Shaping structure and method for packaging outer lead

A technology for encapsulating outer leads and outer leads, applied in the direction of climate sustainability, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of small lead pitch, low shaping efficiency, large quantity, etc., to improve accuracy and efficiency, the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

[0029] A method for shaping outer leads of a package, comprising the following steps:

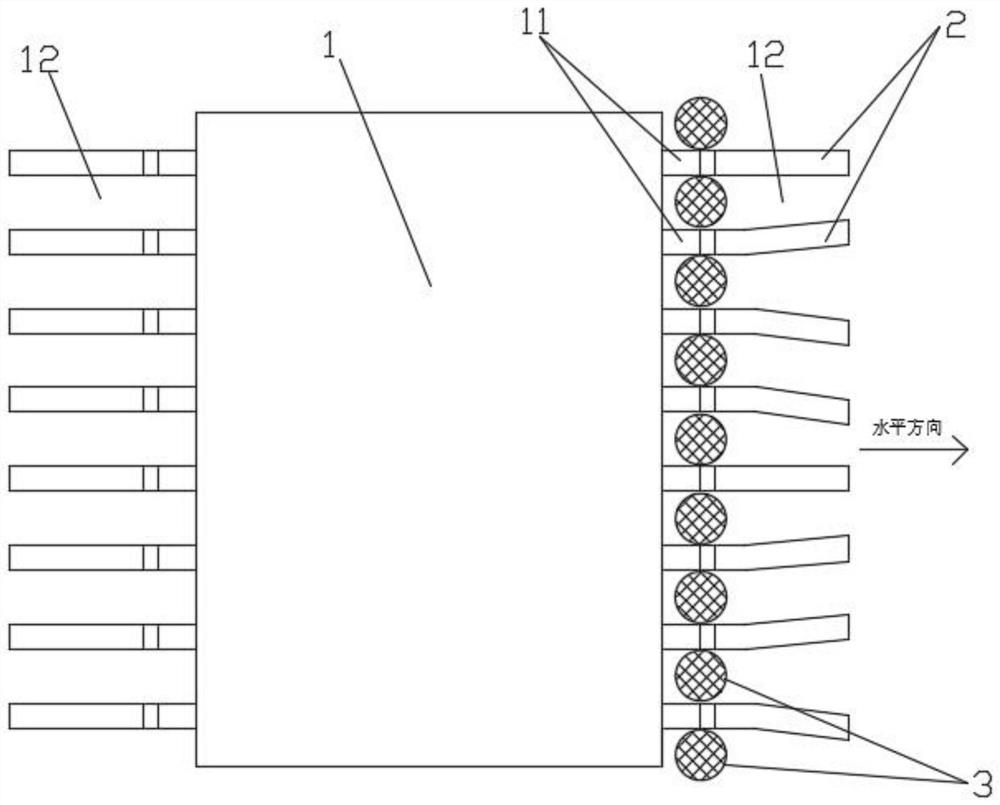

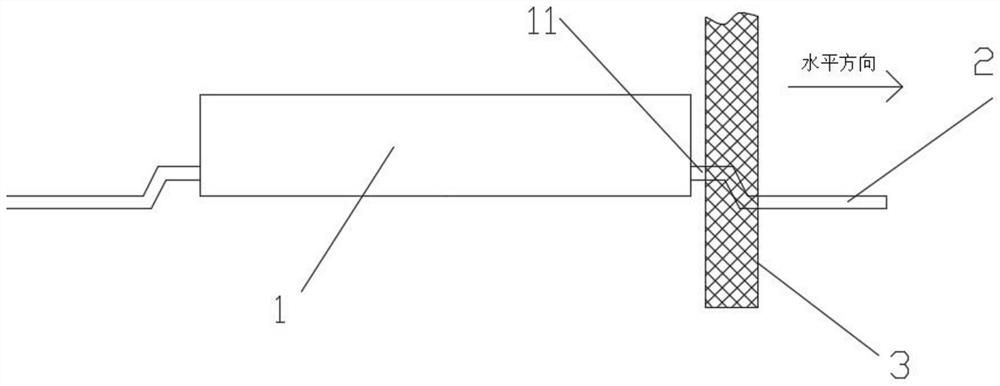

[0030] A shaping rod is arranged in the gap between adjacent outer leads, and the shaping rod vibrates and reciprocates along the gap to shape the outer leads horizontally;

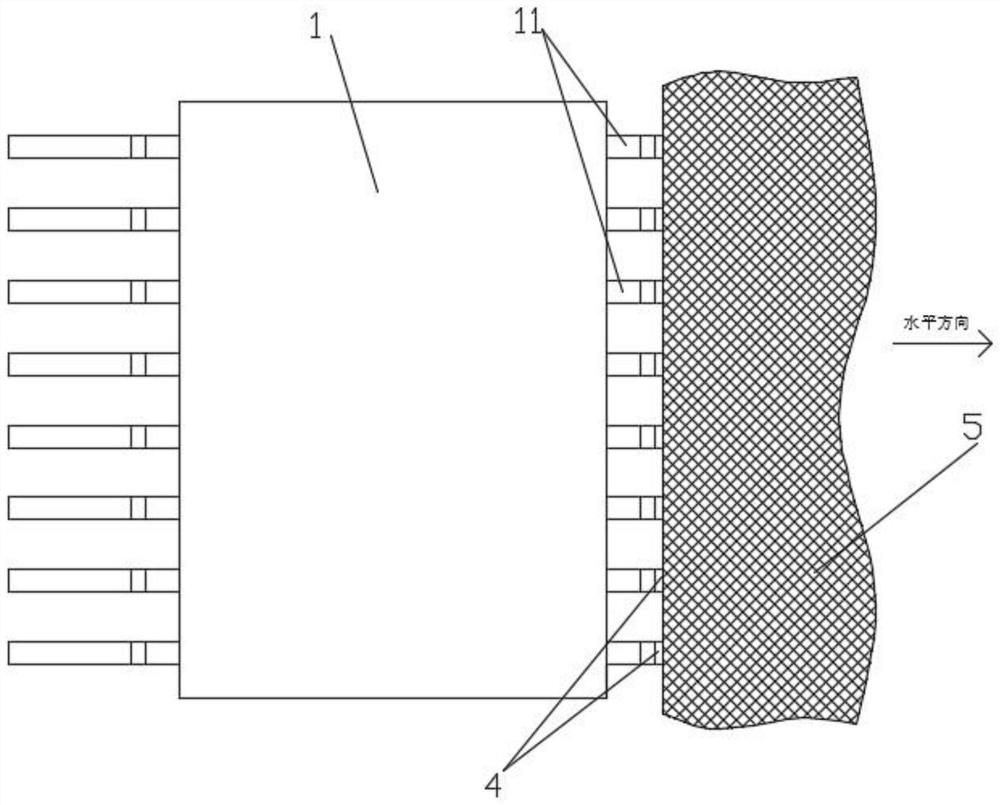

[0031] Two shaping plates are arranged on the upper and lower sides of the outer leads, and the two shaping plates are close to each other so that all the outer leads are continuously pressed together. The two shaping plates are continuously pressing the outer leads and the shaping plates vibrate to shape the outer leads in the vertical direction. .

[0032] In the invention, the shaping rod reciprocates along the gap to resha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com