Cleaning equipment

A technology for cleaning equipment and batteries, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve problems affecting product yield, low work efficiency, welding explosion points, etc., and achieve a simple structure. And effective, reduce labor costs, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to specific embodiments and accompanying drawings.

[0035] Please refer to Figure 1-Figure 6 , a preferred embodiment of the present invention is:

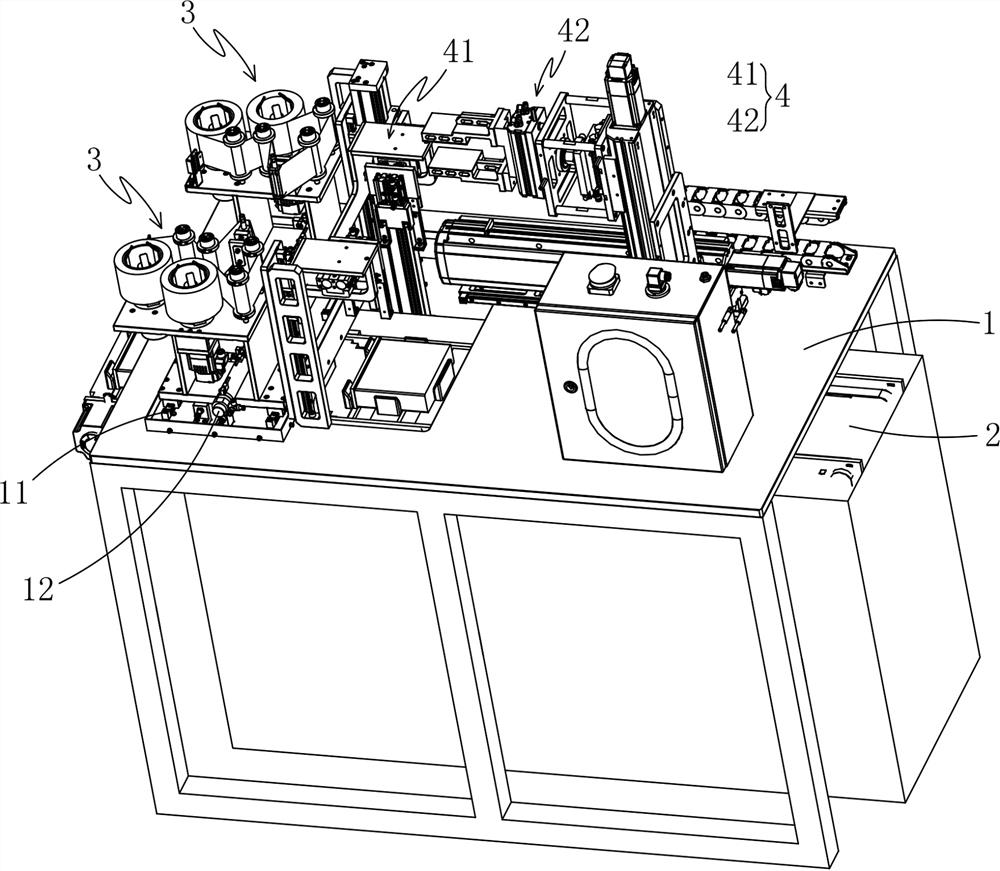

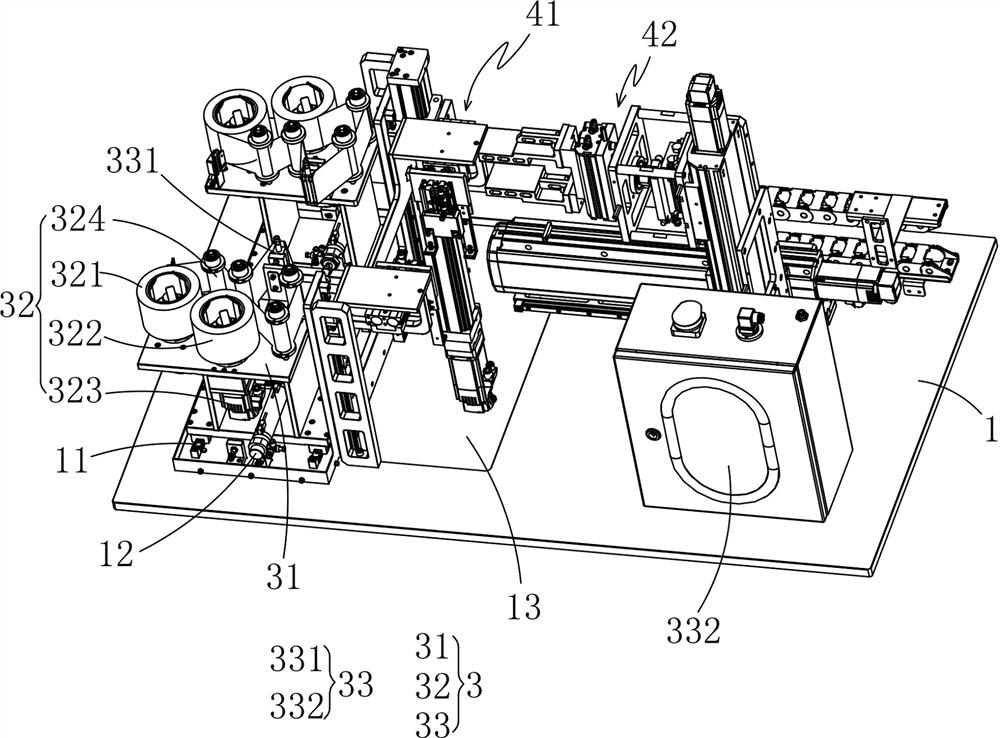

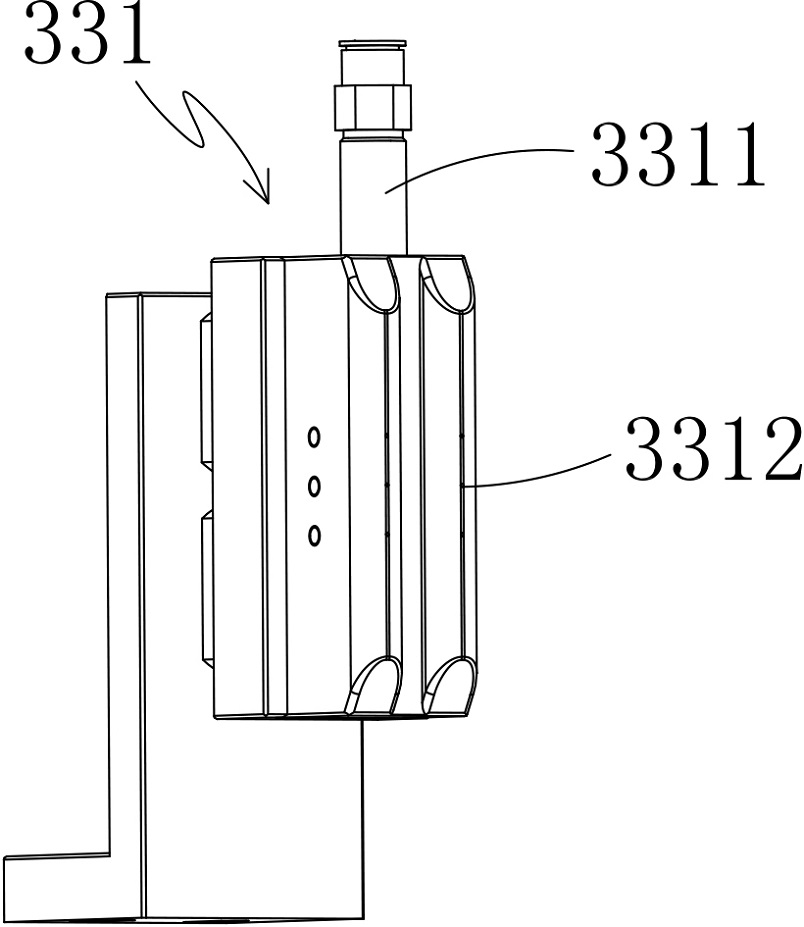

[0036] Please refer to figure 1 , a cleaning device, comprising: an installation table 1; a conveyor belt 2 for conveying batteries; a wiping mechanism 3, arranged on the installation table 1, for wiping the stains on the top cover of the battery; a transfer mechanism 4, arranged on the installation table 1, It is used to clamp the battery on the conveyor belt 2 and transfer the battery to the wiping mechanism 3 ; wherein, the transferring mechanism 4 can drive the rotation of the battery, so that all sides of the battery top cover are in contact with the wiping mechanism 3 .

[0037] For details, please refer to figure 1 and Image 6 , the installation table 1 in this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com