Combined nut with anti-loosening function

A combined nut and anti-loosening technology, which is applied in the direction of nuts, screws, bolts, etc., can solve problems such as falling off, bolt fatigue damage, functional and safety defects, etc., and achieve high reliability and anti-loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

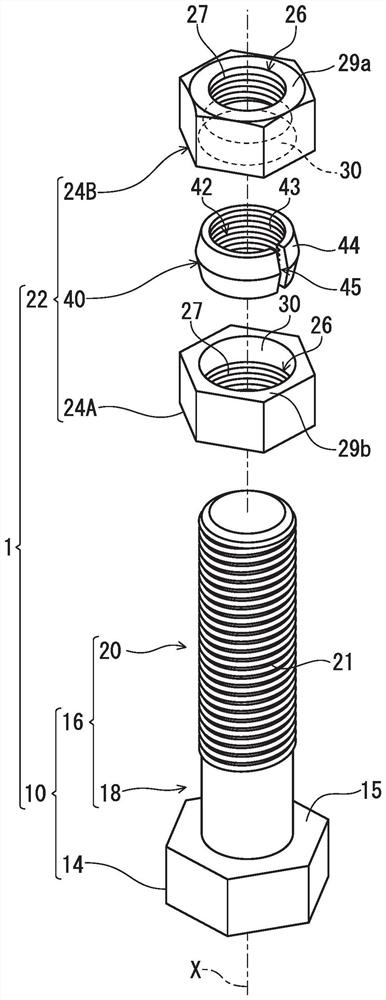

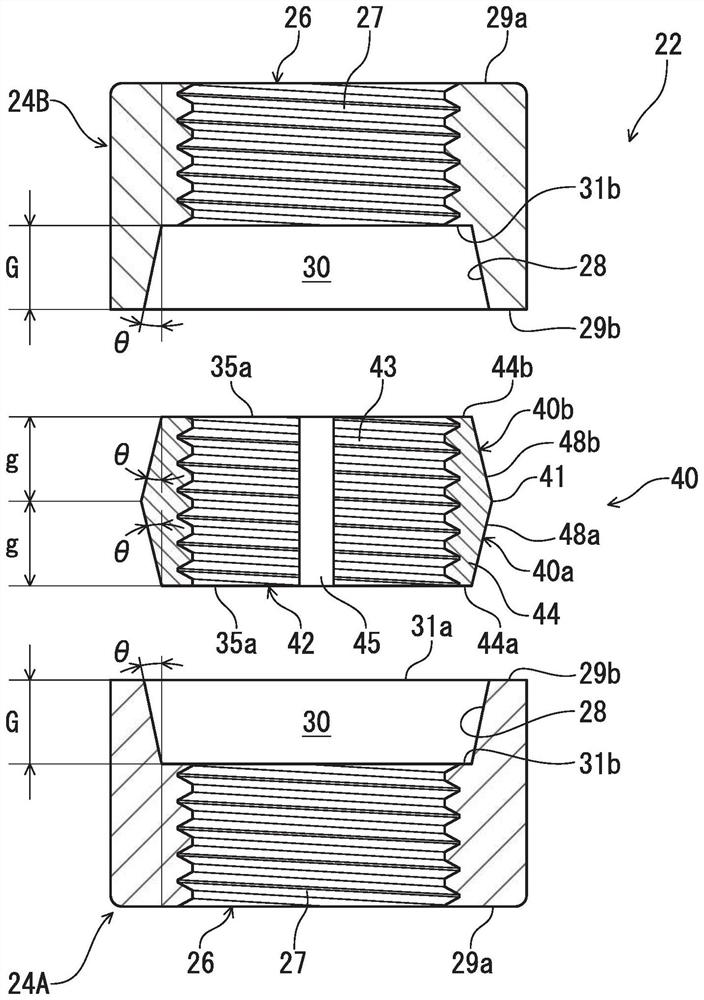

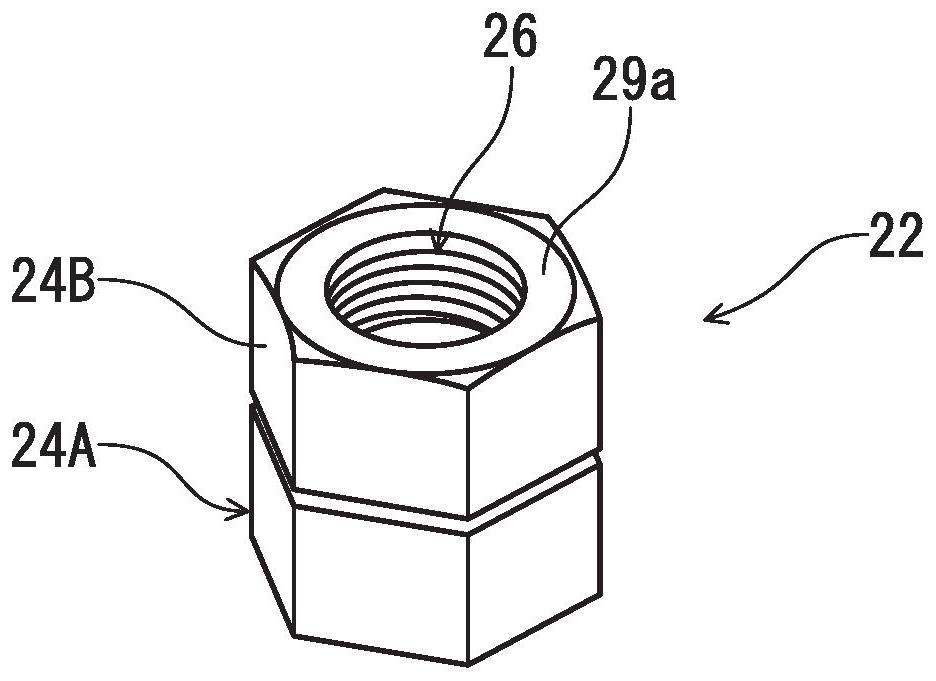

[0065] Preferred embodiments of the present invention will be described below. figure 1 It is an exploded perspective view of a bolt-nut tightening body (hereinafter abbreviated as a screw tightening body) 1 using the combination nut of the present invention, and it is an example showing that, for example, it is used for integrally tightening two flat plate-shaped members to be tightened together. and fixed the situation. The screw-fastening body 1 is constituted by a tightening bolt 10 and a combination nut 22 formed of three single-piece nut parts used in combination with the tightening bolt 10 as described later. The fastening bolts 10 are hexagonal bolts specified by Japanese Industrial Standards, but may be special bolts produced according to the purpose. The tightening bolt 10 is formed of a bolt head 14 having a seat surface 15, and a cylindrical shaft portion 16 integral with the bolt head 14, and the cylindrical shaft portion 16 is formed by a cylindrical portion 18 ...

Embodiment 2

[0105] Image 6 This shows another embodiment of the present invention, and it is possible to perform the tightening work most efficiently, easily and safely at the tightening work site. The combination nut 22 shown in FIGS. 3A and 3B combined in a no-load fitting state, that is, the aggregate of the first and second outer tightening nuts 24A and 24B and the single inner locking nut 40, is axially oriented. It is packaged with a thin cylindrical outer package 100 made of polyethylene resin in a state where both ends are exposed. Two parallel perforated lines 102 extending between the open end edges 101 on both sides are drilled in the cylindrical outer package 100 , and the central part of one of the open end edges 101 between the perforated lines 102 is drilled Tabs 103 for holding are formed. The cylindrical outer body 100 is thermally shrunk into the cylindrical outer body 100 in which the assembly of the unit nuts 22 is inserted, and the three individual nut parts 24A, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com