Moisture-proof corrugated board pressing equipment

A technology for pressing equipment and corrugated cardboard, applied in the direction of mechanical processing/deformation, etc., can solve the problems that the pressing equipment cannot be moisture-proof, cannot be wetted and the corrugated cardboard is pressed and dried, and the pressing effect of the pressing equipment is reduced, so as to prevent the pressing Offset, improve the pressing effect, prevent the effect of water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

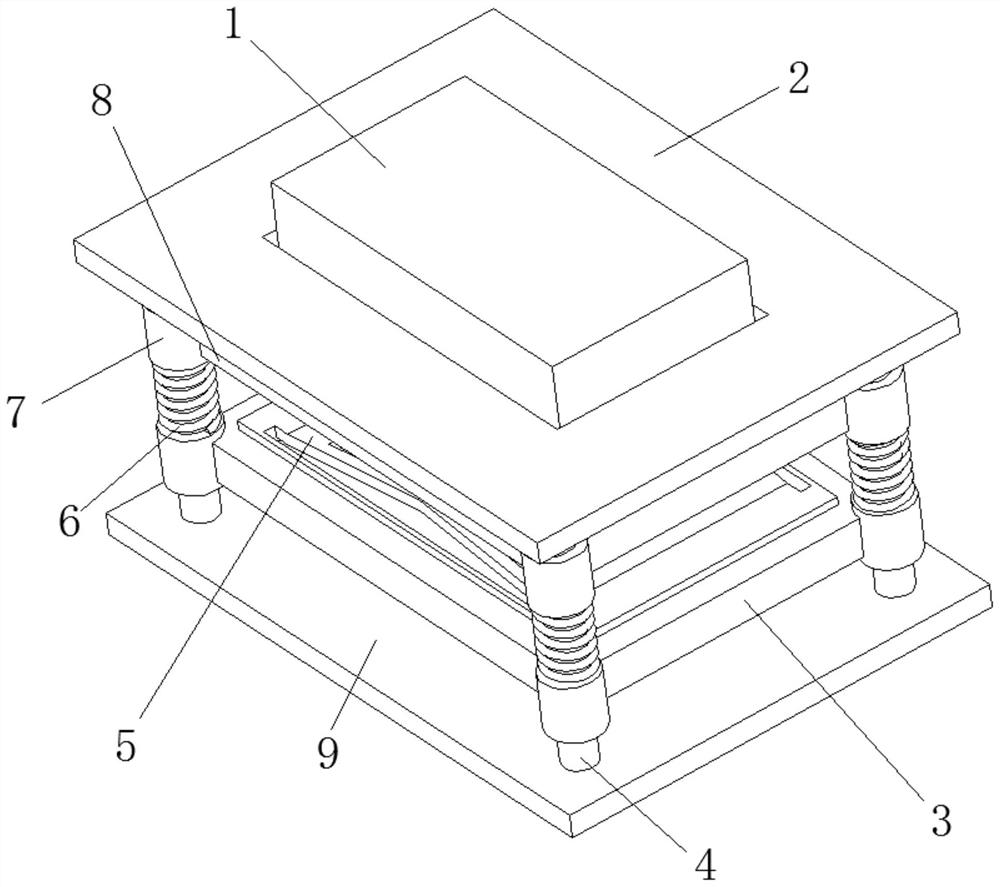

[0033] like Figure 1-2 As shown in the figure, the present invention provides a technical solution: a moisture-proof corrugated cardboard pressing equipment, comprising a bottom plate 9, a support rod 4 is fixedly connected to the upper surface of the bottom plate 9, and the support rod 4 is The outer surface is fixedly connected with a fixed support plate 3, the middle of the fixed support plate 3 is fixedly connected with an internal pressure device 5, and the top of the fixed support plate 3 is fixedly connected with an adapter spring 6, and the adapter spring is 6 sets Set on the outer surface of the support rod 4, the top of the adapter spring 6 is fixedly connected with a sleeved slip ring 7, and the upper pressure plate 8 is fixedly connected between the opposite surfaces of the sleeved slip ring 7, and the support The top of the rod 4 is fixedly connected with the top rack plate 2, the middle of the top rack plate 2 is sleeved with a pressure block plate 1, and the bo...

