Yarn weft knitting machine

A knitting machine and weft knitting technology, which is applied in the field of yarn weft knitting knitting machines, can solve the problems of inconvenient, easy to absorb dust and pull, and achieve the effects of improving automation, reducing precision operations, and reducing start-stop operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

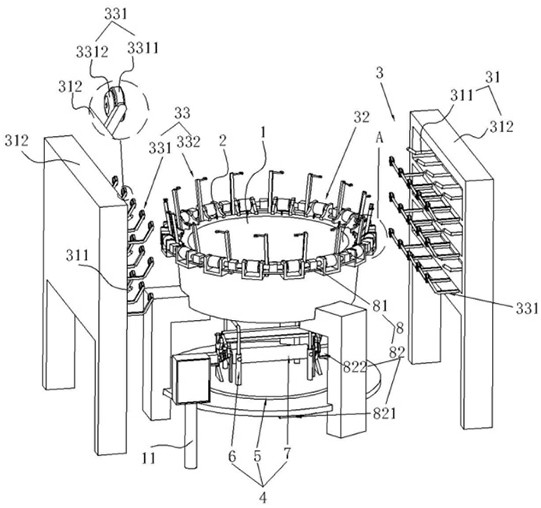

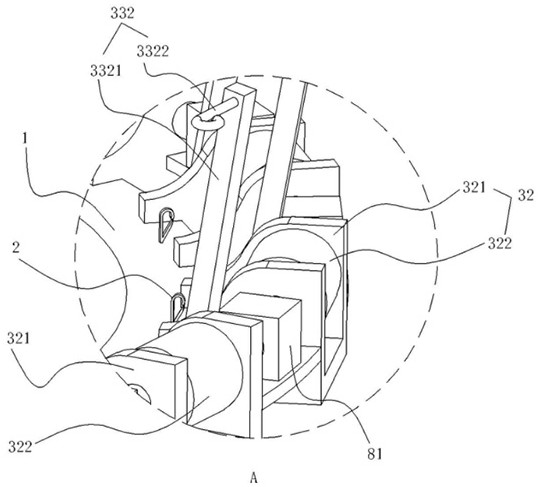

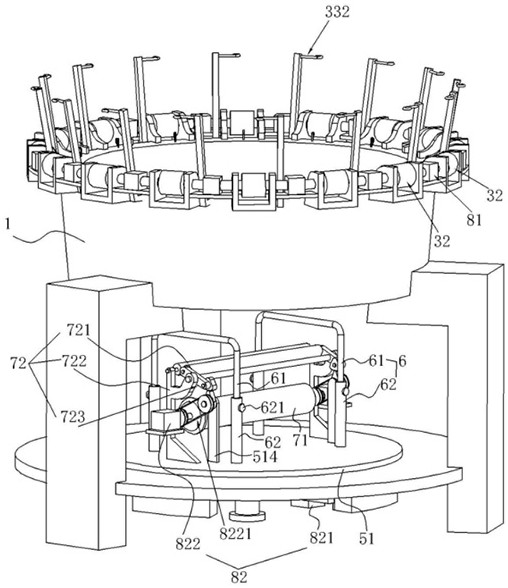

[0042] A yarn weft knitting machine, comprising a dial frame 1 whose diameter decreases in turn from top to bottom and a knitting needle 2 with a hook that is arranged on the dial frame 1 in parallel with the circumference, and the knitting needle 2 is vertically slidably arranged In the dial holder 1, such as figure 1 As shown, it also includes a yarn feeding mechanism 3, a pulling mechanism 4 and a transmission mechanism 8. The yarn feeding mechanism 3 includes a yarn storage device 31, a yarn feeding device 32 and a yarn management device 33. The yarn storage device 31 is arranged opposite to the dial frame 1. The yarn feeding device 32 is arranged on the top of the dial frame 1, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap