Construction platform based on port channel pouring

A technology for construction platforms and port waterways, which is applied in infrastructure engineering, scaffolding accessories, construction, etc., can solve the problems of inconvenient concrete block cleaning, inconvenient use, and construction workers being easily affected by walking on the scaffolding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

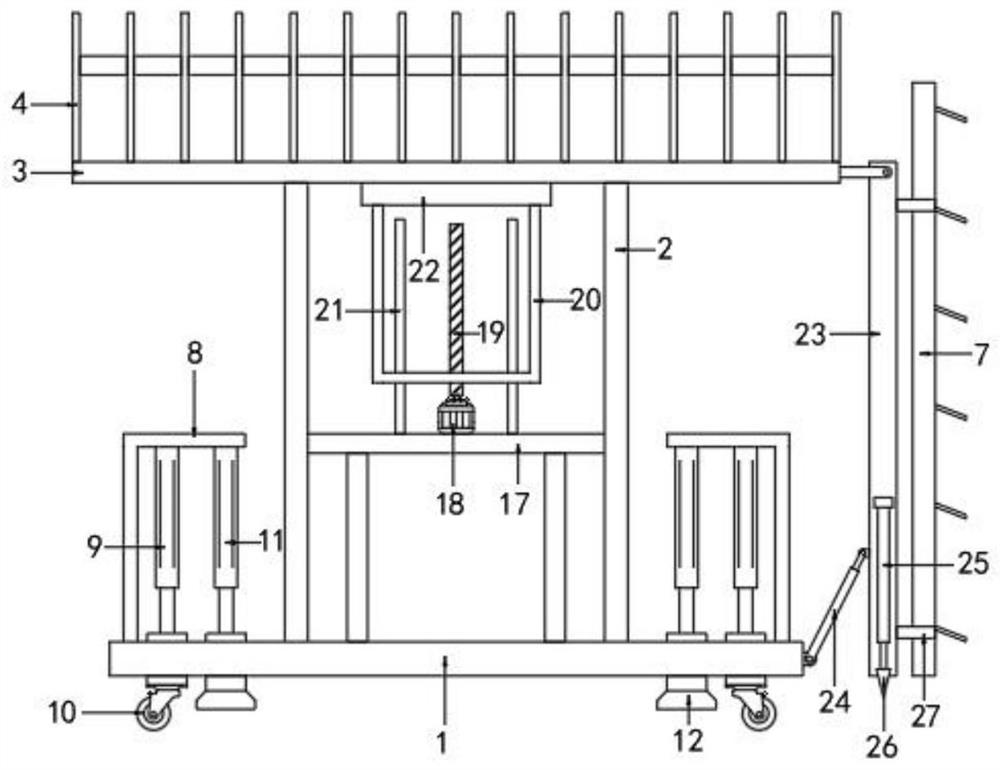

[0022] refer to Figures 1 to 5 , a construction platform based on port waterway perfusion, comprising, a fixed plate 1; a support rod 2 is provided on the top of the fixed board 1, and a top plate 3 is provided on the top of the early support rod 2; in order to protect the construction personnel, on the top of the top plate 3 The outer side is provided with a protective fence 4, and the protective fence 4 is installed on the right side to enter and exit through a hinge, which is convenient for construction personnel to enter and exit;

