Garbage can injection mold constant temperature control system and method

A technology for constant temperature control of injection molds, which is applied in the field of constant temperature control systems for trash can injection molds. It can solve the problems of cracking material properties of workpieces, affecting the quality of workpieces, and changes, so as to achieve stable temperature adjustment, precise temperature control, and prevention of cracking or material occurrence. effect of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

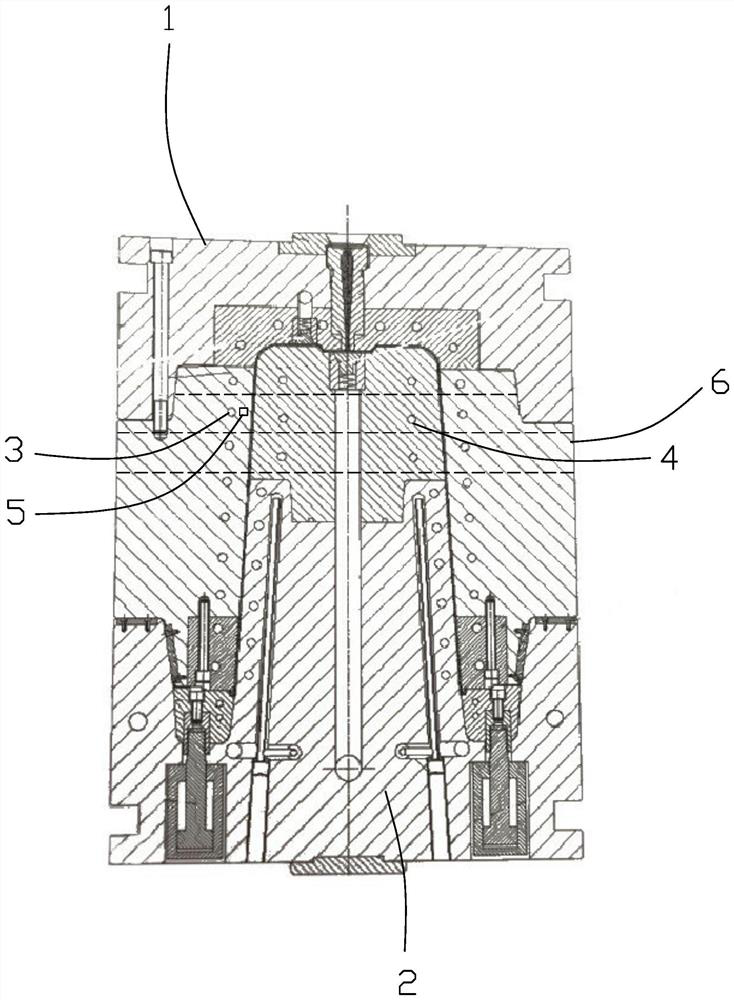

[0034] In this embodiment, a constant temperature control system for an injection mold of a trash can, such as figure 1 As shown, the mold includes a cavity mold 1 and a core mold 2 that are joined together, and the system also includes a controller and a water temperature controller. The cavity mold and the core mold are evenly divided into several layers of temperature adjustment layers along the mold opening direction, which are located between the two dotted lines as shown in the figure, and only part of the temperature adjustment area is marked in the figure. The temperature adjustment layer can be physically separated or just divided. Physically, a partition is set between each temperature adjustment layer in the mold. Between the warm runners, the physical separation is used to reduce the temperature influence between the temperature control layers.

[0035] Each temperature adjustment layer includes an outer temperature adjustment flow channel 3 arranged around the ca...

Embodiment 2

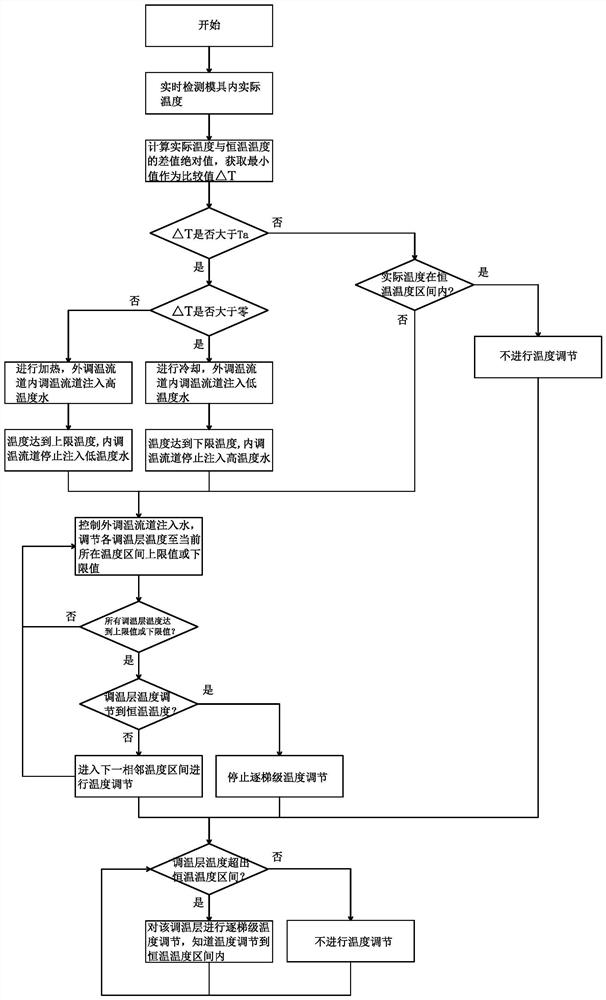

[0039] In the present embodiment, a method for controlling the constant temperature of an injection mold for a trash can, such as figure 2 described, including the following steps:

[0040] Step 1. Set temperature monitoring parameters, including constant temperature, constant temperature interval, upper limit temperature and lower limit temperature, and evenly divide the mold into several temperature-adjusting layers including temperature-adjusting runners along the mold opening direction;

[0041] Step 2. Detecting the actual temperature in the mold in real time, according to the temperature difference between the actual temperature and the constant temperature, the first-stage temperature adjustment judgment is performed on each temperature adjustment layer, and the temperature is adjusted to the upper and lower limit temperatures; specifically including:

[0042] (2-1) Obtain the actual temperature of each temperature control layer, calculate the absolute value of the dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com