Cabinet cable sealing joint

A technology for cable sealing and panel cabinets, which is applied in the direction of cable entry sealing devices and climate change adaptation, which can solve problems such as troublesome use, complex structure, and unsatisfactory effects, and achieve the effects of convenient installation, simple structure, and convenient threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

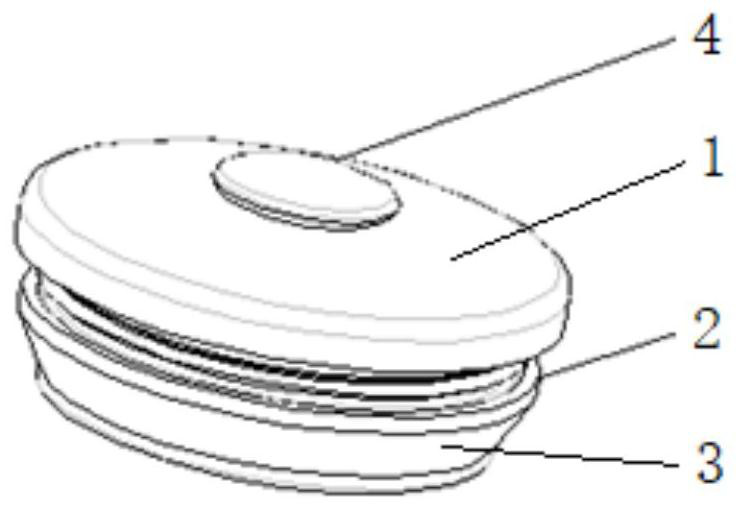

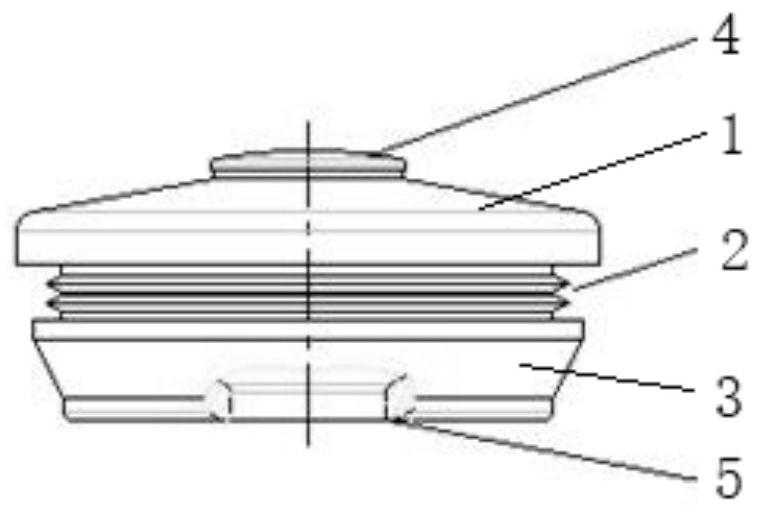

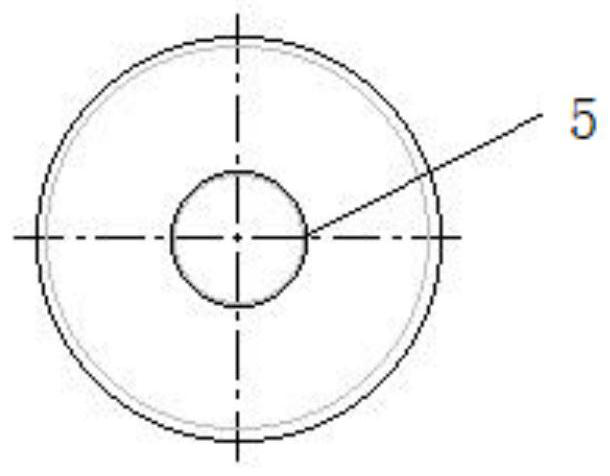

[0014] The main structure of a cable sealing joint of a panel cabinet involved in this embodiment is as follows: figure 1 As shown, it includes an inner sealing ring 1, a threaded pipe 2, an outer sealing ring 3, an interface 4 and a through hole 5; the inner sealing ring 1 is connected with the outer sealing ring 3 through the threaded pipe 2, and the center of the inner sealing ring 1 is provided with an interface 4 , the center of the outer sealing ring 3 is provided with a through hole 5 .

[0015] When the cable sealing joint of the panel cabinet involved in this embodiment is used, the outer sealing ring 3 is pressed into the installation hole of the panel cabinet or the distribution box. After the sealing ring 3 is passed through the through hole 5, it enters the panel cabinet or distribution box. The interface and through hole are based on the self-shrinking properties of the TPU (thermoplastic polyurethane elastomer) material, and are tightly attached to the cable. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com