Ferromagnetic material coercive force measuring method and device based on digital feedback

A ferromagnetic material and measurement method technology, applied in the direction of magnetic performance measurement, etc., can solve the problems of low stability and accuracy, slow measurement speed, etc., to avoid leakage, and the system runs stably and accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

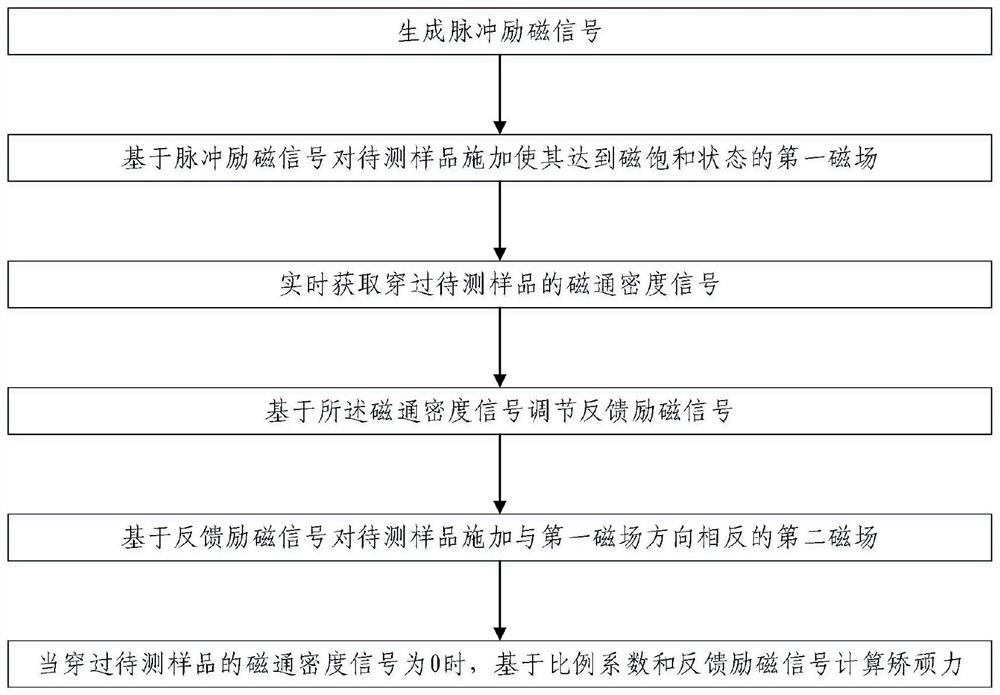

[0059] like figure 1 As shown, the present invention provides a method for measuring coercivity of ferromagnetic materials based on digital feedback, the method comprising:

[0060] Generate pulse excitation signal;

[0061] Applying a first magnetic field to the sample to be tested based on the pulse excitation signal to make it reach a magnetic saturation state;

[0062] Real-time acquisition of the magnetic flux density signal passing through the sample to be tested;

[0063] adjusting the feedback excitation signal based on the magnetic flux density signal;

[0064] Applying a second magnetic field opposite to the direction of the first magnetic field to the sample to be tested based on the feedback excitation signal;

[0065] When the magnetic flux density signal passing through the sample to be tested is 0, the coercive force is calculated based on the proportional coefficient and the feedback excitation signal at this time.

[0066] The beneficial effects of this embo...

Embodiment 2

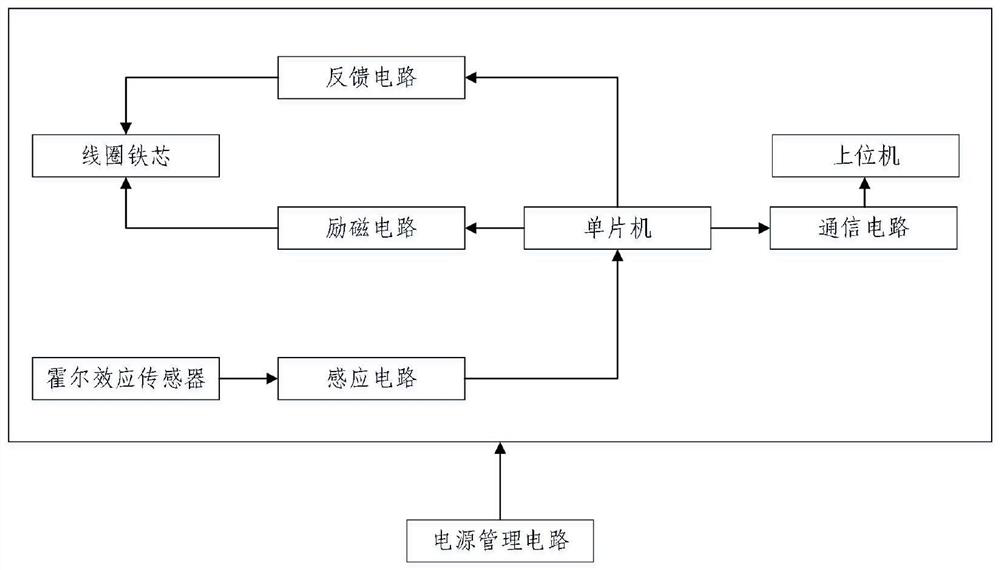

[0094] The present invention also provides a digital feedback-based ferromagnetic material coercive force measurement device, comprising:

[0095] The pulse excitation signal generation module is used to generate the pulse excitation signal;

[0096] a magnetic field generating module for applying a first magnetic field to the sample to be tested based on the pulse excitation signal; the first magnetic field makes the sample to be tested reach a magnetic saturation state;

[0097] The magnetic flux density signal detection module is used to detect the magnetic flux density signal passing through the sample to be tested;

[0098] a feedback excitation signal adjustment module for adjusting the feedback excitation signal based on the magnetic flux density signal;

[0099] The magnetic field generating module is further configured to apply a second magnetic field opposite to the direction of the first magnetic field to the sample to be tested based on the feedback excitation sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com