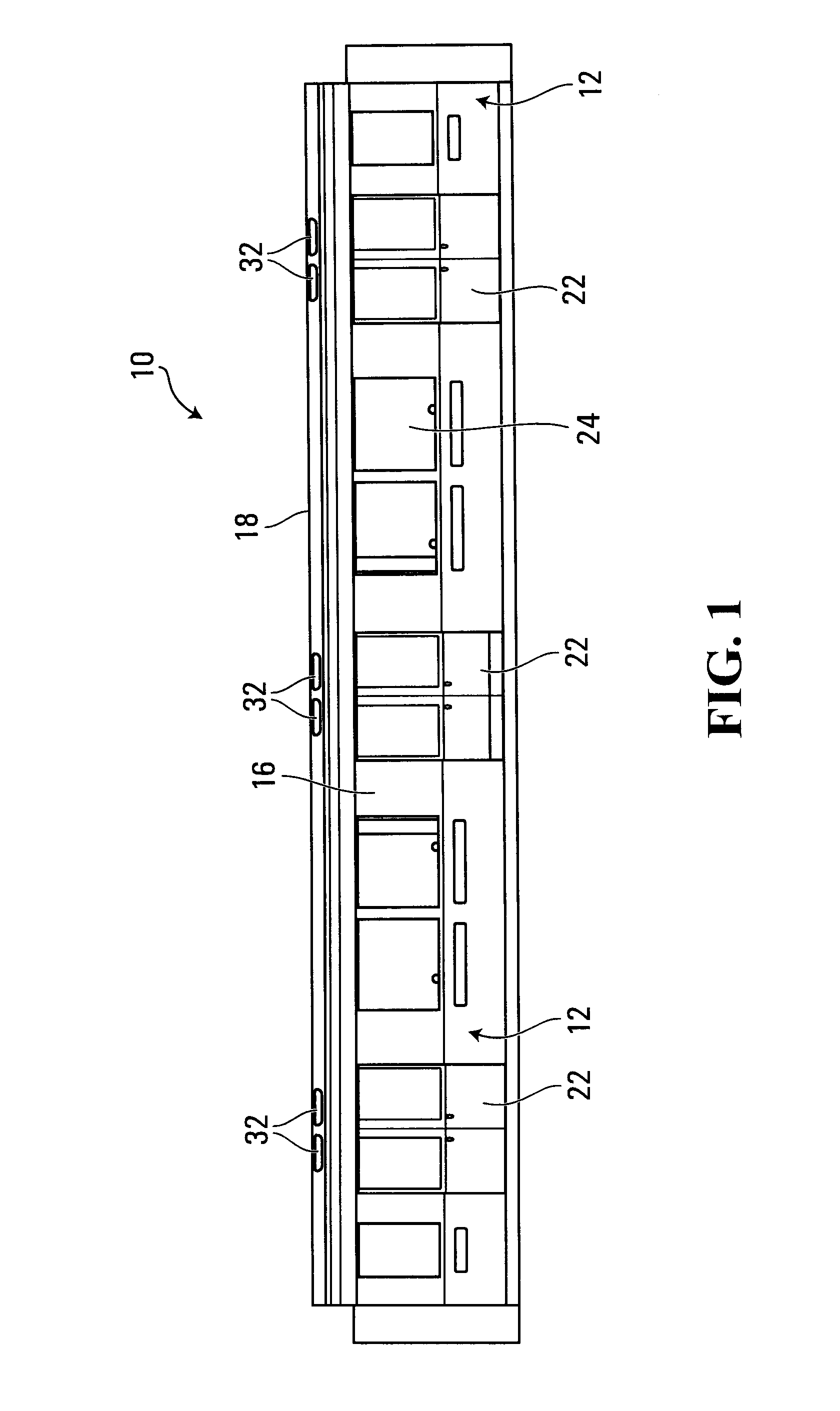

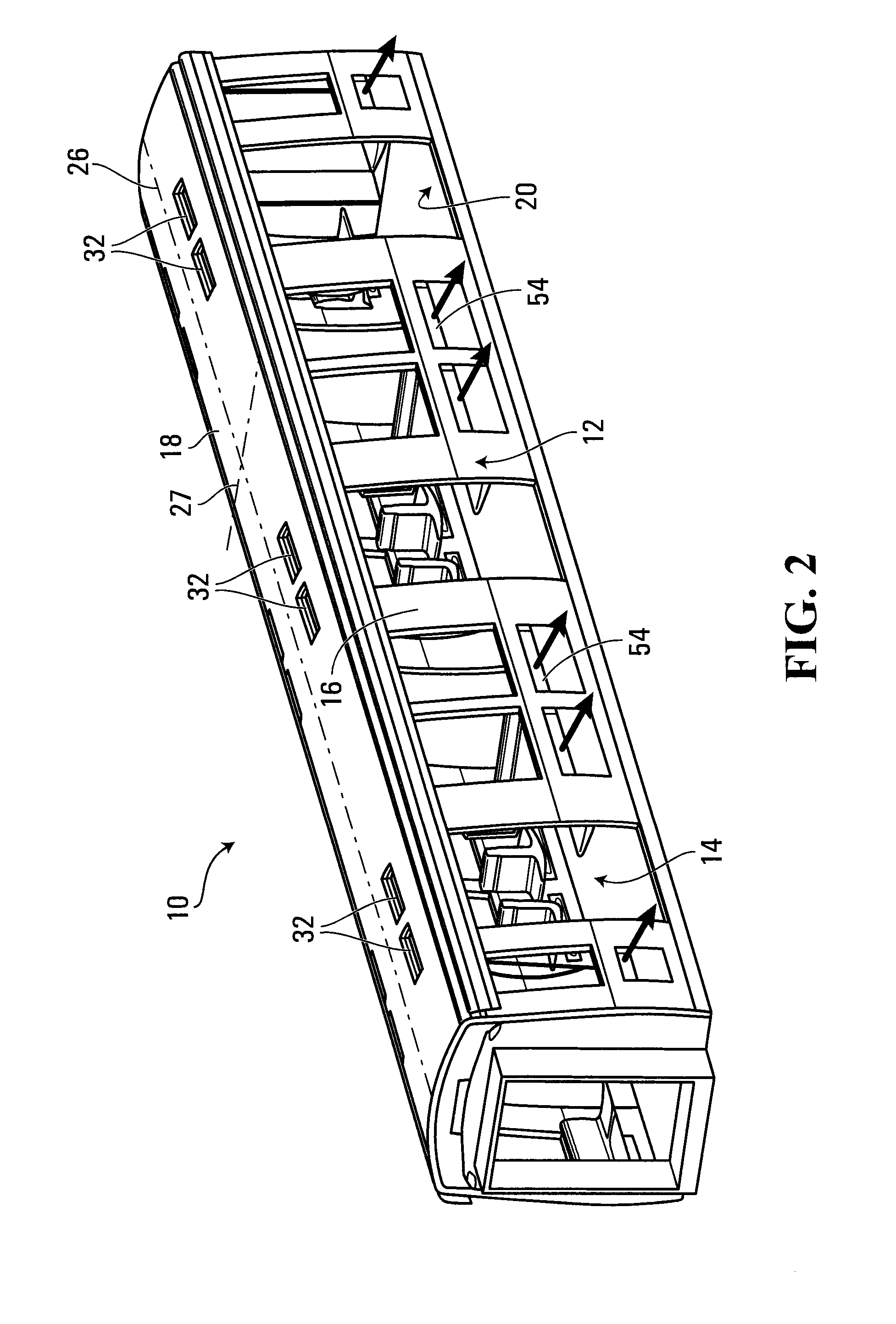

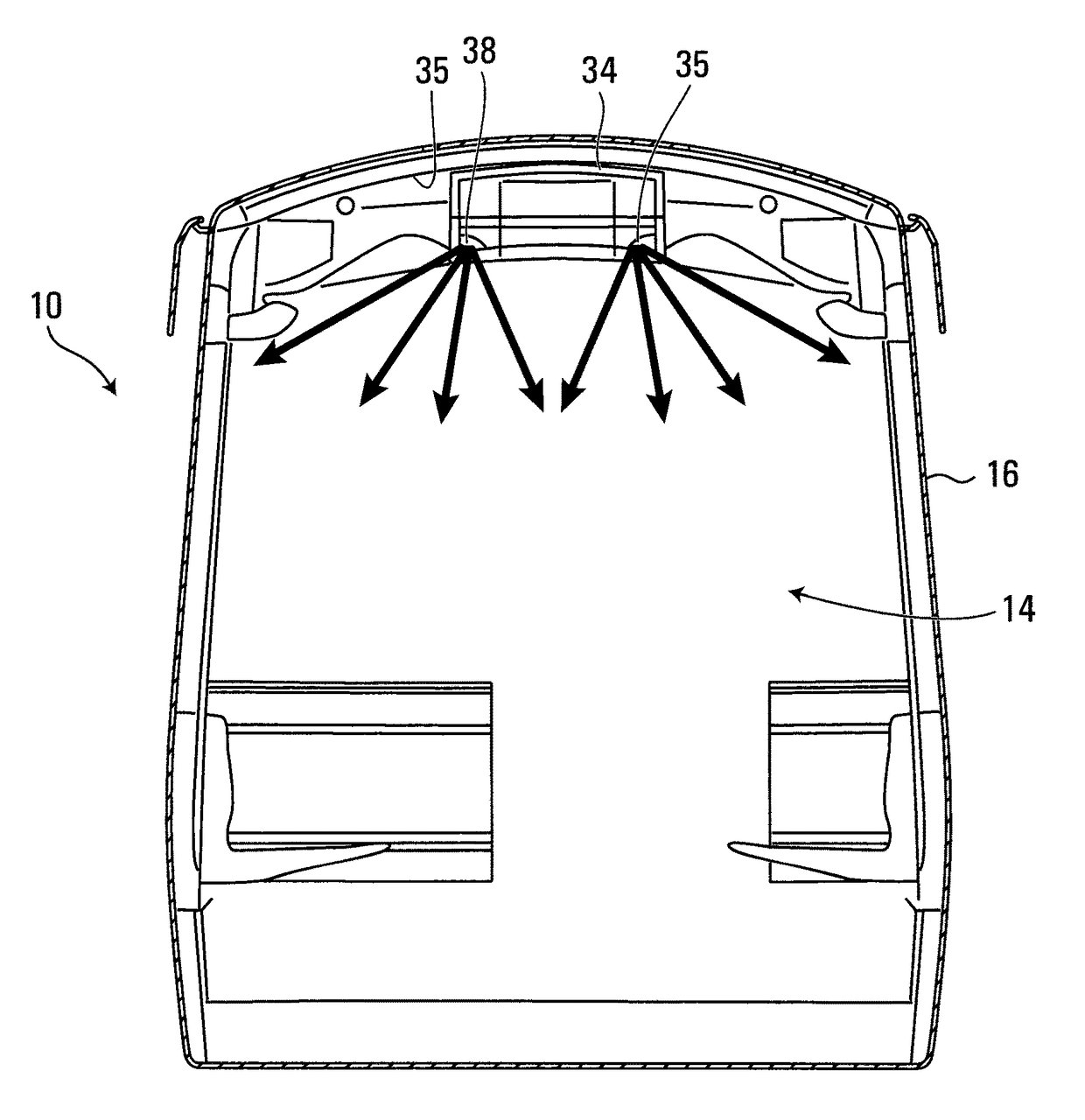

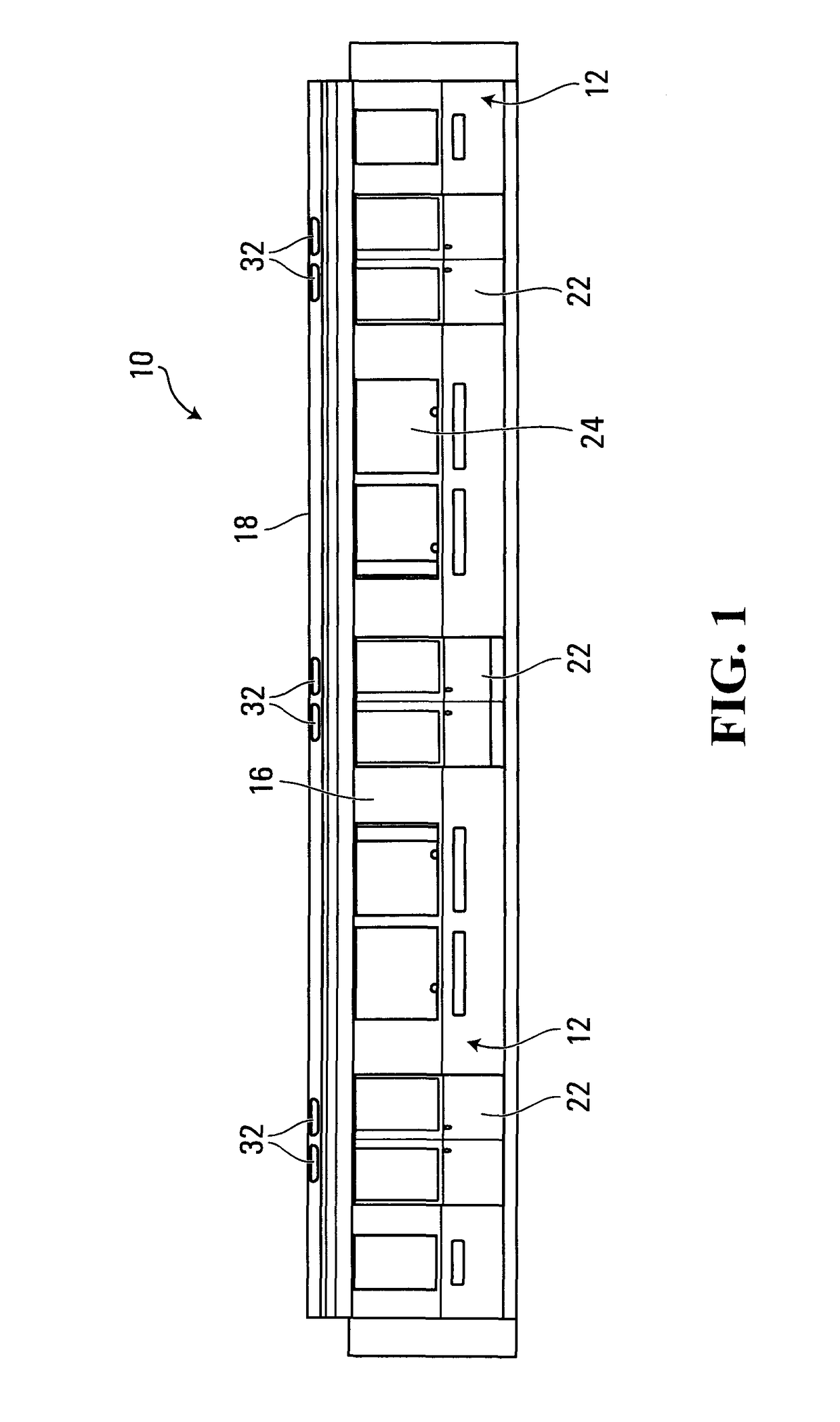

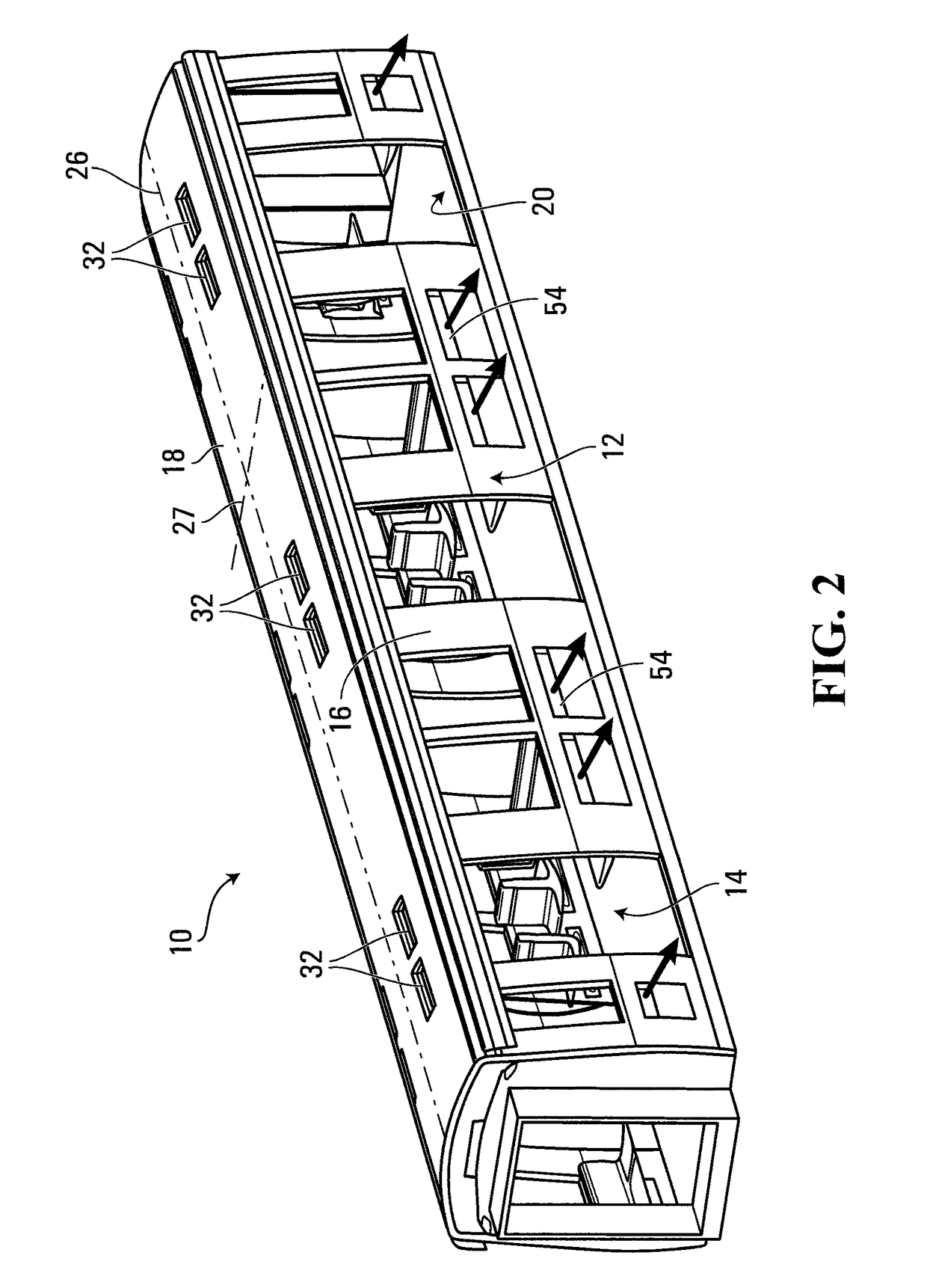

Ventilation System for a Passenger Transit Vehicle

ActiveUS20140295746A1Prevent over-pressurizationRailway roofsAir-treating devicesControl theoryPassenger transport

A ventilation system for a passenger transit vehicle that comprises a passenger compartment. The ventilation system comprises a variable speed fan for providing outside air to the passenger compartment, wherein within a given ambient temperature range, the speed of the variable speed fan is controlled such that the air speed produced by the variable speed fan increases with increasing ambient temperature. The ventilation system further comprises a duct system fluidly connecting the variable speed fan to an air diffuser that directs the air from the variable speed fan towards the passengers within the passenger compartment. The cross sectional area of the duct system decreases along its length for providing substantially constant air pressure along its length. The ventilation system is able to provide outside air into the passenger compartment at an air flow speed of greater than 0.15 m / s.

