Device for preventing strip-through stay wire from falling into groove and packaging machine

A technology for dropping grooves and pulling wires, which is applied in the field of devices and packaging machines for preventing the pulling wires from dropping through the grooves, can solve the problems of dropping grooves, dislocation of the pulling wires, and hidden quality problems, so as to improve the production efficiency and prevent the hidden quality problems. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

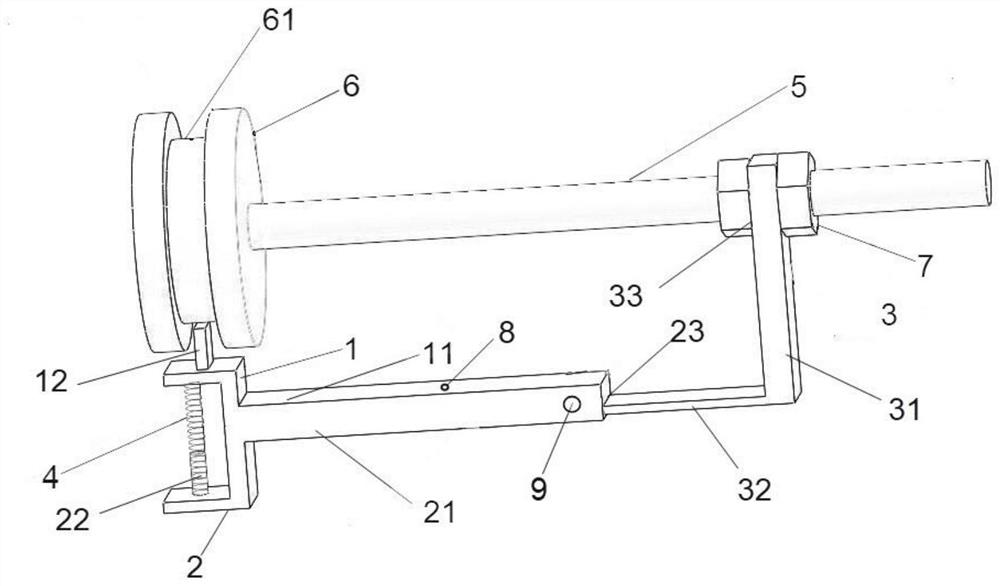

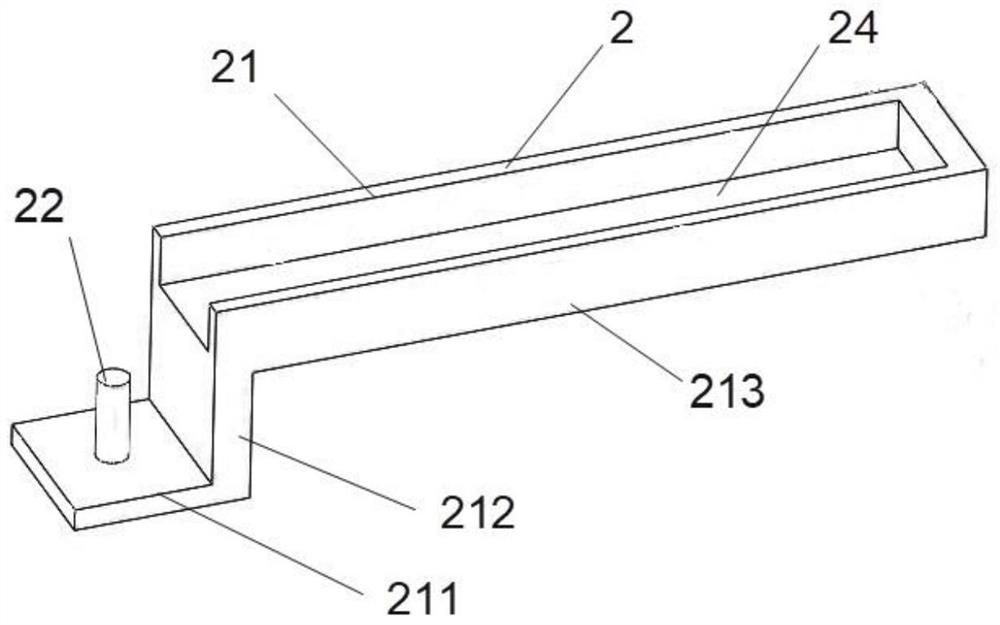

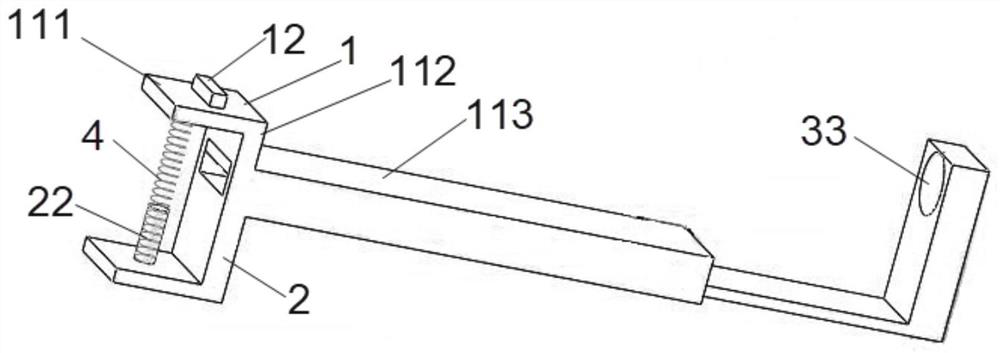

[0058] The present invention discloses a device that prevents the slotting of the groove. Specifically figure 1 Show, the device includes: active gear block 1. Fixed gear block 2. Support rack 3 and spring 4;

[0059] Connect to a fixed gear block 2 in the activity block 1, which is connected to one end of the supporting frame 3, the other end of the supporting frame 3 is connected to one end of the pull roller shaft 5, which The other end is connected to the pull -line roller 6; the activity gear block 1 and the fixed gear block 2 also have a spring 4; the active gear block 1 is set with a voltage line limit block 12, which is limited to the voltage line limit. Block 12 is used to hold the pull line within the pull line roller 6. The spring 4 is installed between the active gear and the fixed gear, and rely on the elasticity to make the pressure line limited block stand the pull line. Activity gear 1 is activity. When the line is worn in the pull -line roller, the block limit blo...

Embodiment 2

[0073] The present invention disclosed a packaging machine, including the packaging machine body, which is set on the packaging machine itself with a device that prevents the grooves from the groove of the stretching line.

[0074] In summary, the technical solutions in all aspects of the present invention have the following advantages compared with the existing technology:

[0075] The present invention provides a device that prevents the grooves from the sliding line, which can effectively prevent the stretching line from jumping out of the pull -up roller to produce quality defects. After the device is installed, the device can ensure that the thread -thorough lines will not drop the groove, prevent quality hazards, and ensure the operational efficiency; when the pull -line detection device is reduced due to the reduction of the external environment, the phenomenon of pulling the lines can be detected. Prevent the tank from pulling out of the slot in a mechanical way to prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com