Method and system for inspecting transparent glass with adjunctions

A technology for glazing and appendages, applied to defects in large-scale glazing, glazing inspection, transportation vehicles and glazing for buildings, which can solve unnoticed glazing, errors, adverse effects on production And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

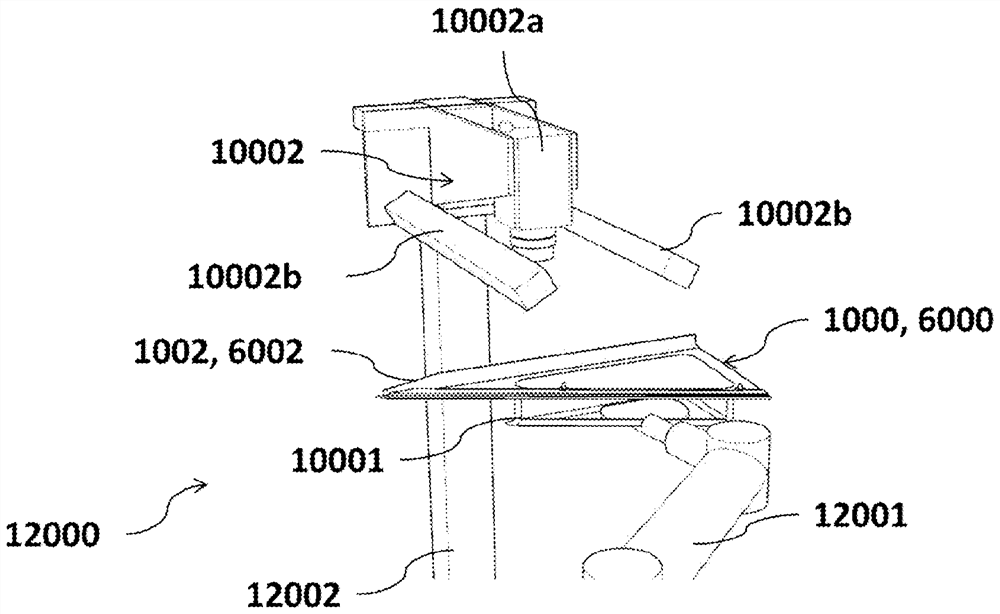

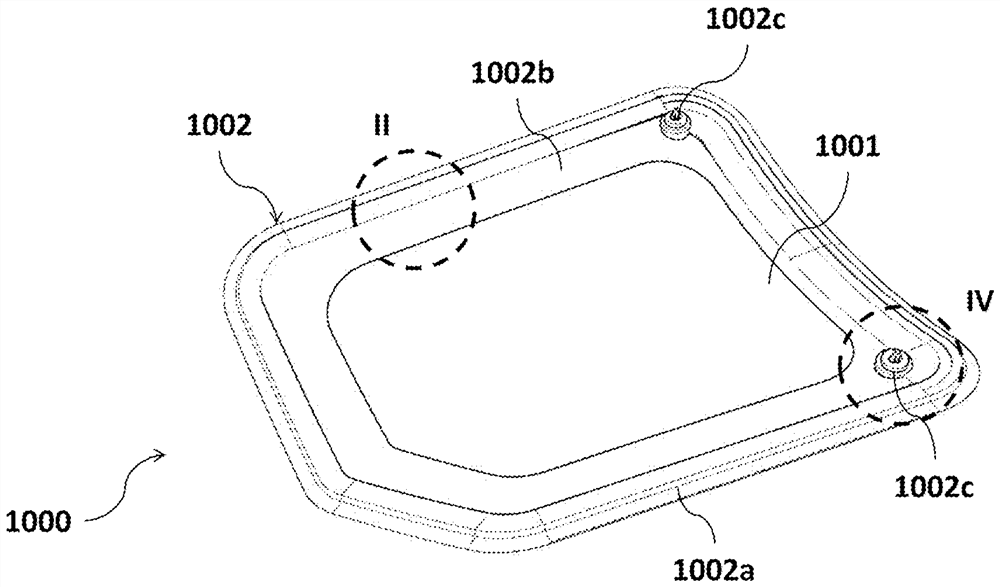

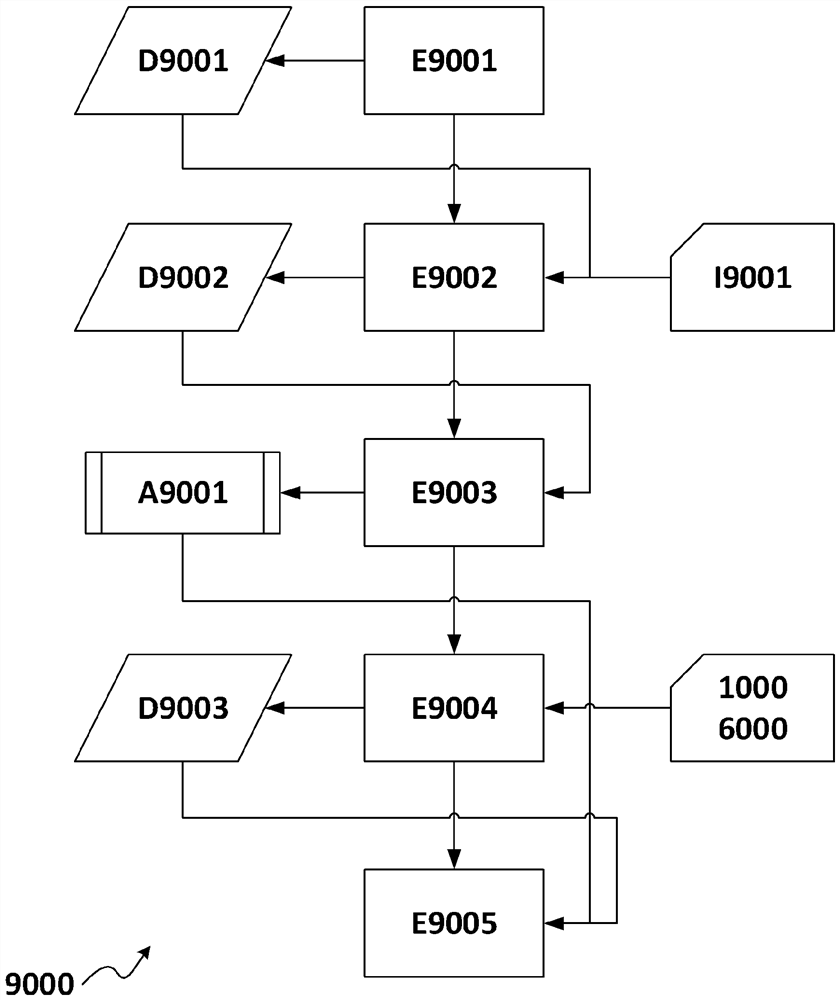

[0034] refer to Figure 1 to Figure 5 , a first example of glazing with appendages may be automotive glazing such as rear windows. Glazing 1000 includes a transparent mineral glass sheet 1001 and appendages 1002 . The appendage 1002 includes a peripheral encapsulation gasket 1002a, a peripheral enamel coating 1002b, and a fastening element 1002c.

[0035] The first detail II of appendage 1002 is in figure 2 and image 3 shown in. Peripheral encapsulation gasket 1002a includes injection points 2001 through which the material of the gasket is injected when peripheral injection gasket 1002a is molded. exist figure 2 , the injection point 2001 is qualified. image 3 An example of a defect of injection point 2001 is shown. Injection site 2001 includes injection residue 3001 . This residue is an example of a defect associated with appendage 1002 of glazing 1000 .

[0036] The second detail IV of appendage 1002 is in Figure 4 and Figure 5 shown in. exist Figure 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com