Connector with novel plug-in structure

A plug-in structure and connector technology, applied in the direction of connection, parts of connection devices, fixed/insulated contact members, etc., can solve the problems of weak connection, space for movement, poor terminal connection accuracy, etc., and achieve the convenience of mold. Structural design, ensuring stable connection, convenient assembly and plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

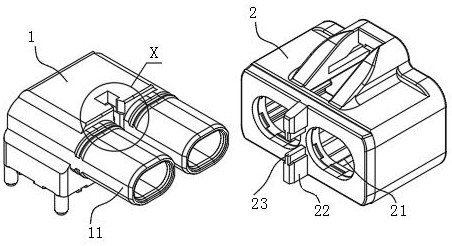

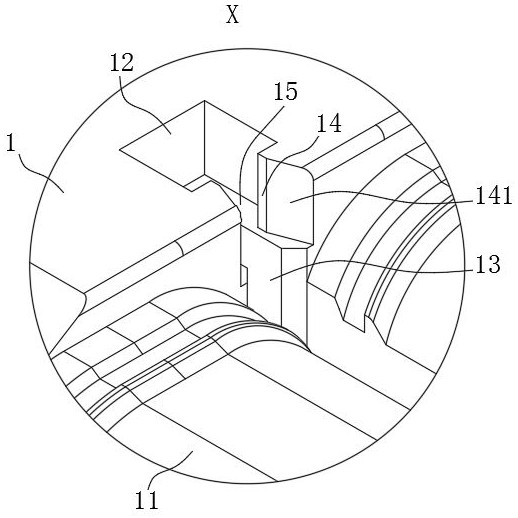

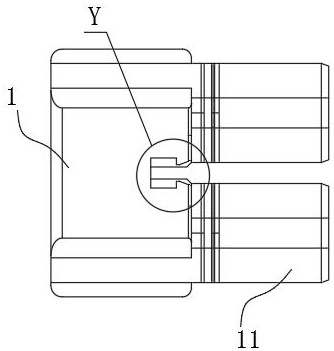

[0022] like Figure 1-9 It is a schematic diagram of the structure of the present invention. A connector with a new plug-in structure includes a metal shell 1 and a plastic shell 2. The metal shell 1 is arranged with a plurality of terminal mounting posts 11 in an array. The plastic shell 2 A plurality of mounting cavities 21 are provided. The terminal mounting posts 11 of the metal housing 1 are inserted into the mounting cavity 21 of the plastic housing 2 . Insertion recesses are provided between the terminal mounting posts 11 . The insertion recesses It includes a plurality of symmetrically arranged T-shaped grooves, the T-shaped grooves are located between two adjacent terminal mounting posts 11 and pass through the side of the metal shell 1 , and the plastic shell 2 is provided with corresponding insertion protrusions The insertion protrusion is a T-shaped column corresponding to the T-shaped slot, the T-shaped column is inserted into the T-shaped slot, and the T-shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com