Fuel tank cap mounting device

A technology for installing devices and fuel tank caps, which is applied in the direction of power devices, transportation and packaging, and the arrangement combined with the fuel supply of internal combustion engines, etc. It can solve the problems of insufficient use effect, insufficient fixation effect, and inconvenient sealing, etc., and achieve a fixation effect Good, simple structure, fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

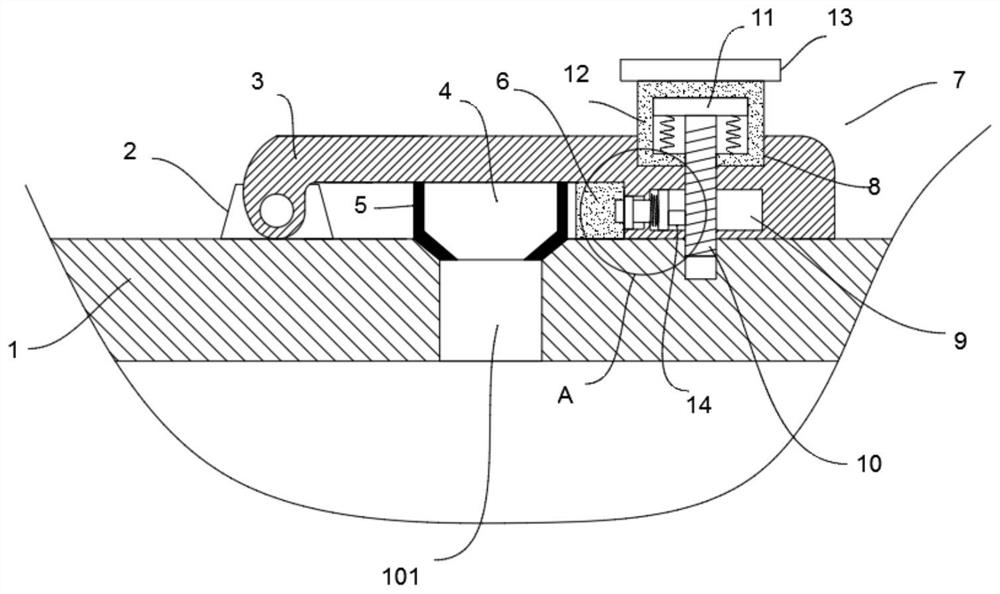

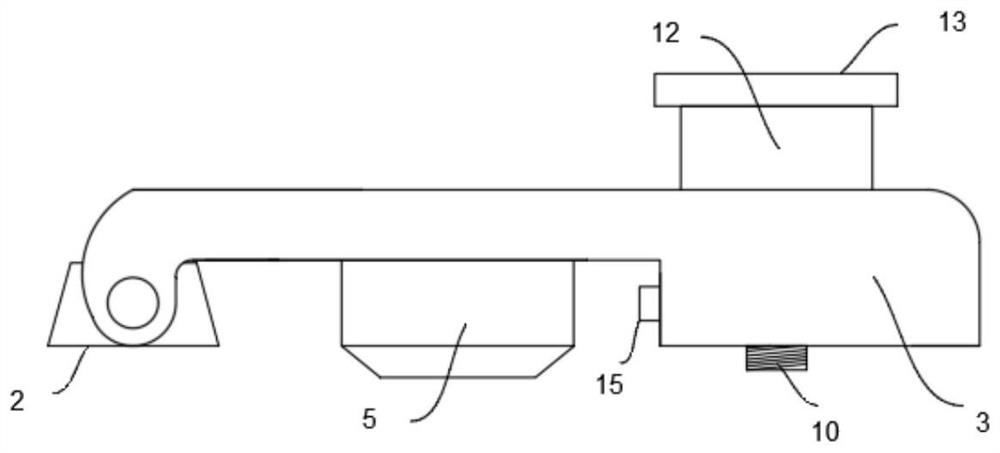

[0033] An installation device for a fuel tank cover, comprising a first fixing block 2 and a second fixing block 6 fixed on the tank wall 1 of the fuel tank, the first fixing block 2 and the second fixing block 6 are respectively arranged on both sides of the filling hole 101, A box cover plate 3 that covers the outside of the oil filling hole 101 is installed on a fixed block 2 through the rotation of the rotating shaft. A rubber sealing layer 5 is provided, and a first fixing mechanism 7 and a second fixing mechanism are provided at the end of the box cover 3 away from the first fixing block 2 . Specifically, the lower end shape of the blocking block 4 is conical.