Owner:BOMBARDIER TRANSPORTATION GMBH

Transportable contaminated remains pouch

Owner:KAPPLER

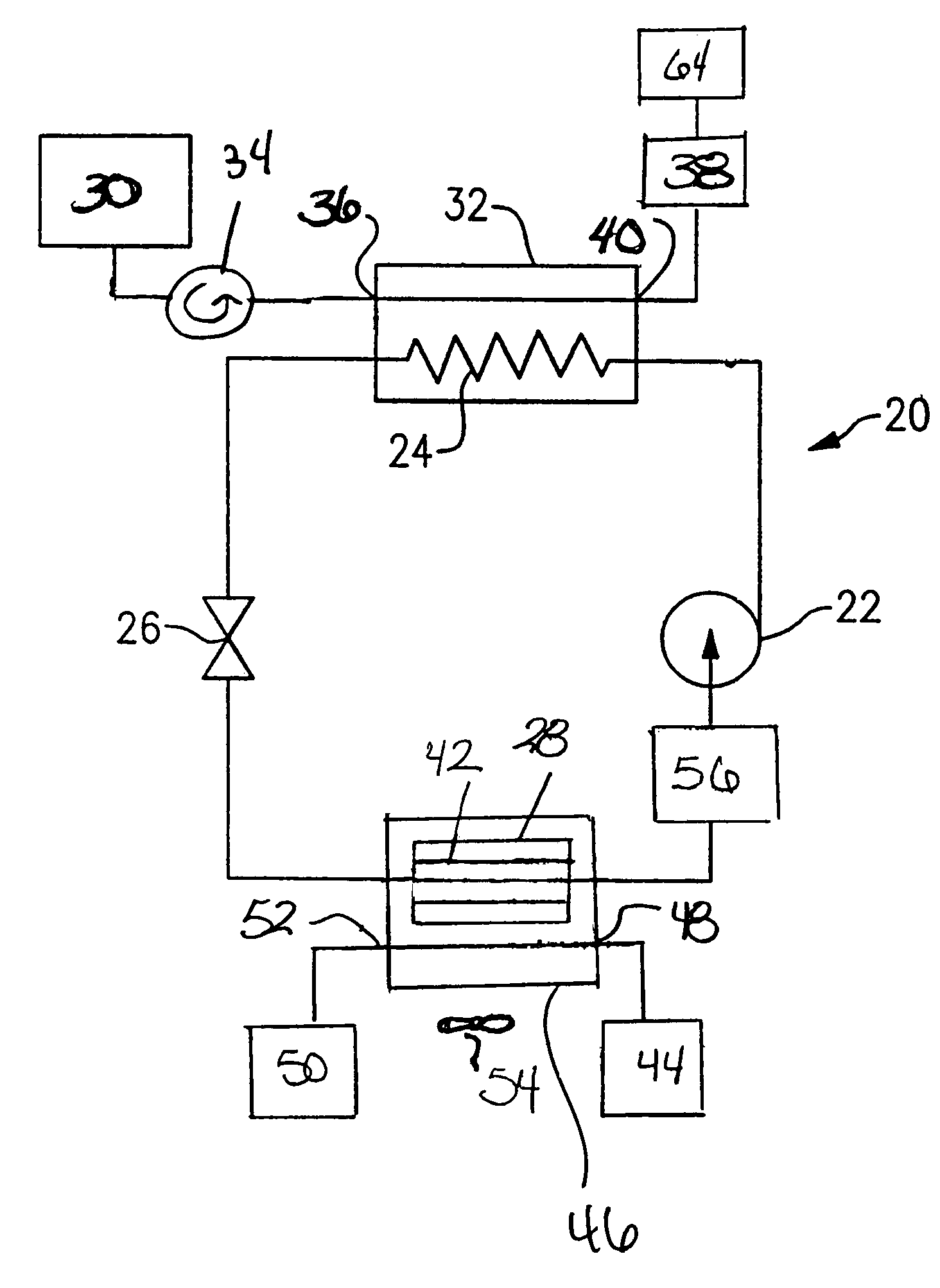

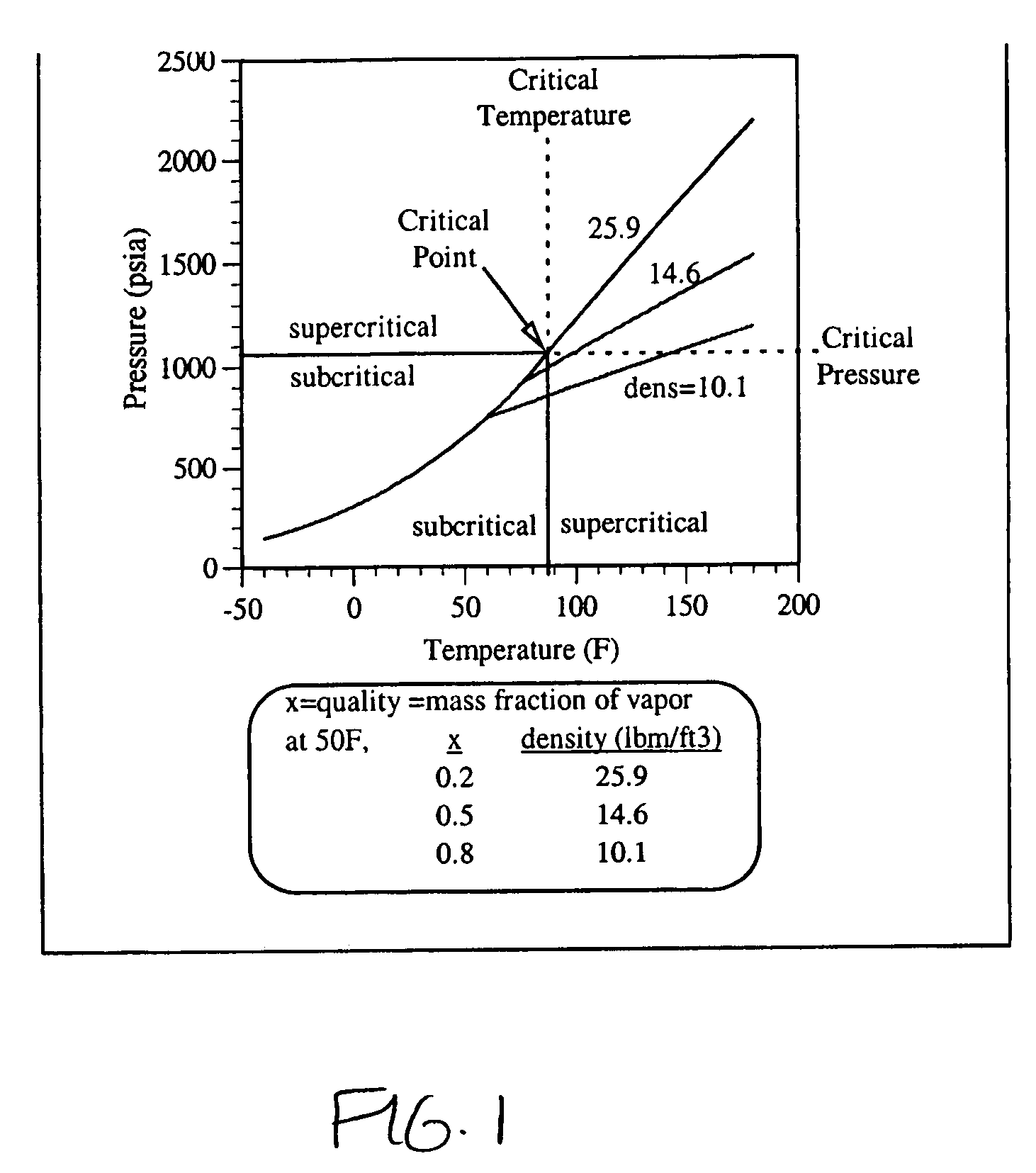

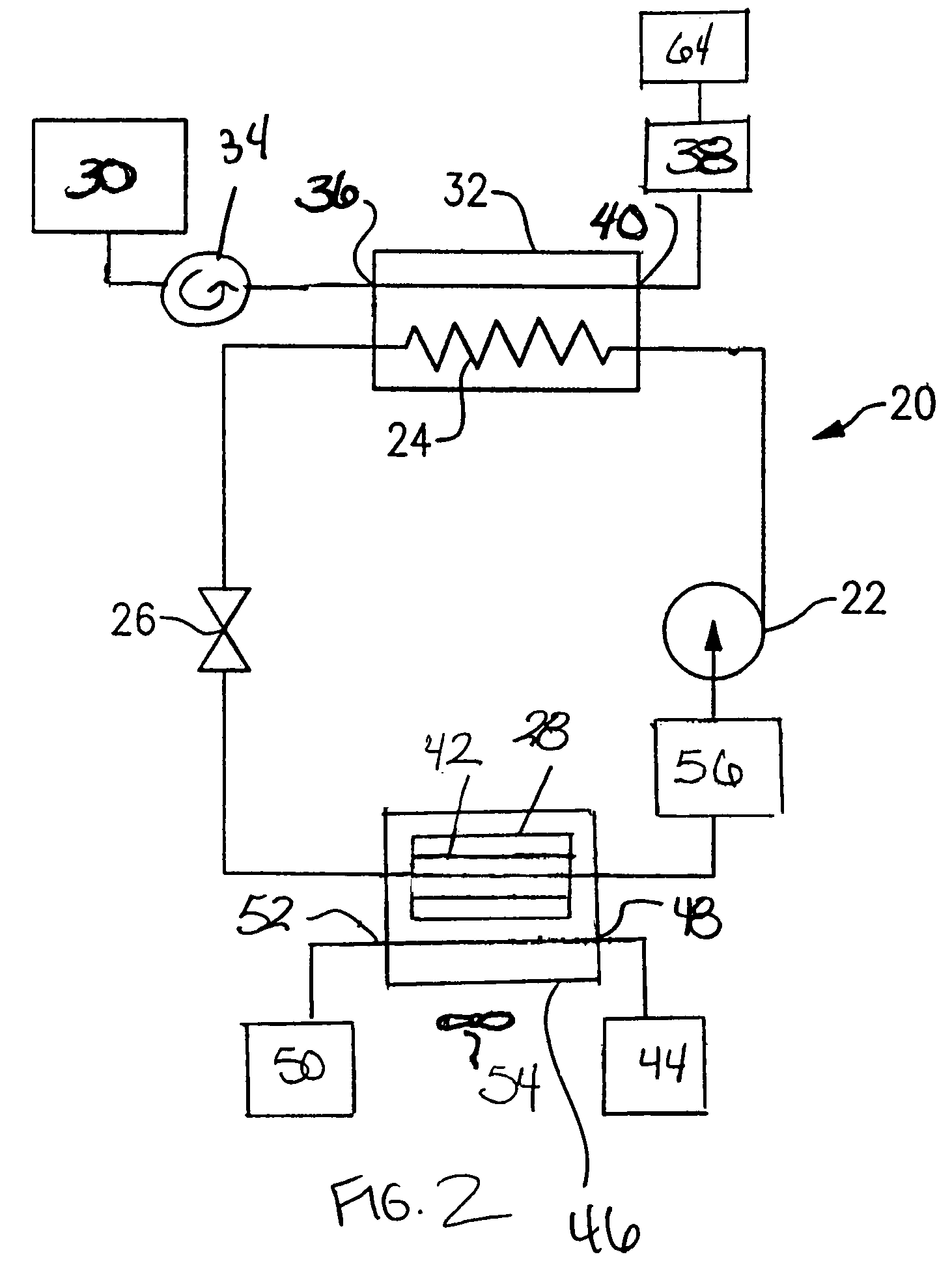

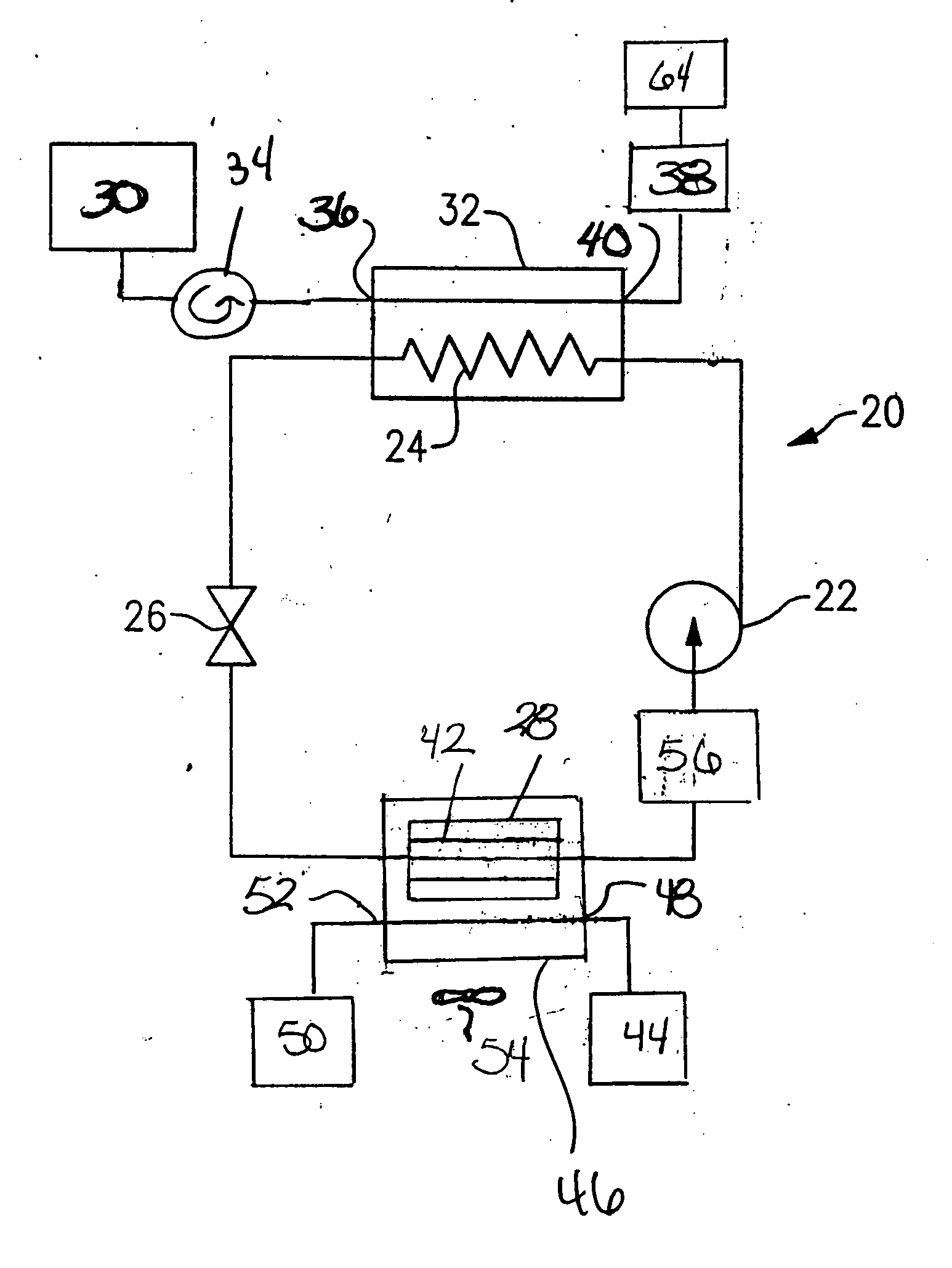

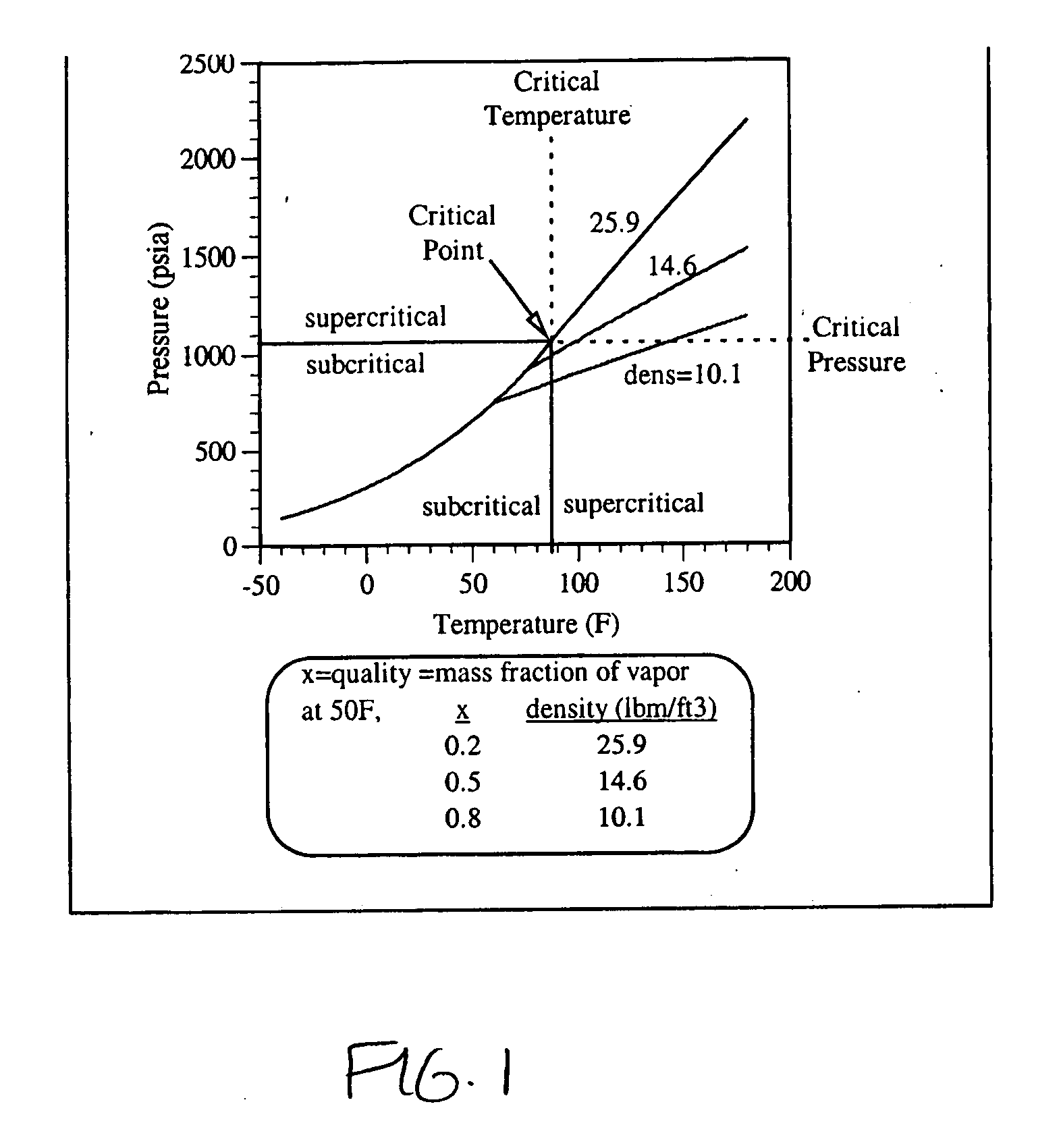

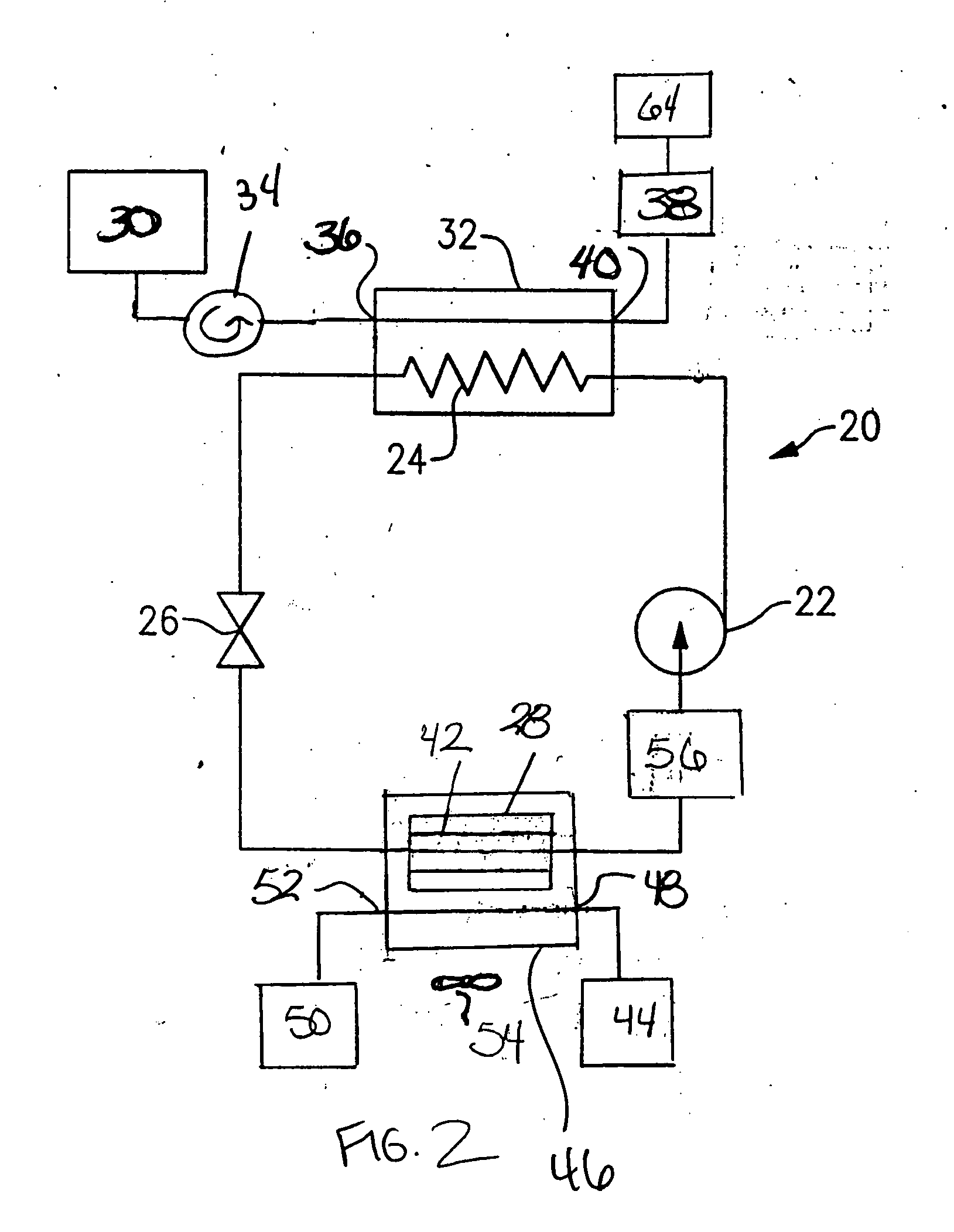

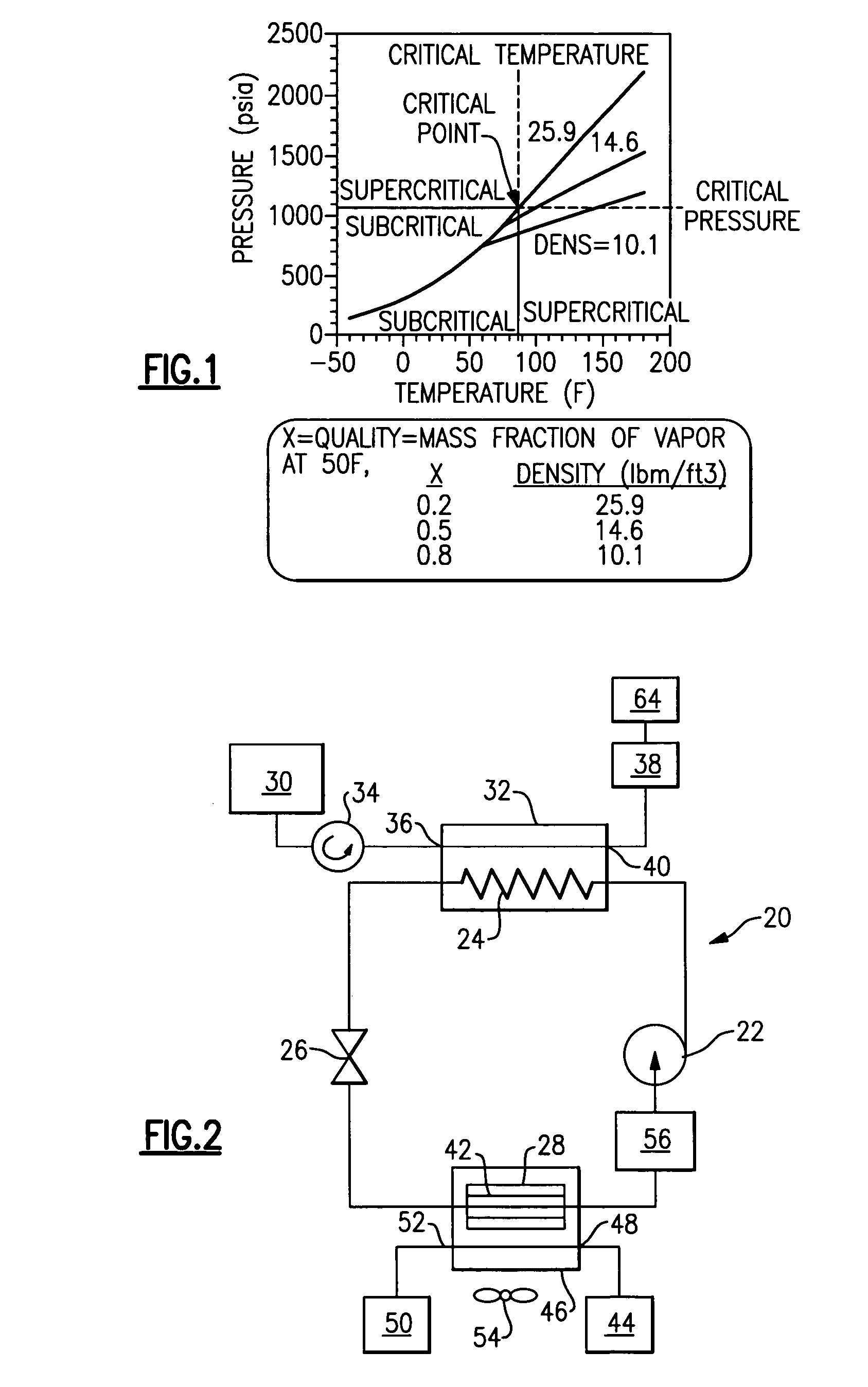

Vapor compression systems using an accumulator to prevent over-pressurization

InactiveUS7024883B2Prevent over-pressurizationCompression machinesRefrigeration componentsEngineeringVolumetric Mass Density

An accumulator acts as a buffer to prevent over-pressurization of the vapor compression system while inactive. By determining the maximum storage temperature and the maximum storage pressure a system will be subject to when inactive, a density of the refrigerant for the overall system can be calculated. Dividing the density by the mass of the refrigerant determines an optimal overall system volume. The volume of the components is subtracted from the overall system volume to calculate the optimal accumulator volume. The optimal accumulator volume is used to size the accumulator so that the accumulator has enough volume to prevent over-pressurization of the system when inactive.

Owner:CARRIER CORP

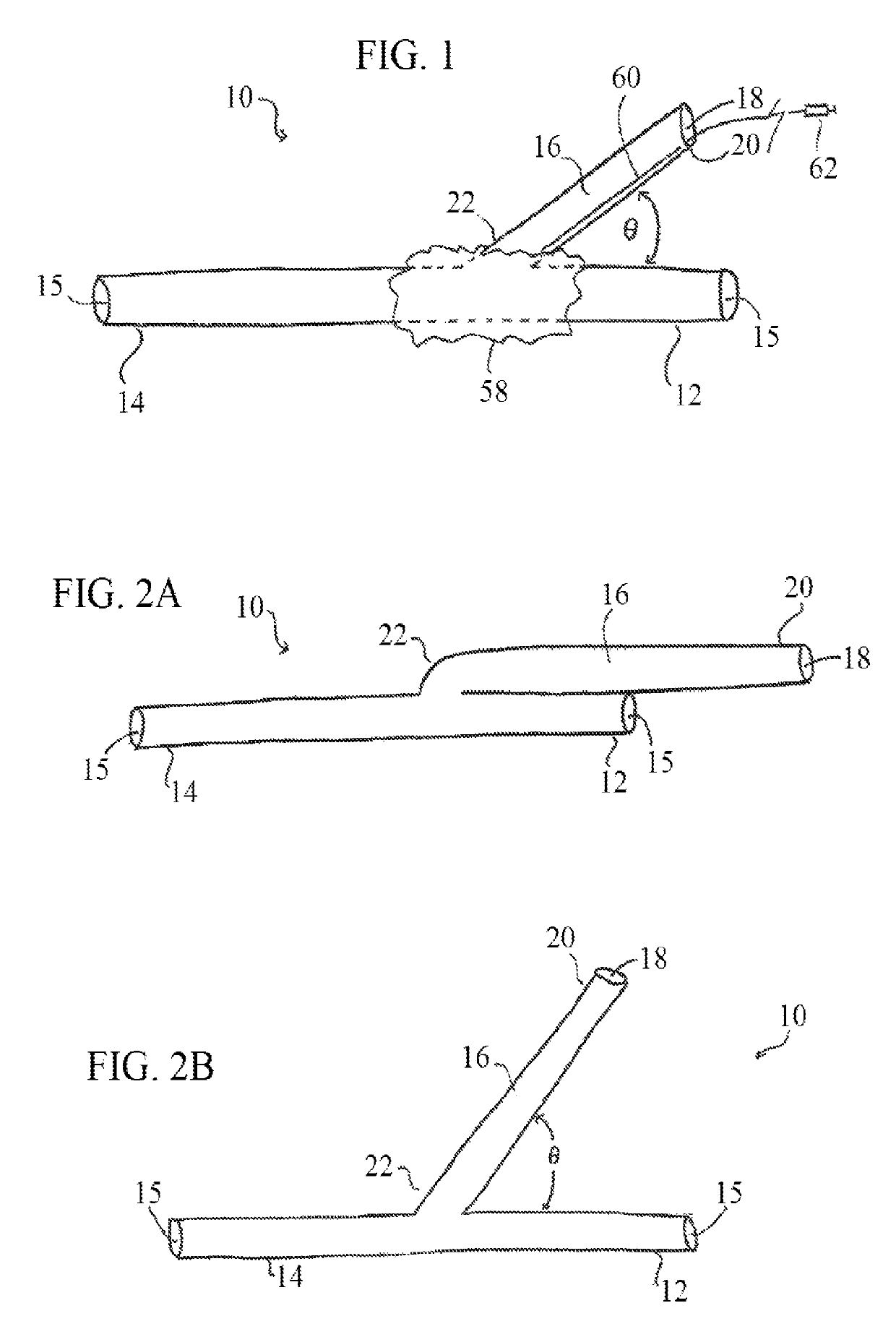

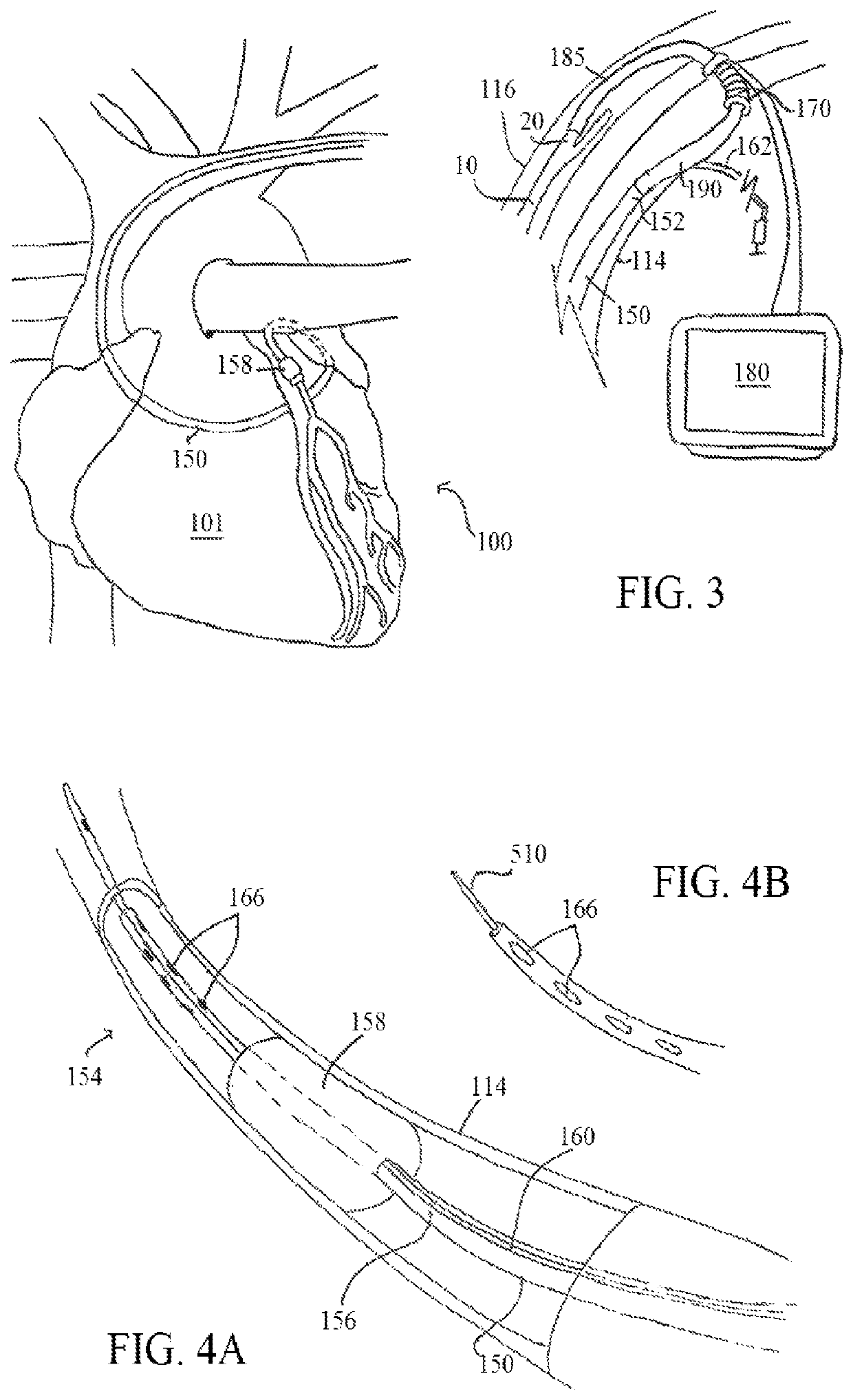

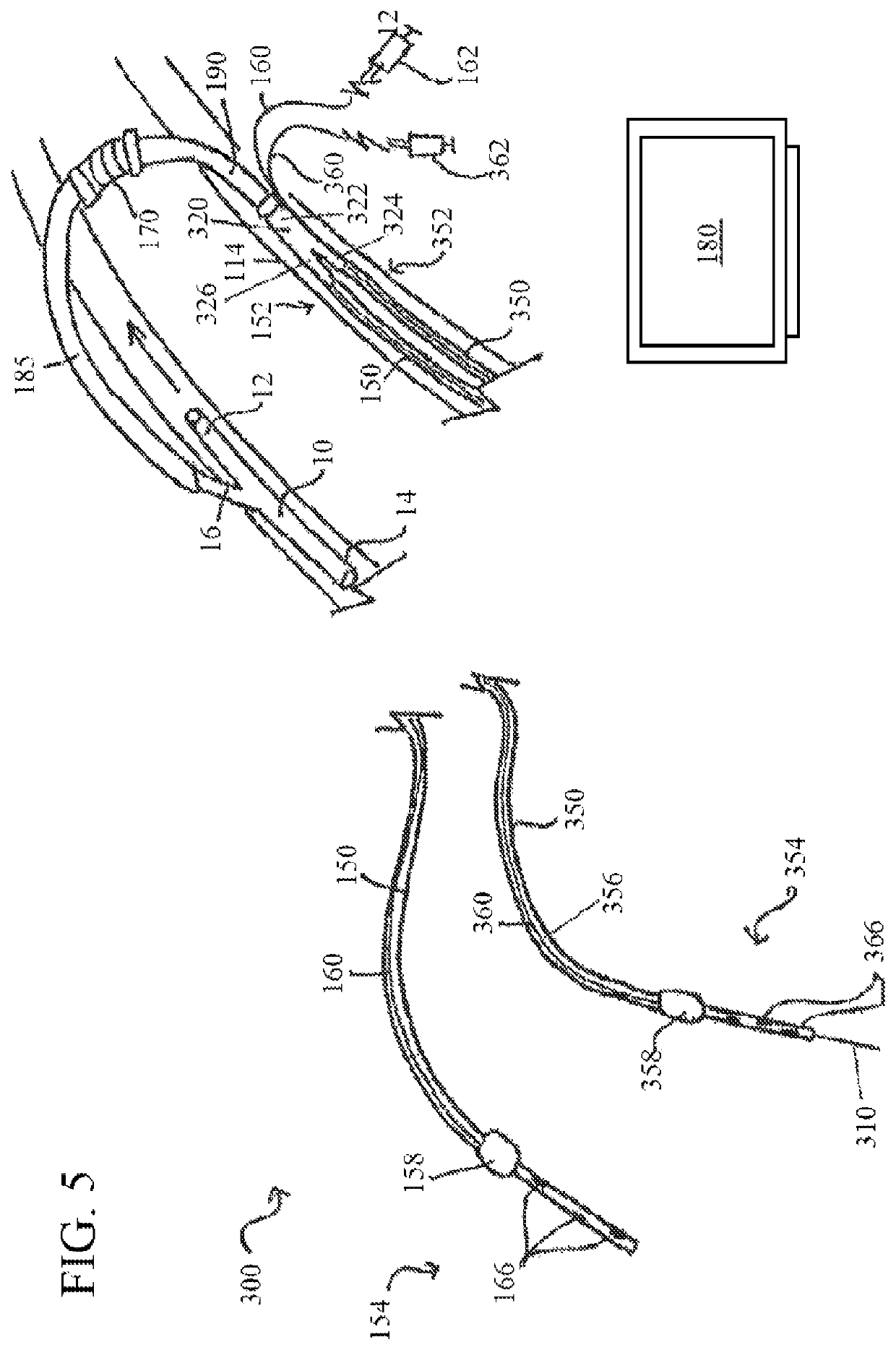

Unitary body systems and devices and methods to use the same for retroperfusion

ActiveUS10363354B2Easy to transformEasy to implantBalloon catheterOther blood circulation devicesVeinMedicine

Unitary body systems and devices and methods to use the same for retroperfusion. In an exemplary device embodiment of the present disclosure, the device comprises a unitary body having a wall and a lumen defined therethrough, a first portion terminating at a first end and configured for at least partial placement within a mammalian artery, a first one-way valve positioned at or near an end of the first portion opposite the first end, a second portion terminating at a second end and configured for at least partial placement within a mammalian vein, and a second one-way valve positioned at or near an end of the second portion opposite the second end.

Owner:CVDEVICES

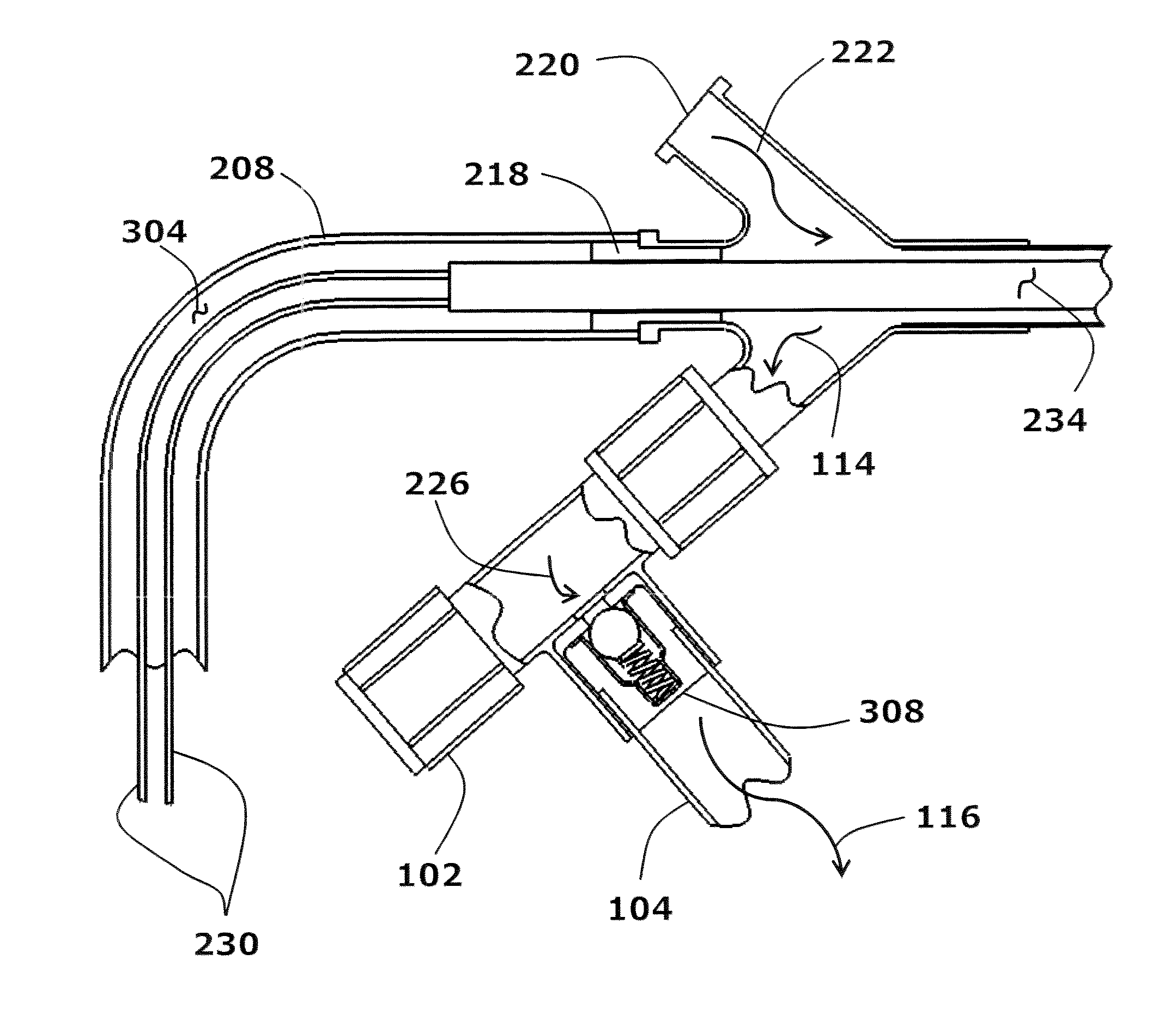

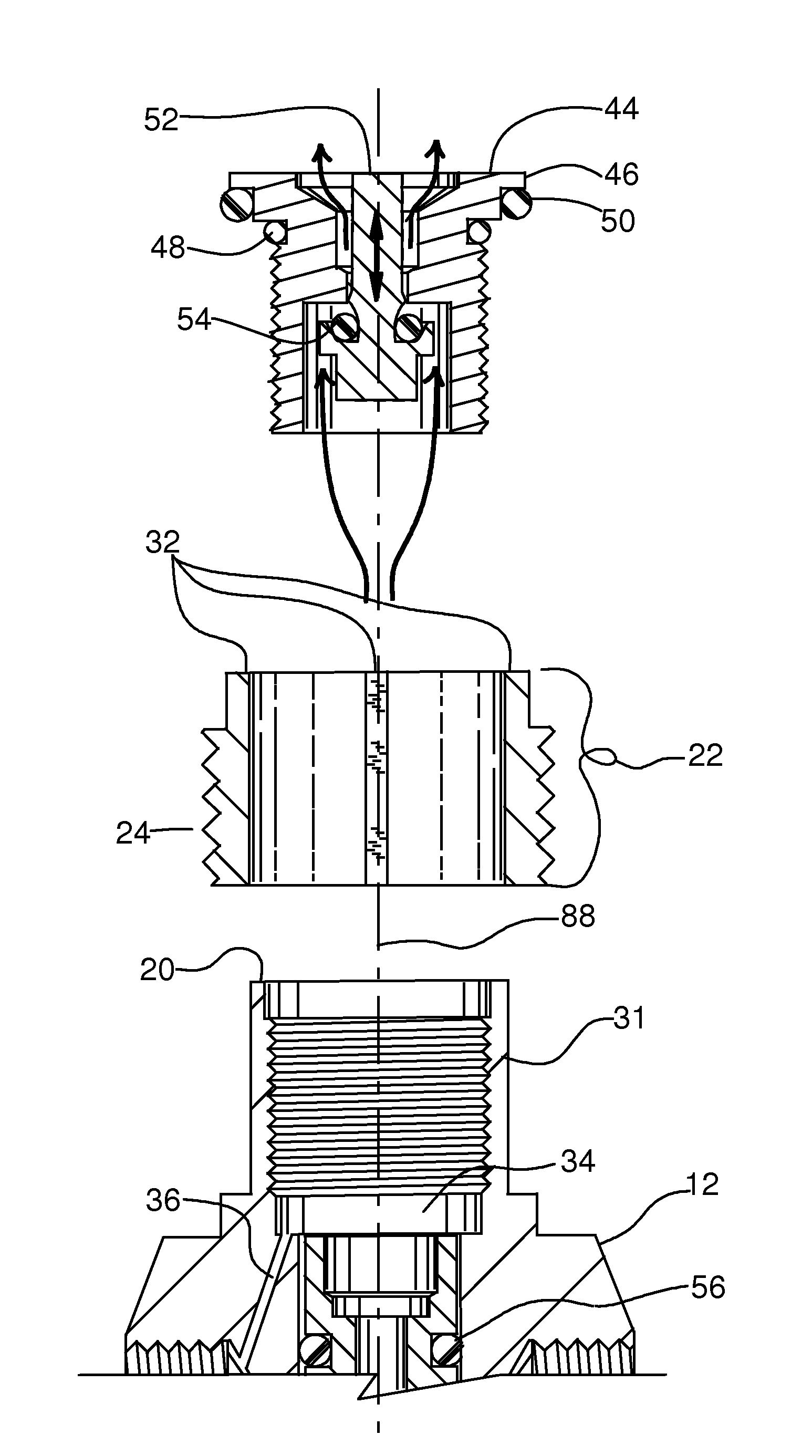

Automated balloon catheter fluid purging system

ActiveUS20150080794A1Optimizes gas escape pathReduces balloon fluid resistanceBalloon catheterOperating means/releasing devices for valvesExhaust valveSolenoid valve

A fluid purging system has a spring-energized relief valve having an inlet port that is coupled to a fluid chamber to receive incoming fluid, and an outlet port through which incoming fluid is relieved. The outlet port is fluidly coupled to a pressurized chamber. The fluid purging system also includes an electro-mechanical pressure switch, and an electrically operated solenoid valve which functions as a pressure exhaust valve. The pressure switch and the solenoid valve are in fluid communication with the pressurized chamber.

