A low-concentration flue gas detection pretreatment water removal method and device and its flue gas detection application system

A flue gas detection and pretreatment technology, applied in the flue gas detection application system, low concentration flue gas detection pretreatment and water removal field, can solve the problem of acid gas component loss, etc., to reduce the component loss rate and acid concentration. The effect of optimizing and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

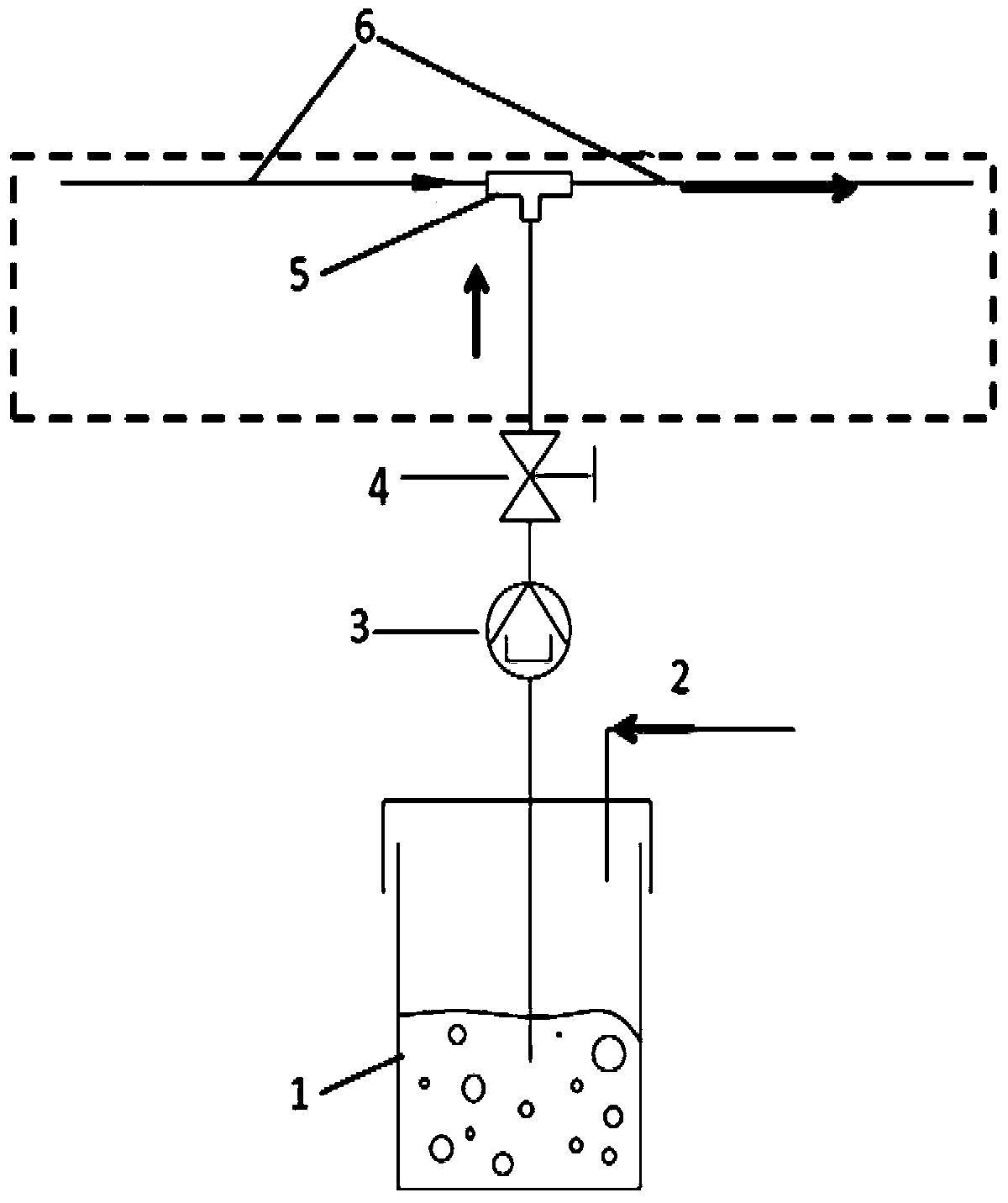

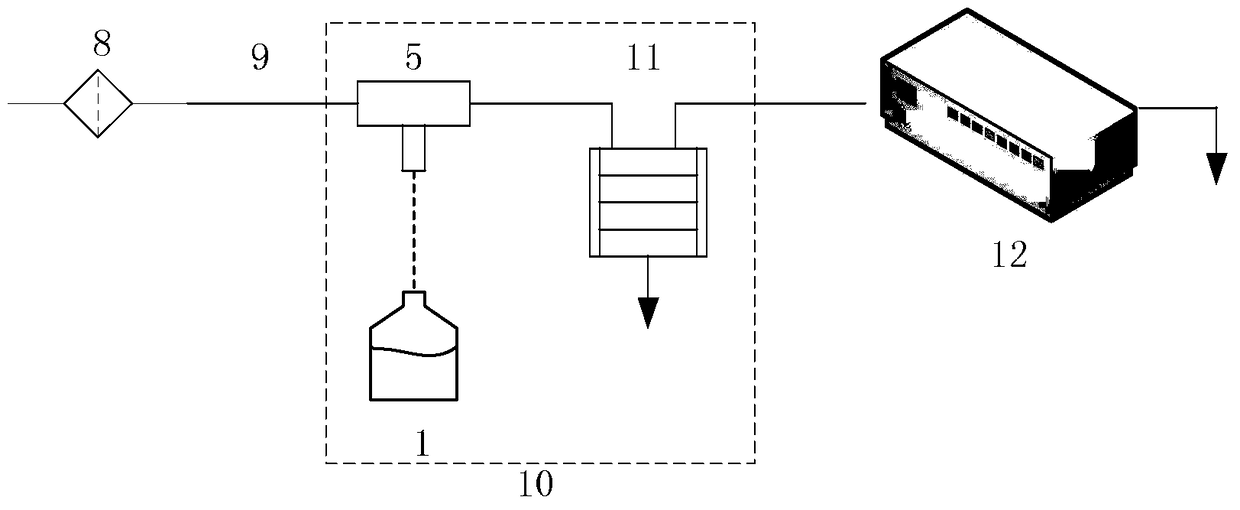

[0037] Such as Figure 4 Shown: a low-concentration flue gas detection pretreatment water removal device, including a sampling pipe 8, a pretreatment unit 10 and a heating line, the pretreatment unit 10 includes an acid addition unit and a condensation unit, such as figure 1 As shown: the acid adding unit is composed of a container 1 for acid liquid, an air circulation pipe 2, a three-way valve 5 and a pump 3. The pump 3 pumps the acid liquid into the pipeline leading to the condensing unit, and the condensing unit is the condenser 11 , the above-mentioned components are connected through pipeline 9, and the container for holding the acid liquid is connected with the pump through a pipeline, and the material of the pipeline is acid corrosion-resistant material such as PTFE; the pump and the three-way valve are connected through a pipeline, and the heating wire is wound around the pipeline 6 Heating, the control temperature range is 70-100°C, and the pipe material is acid corrosi...