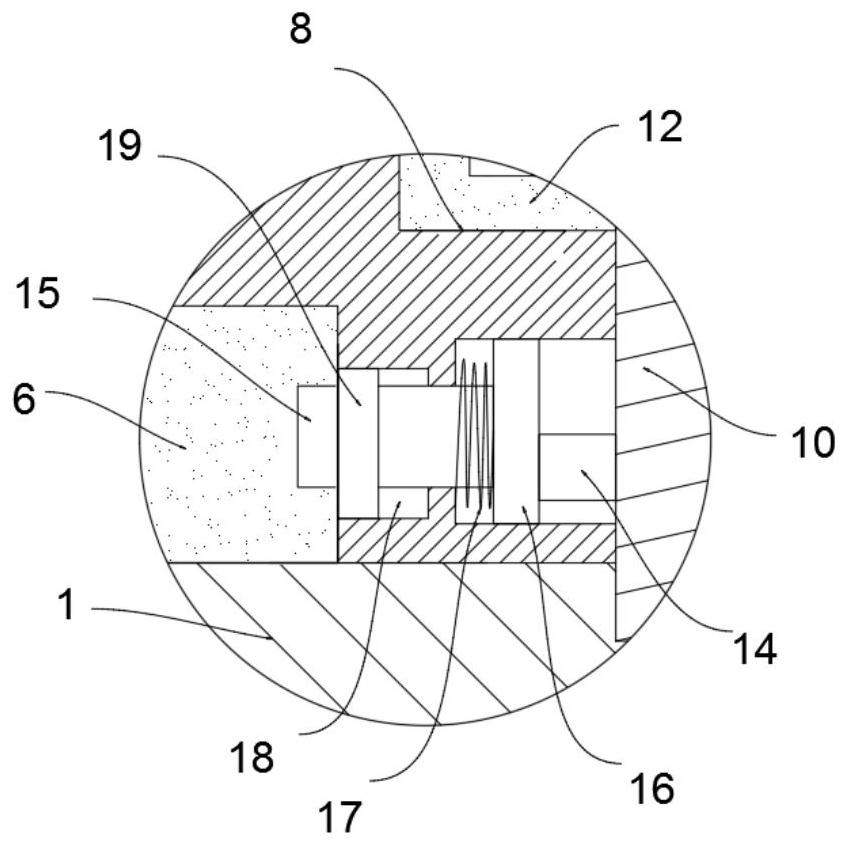

[0034] It should be noted that the first fixing mechanism 7 includes a rectangular slot 8 and an installation cavity 9 disposed at one end of the box cover 3 away from the first fixing block 2 , and the rectangular slot 8 and the installation cavity 9 communicate with each other, and the rectangular slot 8 The i...

Embodiment 2

[0036] A fuel tank cover installation device, on the basis of the first embodiment, the second fixing mechanism includes a hidden groove 18 disposed on the tank cover plate 3 and located on one side of the installation cavity 9, and a rectangular card is movably inserted into the hidden groove 18. Block 15, one end of the rectangular clamping block 15 is clamped with the second fixing block 6, the other end of the rectangular clamping block 15 is fixed with a contact plate 16 located in the installation cavity 9, and the lower end of the threaded rod 10 is fixed with a contact plate 16. The touch block 14 and the rectangular block 15 are provided with a first elastic member.

[0037] It should be noted that the first elastic member includes a first spring 17 sleeved on the rectangular block 15 and located in the installation cavity 9 . The shape of the touch panel 16 is arc-shaped, and the second fixing block 6 is provided with a rectangular hole matching the size of the recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com