Owner:CRYOFOCUS MEDTECH (SHANGHAI) CO LTD

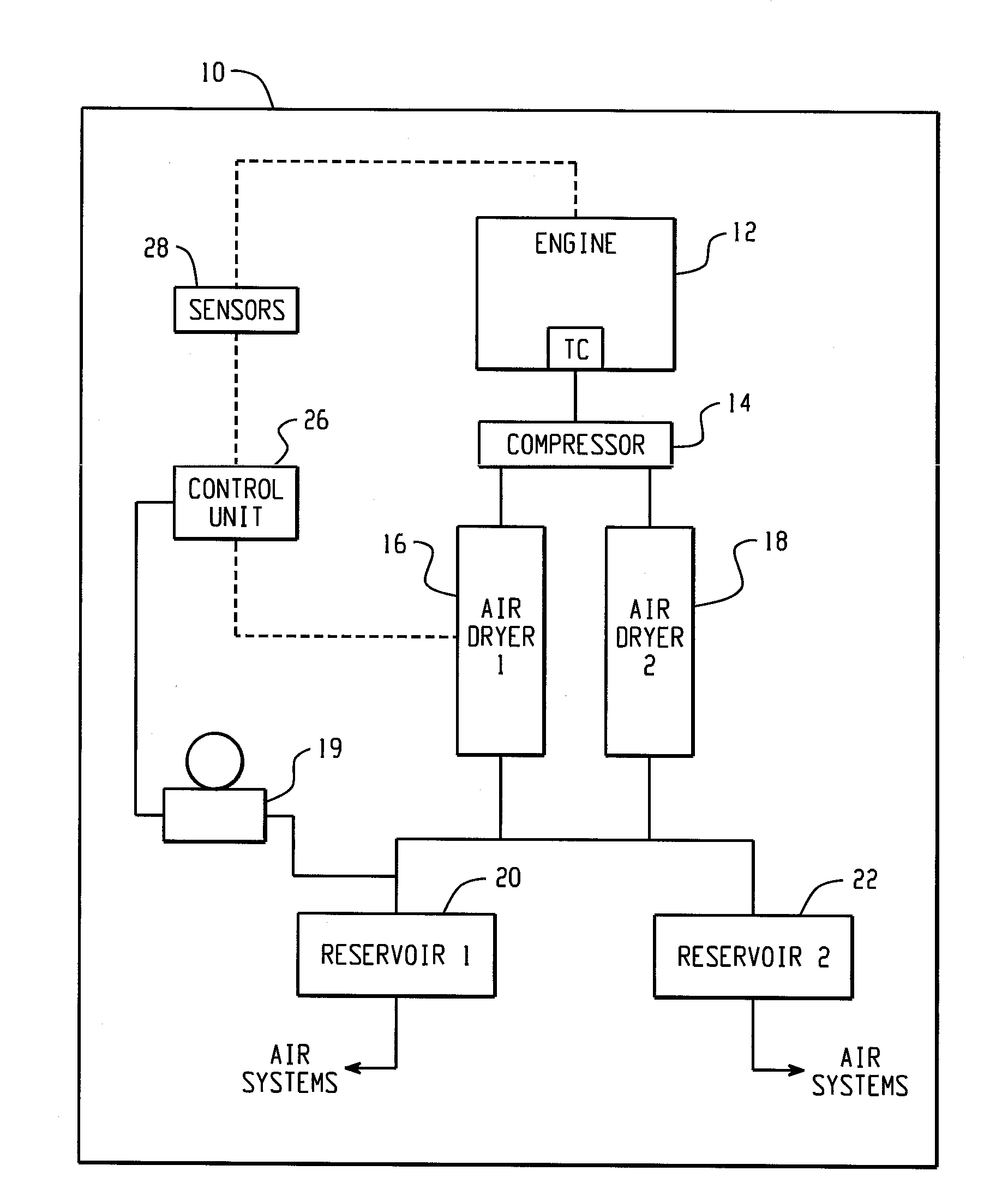

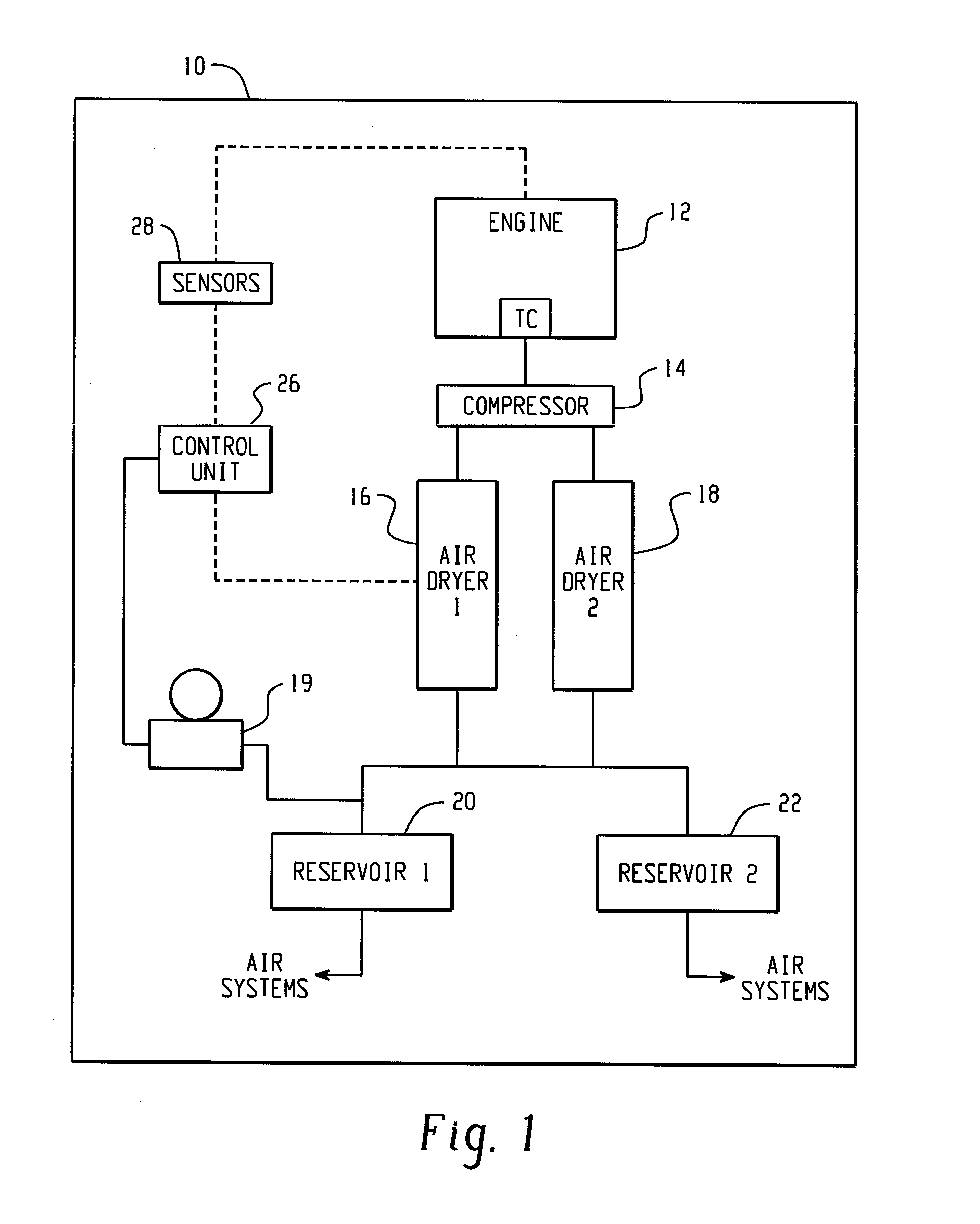

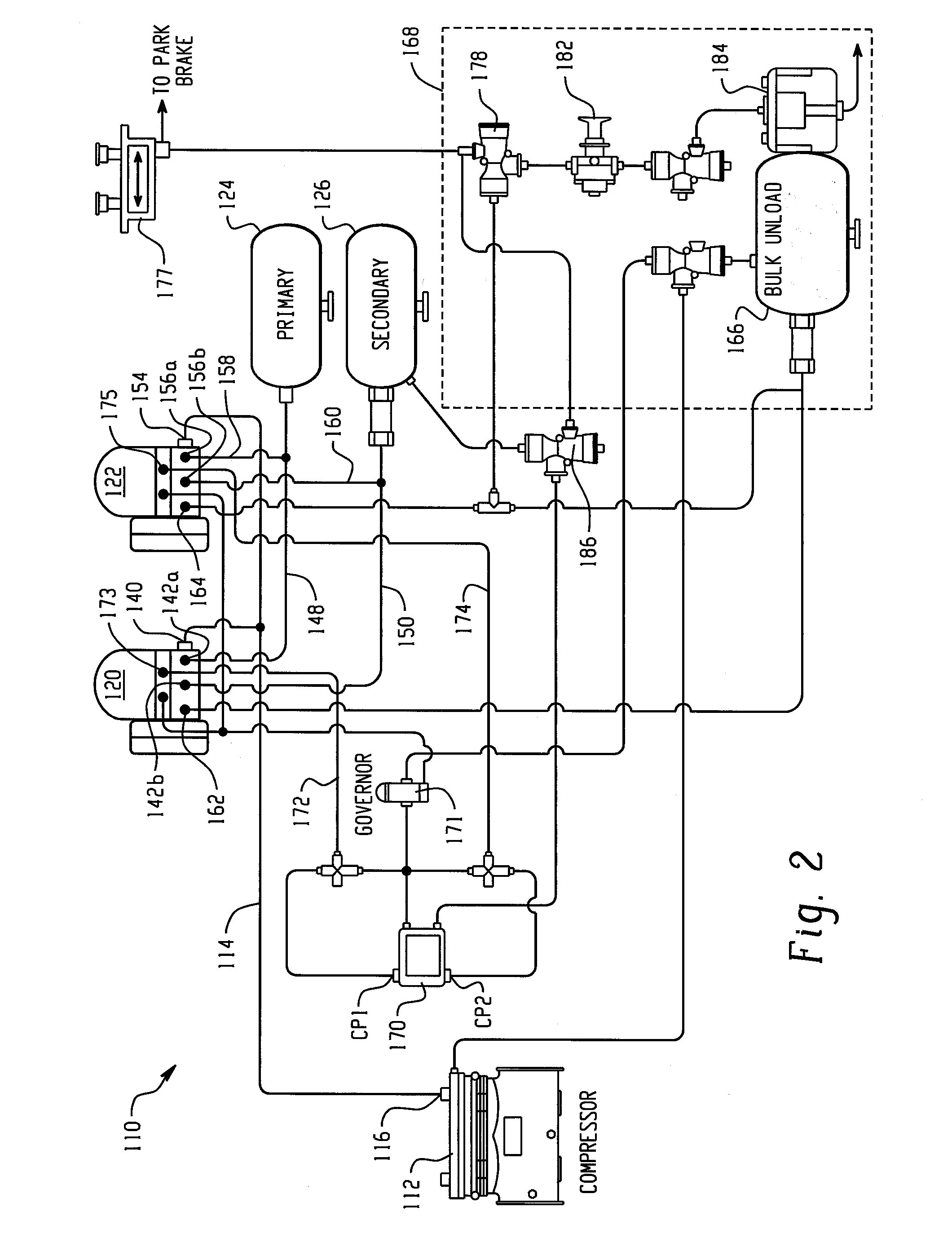

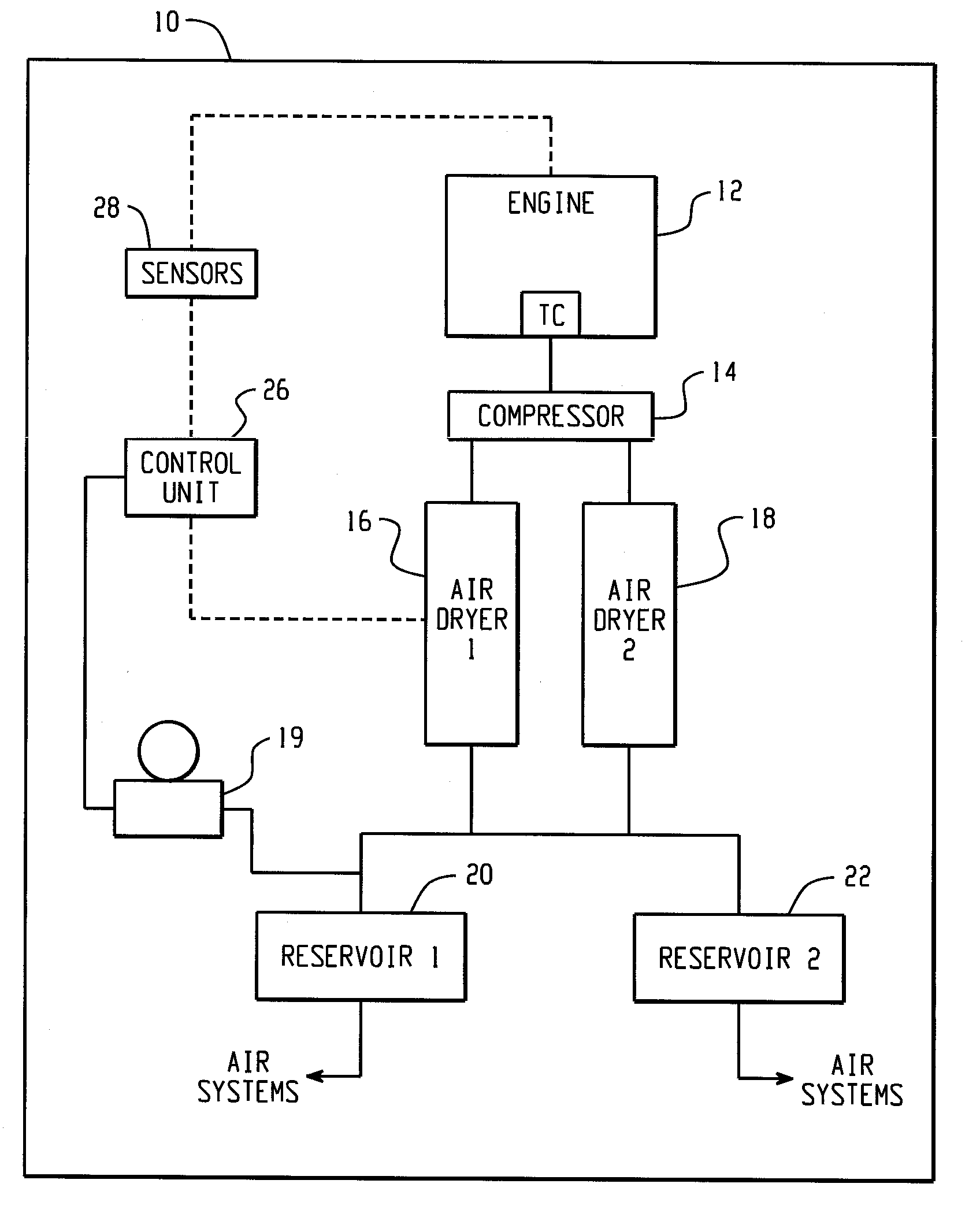

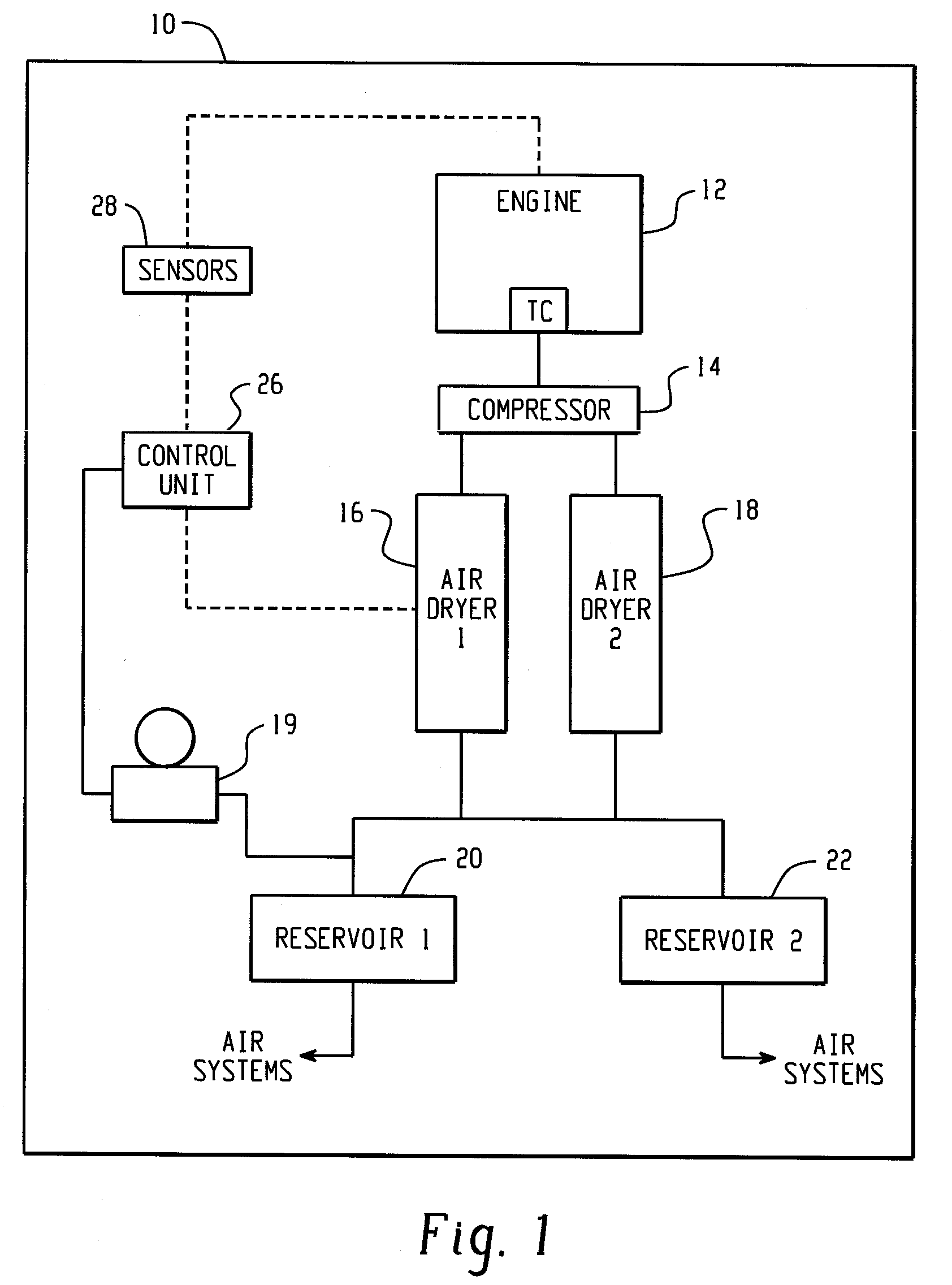

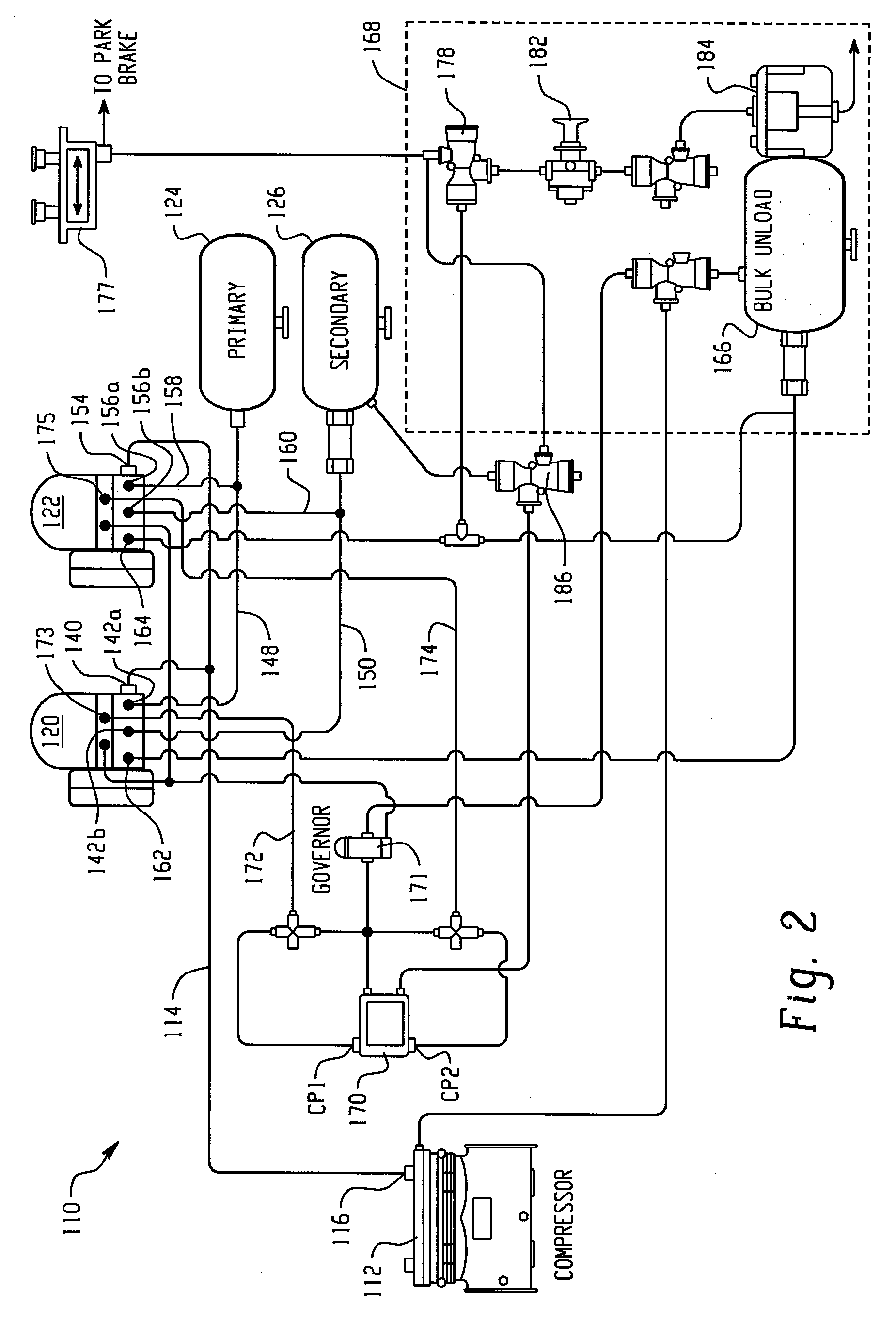

Dual purpose dryers for high flow

ActiveUS20150251646A1Prevent over-pressurizationGas treatmentDispersed particle filtrationAxial compressorDual purpose

A system and method of controlling an air dryer system having first and second air dryers configured to receive compressed air from a compressor, such as a compressor of a vehicle, including operating the first and second air dryers in a first mode corresponding to a high flow mode wherein the first and second air dryers are connected in parallel with the air compressor, monitoring a condition related to a low compressor output state, and operating the first and second air dryers in a second mode corresponding to a continuous flow mode when the low compressor output state is detected.

Owner:BENDIX COMML VEHICLE SYST LLC

System and method for testing fuel tank integrity

InactiveUS20070033987A1Easy and rapid connectionPrevent over-pressurizationDetection of fluid at leakage pointMeasurement of fluid loss/gain rateFuel tankTester device

The invention relates generally to a system and method for testing fuel evaporative systems, and more particularly to a stand-alone tank tester system (and method) for testing vehicle fuel tank integrity. Furthermore, a self-contained calibration tank with switchable leak sizes for calibrating the tank tester to multiple leak sizes is provided. Constant flow and vacuum methods for testing fuel tank integrity are also provided.

