Automatic bag breaking and ice breaking equipment for blood plasma bags

A plasma bag, automatic technology, applied in the field of bioengineering, can solve the problems of slow work efficiency, high cost, time-consuming and labor-consuming, etc., achieve the effect of convenient sterilization, save labor cost, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

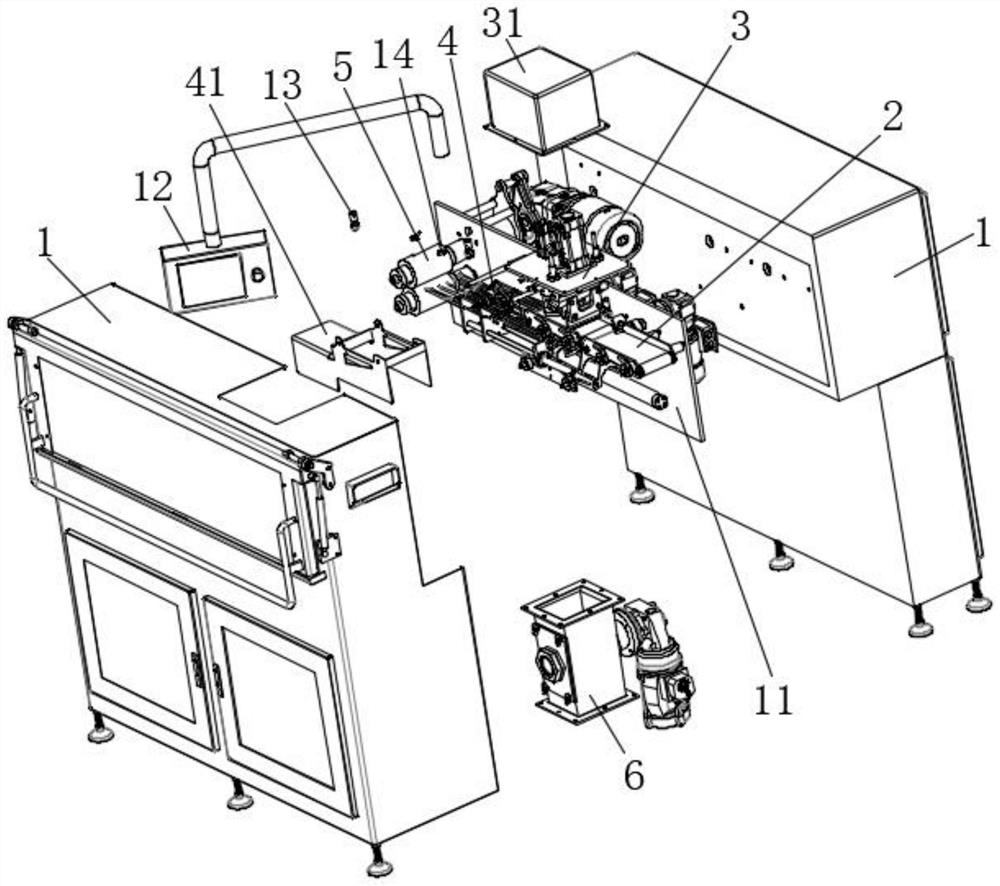

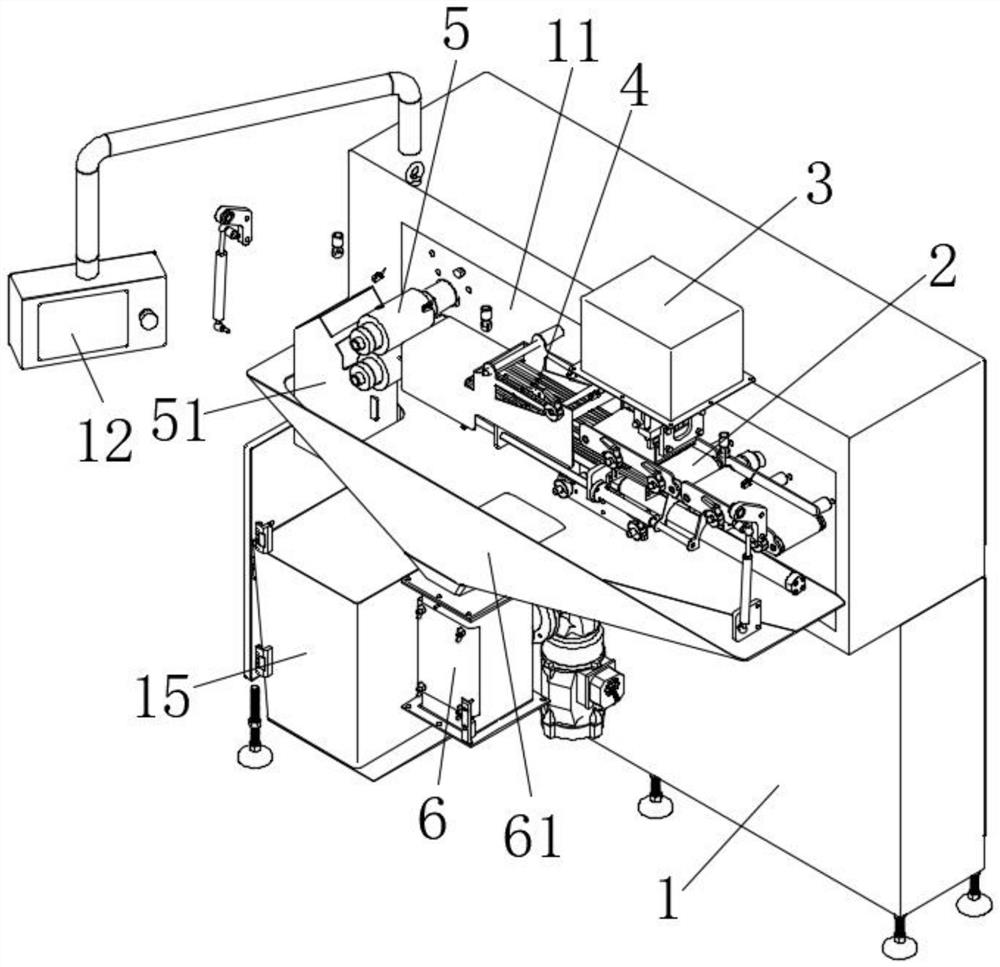

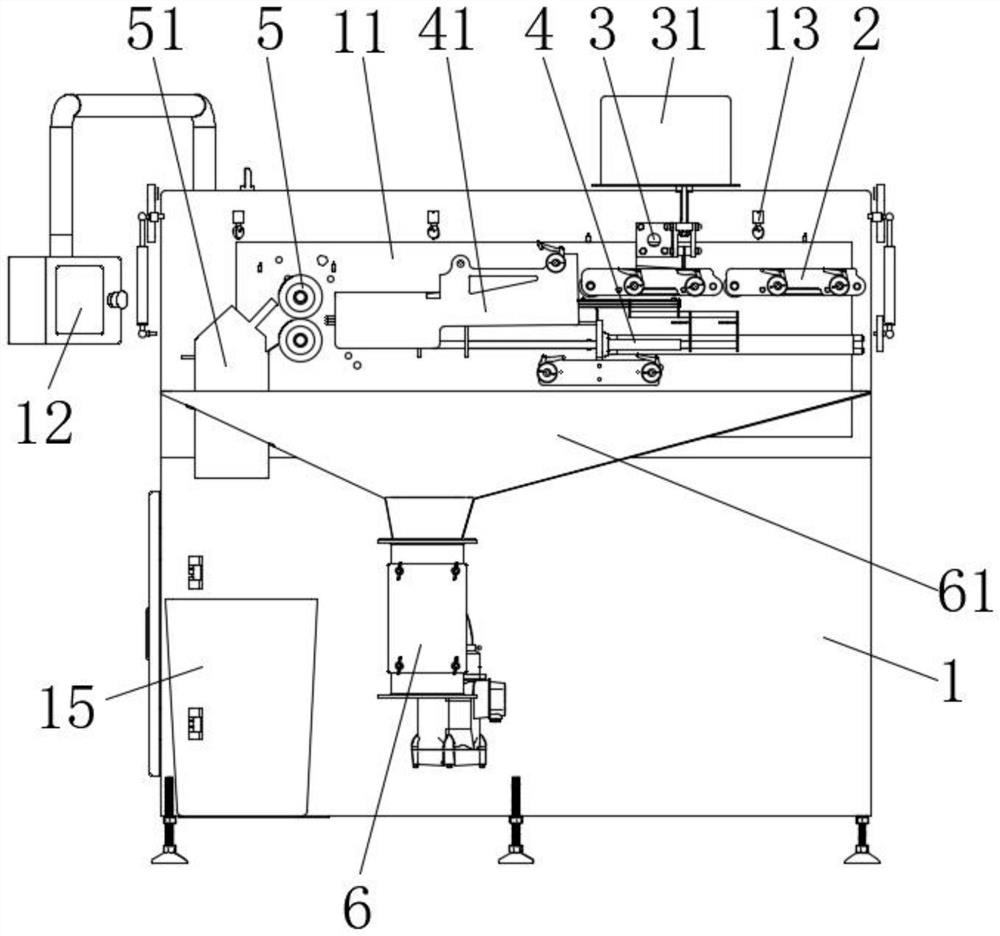

[0031] Example 1, as Figure 1 to Figure 3 As shown in the figure, a plasma bag automatic bag breaking ice crushing equipment includes a cabinet 1, and a pallet 2 is installed at the top feeding port of the cabinet 1, that is, it is used as a transport unit for plasma bags and also as a bag breaking support unit for plasma bags. The top of the pallet 2 is provided with the bag cutting device 3, and the plasma bag is cut or cut by the bag cutting device 3; In 5; the pushing end of the pushing device 4 is equipped with a bag extrusion device 5, which squeezes the plasma in the plasma bag from the bag body through the squeezing force, and also collects the bag body after centralized output; the bottom of the cabinet 1 is installed with Ice breaker 6, the plasma ice cubes are crushed after passing through the ice breaker 6, so as to facilitate biomedical detection; the output end of the ice breaker 6 is connected to the outside of the bottom of the cabinet 1 through a pipeline as ...

Embodiment 2

[0037] Embodiment 2, on the basis of embodiment 1, as a preferred solution, please refer to Figure 4 , the pallet 2 includes a board 21 and a conveyor belt 22, the conveyor belt 22 is driven by a DC motor, and the board 21 is installed on both sides of the conveyor belt 22, respectively. Wherein, the one side backing plate 21 is fixedly connected with the inner wall of the cabinet 1 through bolts. In addition, one side of the backing plate 21 can be installed on the front of the main installation plate 11 , and the DC motor that determines the rotation of the wheel body of the conveyor belt 22 can be installed on the back of the main installation plate 11 . The plasma bag is transported to the cutting station of the bag cutting device 3 through the conveying function of the pallet 2, wherein the backing plate 21 can not only be used to fix the pallet 2, but also can limit the position of the plasma bag. Among them, it is located on the conveyor belt 22 of the pallet 2 so as ...

Embodiment 3

[0038] Example 3, on the basis of Example 1 or 2, see Figure 5 , the bag cutting device 3 includes a cylinder base 32 and an incision mechanism 33, and the cylinder base 32 is fixed inside the cabinet 1 by screws. A driving component is installed on the top of the cylinder base 32 for driving the notch mechanism 33 to act. A dust cover 31 is provided on the outer periphery of the top of the cylinder pedestal 32. Drive connection, through the incision mechanism 33, the plasma bag is incised, cut, and cut.

[0039] Specifically, as a preferred solution, please refer to Image 6 , the incision mechanism 33 includes a first air cylinder 331, a support plate 332 and a cutter group 333, the first air cylinder 331 is installed on the top of the support plate 332, and the cutter group 333 is installed at the bottom of the support plate 332 through a guide column 334, and the guide column 334 The first air cylinder 331 is connected with the cutter group 333 in a driving connection t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com