Intelligent temperature-control energy-saving dry-type transformer

A dry-type transformer, intelligent temperature control technology, applied in the direction of transformer/inductor cooling, transformer/inductor coil/winding/connection, chemical instruments and methods, etc., can solve the problem of affecting transformer heat dissipation, winding insulation aging, filter blockage Air intake and other issues to achieve the effect of ensuring normal heat dissipation, slowing down aging, and accelerating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

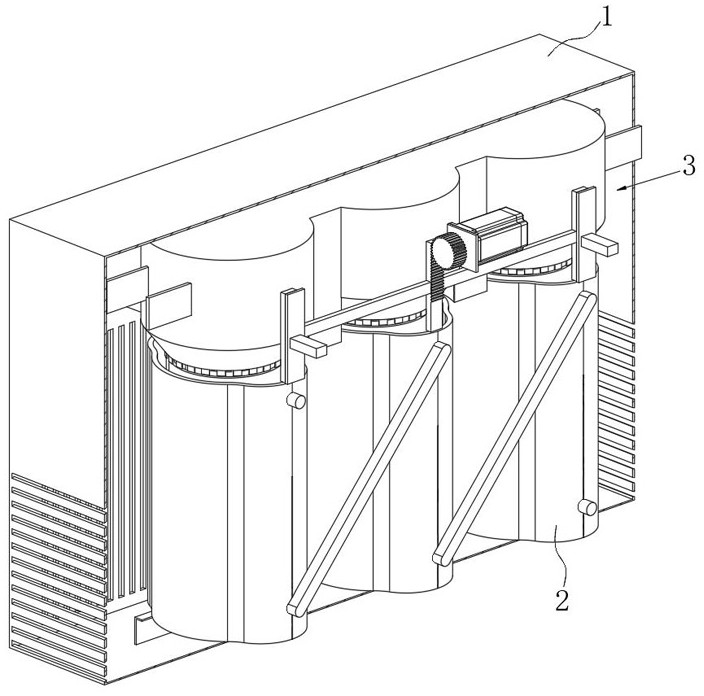

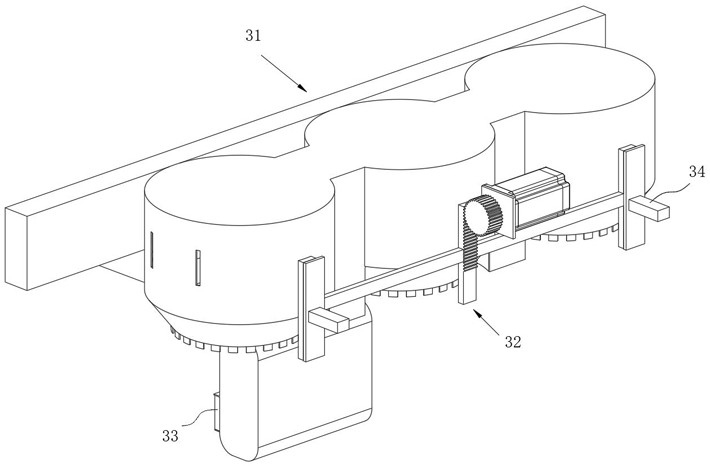

[0041] see Figure 1-Figure 2As shown, the purpose of this embodiment is to provide an intelligent temperature-controlled energy-saving dry-type transformer, including a transformer box 1 and a dry-type transformer 2 arranged inside the transformer box 1, and the upper side of the dry-type transformer 2 is provided with a useful For the heat dissipation device 3 that dissipates heat inside the dry-type transformer 2 and the interior of the transformer box 1, the transformer box 1 protects the dry-type transformer 2 inside, and the heat generated by the dry-type transformer 2 during operation passes through the heat dissipation device 3. Blowing away the heat generated by the dry-type transformer 2, speeding up the diffusion of the heat generated by the dry-type transformer 2, avoiding heat accumulation at the dry-type transformer 2, so that the dry-type transformer 2 can work for a long time;

[0042] In the process of using the dry-type transformer 2, the humidity of the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com