Owner:OPUS INSPECTION

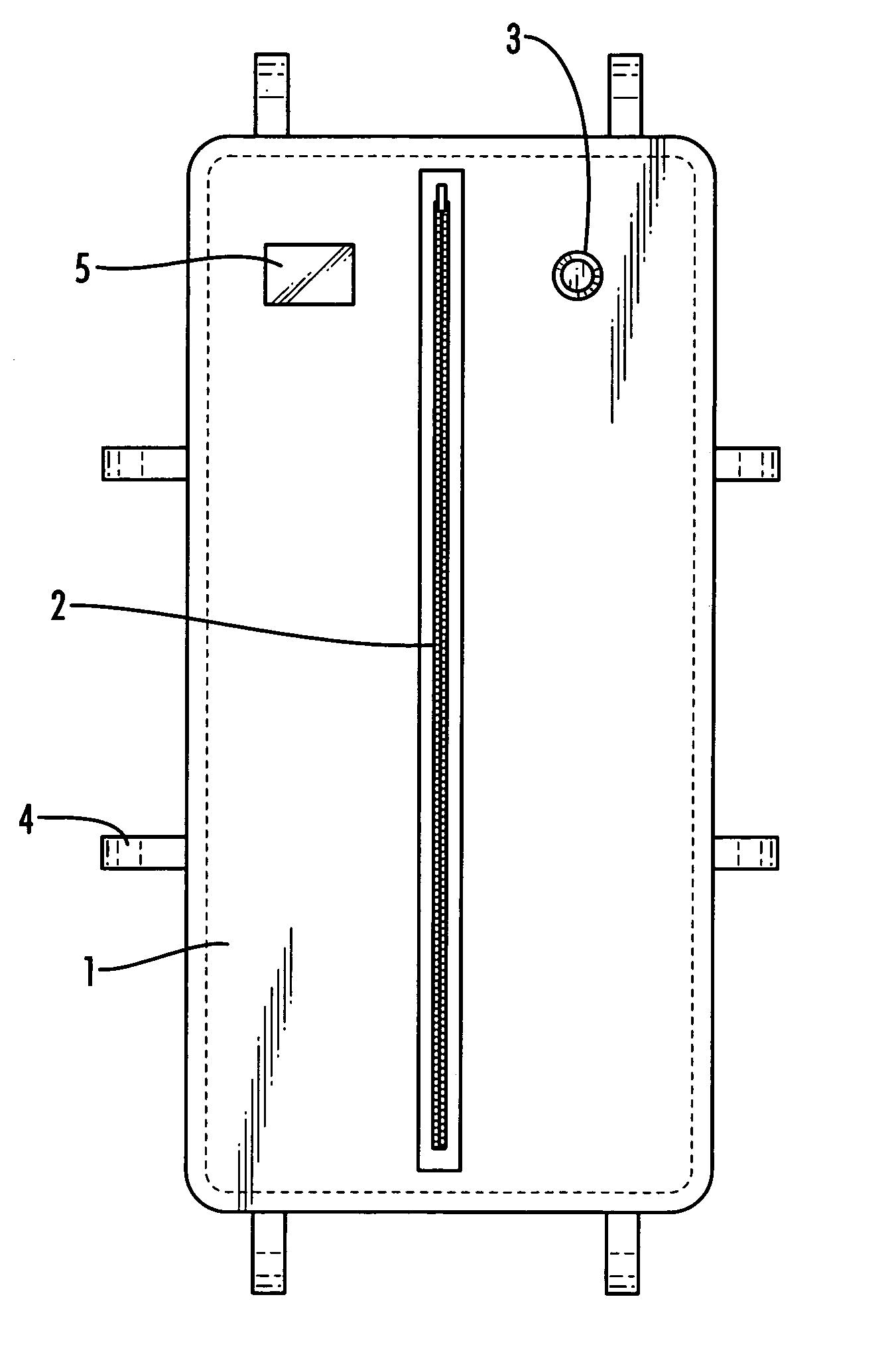

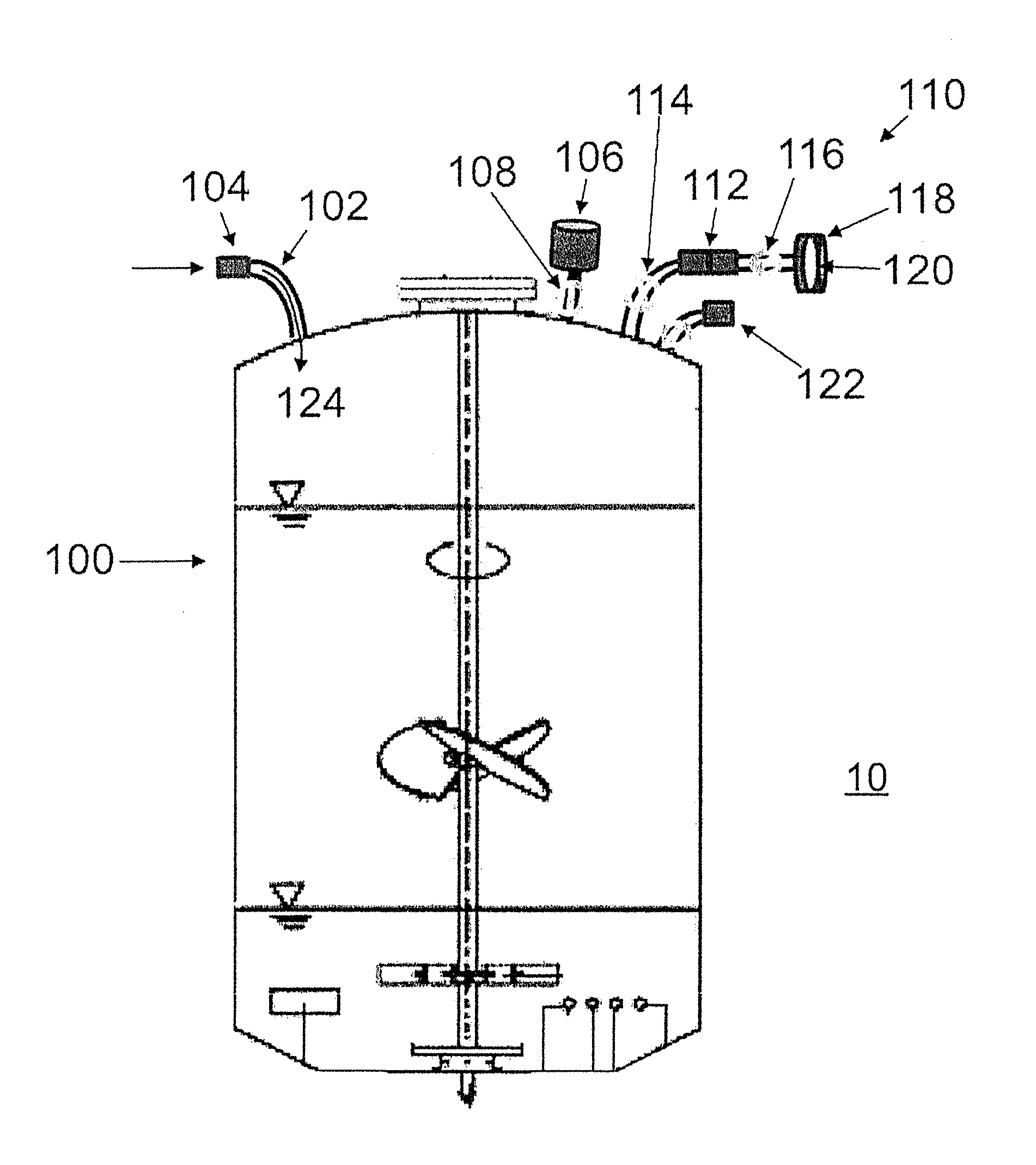

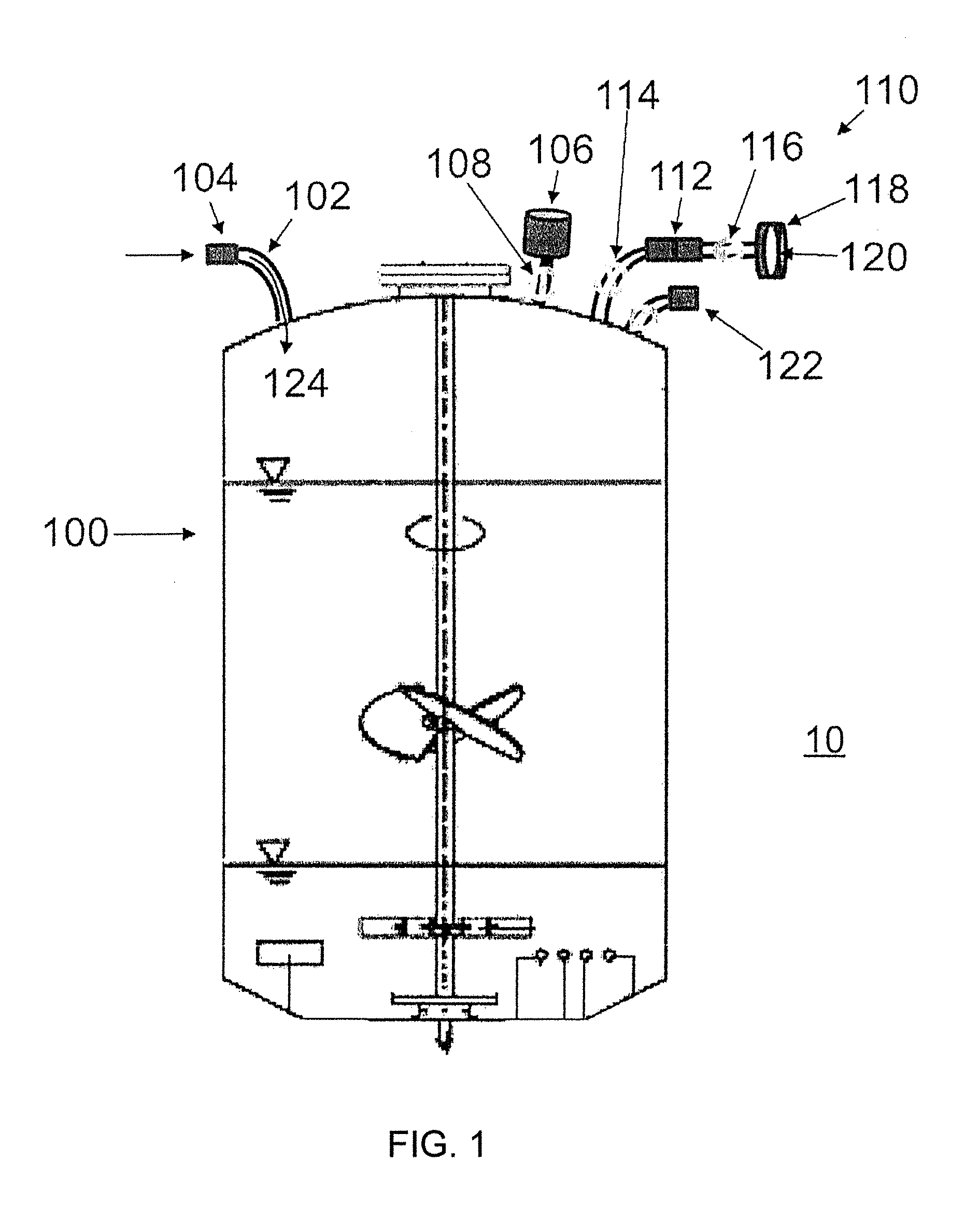

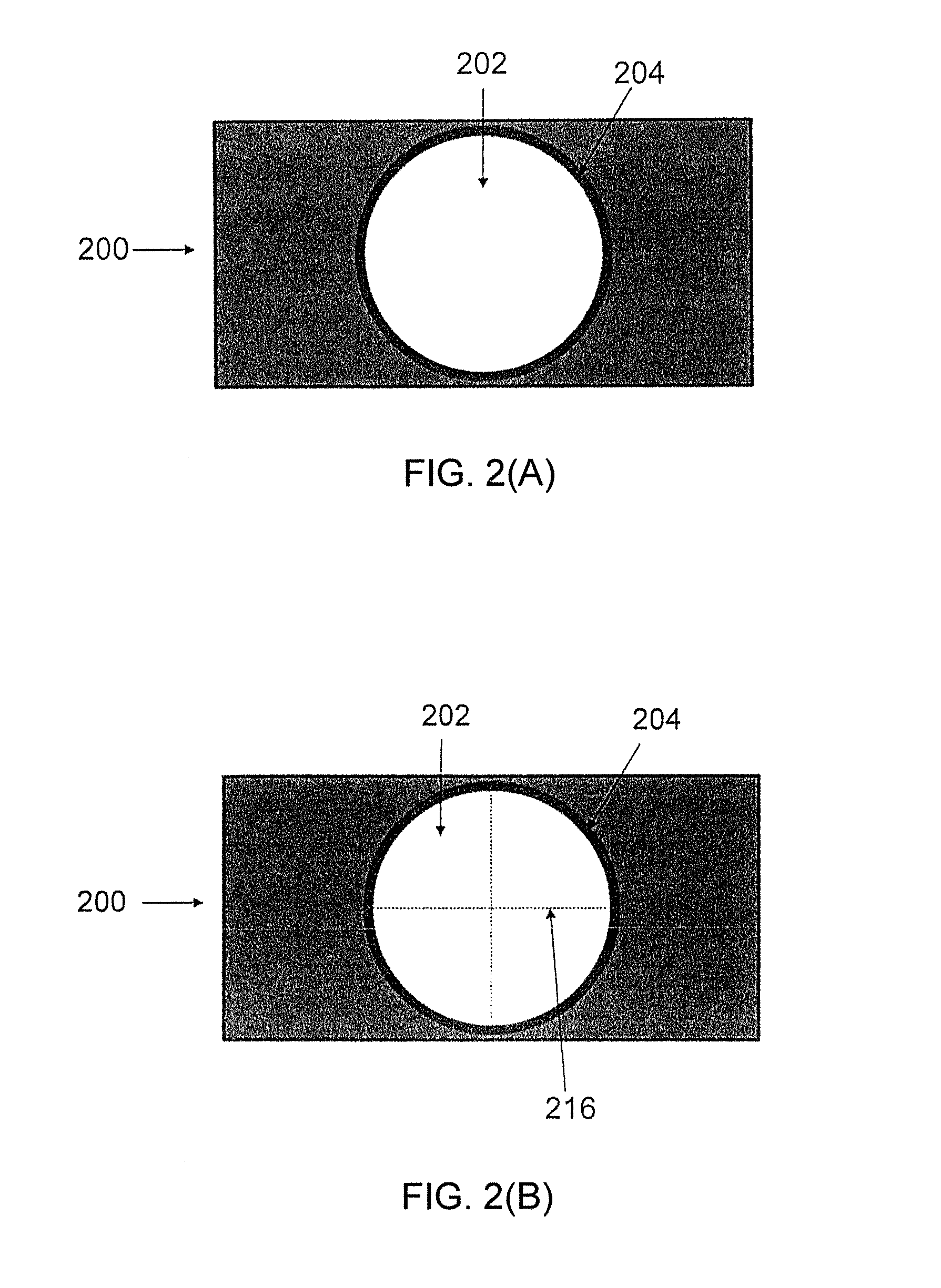

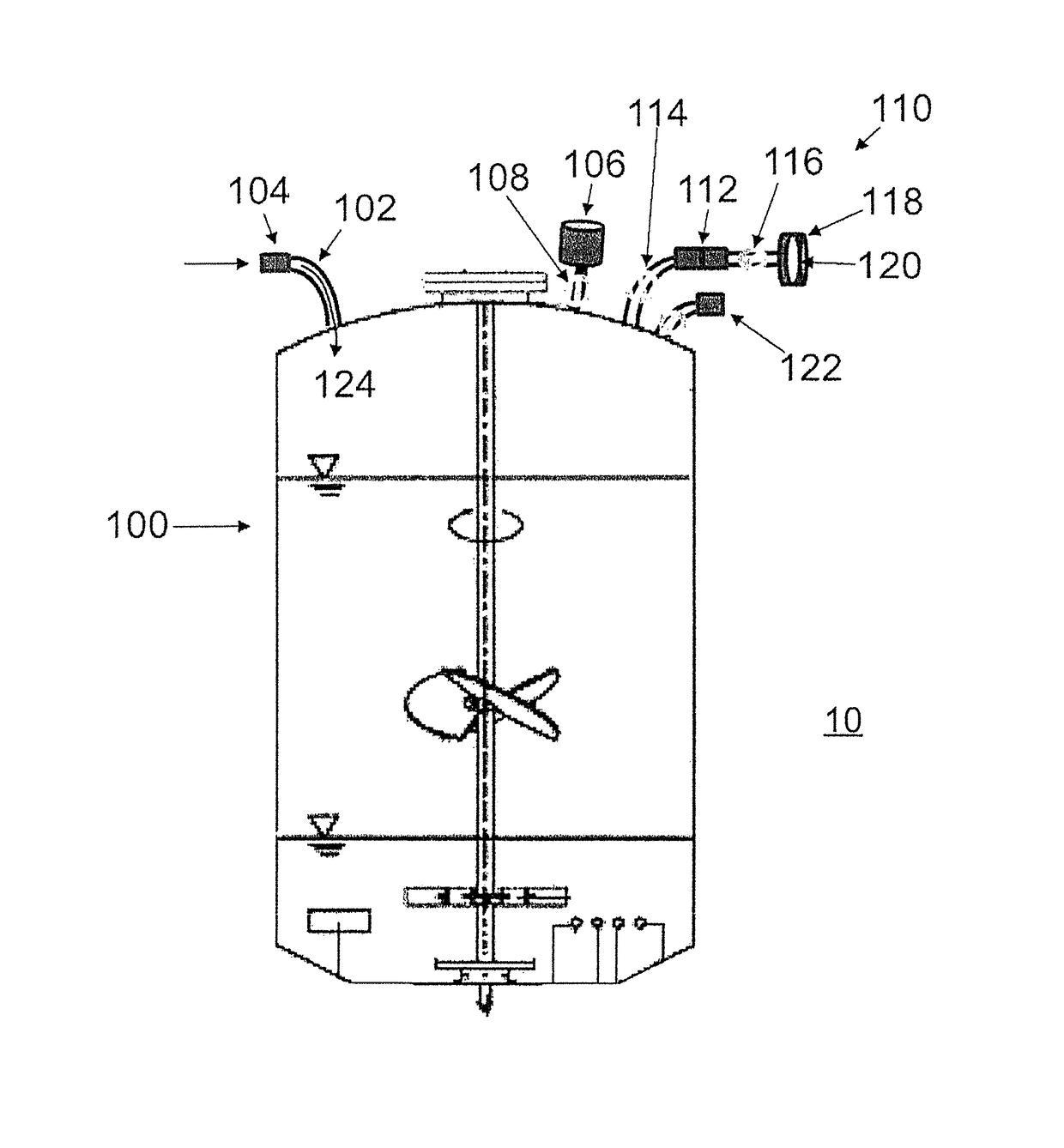

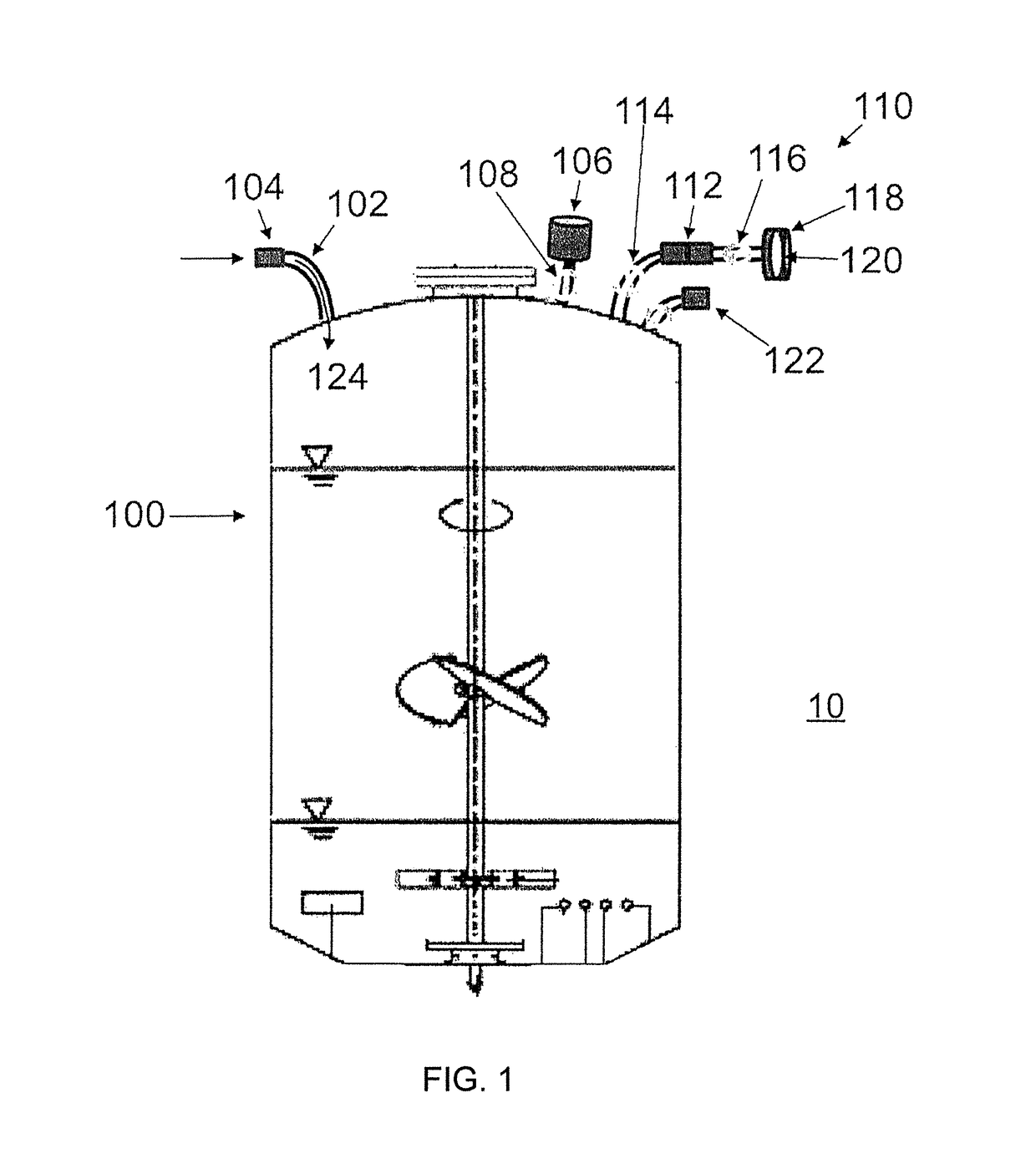

Single-use container, system and method for the prevention of over-pressurization

ActiveUS20160298810A1Prevent over-pressurizationVessel mounting detailsVessel manufacturingControl mannerEngineering

A single-use container for the prevention of over-pressurization is provided. The single-use container has an enclosure for a fluid and an over-pressurization relief device fluidly connected to the enclosure. The over-pressurization relief device is configured to relieve pressure from the enclosure when a pressure of the fluid within the enclosure exceeds a specified relief pressure. The specified relief pressure is set to be lower than the burst pressure of the enclosure. The over-pressurization relief device is connectable to a controlled pathway for relieving the fluid from the enclosure in a controlled manner.

Owner:SARTORIUS STEDIM BIOTECH GMBH

Vapor compression systems using an accumulator to prevent over-pressurization

InactiveUS20050132742A1Prevent over-pressurizationCompression machinesRefrigeration componentsRefrigerantEngineering

An accumulator acts as a buffer to prevent over-pressurization of the vapor compression system while inactive. By determining the maximum storage temperature and the maximum storage pressure a system will be subject to when inactive, a density of the refrigerant for the overall system can be calculated. Dividing the density by the mass of the refrigerant determines an optimal overall system volume. The volume of the components is subtracted from the overall system volume to calculate the optimal accumulator volume. The optimal accumulator volume is used to size the accumulator so that the accumulator has enough volume to prevent over-pressurization of the system when inactive.