Embodiment 2

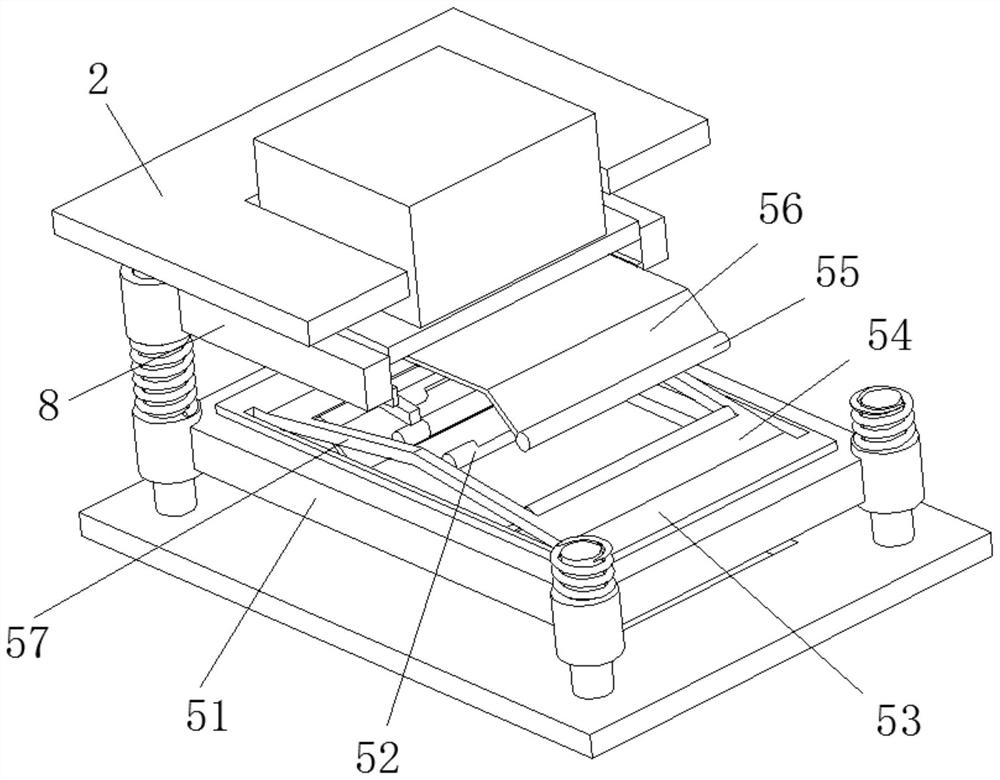

[0039] like Figure 3-4 As shown, on the basis of the first embodiment, the present invention provides a technical solution: the side limiting device 57 includes a limiting frame rod 571, and an inner sliding block 572 is sleeved inside the limiting frame rod 571 , the side of the inner sliding block 572 is fixedly connected to the pressing device 52 , and the side of the bottom of the limit frame rod 571 is fixedly connected with a bottom connecting cross bar 576 . The inner sliding block 572 is provided on the side of the pressing device 52. When the corrugated cardboard is subjected to the downward pressing force of the top pressing block 1, the pressing device 52 can slide down with the inner sliding block 572 to achieve Squeeze drain effect.

[0040] A side-set axle frame 575 is fixedly connected to the side of the top of the bottom-connecting cross bar 576 , and a sleeve-set axle rod 574 is fixedly connected between the top of the side-set axle frame 575 and the side surf...