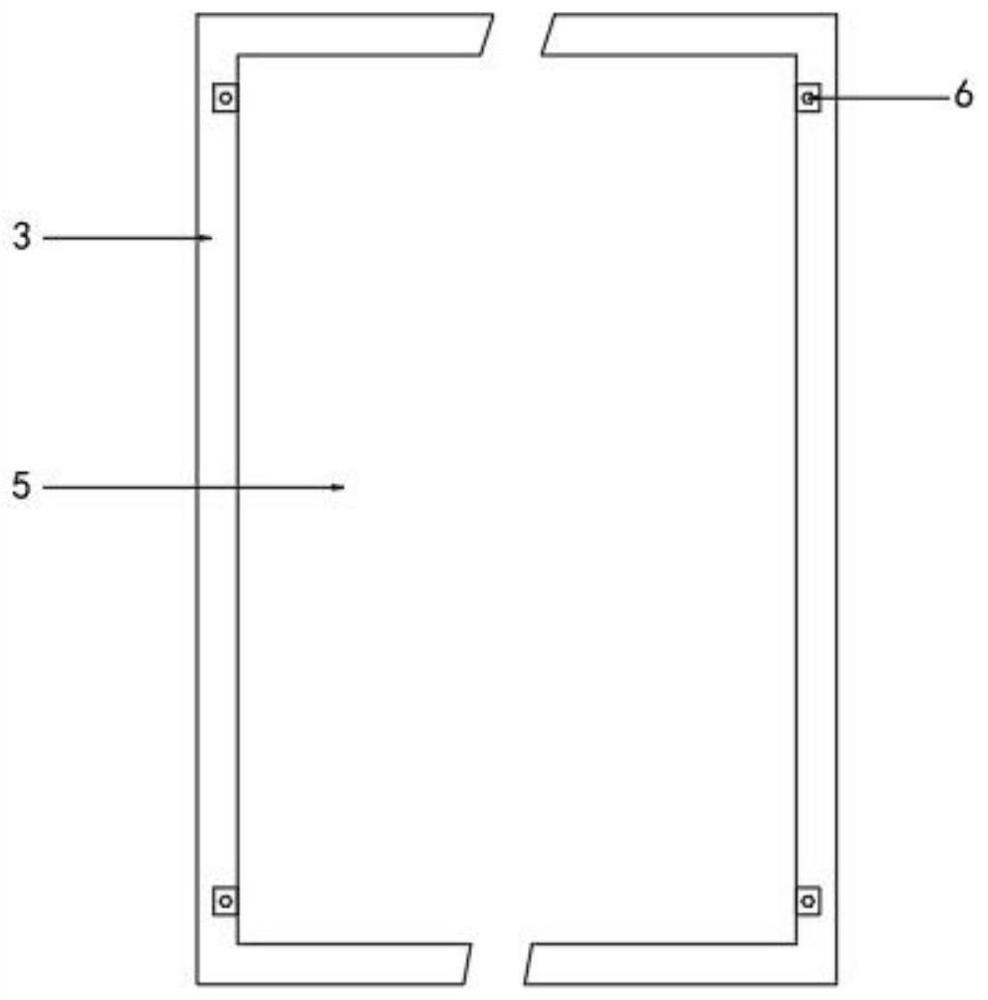

[0023] A groove is provided on the top of the top plate 3, and an iron plate 5 whose top is flush with the top plate 3 is attached and connected in the groove. There are fixing bolts 6 connected with the top plate 3 to fix the iron plate 5. When the concrete blocks on the iron plate 5 need to be cleaned, the iron plate 5 can be taken out upward by removing the fixing bolts 6; An angle adjustment device is arranged; a buffer device is arranged...

Embodiment 2

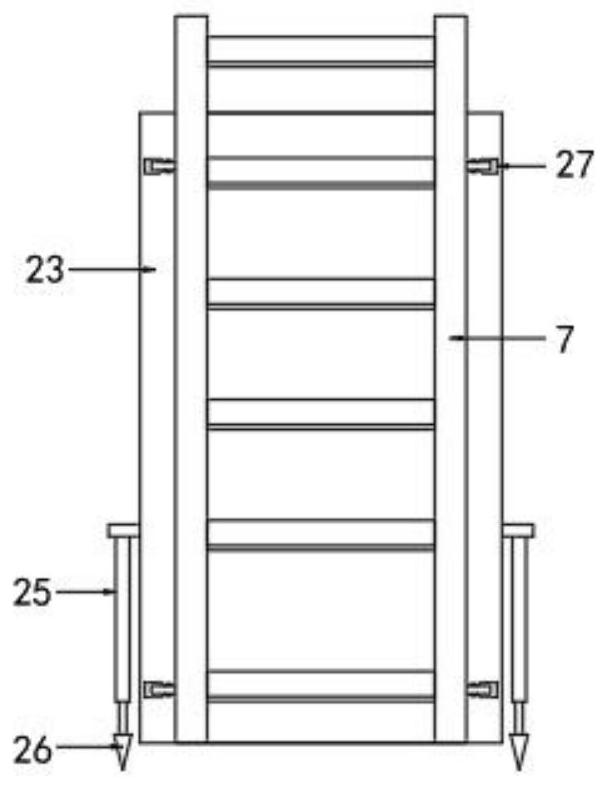

[0030] refer to Figure 1 to Figure 2 , the bottom ends of the front and rear sides of the mounting plate 23 are provided with electric push rods 25, and the output ends of the electric push rods 25 are provided with support rods 26 whose bottom ends are tapered. The support rod 26 can be driven to lean against the ground, so as to cooperate with the electric telescopic rod 24 and further play the role of supporting the ladder 7 .

[0031] The rest of the structure is the same as that of Example 1.

[0032]Using process: push the fixed plate 1 to the required position through the universal wheel 10, drive the support base 12 to contact the ground through the action cylinder 2 11, so that the fixed plate 1 can be placed flat on the uneven ground, and then drive the universal direction through the action cylinder 1 9 When the wheel 10 moves upward, it can be placed stably through the support base 12; when the construction worker needs to get on the iron plate 5, the electric te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com