Owner:CARRIER CORP

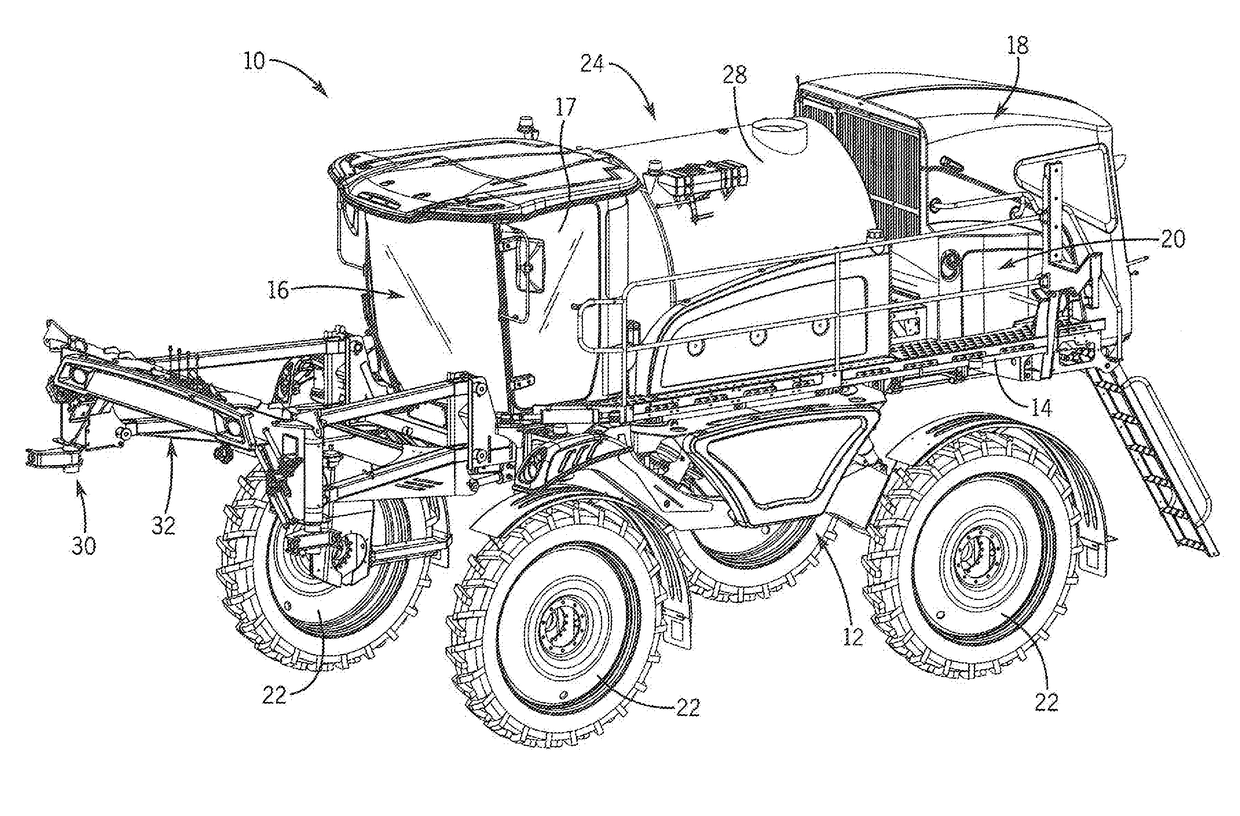

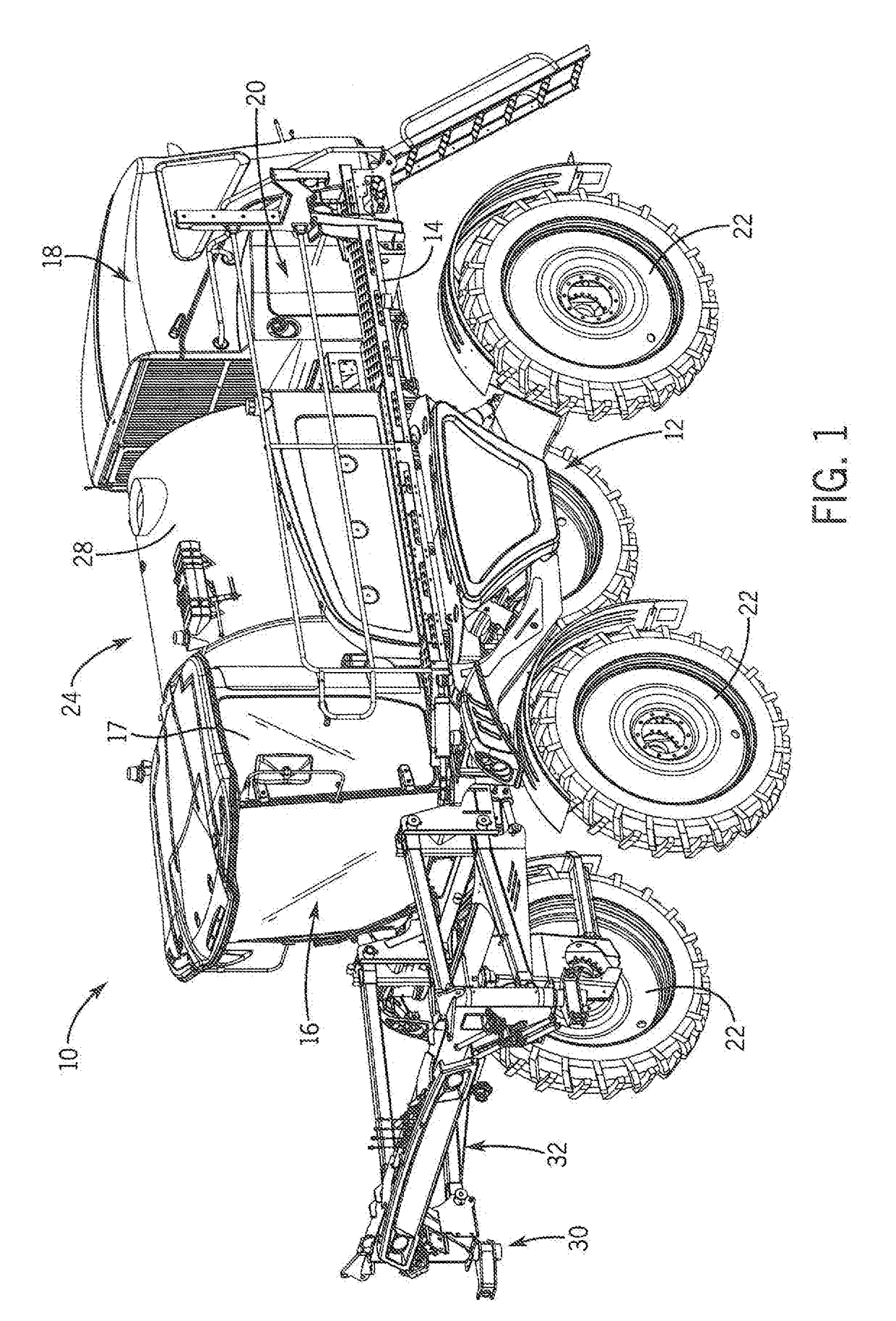

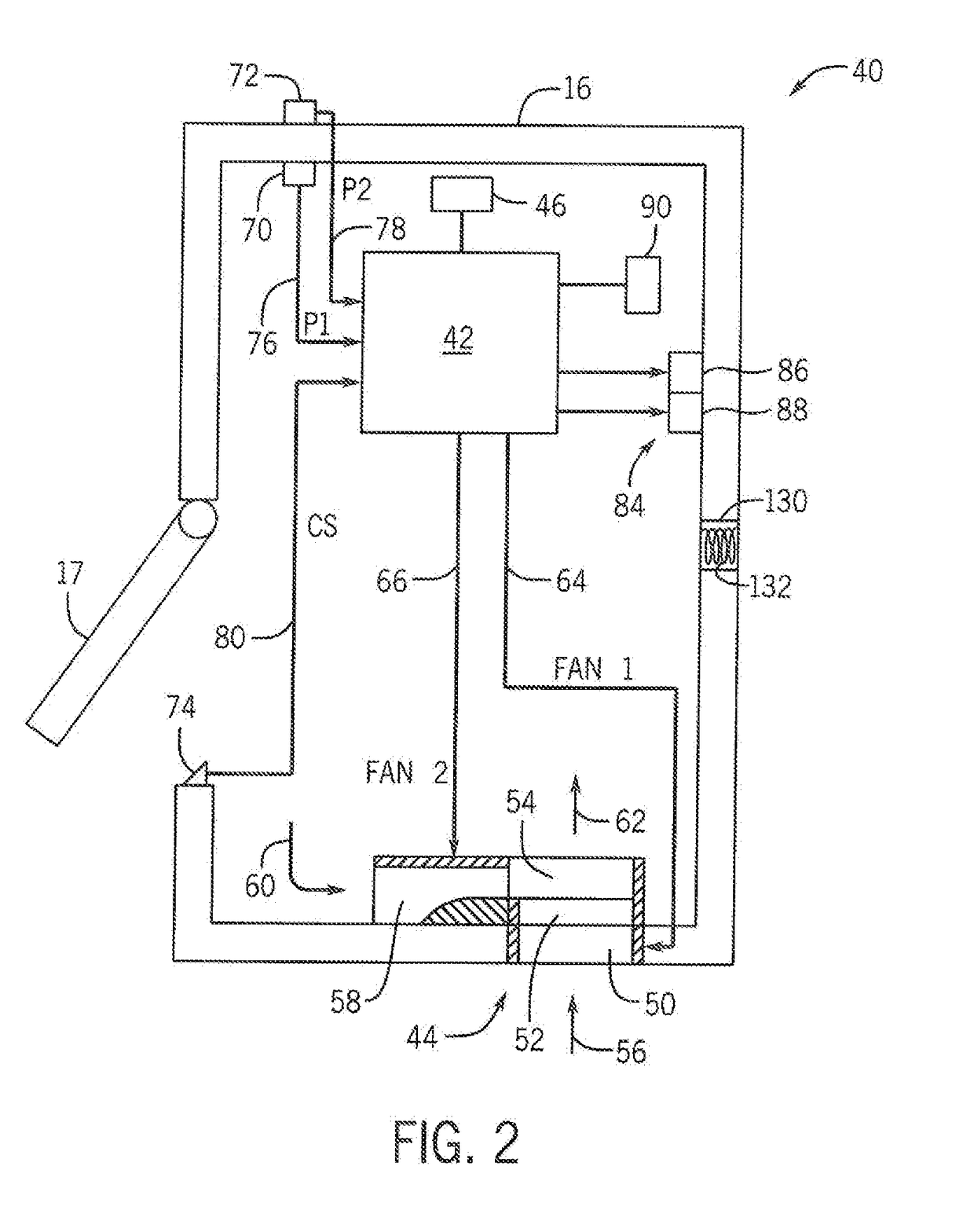

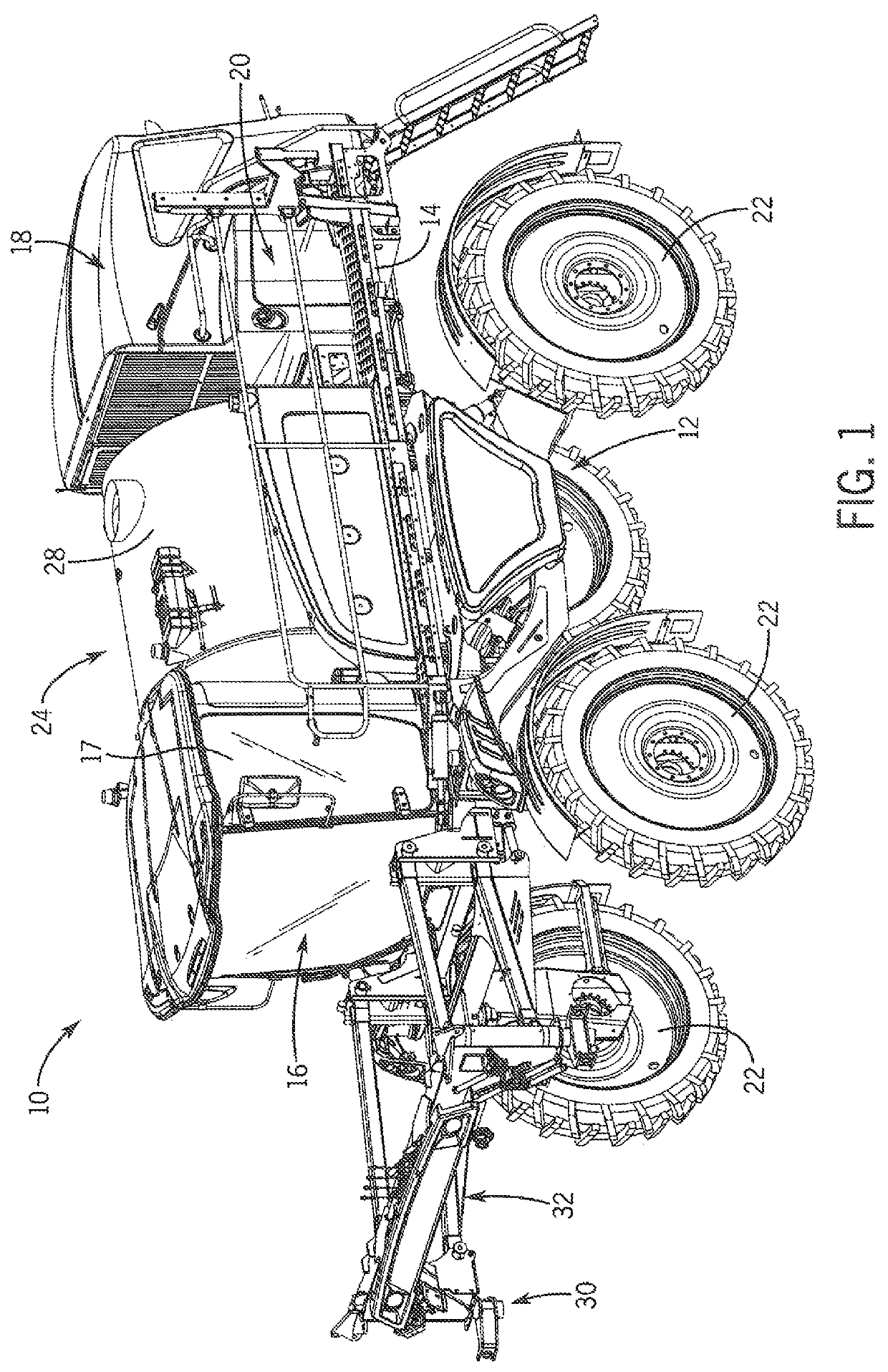

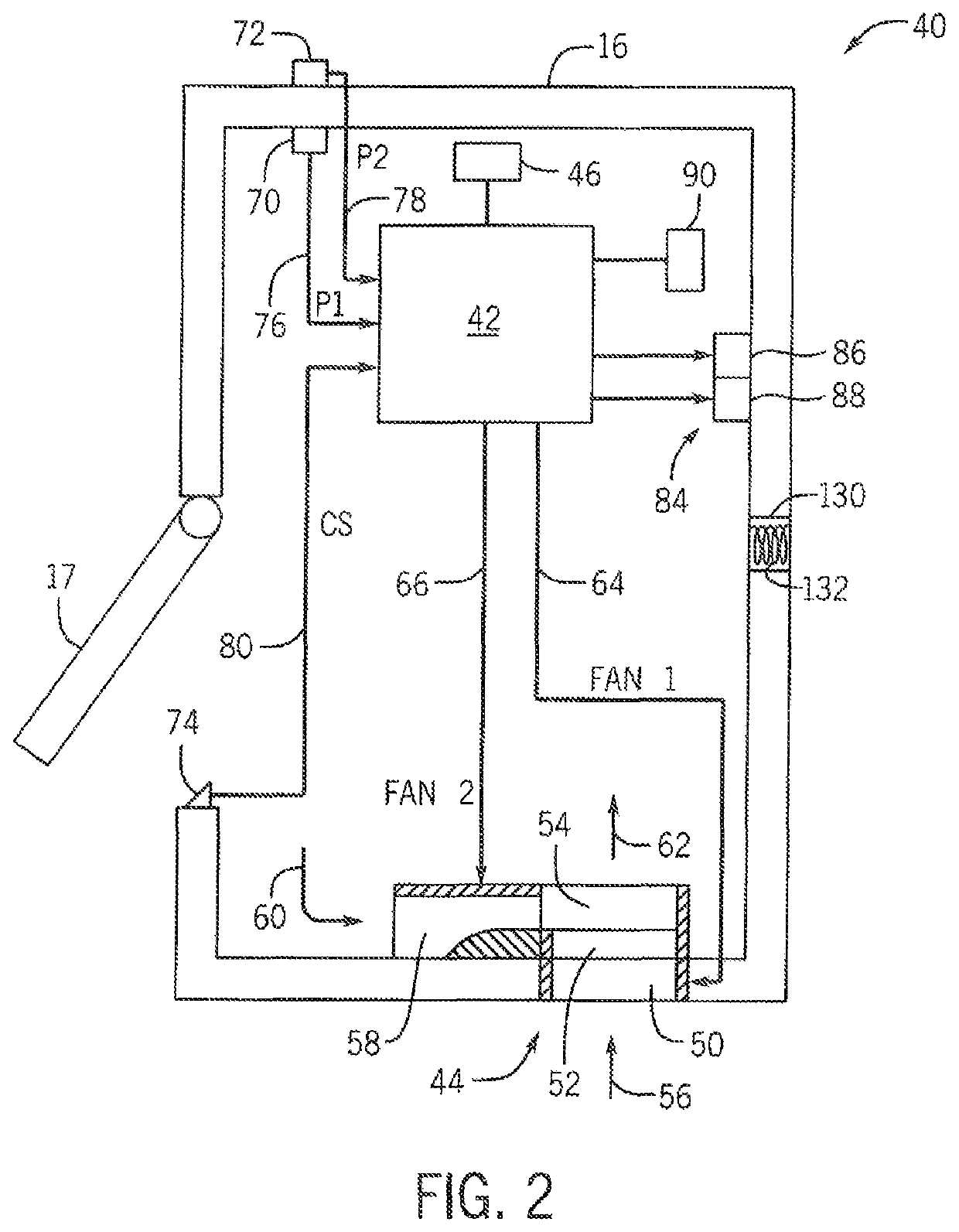

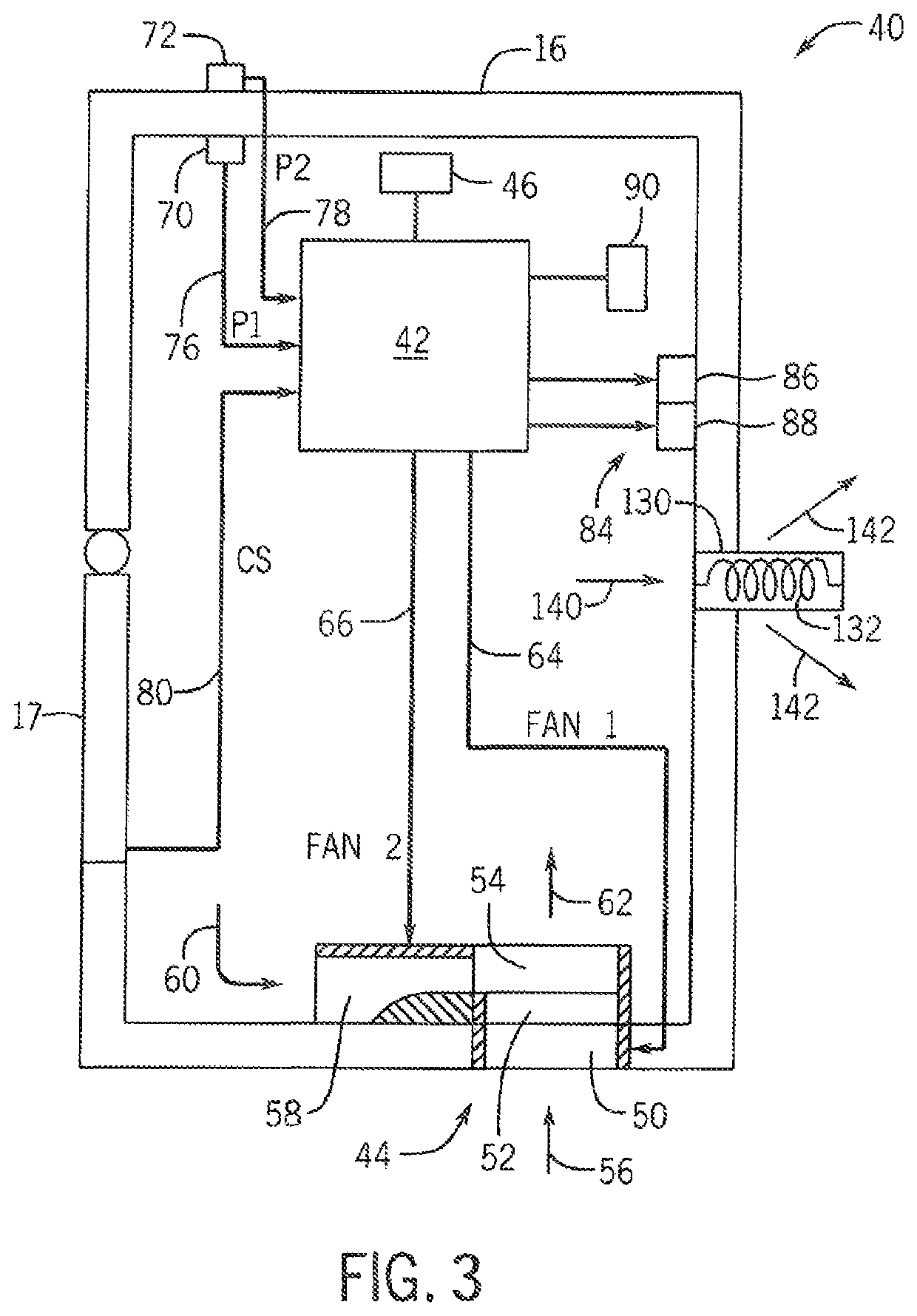

Overpressure Prevention System For An Agricultural Machine

ActiveUS20180288932A1Prevent over-pressurizationKeep the pressureAgricultural machinesCrop conditionersClosed loopEngineering

Agricultural machines such as sprayers can be improved by providing a pressure relief system in the operator cab to allow the operator cab to be pressurized while avoiding over-pressurization. The pressure relief system can be arranged to allow air to freely escape from the operator cab during what would otherwise be an over-pressurization event, such as a door or window being closed. In one aspect, the pressure relief system can include a spring-loaded pressure relief valve configured to passively allow air to escape from the cab in order to maintain a cab pressure at or below a predetermined threshold, such as 100 Pascals. In addition, interior and exterior pressures can be monitored for implementing a closed loop control for the pressurization system to enable a more comfortable experience for the operator.

Owner:BLUE LEAF I P INC

Compressed Gas Regulator Apparatus

InactiveUS20120204976A1Function increaseReduce complexityOperating means/releasing devices for valvesCompressed gas gunsDistal portionEngineering

Regulators for regulating gas that is delivered in discrete charges from a tank that contains compressed gas to a paintball gun, marker, or other application that utilizes or is activated by pressure controlled discrete charges of gas. The regulator has holding, discharge, and fill configurations, controlled by the movement of a piston member in a pressurized chamber, and the activation of a poppet valve on the discharge of the system. One or two low side pressure relief members are provided to prevent the over-pressurization of the pressurized chamber. An externally threaded sleeve member is non-rotatably, but axially slidably received on a distal portion of the body of the regulator so that the sleeve member and distal portion may be axially slidably disengaged, and the regulator can be rotationally positioned so that the pressure gauge is easily viewed by an operator.

Owner:YSN IMPORTS INC

Vapor compression systems using an accumulator to prevent over-pressurization

InactiveUS20060090500A1Prevent over-pressurizationCompression machinesRefrigeration componentsEngineeringVolumetric Mass Density

An accumulator acts as a buffer to prevent over-pressurization of the vapor compression system while inactive. By determining the maximum storage temperature and the maximum storage pressure a system will be subject to when inactive, a density of the refrigerant for the overall system can be calculated. Dividing the density by the mass of the refrigerant determines an optimal overall system volume. The volume of the components is subtracted from the overall system volume to calculate the optimal accumulator volume. The optimal accumulator volume is used to size the accumulator so that the accumulator has enough volume to prevent over-pressurization of the system when inactive.

Owner:SIENEL TOBIAS H +1

Ventilation system for a passenger transit vehicle

ActiveUS9623722B2Prevent over-pressurizationRailway roofsAir-treating devicesEngineeringControl theory

A ventilation system for a passenger transit vehicle that comprises a passenger compartment. The ventilation system comprises a variable speed fan for providing outside air to the passenger compartment, wherein within a given ambient temperature range, the speed of the variable speed fan is controlled such that the air speed produced by the variable speed fan increases with increasing ambient temperature. The ventilation system further comprises a duct system fluidly connecting the variable speed fan to an air diffuser that directs the air from the variable speed fan towards the passengers within the passenger compartment. The cross sectional area of the duct system decreases along its length for providing substantially constant air pressure along its length. The ventilation system is able to provide outside air into the passenger compartment at an air flow speed of greater than 0.15 m / s.

