Molding method of atomizing core with multifunctional areas

A molding method and multi-functional zone technology, applied in the field of 3D molding of atomizing cores, can solve the problems of complex embryo shape, short service life of atomizing cores, loose and loose bonding, etc., so as to shorten the process chain and improve the comprehensive performance. , the effect of reducing the defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

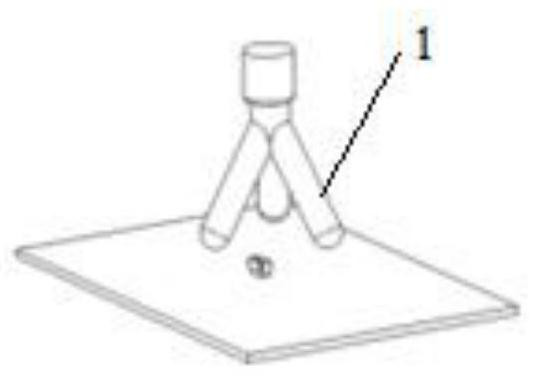

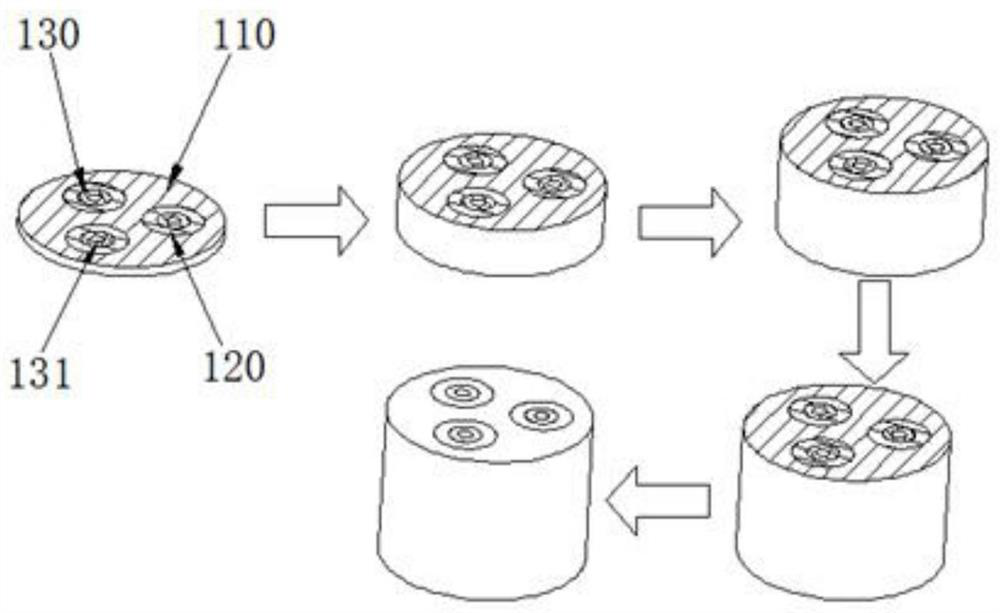

[0034] The forming method of the atomizing core with multi-functional area in this embodiment is prepared by stacking forming method, such as figure 1 As shown, three nozzles are used to spray raw materials with different compositions to spray the raw materials of the support area 110, the oil guide area 120 and the atomization area 130 respectively, and the functional areas of the atomization core are formed layer by layer, and finally stacked layer by layer to form a complete body. The method of 3D atomizing core is as follows: figure 2 As shown, calcining and sintering can obtain the finished atomizing core.

[0035] The raw materials of the supporting area (110) are: 10-75 parts by weight of a mixture of alumina powder and zirconia powder; 5-50 parts by weight of a mixture of polymethyl methacrylate and sucrose, wherein the mass ratio of polymethyl methacrylate to sucrose is It is 1: (0.5-1.5); The mixture of paraffin wax, low-temperature glass and dibutyl phthalate is 0...

Embodiment 2

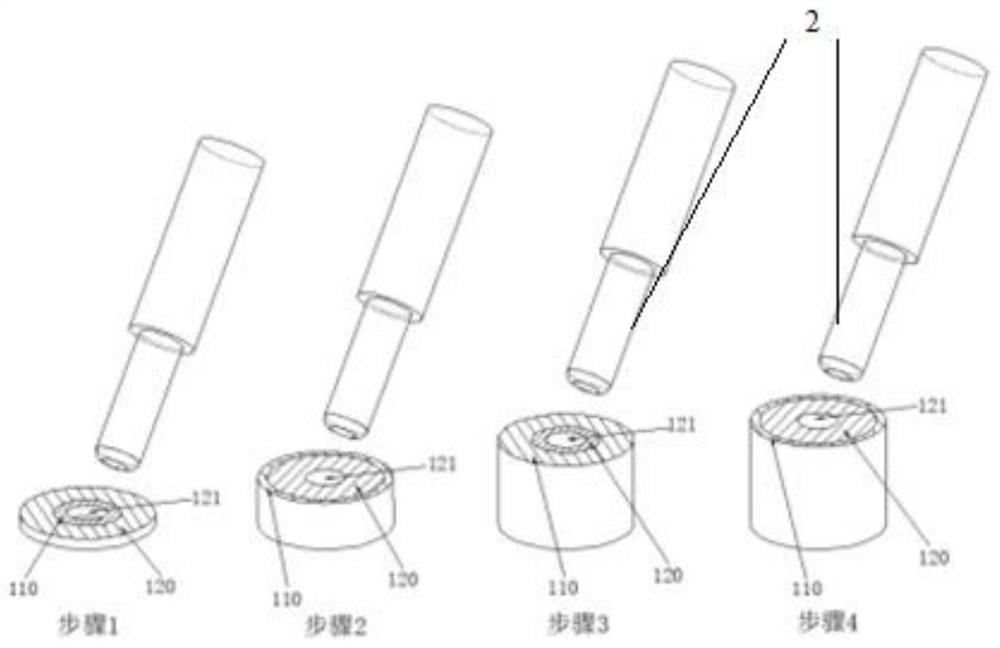

[0045] The molding method of this embodiment is prepared using a solidification molding method, such as image 3 As shown, the laser irradiation head is used to irradiate the powdered raw material, so that the binder in the raw material melts and other materials in the raw material are bonded together to form a complete 3D atomizing core layer by layer. The steps of the curing molding method are as follows: the formed layer contains functional area materials at the same time, such as the support area, the atomization area and the powder material of the oil guide area. Then remove the powder material in the oil guide area, and then lay the powder material in the atomization area for molding; then lay the powder material in the support area for molding, forming layer by layer, and finally forming a green embryo with a complete and integrated 3D atomizing core. The composition of the powder material in the support area, the atomization area and the oil guide area is as follows: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap