End part type electric heating electrolytic copper foil anti-warping equipment and working method thereof

An electrolytic copper foil and anti-warping technology, which is applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of scrapping copper foil and achieve the effect of reducing warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074]

[0075]

[0076] The solution of the previous application for "a treatment equipment and method for reducing warpage of electrolytic copper foil" has the disadvantage that once the voltage is not properly selected, damage is caused and the entire roll of copper foil will fail. Therefore, in the actual application of the scheme, the voltage value selection needs to be cautious.

[0077] For this issue, the project research and development team broke the technical prejudice brought by the previous application and proposed the idea of energizing on both sides.

[0078] The source of this idea is: even if there is damage, the damage will occur on both sides of the width direction of the rolled copper foil; after the power is turned on, it is only necessary to rewind and trim the edges first.

[0079]

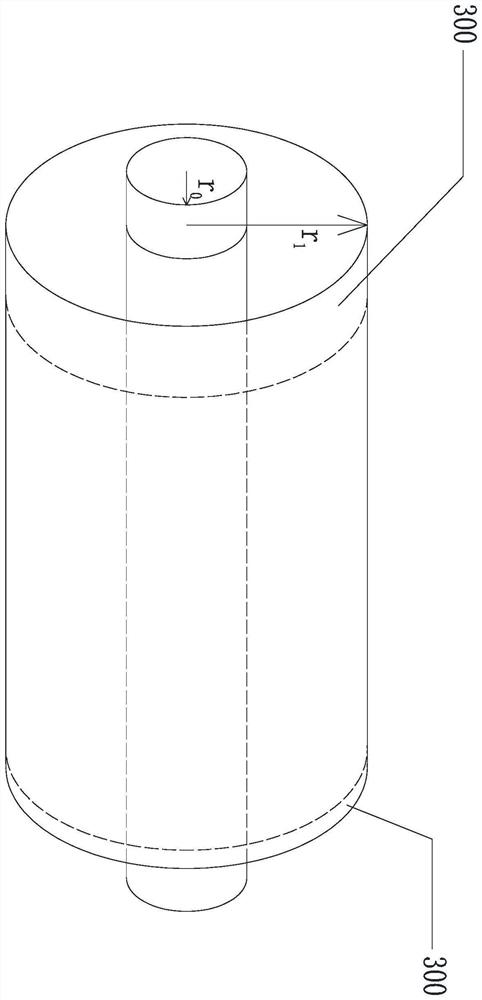

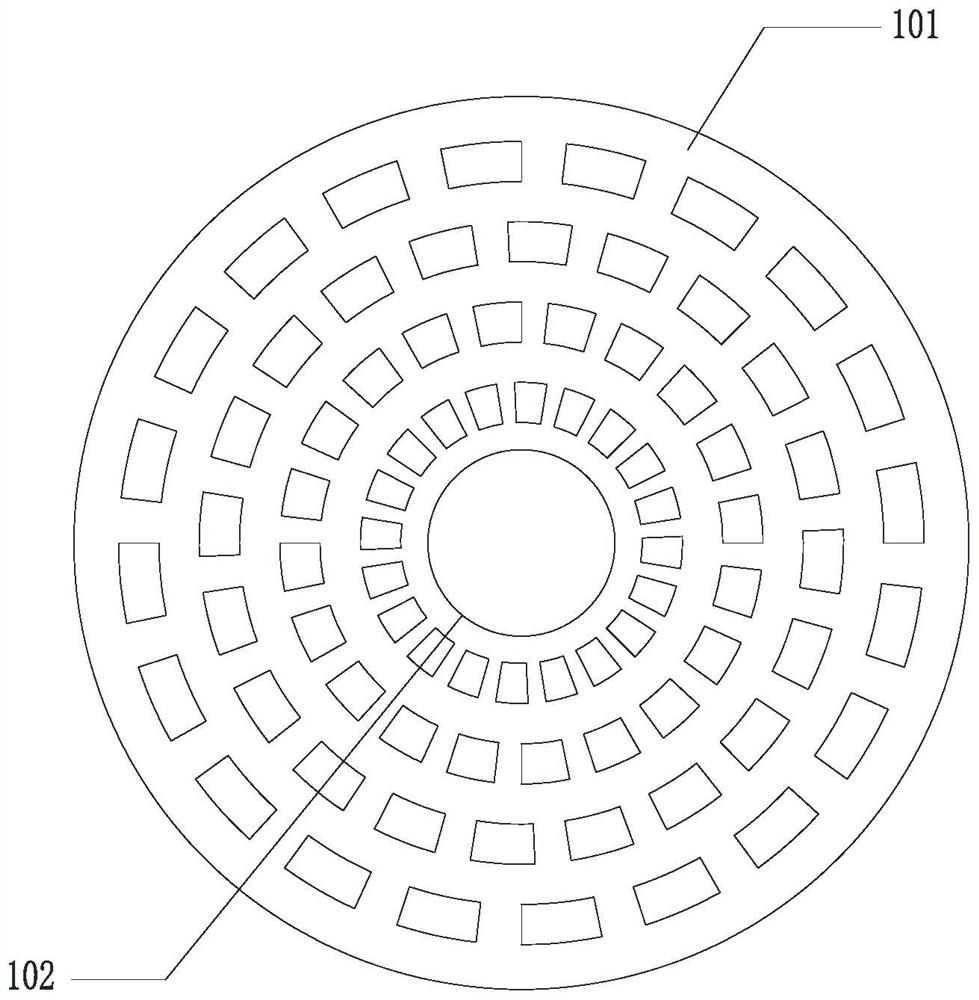

[0080] An end-type electric heating electrolytic copper foil anti-warping device, comprising: a first end cover 100 and a second end cover 200;

[0081] The firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com