Single-target flexible job shop energy-saving scheduling method based on improved grey wolf algorithm

A technology of flexible operation and scheduling method, applied in calculation, calculation model, energy industry, etc., can solve the problem of high energy consumption, achieve the effect of improving solution accuracy and speed of evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0082] The present invention is based on the single-objective flexible job shop energy-saving scheduling method based on the improved gray wolf algorithm, and is specifically implemented according to the following steps:

[0083] Step 1. Build a flexible job shop energy-saving scheduling problem model: including the flexible job shop energy-saving scheduling problem description and model assumptions;

[0084] The energy-saving scheduling problem of flexible job shop is described as follows:

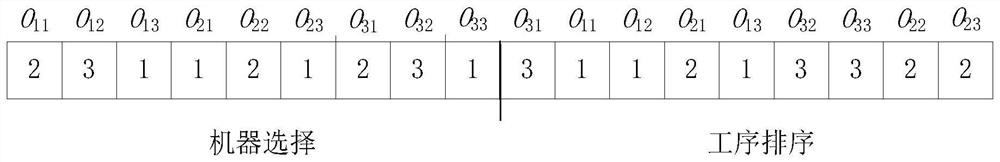

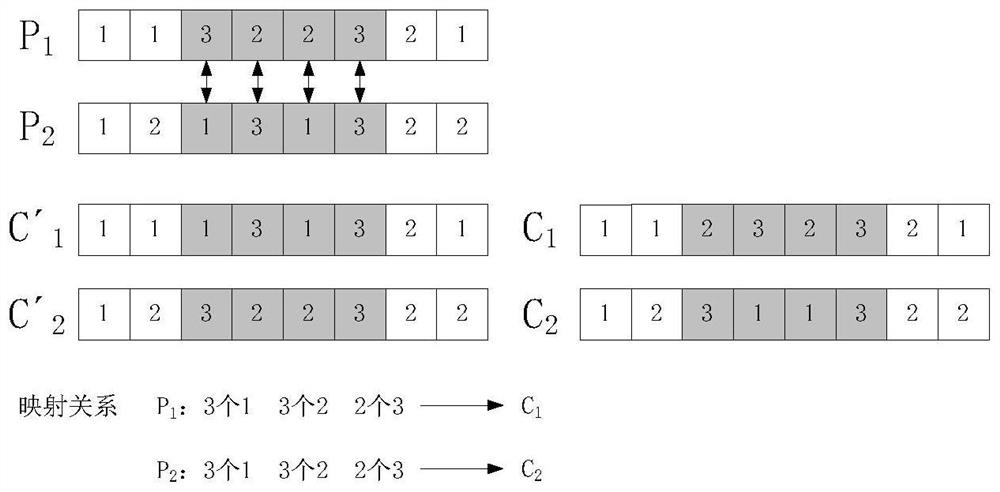

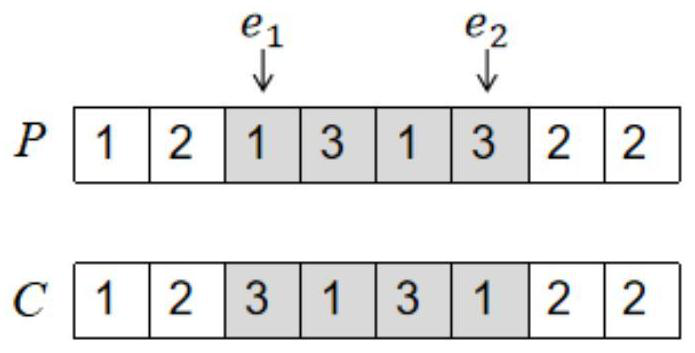

[0085] The flexible job shop scheduling problem is an extension of the classic job shop scheduling problem, which can be described as: n workpieces are processed on m equipment, and each workpiece is processed by J i Each process can be processed at different times on multiple different equipments. However, in the classical flexible job shop scheduling p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com