Embodiment 3

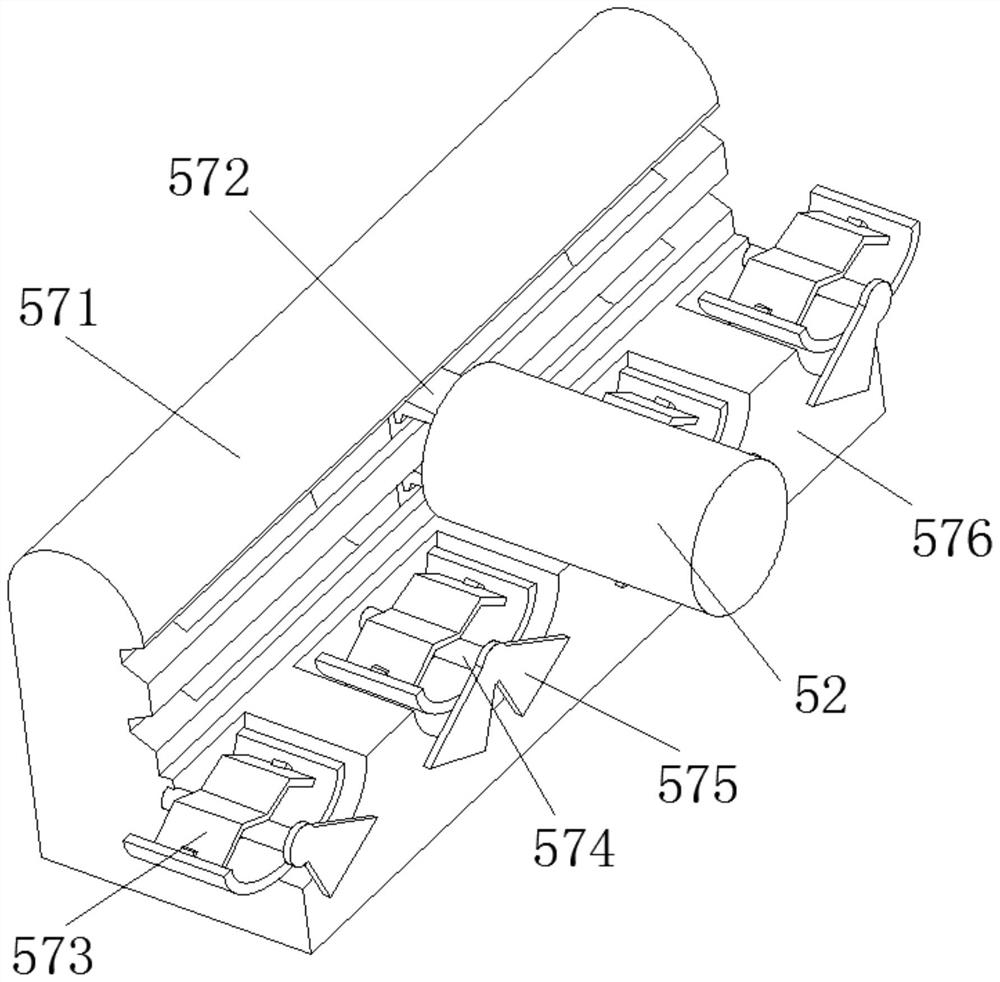

[0047] like Figure 5-6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the pressing device 52 includes a pressing tube 521, and the interior of the pressing tube 521 is fixedly connected to the limiting ring plate 523 , the interior of the limiting ring plate 523 is sleeved with an internal rotating shaft 524 , and a torsion spring 522 is fixedly connected between the internal rotating shaft 524 and the opposite surface of the inner wall of the pressing tube 521 .

[0048] The outer surface of the inner rotating shaft 524 is fixedly connected with a pull rod 525, and the end of the pull rod 525 is fixedly connected to the outer surface of the pressing tube 521, and the outer side of the pressing tube 521 is fixedly connected with a pressing rod unit 526, An outer cover plate 527 is fixedly connected to the outer surface of the bottom of the pressing tube 521 . When the pressing rod unit 526 is attached to the surf...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap