High-precision direction finding method under large-step beam scanning condition

A high-precision direction-finding and beam-scanning technology, which is applied in direction-determining orientators, radio wave measurement systems, measuring devices, etc., can solve the problem of difficulty in balancing direction-finding accuracy and system response speed, increasing data processing difficulty, and occupying a large system Resources and other issues, to achieve both processing speed and direction-finding accuracy, reduce resource overhead, and high direction-finding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

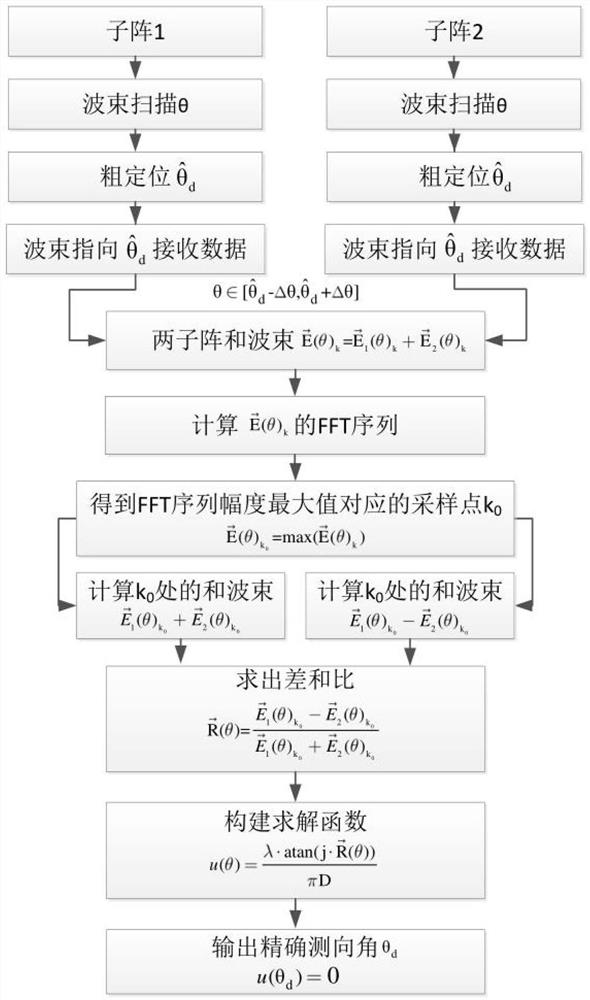

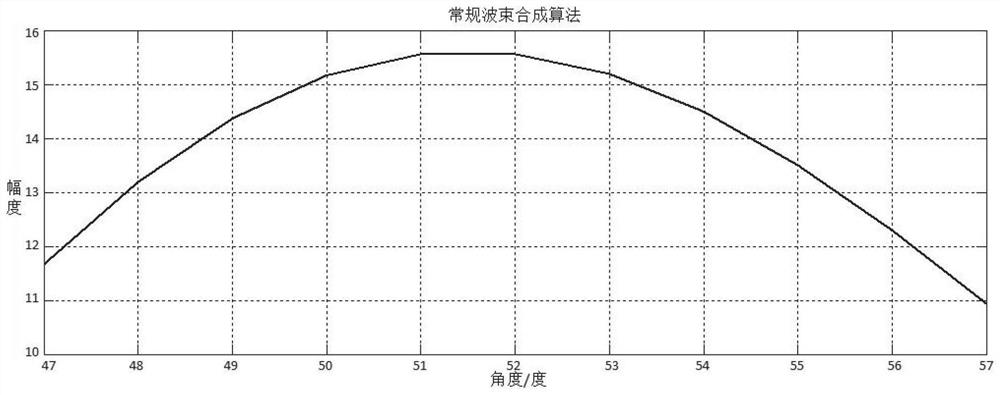

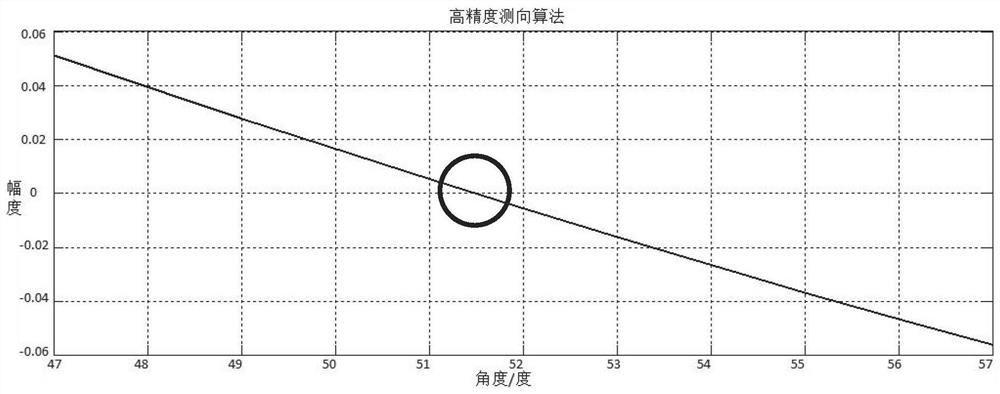

[0032] A high-precision direction finding method under the condition of large stepping beam scanning, refer to figure 1 , through the weighted control of the array, the synthetic beam is scanned in the airspace to obtain a preliminary estimate of the source azimuth angle, and the center of the beam is pointed to the rough measurement direction, and the array is divided into two symmetrical sub-arrays to sum the beams. , difference calculation, using the amplitude and phase relationship between the sum and difference beams to accurately estimate the source azimuth angle.

[0033] The process of the method mainly includes: after both sub-arrays point to the rough angle measurement, calculate the amplitude value of the Fourier transform of the data received by the composite array, and find the sampled data corresponding to the maximum amplitude value. At the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com