Production line for lamp assembly

A production line and lamp technology, applied in assembly machines, manufacturing tools, metal processing equipment, etc., can solve problems such as low work efficiency, achieve the effects of improving efficiency, reducing labor intensity, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

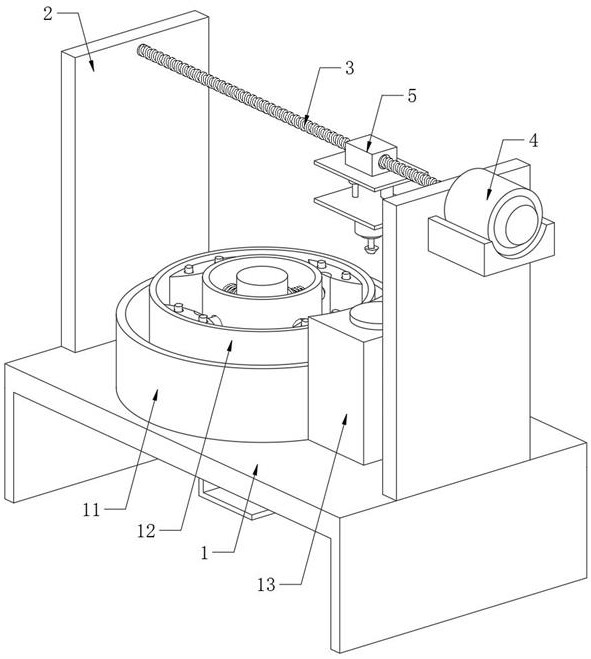

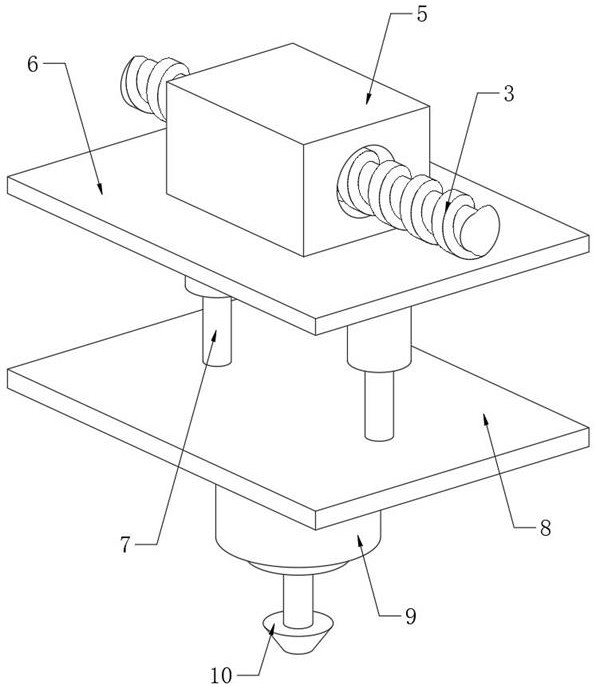

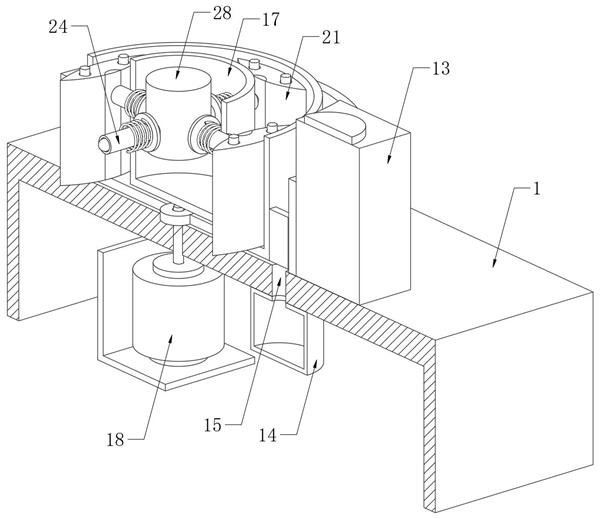

[0021] refer to figure 1 , image 3 , Figure 4 and Figure 5 As shown in the figure, a production line for lamp assembly includes a workbench body 1, the upper end of the workbench body 1 is symmetrically and vertically connected with two fixed plates 2, and the two fixed plates 2 are connected by a reciprocating mechanism. Wire mechanism, the upper end surface of the worktable body 1 is installed with a first shell 12 with an open upper end, and the inner bottom wall of the first shell 12 is coaxially installed with a second shell 17 with an open upper end. The horizontal cross-sections of the casing 12 and the second casing 17 are annular, and a plurality of arc-shaped plates 21 are vertically slidably connected to the inner wall of the first casing 12 through a limiting mechanism, and each arc-shaped plate 21 is close to the second casing. One side of the body 17 is an arc-shaped convex surface, and a plurality of horizontal holes are evenly and horizontally opened on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com