Electric motor having a rotor with a block protection sleeve, which

An electric motor and protection sleeve technology, which is applied to synchronous motors with static armatures and rotating magnets, electrical components, electric components, etc., can solve the problems of high manufacturing cost and high reluctance, and achieve easy assembly, The effect of reducing the amount of assembly work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

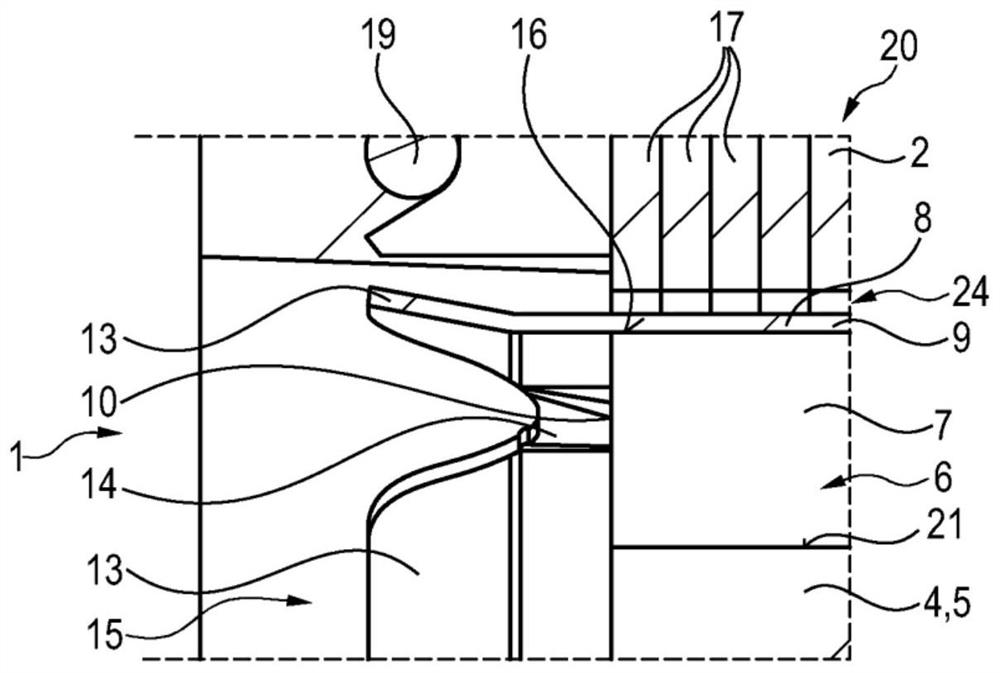

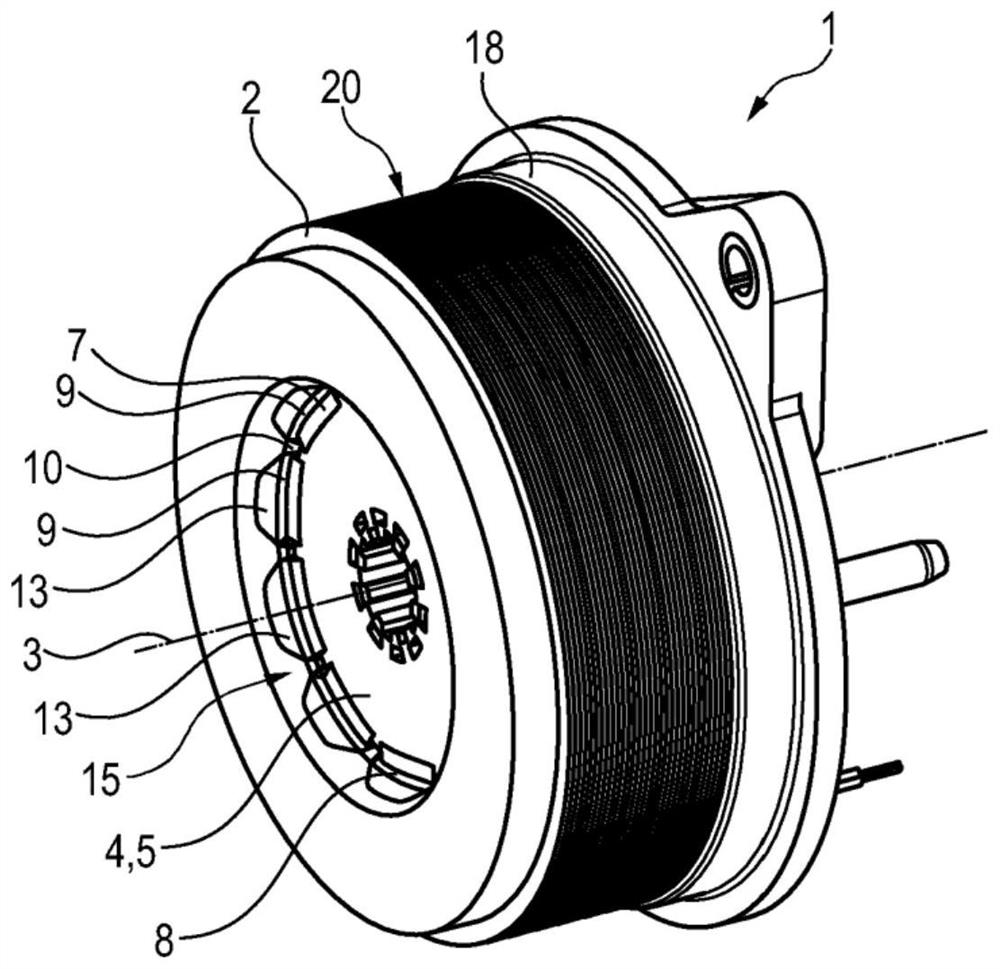

[0033] The drawings are only schematic in nature and are used only for the understanding of the invention. Identical elements are provided with the same reference numerals.

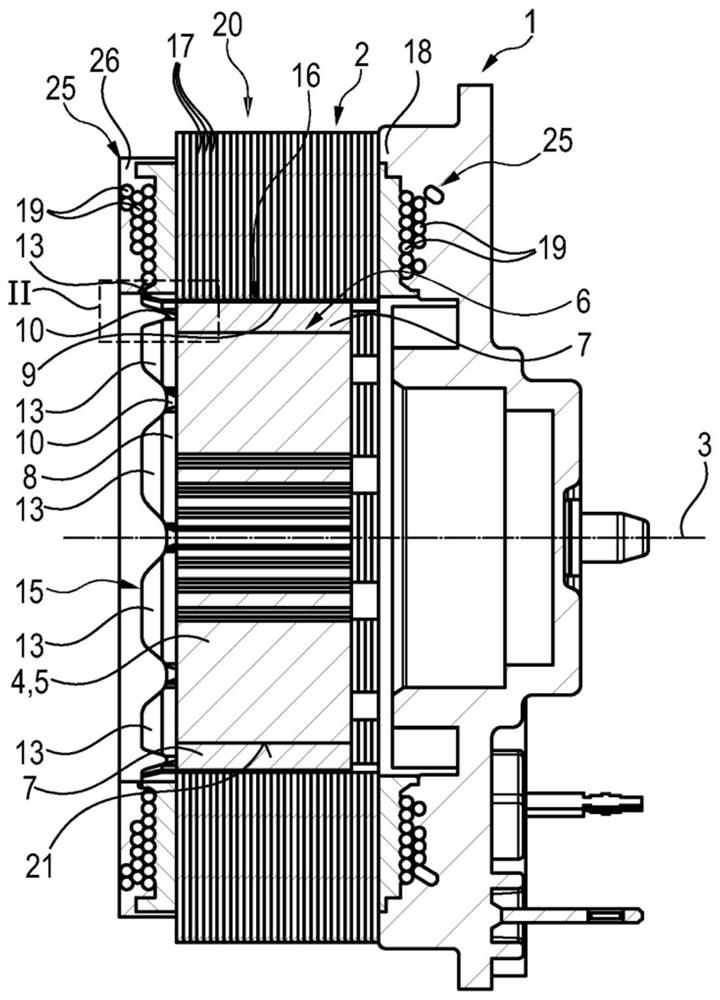

[0034] use figure 1 , image 3 and Figure 12 The basic structure of the electric motor 1 according to the invention can be easily recognized. The electric motor 1 is equipped with a stator 2 of integral annular design. In this embodiment, the stator 2 has a plurality of stator laminations 17 arranged in a stack in the axial direction, ie along the axis of rotation 3 of the rotor 4 of the electric motor 1 . The stator laminations 17 are received on the stator housing / stator carrier 18 . Windings 19 are also provided in a typical manner, which can be figure 1 The sectional view in is seen close to the axial end face of the stack 20 on the stator laminations 17 .

[0035] Furthermore, a rotatably mounted rotor 4 is arranged radially inside the stator 2 (relative to the axis of rotation 3). In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com