Embodiment 2

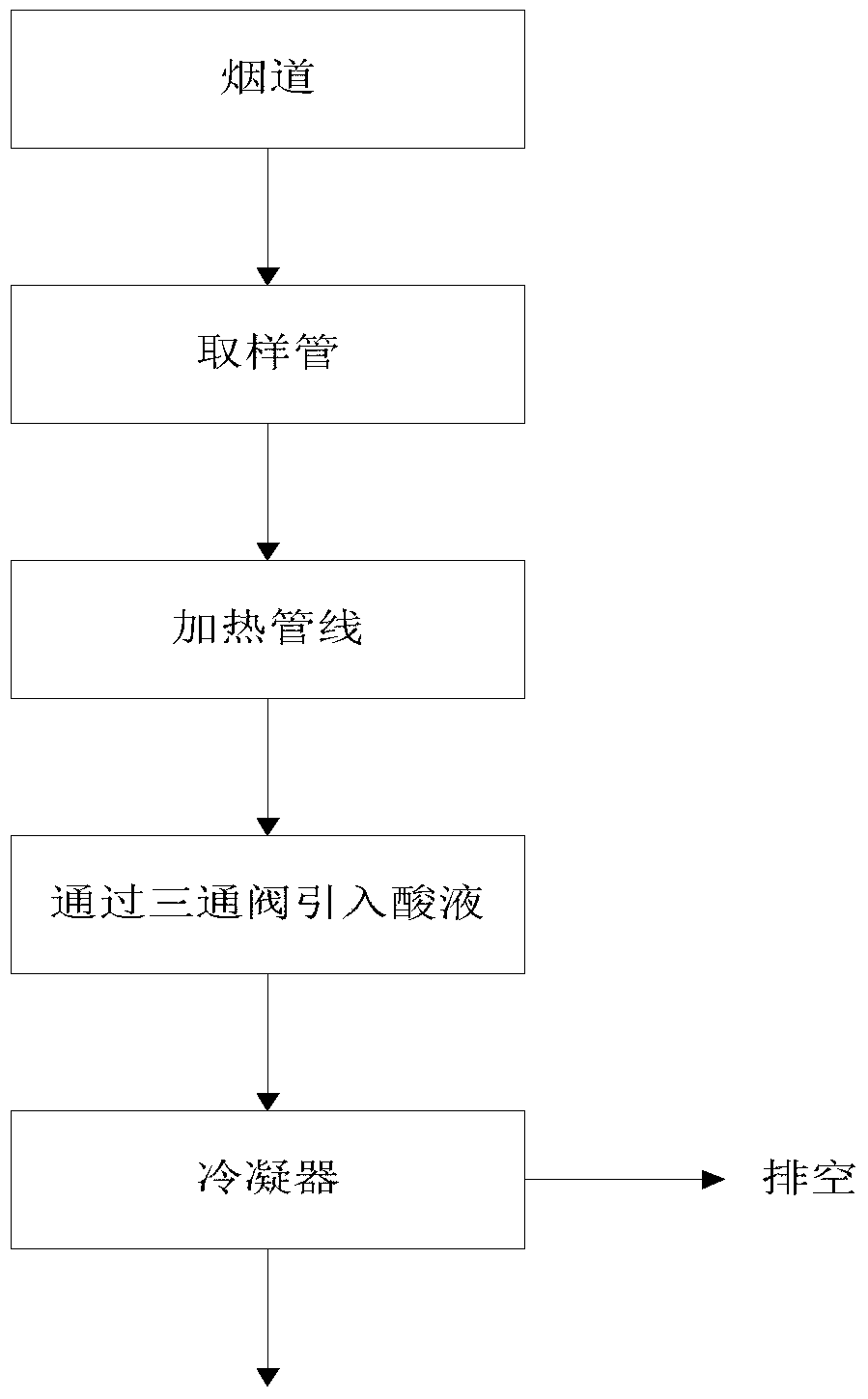

[0047] Device and system, with embodiment 1. The flue gas passes through the sampling pipe from the flue, which contains a filter to filter out large particles of smoke, and then enters the condenser through the heating pipe. At the connection between the heating pipe and the condenser, a three-way valve is used to inject 30% (mass percentage ) phosphoric acid solution, the phosphoric acid solution enters the condensing condenser together with the flue gas, and after condensation removes water, the flue gas enters the gas analyzer through the gas pipeline to analyze SO 2 , NO, NO 2 Concentrations of other gas components.

[0048] Heat the pipeline between the pump and the three-way valve to 100°C, the three-way valve to 100°C, and the connection between the three-way valve and the condenser to 100°C.

[0049] To verify the loss rate of gas components in the above method, the method is as follows:

[0050] Pass SO through the sampling tube 2 , NO, NO 2 The content is 50mg / ...

Embodiment 3

[0053] Device and system, with embodiment 1. The flue gas passes through the sampling pipe from the flue, which contains a filter to filter out large particles of smoke, and then enters the condenser through the heating pipe. At the connection between the heating pipe and the condenser, a three-way valve is used to inject 1% (mass percentage ) phosphoric acid solution, the phosphoric acid solution enters the condensing condenser together with the flue gas, and after condensation removes water, the flue gas enters the gas analyzer through the gas pipeline to analyze SO 2 , NO, NO 2 Concentrations of other gas components.

[0054] Heat the pipeline between the pump and the three-way valve to 70°C, the three-way valve to 70°C, and the connection between the three-way valve and the condenser to 70°C.

[0055] To verify the loss rate of gas components in the above method, the method is as follows:

[0056] Pass SO through the sampling tube 2 , NO, NO 2 The content is 50mg / m 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com