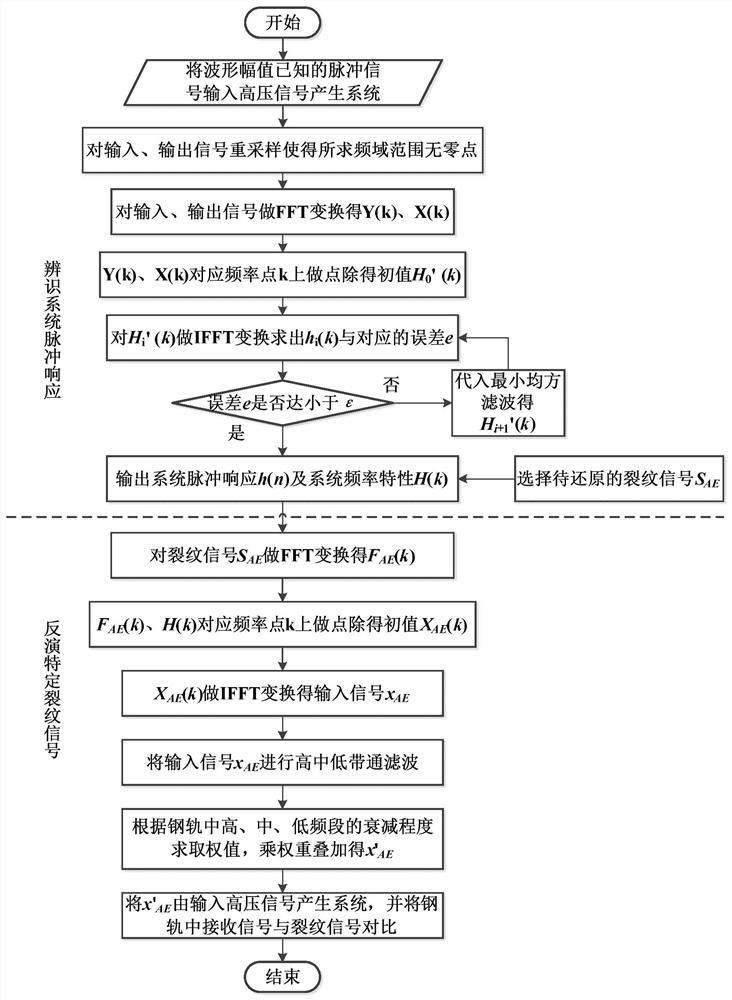

A Segmented Adjustment Least Mean Square Deconvolution Rail Crack Signal Restoration Method

A deconvolution, segmented technology, applied in the analysis of materials, material analysis using sonic emission technology, material analysis using sonic/ultrasonic/infrasonic waves, etc., can solve the problem of broken lead, research and restoration, crack signal characteristics Big difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

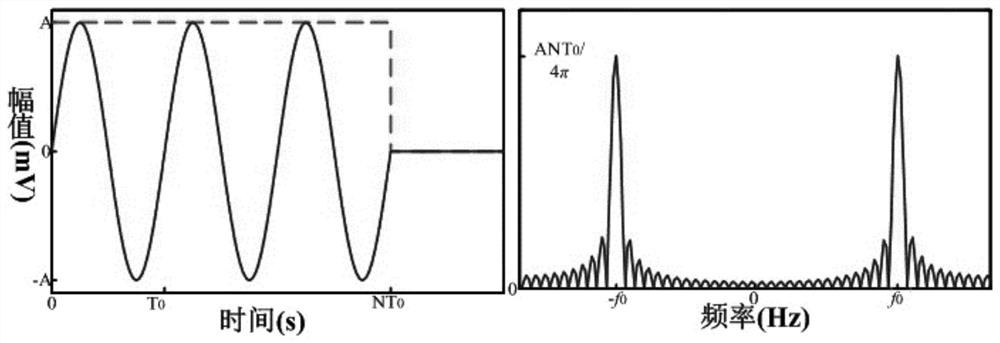

[0032] Below in conjunction with embodiment and accompanying drawing illustrate the specific implementation of the present invention, in the railway field experiment described in the present embodiment acoustic emission signal reduction and collection hardware system are made up of signal generator, waveform amplifier, acoustic emission piezoelectric probe and sensor, rail , Acoustic emission data acquisition equipment, the sampling frequency of the acquisition system is 5MHz, each signal contains 4096 sampling points, a total of 819.2 microseconds, such as figure 2 Connect the device as shown. The crack signal to be restored is selected from the fracture signal in the tensile test, the sampling frequency is 5MHz, and the length of each signal is 2048 sampling points. The receiving acoustic emission sensor is placed 9cm from the rail waist to the rail bottom, the acoustic emission probe excitation source is placed at the same height as the receiving sensor on the same side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com