Side slope anchoring and shotcreting supporting structure

A technology for bolting and shotcrete support and slope, which is applied in the directions of infrastructure engineering, construction, excavation, etc., can solve the problems that the preset holes cannot be closely matched, the supporting structure cannot be given, and the slope support and traction are easy to adjust. , The effect of ensuring strength and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

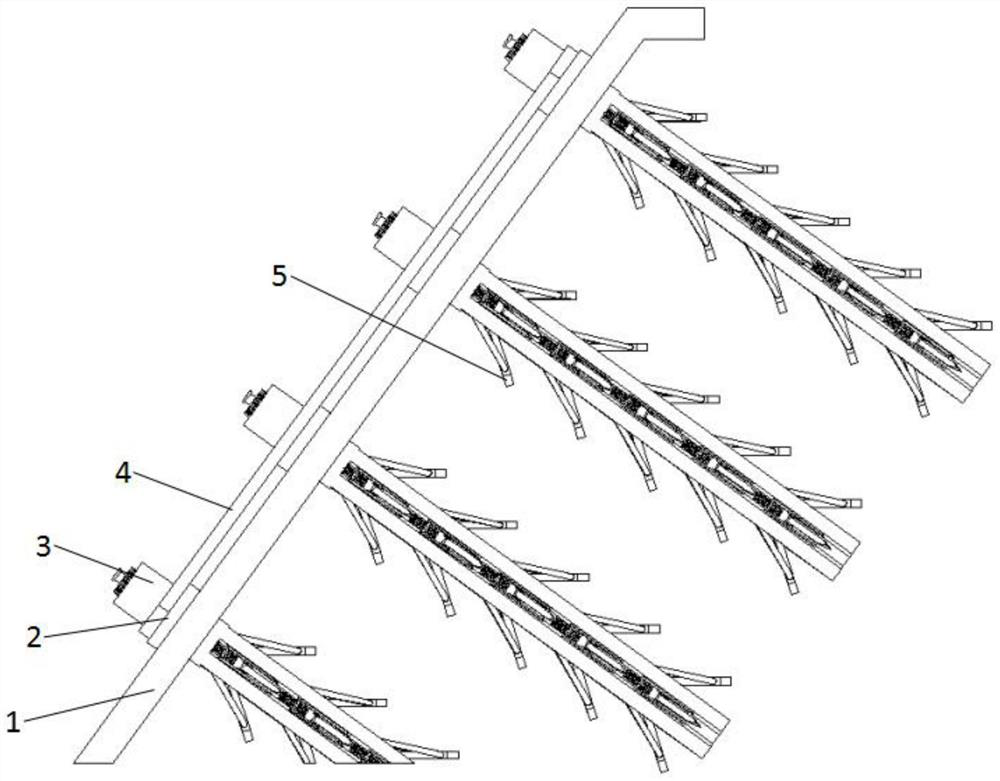

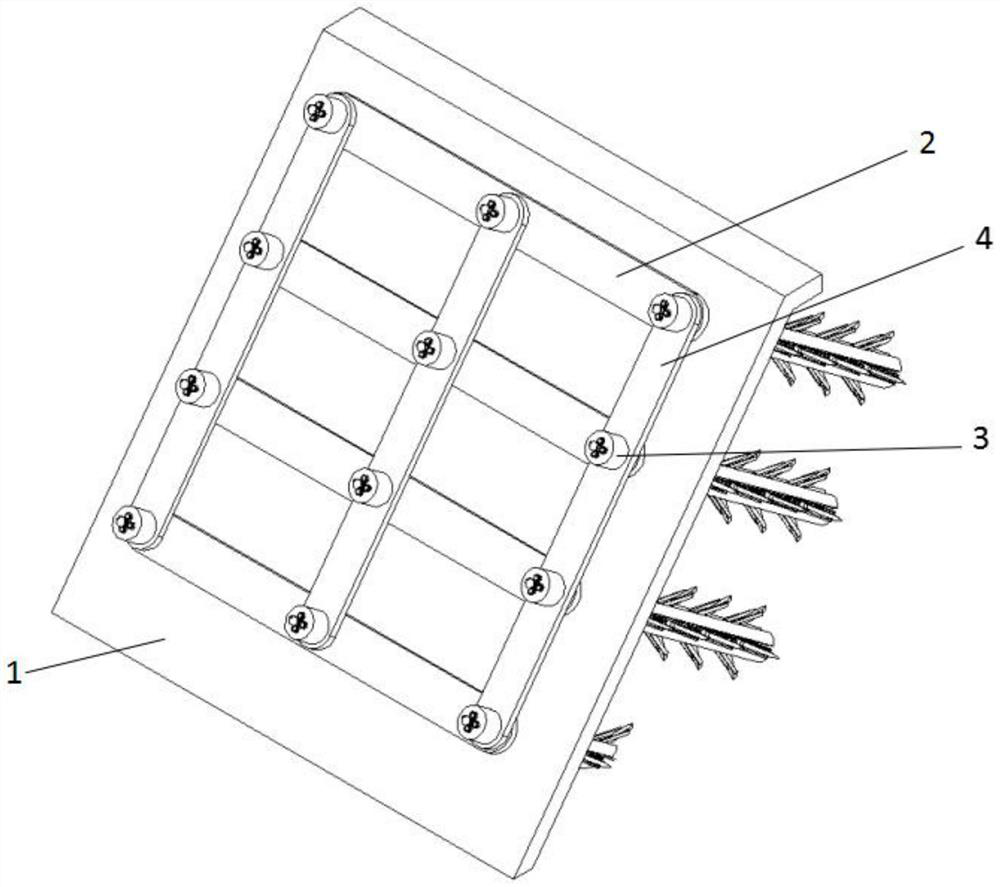

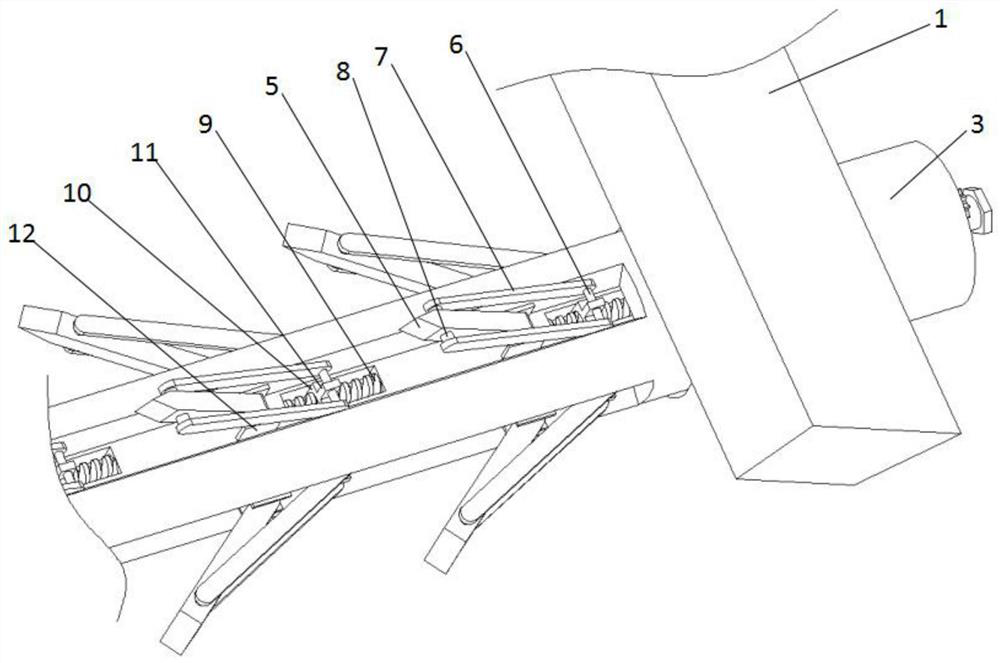

[0040] A kind of slope bolt and shotcrete support structure, such as Figure 1-4 As shown, it includes: a plurality of anchor rods 3, one end of which is respectively inserted into a plurality of arrays of through holes preset in the side slope 1; each anchor rod 3 is provided with a plurality of long grooves along the length direction, The grooves are evenly arranged along the circumferential direction of the anchor rod 3; a plurality of limit plates 5 are respectively rotated and erected in the plurality of elongated slots through the rotating assembly, and are evenly arranged along the longitudinal direction of the elongated slots. Specifically, as figure 2 and image 3 As shown in the figure, a square groove is formed at the bottom of each long groove; each set of rotating components includes: two shelf plates 12, both of which are fixedly arranged on the groove bottom of the long groove, and are located at one end of a corresponding square groove; A rotating shaft pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com