Composite positive electrode material and preparation method thereof

A technology of composite positive electrode material and positive electrode material, which is applied in the field of composite positive electrode material and its preparation, can solve the problems of poor bonding force between the coating layer and the material matrix, the overall performance of the battery is not ideal, and the side reactions are serious, etc., and achieve long-term cycle stability. and electrochemical performance, rapid mass production, and improved binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

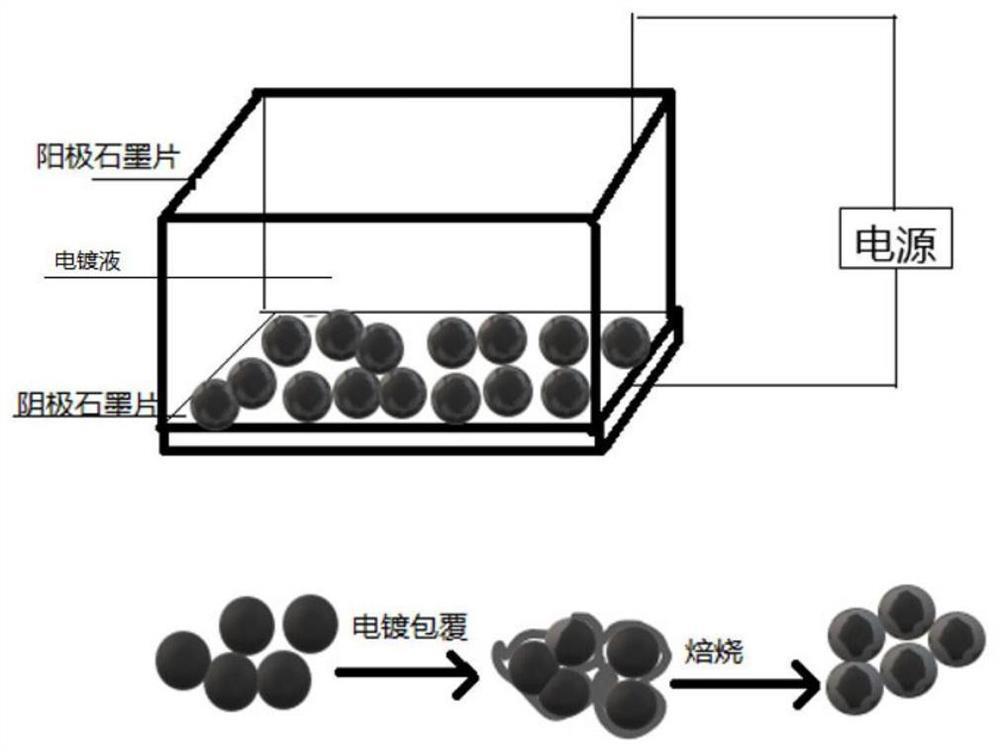

[0081] In a second aspect, the present application also provides a method for preparing a composite positive electrode material, the preparation method comprising the following steps:

[0082] Placing the active material flat on the surface of the cathode, and arranging the cathode and the anode in the electroplating solution in parallel along the horizontal direction, and performing electroplating treatment to obtain a positive electrode material precursor;

[0083] The positive electrode material precursor is sintered to obtain a composite positive electrode material.

[0084] The anode and the cathode are independently prepared from materials with electrical conductivity, specifically, materials such as graphite, aluminum, copper, nickel, stainless steel, and nickel-plated steel can be used.

[0085] The electroplating tank used in the electroplating treatment can be made of, but not limited to, acrylic, stainless steel, titanium, PP, PVC, FRP and other materials. The cros...

Embodiment 1

[0130] A preparation method of a composite positive electrode material includes the following steps S10 to S40:

[0131] In step S10, the thin graphite sheet is used as the anode and the thick graphite sheet is used as the cathode, such as figure 1 As shown, the anode and cathode are placed on the top and bottom surfaces of the electroplating tank, respectively, so that the anode and cathode are arranged in parallel up and down.

[0132] Step S20, configuring an ionic liquid electroplating solution: in an inert atmosphere, choline chloride and urea are mixed in a molar ratio of 1:1 to form an ionic liquid. Then, aluminum chloride with a mass of 5% of the mass of the ionic liquid is added to the ionic liquid, and the mixture is uniformly mixed to obtain an electroplating solution with a pH value of 7.8.

