Discharging device of injection molding machine for fitness equipment production

A technology of fitness equipment and injection molding machine, applied in the field of injection molding machine, can solve problems such as blockage, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

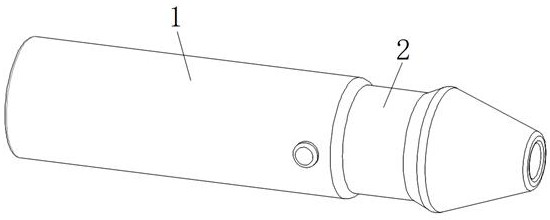

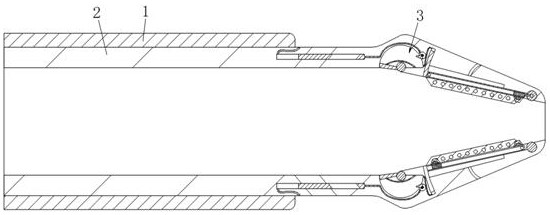

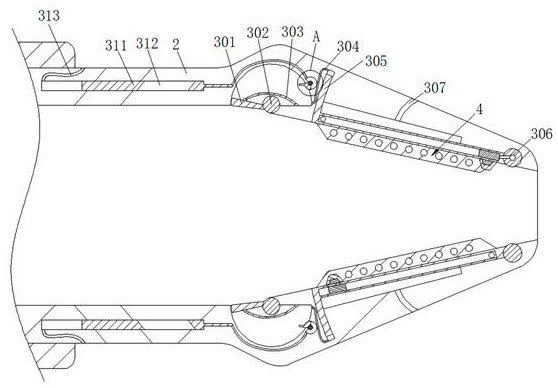

[0025] see Figure 1-5 , The present invention provides a technical solution: a discharge device for an injection molding machine for the production of fitness equipment, comprising a long nozzle 2, a heating jacket 1 is fixedly connected to the outer wall of the long nozzle 2, and a blocking automatic crushing and dredging mechanism 3 is arranged inside the long nozzle 2;

[0026] The blocking automatic crushing and dredging mechanism 3 includes a connecting rod 301, a rotating shaft A302, an elastic plate 303, an air groove 304, and an opening and closing plate 305. The opening and closing plate 305 and the rotating shaft B306 are provided with an air inlet groove. Passing through the rotating shaft B306 and the back of the long nozzle 2 and communicating with the outside of the long nozzle 2, a check valve B is arranged inside the air inlet, the rotating shaft B306, the communicating air groove A307, the interior of the communicating air groove A307 is communicated with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com