Plastic woven bag leveling device

A plastic woven bag and leveling device technology, which is applied in the field of plastic woven bags, can solve the problems of reduced cutting accuracy and loose plastic woven bags, so as to improve the leveling effect and ensure the cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

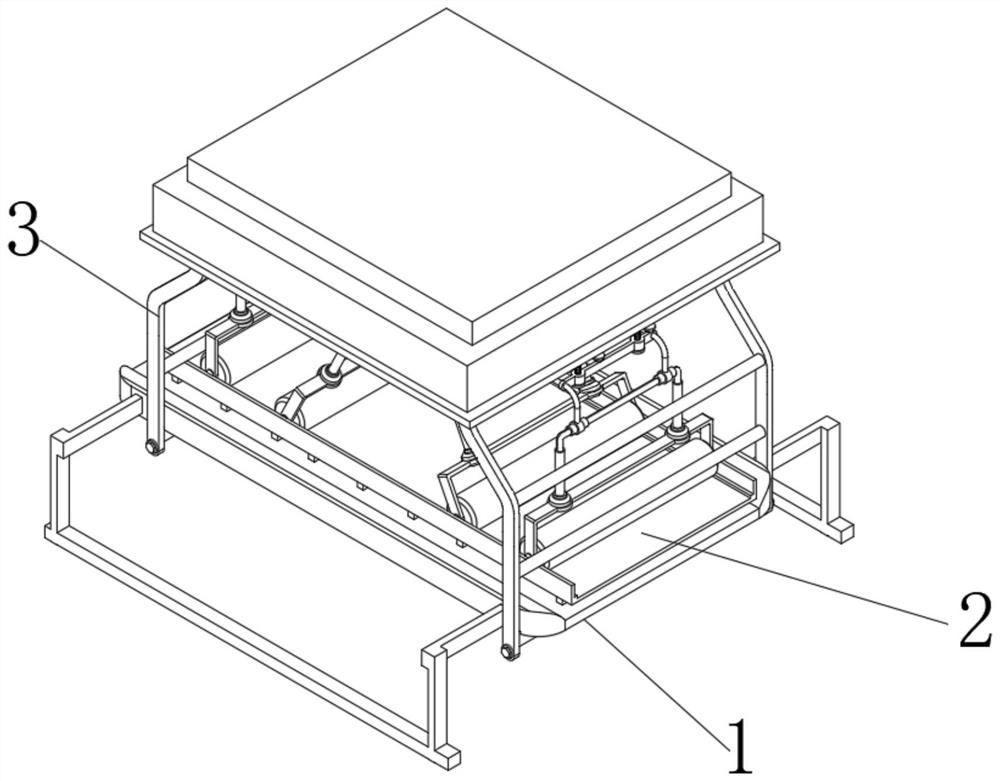

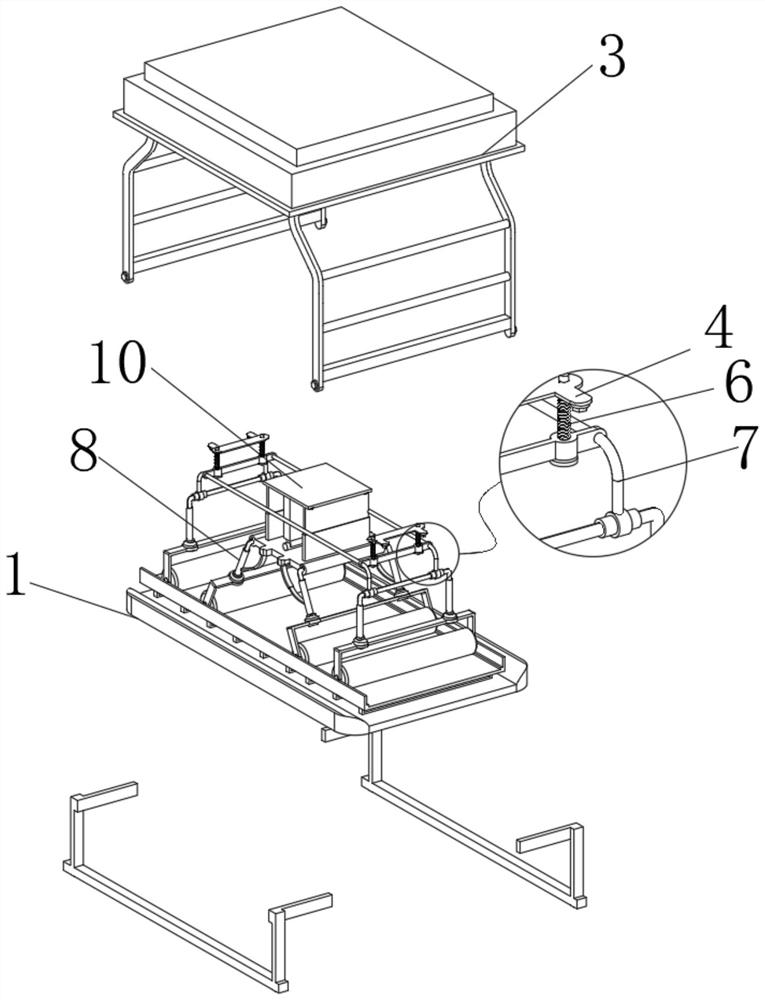

[0032] see Figure 1 to Figure 6 , the present invention provides a technical solution: a plastic woven bag leveling device, comprising a bearing platform 1, the upper surface of the bearing platform 1 is fixedly connected with a leveling seat 2, and the bottom of the bearing platform 1 is fixedly connected with a fixing frame 3 by bolts , the inner top wall of the fixing frame 3 is fixedly connected with a secondary leveling mechanism by bolts, and the main leveling mechanism is fixedly installed in the middle of the inner top wall of the fixing frame 3;

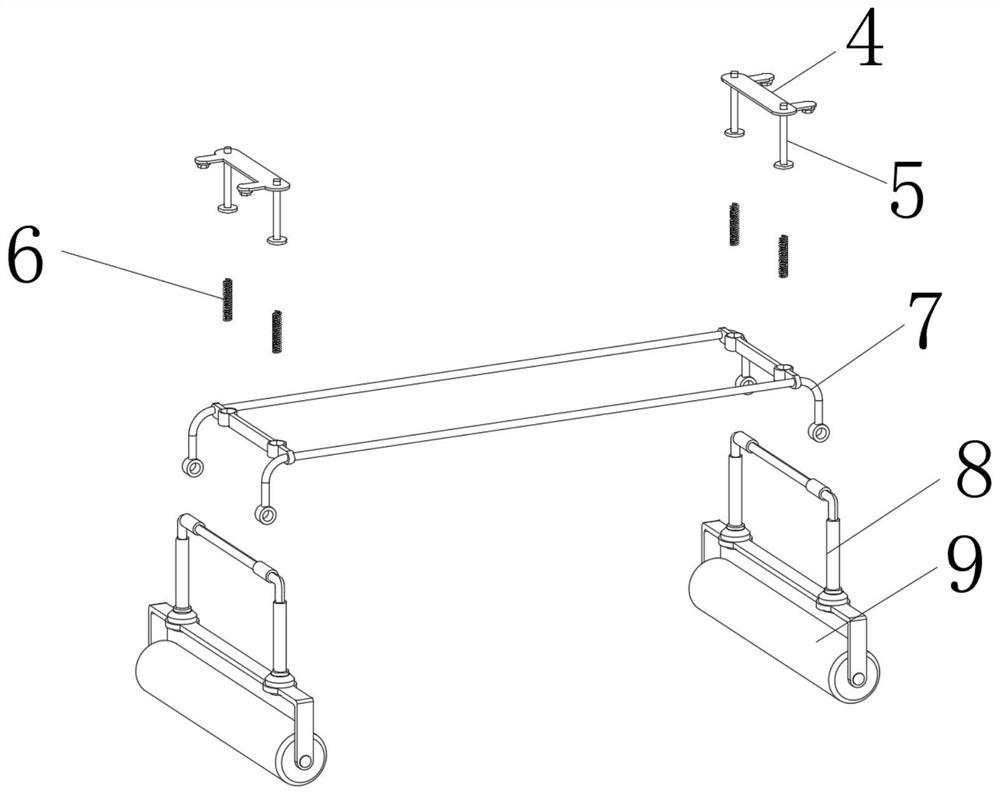

[0033] Among them, the auxiliary leveling mechanism includes a positioning seat 4 installed on both sides of the inner top wall of the fixing frame 3, the lower surface of the positioning seat 4 is fixedly connected with a stabilizer bar 5, the surface of the stabilizer bar 5 is sleeved with a spring 6, and the The number is four, and the surfaces of the four stabilizer bars 5 are jointly slidably sleeved with a connecting ...

Embodiment 2

[0037] After the installation of the mechanism in Example 1 is completed, in order to better achieve smoothing of the plastic woven bag, the main smoothing mechanism is installed;

[0038] Specifically: the main leveling mechanism includes a U-shaped plate 10 that is fixedly connected to the inner top wall of the fixing frame 3 , and movable plates 11 are slidably sleeved on both sides of the lower surface of the U-shaped plate 10 , and the surface of the movable plate 11 is fixedly connected with a support The plate 12, the two sides of the support plate 12 are rotatably installed with a turret 13 through bearings, the inner side of the turret 13 is movably installed with a second leveling roller 14 through the axle seat, and the U-shaped plate 10 is fixedly connected with the support plate 12 for driving up and down. Active drive mechanism, the lower surface of the support plate 12 is fixedly connected with a reset mechanism close to the turret 13;

[0039] like Figure 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com