Transportation tool for mold forming

A transportation tool and mold forming technology, which is applied in the direction of transportation and packaging, anti-rot containers, external accessories, etc., can solve the inconvenience of improving the moisture-proof effect of mold transportation, the shock-absorbing stability effect of the inconvenient device structure, and the inconvenient device for wind shielding Problems such as rain-proof effect, to achieve the effect of ensuring stability, improving moisture resistance, and improving stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

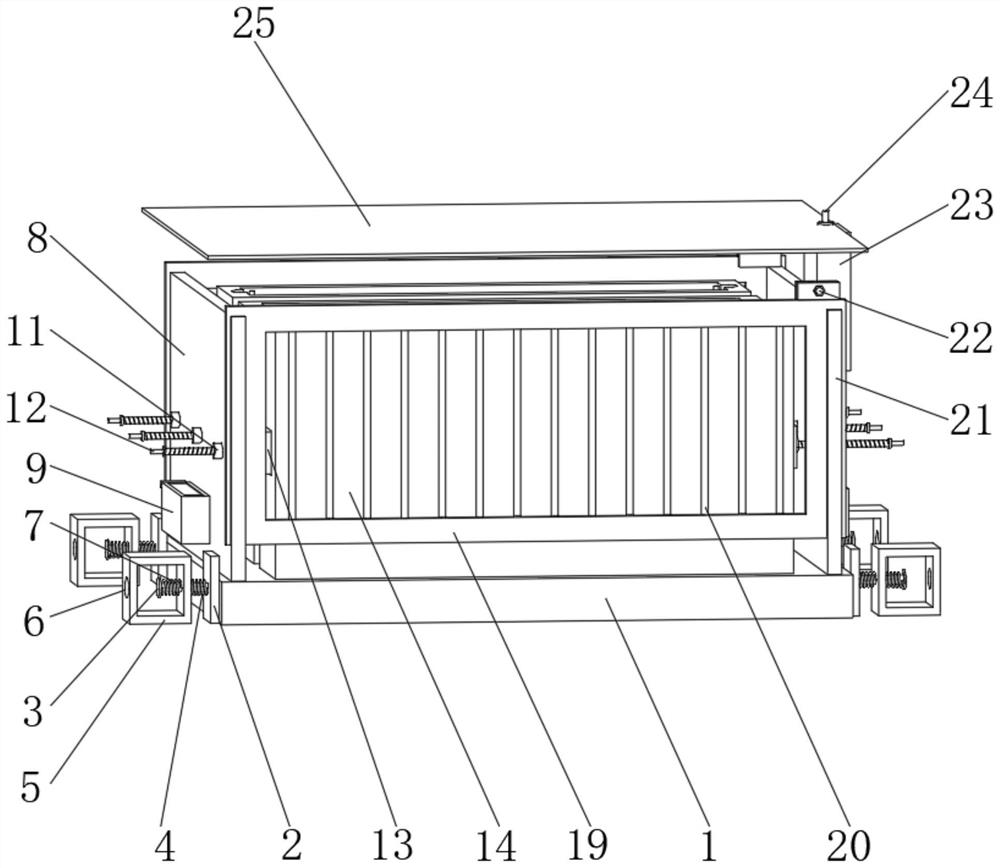

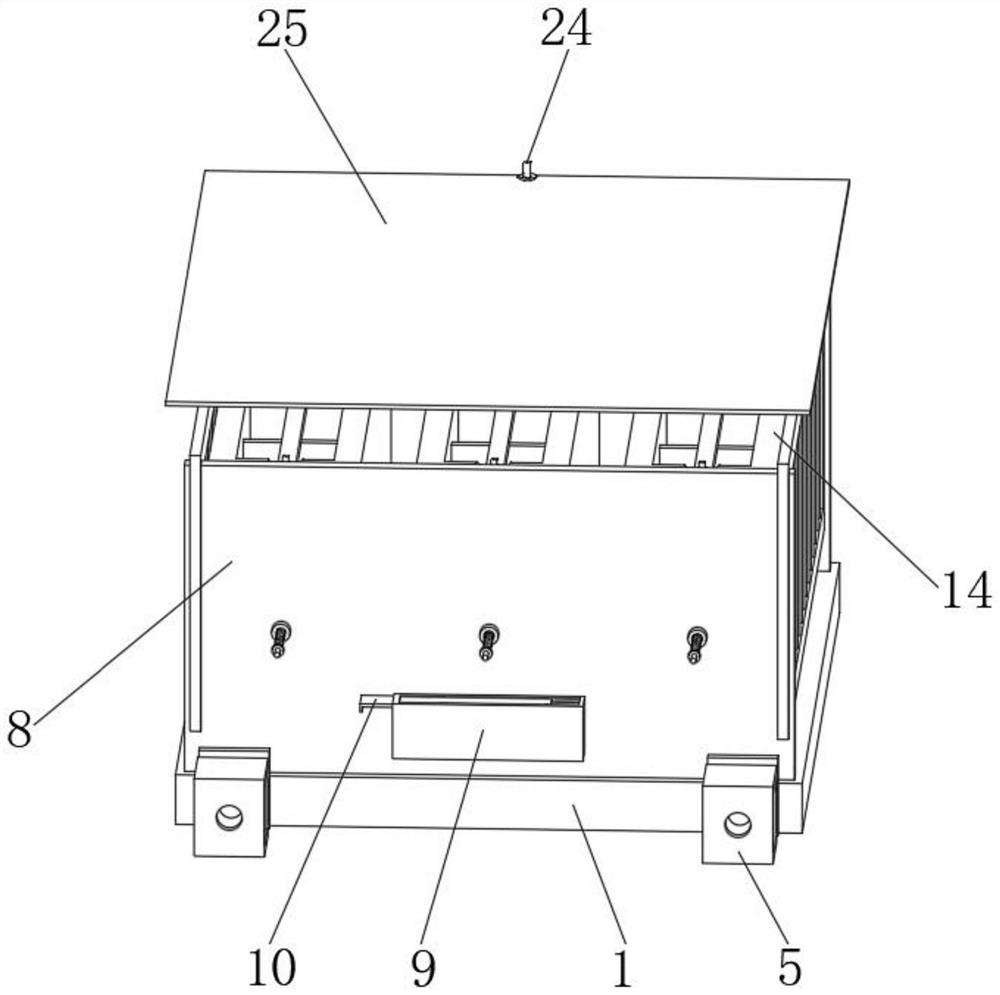

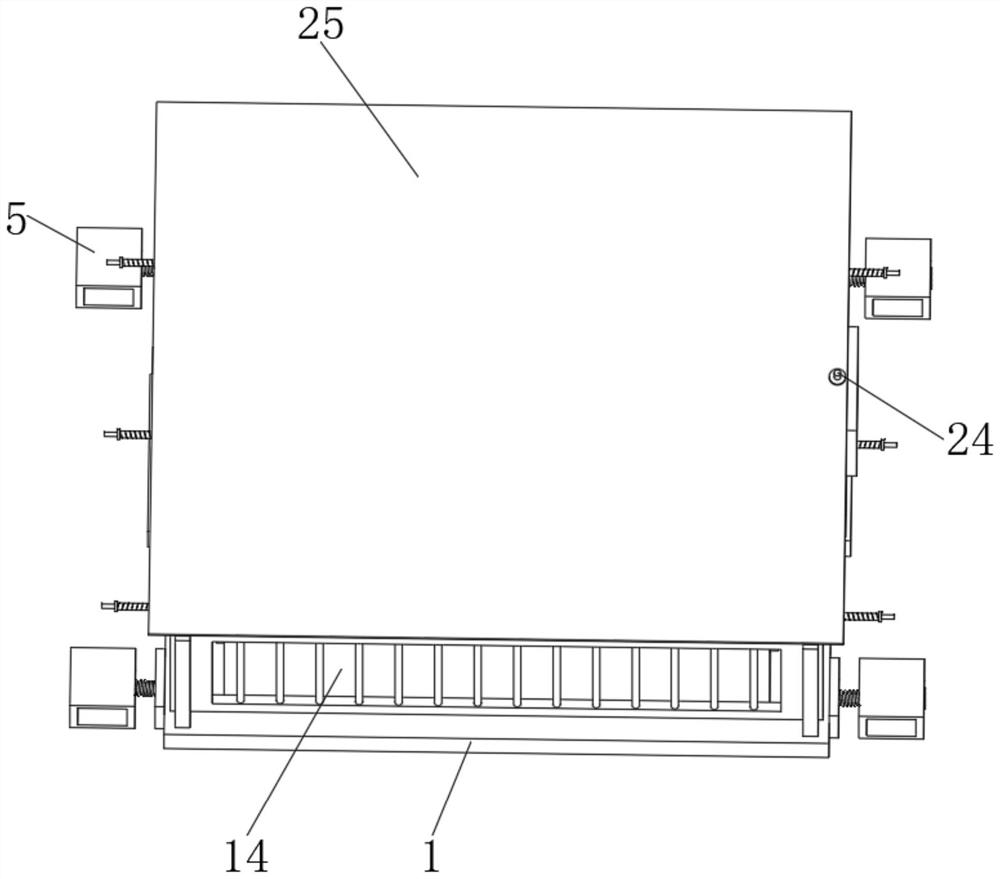

[0027] see Figure 1-3 As shown, a transportation tool for mold forming includes a bottom plate 1 and a first vertical plate 8, the side of the bottom plate 1 is provided with a connecting plate 2, and the middle position of the connecting plate 2 is connected with a connecting rod 3, and the connecting rod 3 A first spring 4 is arranged on the outer side of the cable, an installation frame 5 is arranged at the end of the first spring 4, and an installation hole 6 is opened on the inner side of the installation frame 5, and a second spring 7 is arranged at the end of the connecting rod 3.

[0028] The installation frame 5 constitutes an elastic structure by the first spring 4, the second spring 7 and the connecting rod 3, and the connecting rod 3 and the connecting plate 2 are vertically integrated, and the connecting plate 2, the connecting rod 3, the first spring 4 , The installation frame 5, the installation hole 6, and the second spring 7 are symmetrically arranged in two ...

Embodiment 2

[0030] see Figure 1-5 As shown, Comparative Example 1, as another embodiment of the present invention, the first vertical plate 8 is arranged on the top of the bottom plate 1, and the outer wall of the first vertical plate 8 is provided with a moisture-proof box 9, and the inner side of the moisture-proof box 9 A sealing plate 10 is provided, a threaded pipe 11 penetrates through the inner side of the first vertical plate 8, and a threaded rod 12 penetrates through the inner side of the threaded pipe 11. A placing box 14 is provided, the inner side of the placing box 14 is provided with an isolation plate 15, and the top of the isolation plate 15 is provided with a top plate 16, the end of the top plate 16 is provided with a fixing bolt 17, and the bottom end of the fixing bolt 17 is provided with a fixing plate 18. The side of the first vertical plate 8 is provided with a protective plate 19, and the inner side of the protective plate 19 is provided with a protective rod 20,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com