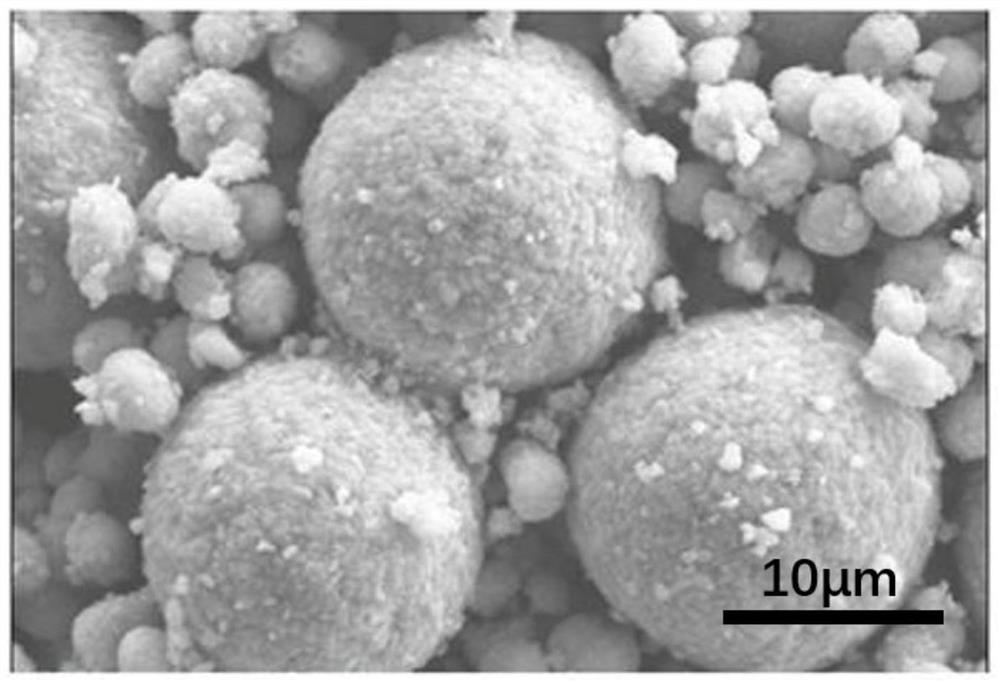

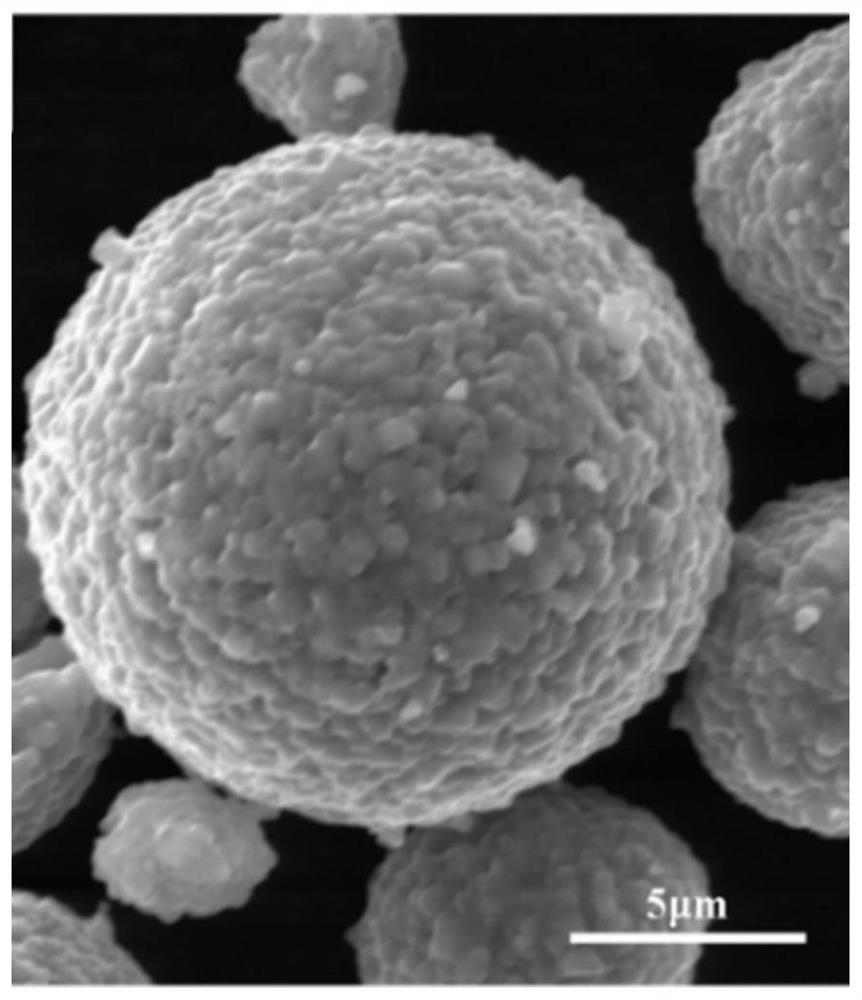

[0133] Step S30, 5g of positive electrode material NCM811 powder (d 0 = 15 μm) on the surface of the cathode, the NCM811 powder was uniformly adsorbed on the surface of the ...

Embodiment 2

[0137] Compared with Example 1, except that the metal salt in step S20 is tungsten chloride, the others are the same as Example 1.

[0138] The composite positive electrode material prepared in this example includes an active material and a coating layer existing on the surface of the active material, and the coating layer includes tungsten oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap