A method for removing fermentation inhibitors in lignocellulosic prehydrolyzate

A technology of fermentation inhibitors and pre-hydrolyzed liquid, which is applied in fermentation, biofuel, etc., can solve the problems of poor detoxification effect of lignocellulosic pretreatment liquid, and achieve the effect of mild conditions, good removal effect and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

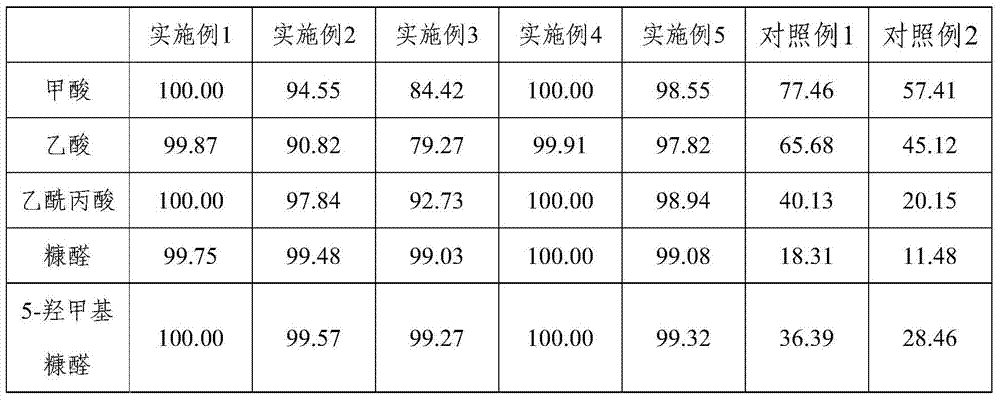

[0031] Embodiment 1 The method for removing fermentation inhibitors in bamboo prehydrolyzate

[0032] Bamboo was pretreated with chemical dilute acid, 10 mL of the obtained hydrolyzate was taken, its pH value was adjusted to 5, placed in a centrifuge tube, and centrifuged at a speed of 12000 rpm for 10 minutes, after centrifugation, 1 mL of the supernatant was taken, Add it to a 5mL elution column equipped with 1000mg graphitized carbon, install the elution column in a solid phase extraction device, use air as the eluent, 25°C, pH value 5, adjust the elution flow rate to 0.2ml / min, receive the eluate, filter it with a 0.1 micron water filter membrane, and take the filtrate for analysis.

[0033] Wherein, the sum of the concentrations of formic acid, acetic acid, levulinic acid, furfural and 5-hydroxymethylfurfural in the supernatant was 26.2 g / L.

[0034] The graphitized carbon is granular, with a particle size of 80 mesh.

Embodiment 2

[0035] Embodiment 2 The removal method of fermentation inhibitor in wood prehydrolyzate

[0036] The method of Example 1 is used to remove the wood prehydrolyzate, the difference is: the elution flow rate is 0.5ml / min; the graphitized carbon is powdery, and the particle size is 400 mesh; the pore size of the water filter membrane is 1 micron.

Embodiment 3

[0038] The method of Example 1 is used to pre-hydrolyze the corn stalks after dilute acid pretreatment. The difference is: adjust its pH value to 6, and filter it with a 0.5 micron water filter membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com