Self-purification blow-down valve for breeding container

A sewage valve, self-purification technology, applied in the direction of lifting valve, valve device, fish farming, etc., can solve the problems of limited discharge time, pollutant deposition, etc., to improve operability, good living environment, and prevent escape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

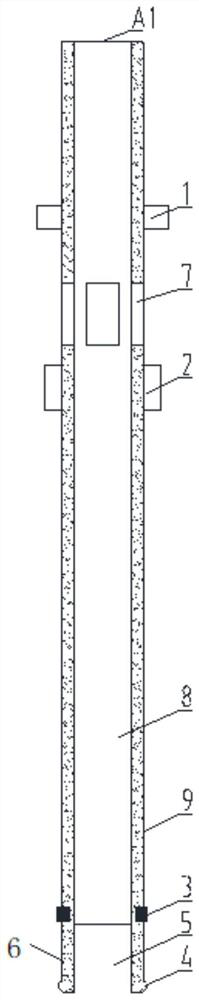

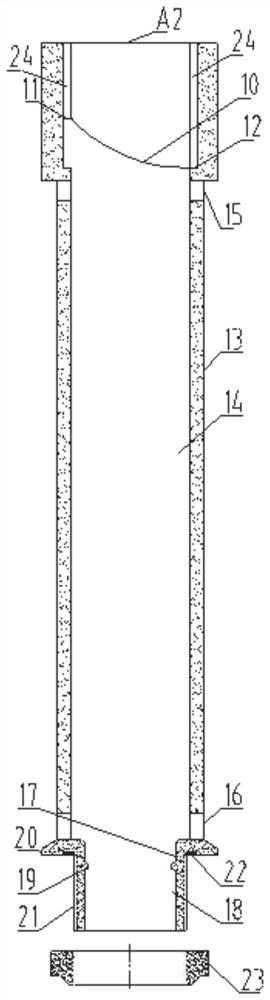

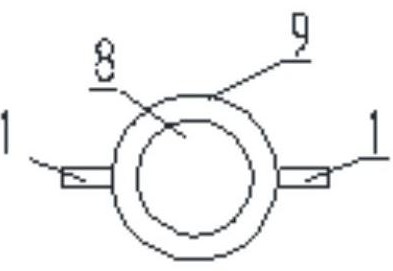

[0039] A self-purification drain valve of a culture container in this embodiment, such as Figure 1-4 As shown, the valve core A1 and the valve body A2 are both hollow cylinders, and the valve core A1 is located inside the valve body A2.

[0040] The upper outer surface of the valve core cylinder 9 of the valve core A1 has a convex valve core guide column 1, and a plurality of valve core overflow ports 7 connecting the valve core inner cavity 8 and the outside are provided below the valve core guide column, so The bottom of the valve core cylinder 9 is provided with a valve core drain port 5, the bottom end of the valve core cylinder body 9 has a raised valve core guide limit block 4, and a valve core seal is provided on the upper side of the bottom core drain port 5 Ring 3, the valve core cylinder 9 connected to the upper side of the valve core guide limit block 4 is an elastic valve core elastic sheet 6 that can be bent inward. The outer wall of the valve core cylinder 9 al...

Embodiment 2

[0049] like Figure 9 and 10 As shown, this embodiment also includes a wire mesh cylinder A3 outside the valve body, the wire mesh cylinder A3 has a wire mesh water inlet 27 on the cylinder body to block aquatic organisms, and the upper part of the cylinder body has a wire mesh cylinder overflow port 26. This embodiment can further prevent the escape of cultured aquatic organisms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com