Automatic efficient spring manufacturing process and production line

A production process and high-efficiency technology, applied in the direction of manufacturing tools, wire-made springs, other manufacturing equipment/tools, etc., can solve the problems of inability to assemble the whole process, low degree of automation, time-consuming and labor-intensive, etc., to reduce manual participation, reduce The effect of assembly and weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

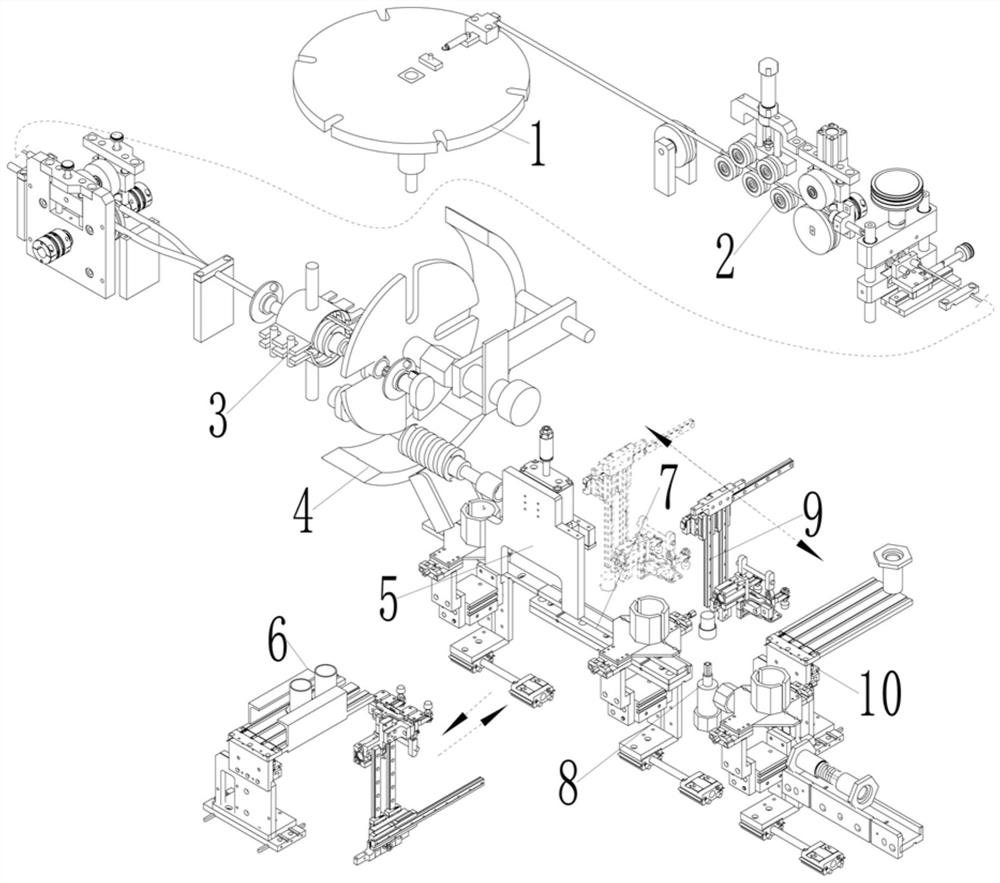

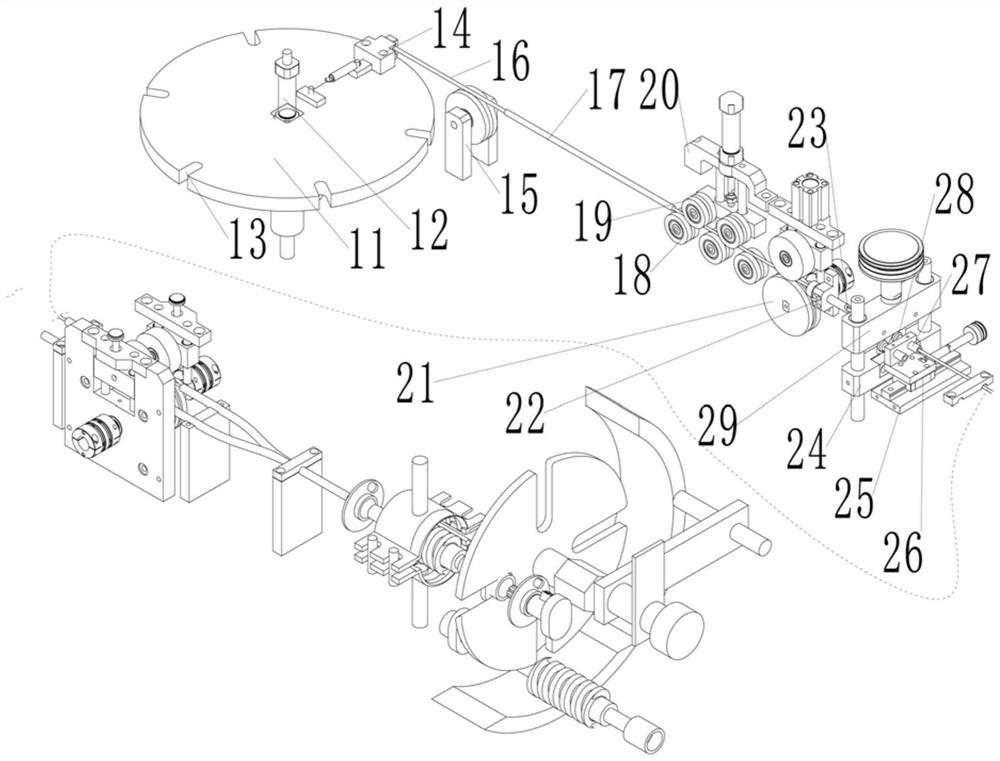

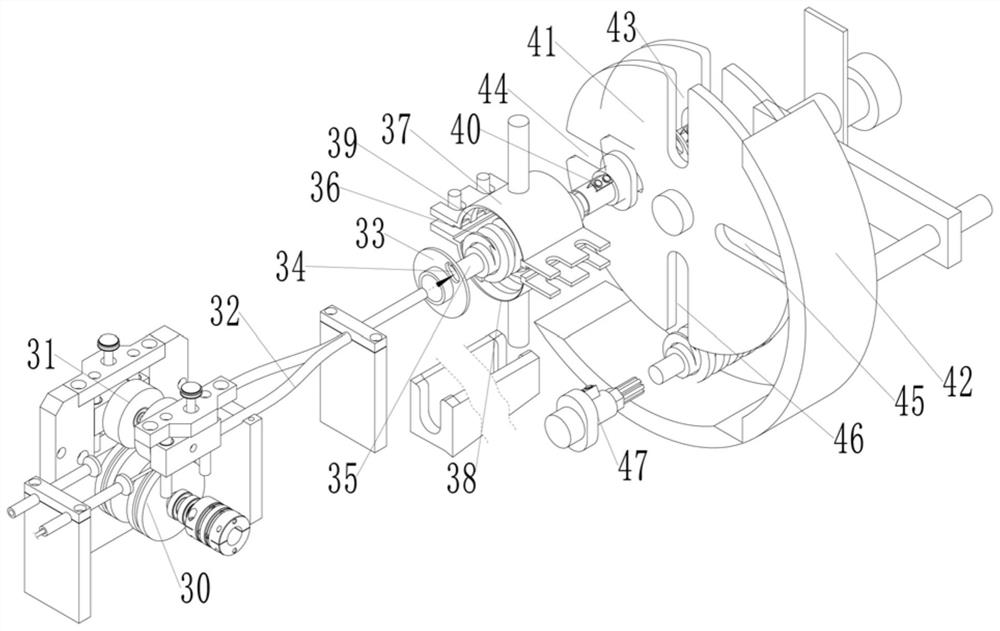

[0043] like Figure 1-6 As shown, in the spring product of this embodiment, the spring product 61 includes a helical shaped spring 62; the shaped spring 62 has two ends, and a first end cap 63 and a second end cap are respectively connected to the two ends of the shaped spring 62 end cap 64;

[0044] The first end cap 63 and / or the second end cap 64 has a hollow hole and a connecting flange; the hollow hole is welded to the end of the formed spring 62, and the connecting flange is used to connect the corresponding pulling member.

[0045] In the production line for automatic and efficient production of springs in this embodiment, the produced spring products 61 include a helical shaped spring 62; second end cap 64;

[0046] The first end cap 63 and / or the second end cap 64 have a hollow hole and a connecting flange; the hollow hole is welded to the end of the formed spring 62, and the connecting flange is used to connect the corresponding pulling member;

[0047] A blocking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com