Mortar spraying machine

A spraying machine and mortar technology, which is applied in the direction of construction and building structure, can solve the problems of large influence of mortar spraying effect, and achieve the effect of wide spraying range, uniform spraying process and high spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

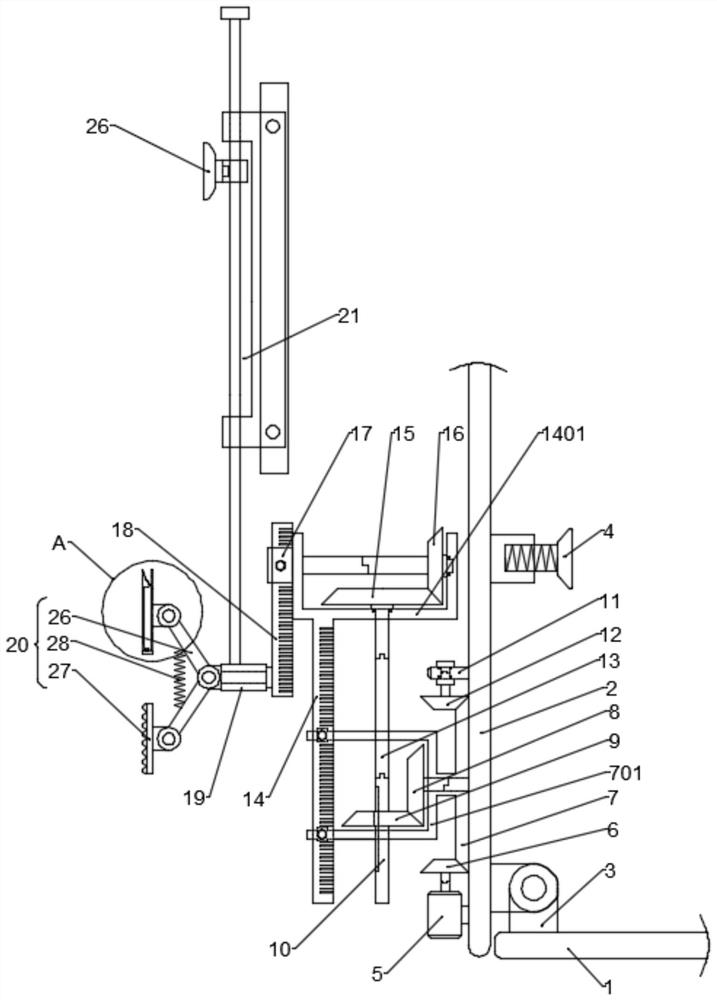

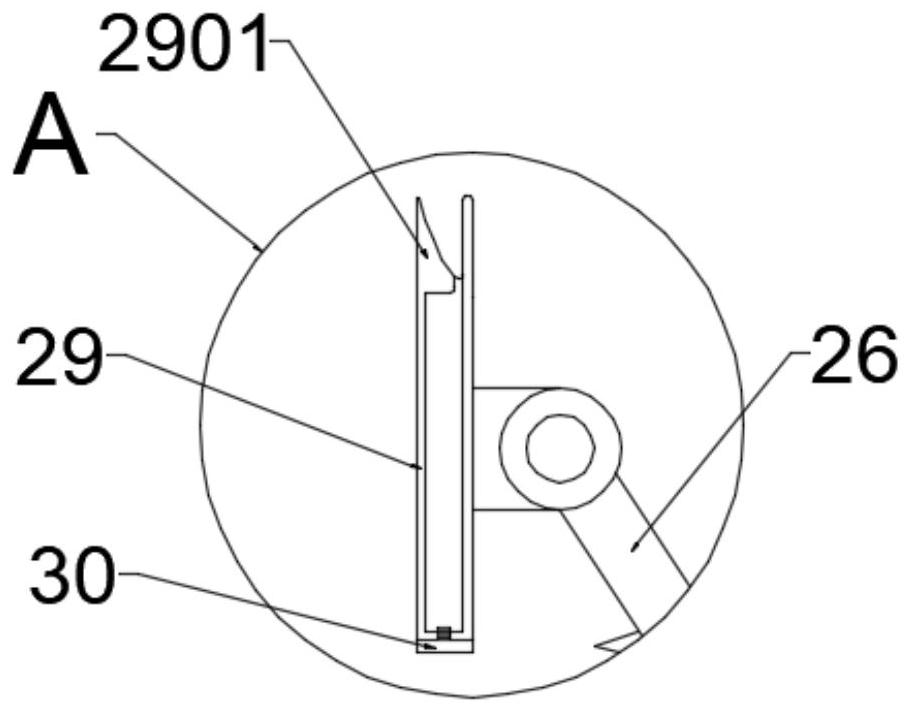

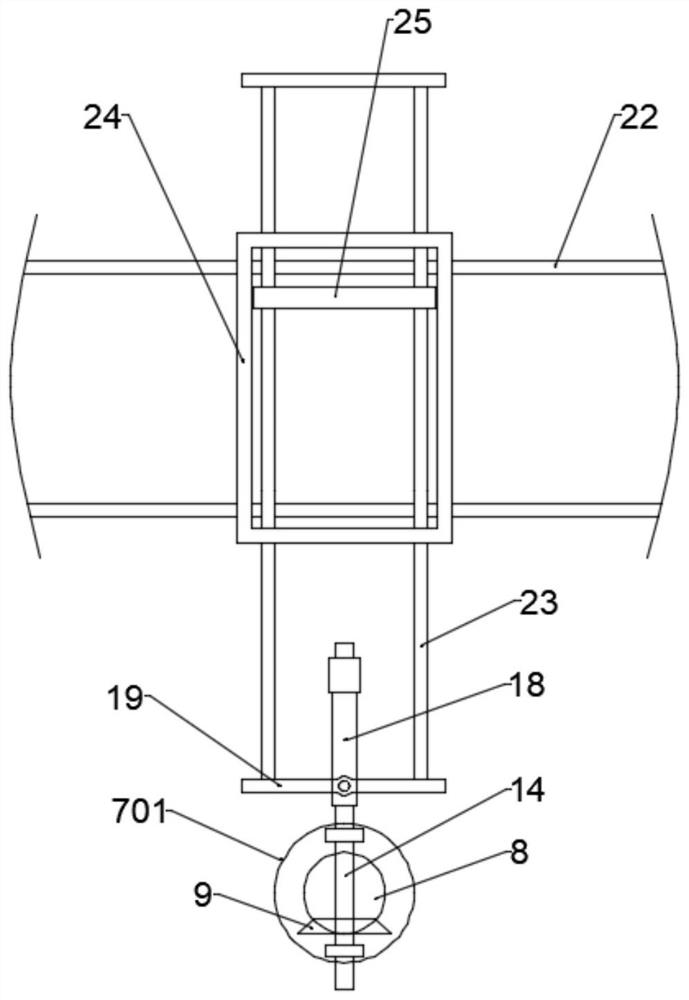

[0048] see Figure 1 to Figure 6 , In the embodiment of the present invention, a mortar spraying machine, the spraying machine comprises:

[0049] The base body, the base body includes a first base 1 and a second base 2, the first base 1 and the second base 2 are provided with ear seats 3, and the ear seats 3 are rotatably connected; the base body As the name implies, it is the support structure of each part in the technical solution of the present invention. Those skilled in the art can add some components on the base body as needed. For example, a universal wheel can be installed on the first base 1 to provide a moving function, A shock pad can also be installed on the first base 1 to improve the stability of the spraying process.

[0050] The power device installed on the second base 2, the power device includes a second gear 7 rotatably connected with the second base 2, and the second gear 7 is provided with a first transmission frame 701; the A first connecting rod 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com