Current sensor and current detection method

A current sensor and current technology, applied in the sensor field, can solve the problems of unmaintainable, high signal-to-noise ratio, etc., to achieve the effect of flexible use, high precision, and improved system signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

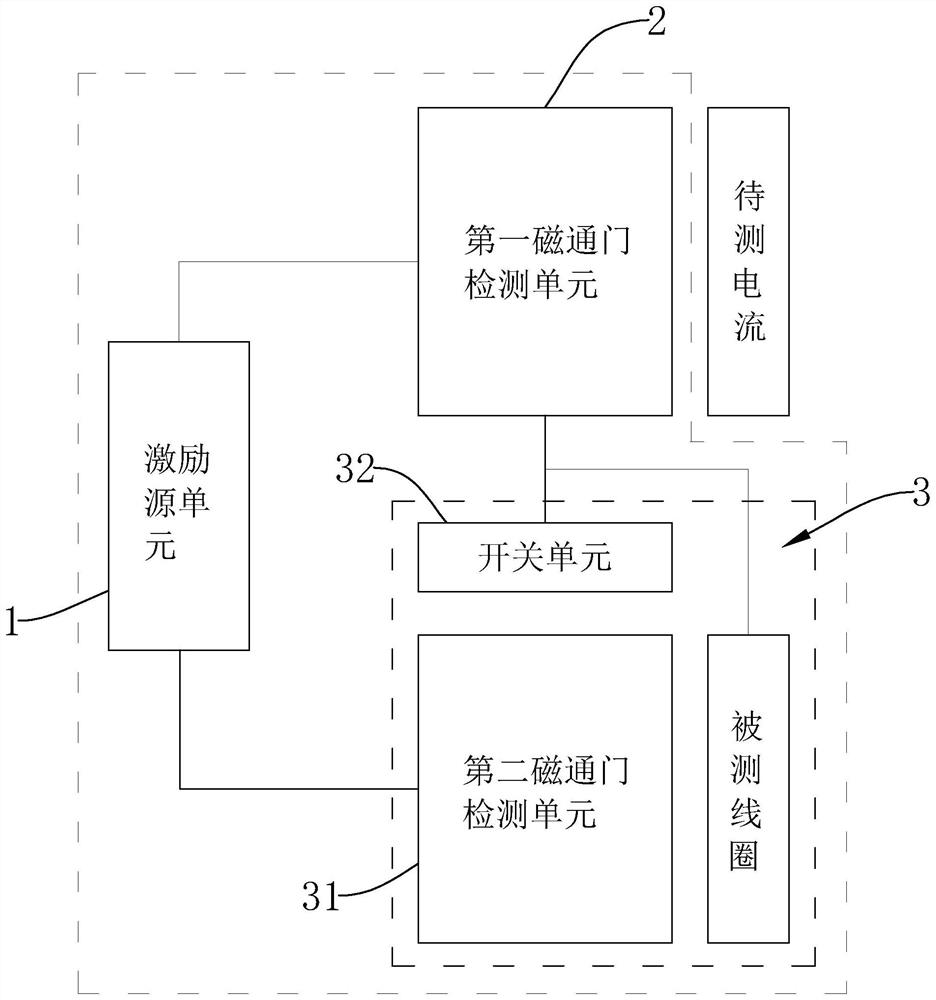

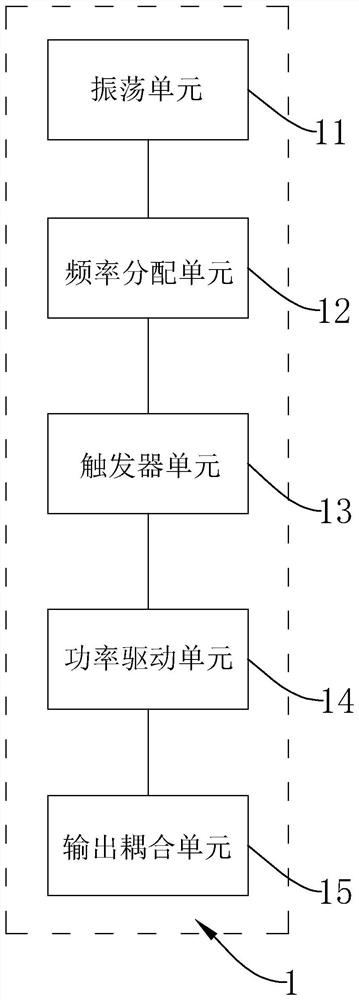

[0070] Example 1: as figure 1 As shown, this embodiment provides a current sensor, the current sensor includes an excitation source unit 1, a first fluxgate detection unit 2 and an expansion module 3, the expansion module 3 includes a second fluxgate detection unit 31, a switch unit 32 and the coil under test. The output end of the excitation source unit 1 is respectively connected to the input end of the first fluxgate detection unit 2 and the input end of the second fluxgate detection unit 31, and the output end of the first fluxgate detection unit 2 is respectively connected to the input end of the switch unit 32 and the input end of the switch unit 32. The input end of the detection coil is connected, and the first fluxgate detection unit 2 is used to detect the current to be measured, generate a first compensation current according to the current to be measured, and output the first compensation current from the current output end of the first fluxgate detection unit 2; ...