Owner:BOMBARDIER TRANSPORTATION GMBH

Overpressure prevention system for an agricultural machine

ActiveUS10823285B2Prevent over-pressurizationComfortable experience for the operatorAir-treating devicesGearing controlAgricultural scienceSprayer

Agricultural machines such as sprayers can be improved by providing a pressure relief system in the operator cab to allow the operator cab to be pressurized while avoiding over-pressurization. The pressure relief system can be arranged to allow air to freely escape from the operator cab during what would otherwise be an over-pressurization event, such as a door or window being closed. In one aspect, the pressure relief system can include a spring-loaded pressure relief valve configured to passively allow air to escape from the cab in order to maintain a cab pressure at or below a predetermined threshold, such as 100 Pascals. In addition, interior and exterior pressures can be monitored for implementing a closed loop control for the pressurization system to enable a more comfortable experience for the operator.

Owner:BLUE LEAF I P INC

Automated balloon catheter fluid purging system

ActiveUS9468484B2Prevent over-pressurizationBenefit response timeBalloon catheterBlood pumpsExhaust valveSolenoid valve

A fluid purging system has a spring-energized relief valve having an inlet port that is coupled to a fluid chamber to receive incoming fluid, and an outlet port through which incoming fluid is relieved. The outlet port is fluidly coupled to a pressurized chamber. The fluid purging system also includes an electro-mechanical pressure switch, and an electrically operated solenoid valve which functions as a pressure exhaust valve. The pressure switch and the solenoid valve are in fluid communication with the pressurized chamber.

Owner:CRYOFOCUS MEDTECH (SHANGHAI) CO LTD

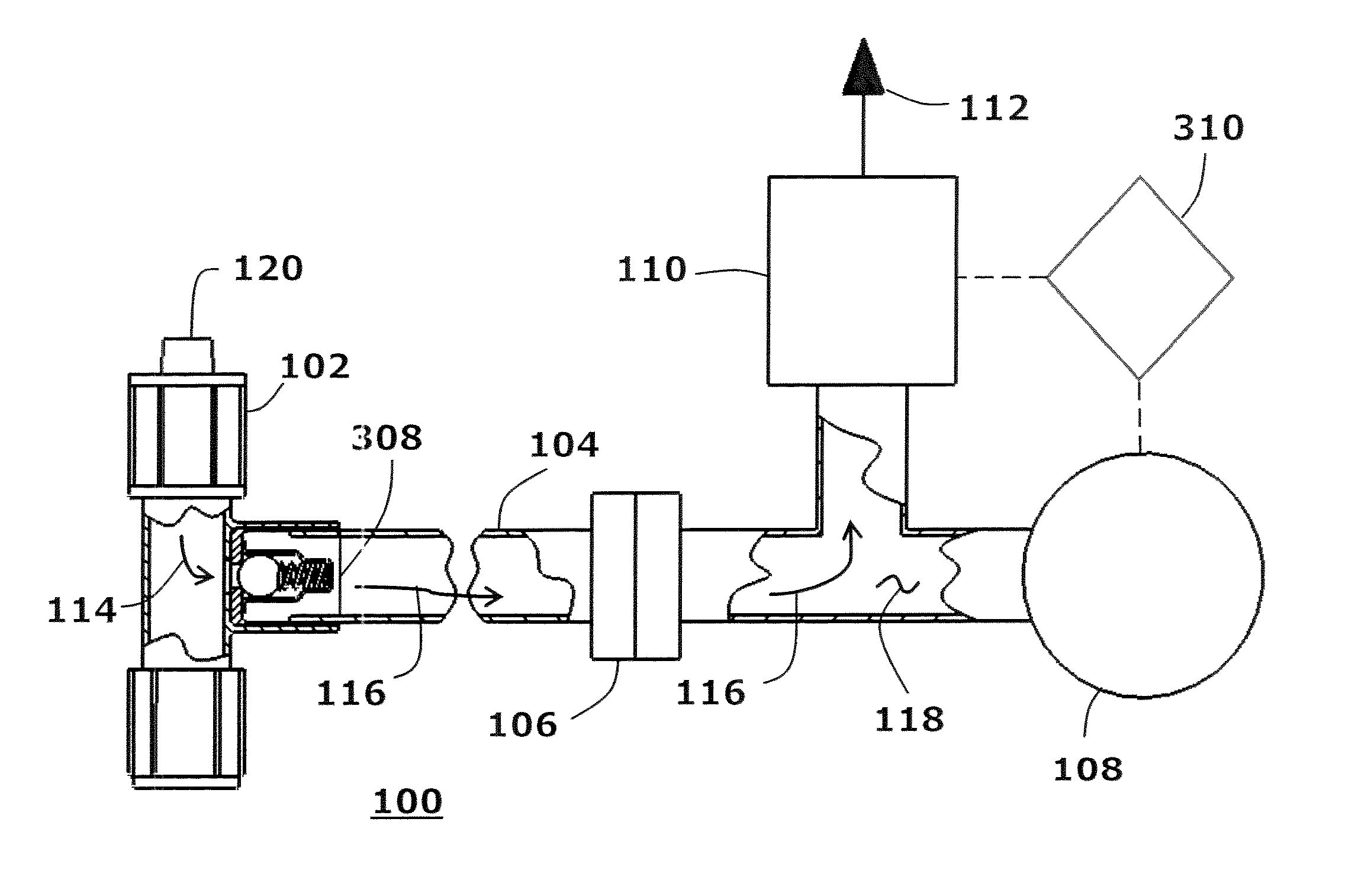

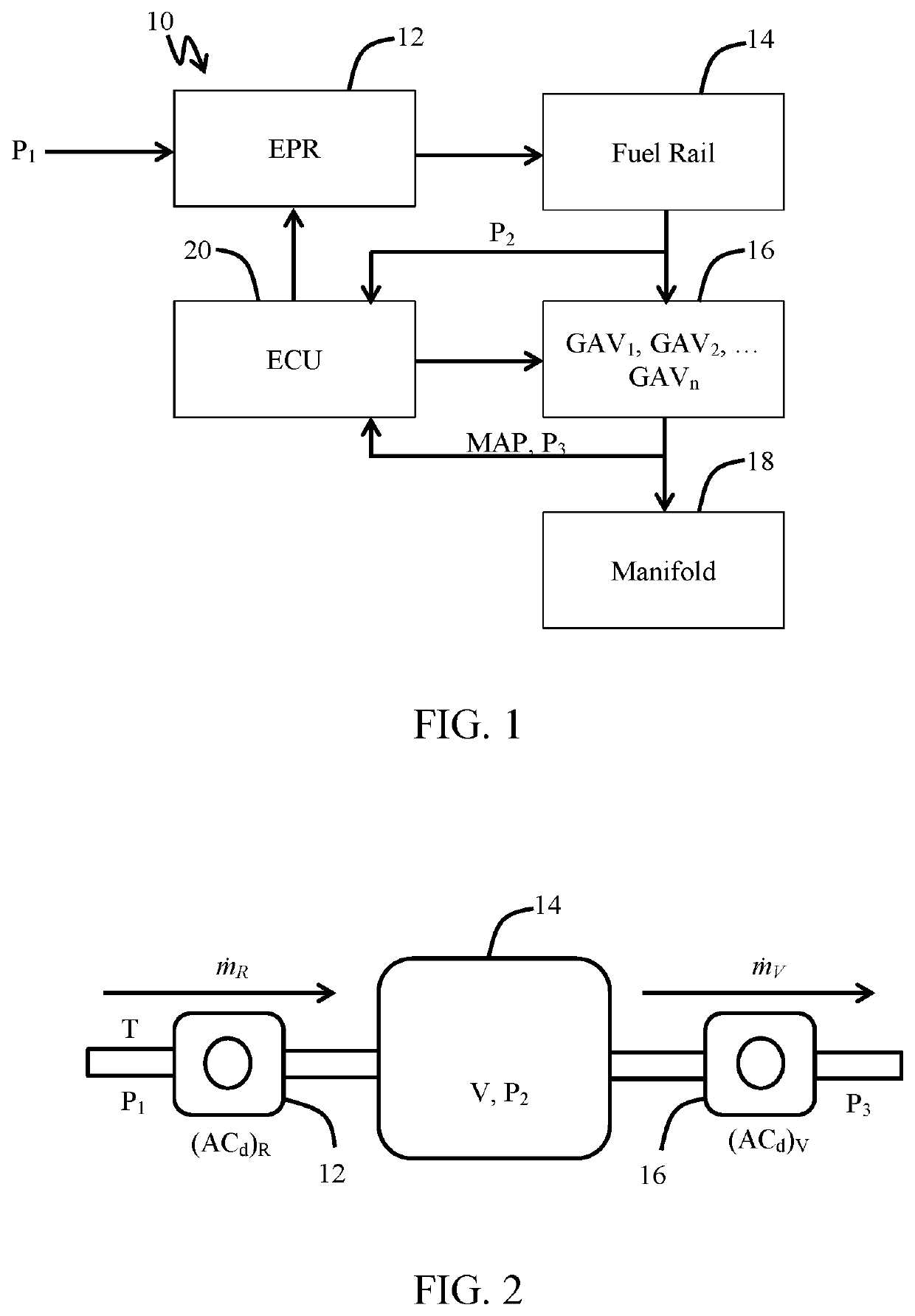

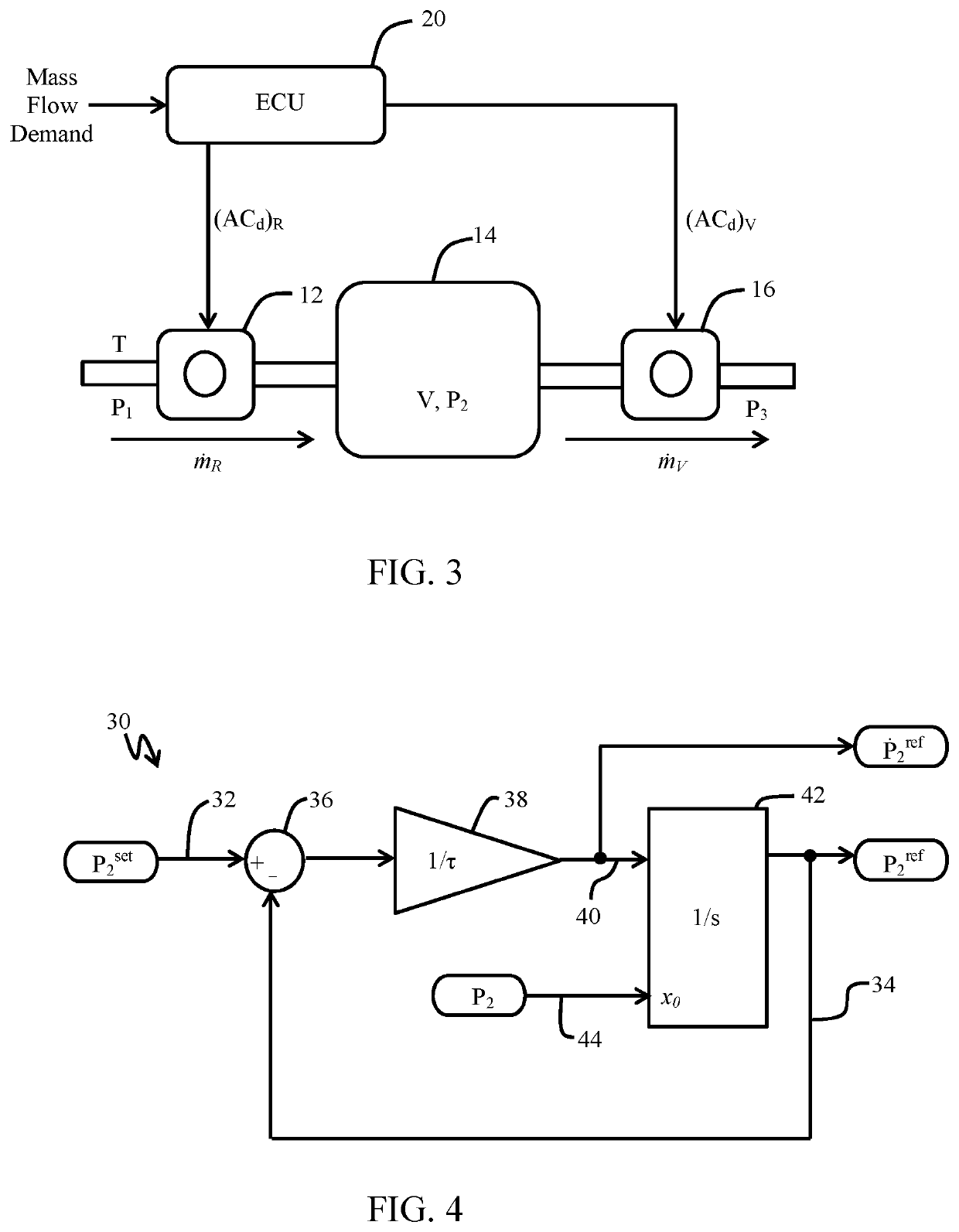

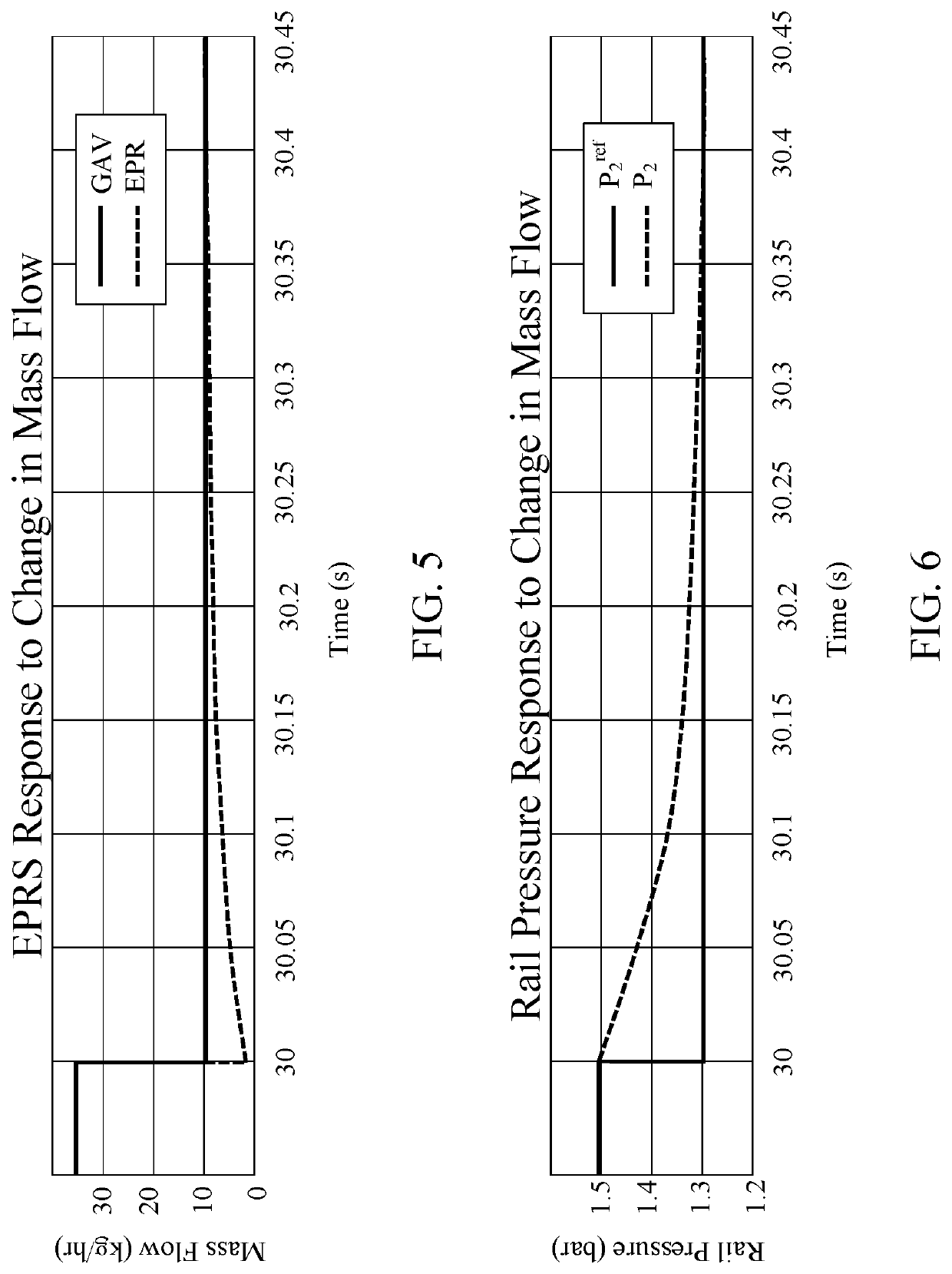

Pressure regulating mass flow system for multipoint gaseous fuel injection

ActiveUS11092091B2Improvement in turn downReduce in quantityElectrical controlInternal combustion piston enginesControl theoryCylinder (engine)

Embodiments of a gaseous or dual fuel electronic pressure regulation system (EPRS) for a multipoint fuel injection engine are described herein. Additionally, embodiments of a method for controlling the EPRS are provided. In particular, the EPRS employs an electronic pressure regulator (EPR) capable of accurately determining and controlling the mass flow of gaseous fuel into a fuel rail so as to avoid pressure droop and over- and under-pressurization of the gas admission valves (GAVs). By using the EPRS described above, mass flow is able to be distributed to the downstream manifold or engine cylinders very accurately, and the GAVs are able to be driven simultaneously in a pressure / pulse duration that is optimal for accurate and repeatable operation.

Owner:WOODWARD GOVERNOR CO

Dual purpose dryers for high flow

ActiveUS9180854B2Prevent over-pressurizationGas treatmentDispersed particle separationAxial compressorDual purpose

A system and method of controlling an air dryer system having first and second air dryers configured to receive compressed air from a compressor, such as a compressor of a vehicle, including operating the first and second air dryers in a first mode corresponding to a high flow mode wherein the first and second air dryers are connected in parallel with the air compressor, monitoring a condition related to a low compressor output state, and operating the first and second air dryers in a second mode corresponding to a continuous flow mode when the low compressor output state is detected.

Owner:BENDIX COMML VEHICLE SYST LLC

Unitary body systems and devices and methods to use the same for retroperfusion

InactiveUS20190351127A1Easy to transformEasy to implantBalloon catheterOther blood circulation devicesVeinAnatomy

Unitary body systems and devices and methods to use the same for retroperfusion. In an exemplary device embodiment of the present disclosure, the device comprises a unitary body having a wall and a lumen defined therethrough, a first portion terminating at a first end and configured for at least partial placement within a mammalian artery, a first valve positioned at or near an end of the first portion opposite the first end, a second portion terminating at a second end and configured for at least partial placement within a mammalian vein, and a second valve positioned at or near an end of the second portion opposite the second end.

Owner:CVDEVICES

Smoke evacuation system for continuously removing gas from a body cavity

ActiveUS11147935B2Prevent over-pressurizationEasy to adjustCannulasSurgical needlesMedicineEngineering

An evacuation system for continuously removing gas from a body cavity of a patient during an endoscopic surgical procedure is disclosed, which includes an inlet flow path leading to a first trocar communicating with the body cavity through which an essentially continuous flow of gas is delivered to the body cavity, an outlet flow path leading from a second trocar communicating with the body cavity though which an essentially continuous flow of gas is removed from the body cavity, a pump communicating at least with the outlet flow path for removing an essentially continuous flow of gas from the surgical cavity, and a processor operatively associated with the pump for controlling at least the essentially continuous flow of gas from the body cavity.

Owner:CONMED CORP

Single use container, system and method for the prevention of over-pressurization

ActiveUS9933118B2Prevent over-pressurizationBioreactor/fermenter combinationsVessel mounting detailsControl mannerEngineering

A single-use container for the prevention of over-pressurization is provided. The single-use container has an enclosure for a fluid and an over-pressurization relief device fluidly connected to the enclosure. The over-pressurization relief device is configured to relieve pressure from the enclosure when a pressure of the fluid within the enclosure exceeds a specified relief pressure. The specified relief pressure is set to be lower than the burst pressure of the enclosure. The over-pressurization relief device is connectable to a controlled pathway for relieving the fluid from the enclosure in a controlled manner.

Owner:SARTORIUS STEDIM BIOTECH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com