Flue flow field measuring device and flue flow field measuring method

A measurement device and flow field technology, which is applied in the direction of measurement device, fluid velocity measurement by pressure difference, velocity/acceleration/impact measurement, etc., can solve the problems of not being able to restore the real flow field of the flue to the maximum extent, and achieve safety and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

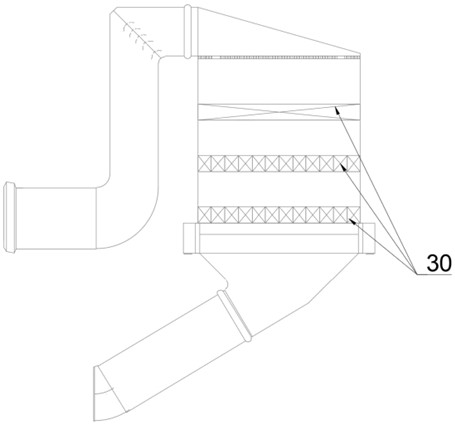

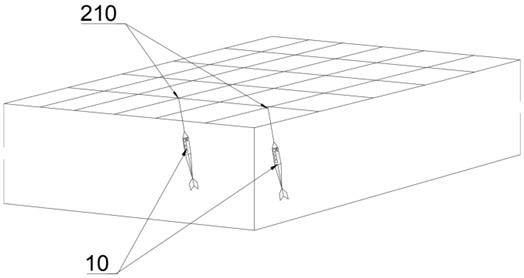

[0052] refer to Figure 1 to Figure 5 , the first embodiment provides a flue flow field measurement device, the flue flow field measurement device includes a streamlined casing 101, the head end of the streamlined casing 101 is connected to a traction rope 103; The sensor 105, the acquisition control circuit 106 and the wireless transmission module 107; the differential pressure sensor 104 is used to acquire the differential pressure signal of the airflow, the differential pressure sensor 104 is electrically connected with the acquisition control circuit 106, and the acquisition control circuit 106 is used to calculate the differential pressure signal Converted into a wind speed signal; the attitude sensor 105 is used to calculate the three-dimensional attitude signal of the flue flow field measurement device in the flue through the three-axis acceleration value and the angular velocity value, the attitude sensor 105 is electrically connected with the acquisition control circui...

Embodiment 2

[0071] The second embodiment also provides a flue flow field measurement method, comprising the following steps:

[0072] The measuring device 10 is hoisted in the flue;

[0073] blowing air to the measuring device 10 by means of a fan;

[0074] Under the action of the wind force, the traction rope 103 and the measuring device 10, the measuring device 10 presents an attitude similar to the parallel airflow;

[0075] Obtain differential pressure information through the differential pressure sensor 104 in the measuring device 10, and convert it into a wind speed signal;

[0076] Acquire the three-dimensional attitude signal of the measuring device 10 in the flue by the attitude sensor 105 in the measuring device 10, and convert it into a three-dimensional coordinate signal;

[0077] The wind speed signal and three-dimensional coordinate signal are transmitted to the analysis system and displayed through images.

[0078] In the step of hoisting the measuring device 10 in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com