Flexible, insulating and heat-conducting ribbon

A technology of insulating and heat-conducting webbing, applied in the field of webbing production, can solve the problems of poor durability, poor washing resistance, low resistivity and other problems, and achieve the effect of high resistance to bending and stability, excellent stability and high thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

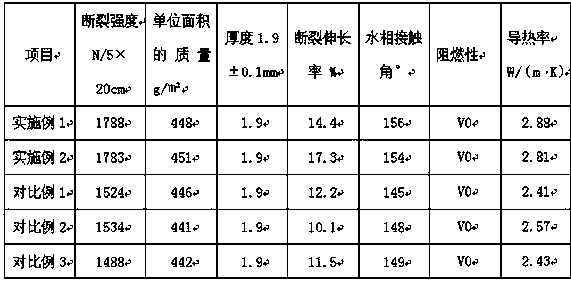

Examples

Embodiment 1

[0021] A flexible insulating and heat-conducting ribbon, prepared from the following components in parts by weight: 80 parts of polyphenylene sulfide, 85 parts of soluble polytetrafluoroethylene, 15 parts of polyoxymethylene, 3 parts of carbon nanotubes, 25 parts of red mud, and 7 parts of carbon fiber , 5 parts of silicon carbide short fiber, 7.5 parts of barium titanate whiskers, 12 parts of boron nitride nanosheets, 1.5 parts of coupling agent, and 1 part of anti-aging agent.

[0022] Further, the barium titanate whiskers are roasted in a vacuum furnace, stirred and dispersed in absolute ethanol with sodium hexametaphosphate after cooling, then treated with normal pressure plasma, and then deionized in the calcium stearate-containing dispersion. Ultrasonic dispersion and cleaning in water, taking the suspended whiskers in the upper layer of the solution and filtering, taking the modified whisker mixed solution, and repeating the operation until filtering, drying in a vacuum ...

Embodiment 2

[0027] A flexible insulating and heat-conducting ribbon, prepared from the following components in parts by weight: 90 parts of polyphenylene sulfide, 85 parts of soluble polytetrafluoroethylene, 13 parts of polyoxymethylene, 3 parts of carbon nanotubes, 23 parts of red mud, and 7 parts of carbon fiber , 7 parts of silicon carbide short fiber, 15 parts of barium titanate whisker, 15 parts of boron nitride nanosheet, 1.5 parts of coupling agent, and 1 part of anti-aging agent.

[0028] Further, the barium titanate whiskers are roasted in a vacuum furnace, stirred and dispersed in absolute ethanol with sodium hexametaphosphate after cooling, then treated with normal pressure plasma, and then deionized in the calcium stearate-containing dispersion. Ultrasonic dispersion and cleaning in water, taking the suspended whiskers in the upper layer of the solution and filtering, taking the modified whisker mixed solution, and repeating the operation until filtering, drying in a vacuum ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com