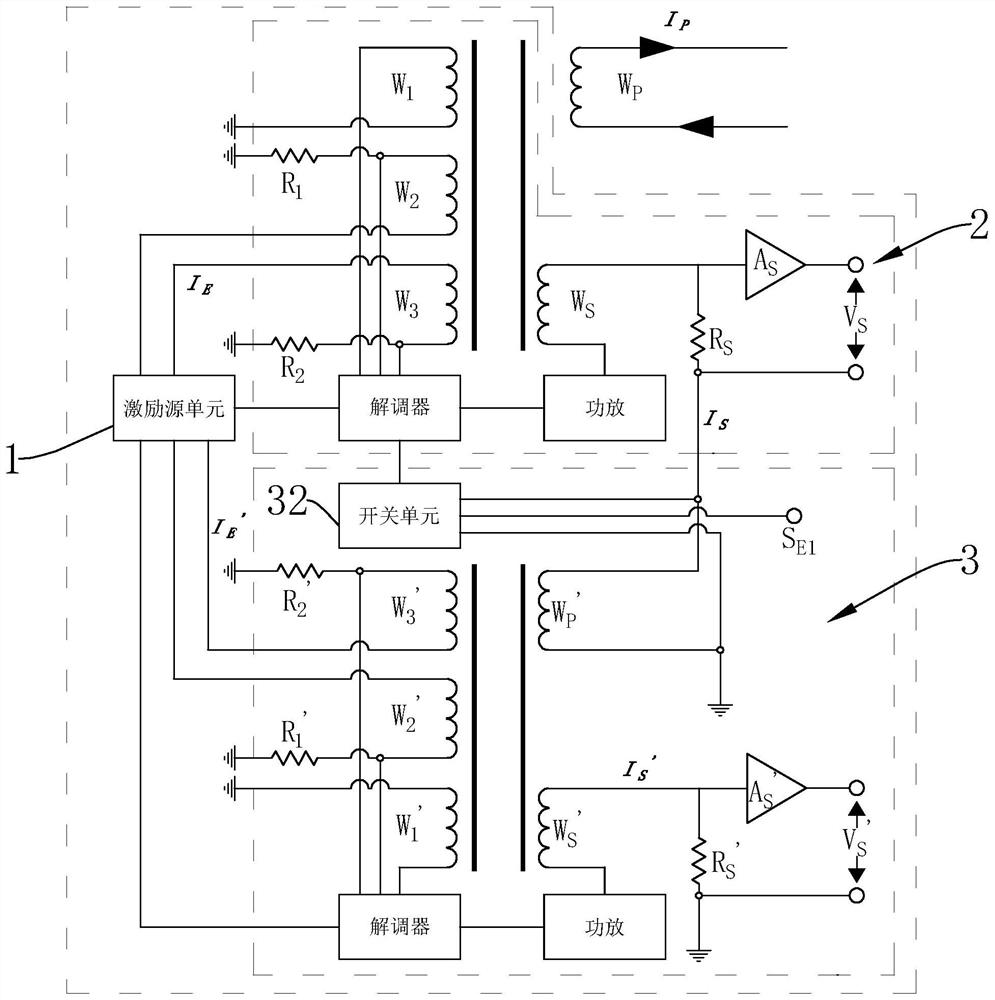

Embodiment 2

[0094] Example 2: as Figure 4 As shown, this embodiment provides a current sensor, the current sensor includes an excitation source unit 1, a first fluxgate detection unit 2 and an expansion module 3, and the expansion module 3 includes a first expansion module 3 and a second expansion module 3 , the first expansion module 3 and the second expansion module 3 have the same structure and connection relationship, but the size, size and specification of each element are different; the output end of the excitation source unit 1 is respectively connected with the input end of the first fluxgate detection unit 2, the The input end of the expansion module 3 is connected to the input end of the second expansion module 3, and the output end of the first fluxgate detection unit 2 is respectively connected with the input end of the switch unit 32 in the first expansion module 3 and the coil under test in the first expansion module 3 The input end is connected, and the output end of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Snr | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com