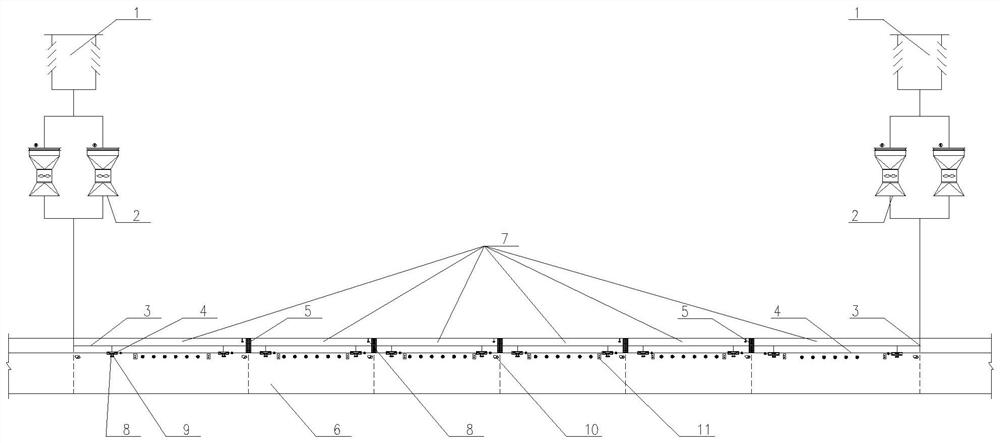

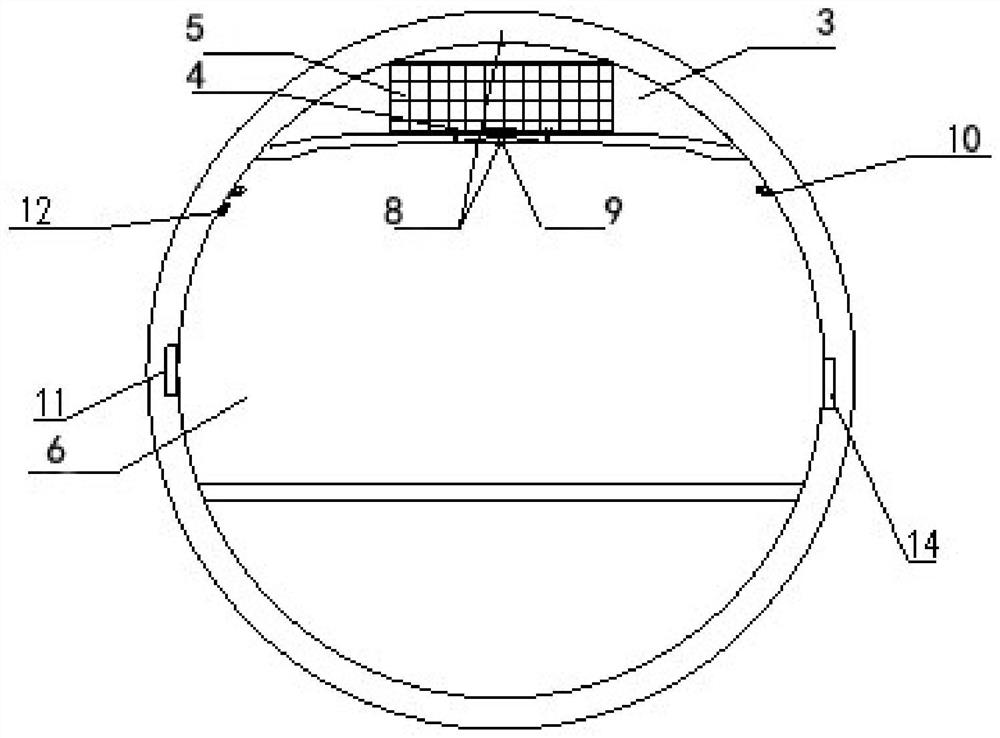

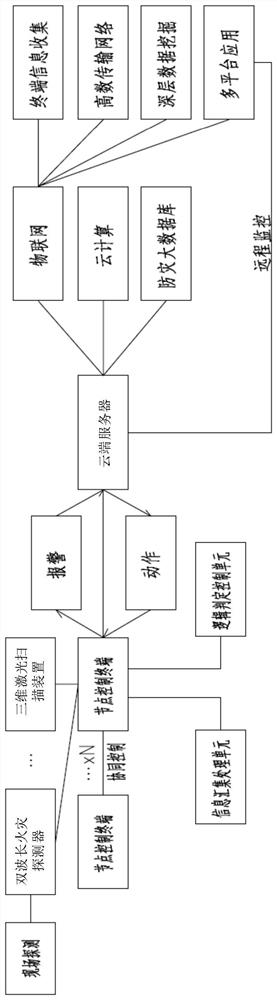

Long tunnel fire smoke exhaust control system

A control system and fire technology, which is applied in mine/tunnel ventilation, mining equipment, climate change adaptation, etc. It can solve the problems of multiple smoke exhaust conditions, long smoke exhaust ducts, and a large range of resistance loss of fixed-point smoke exhaust systems, etc. problem, to achieve the effect of precise smoke exhaust and high smoke exhaust efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical solutions and advantages of the embodiments of the present application more clear, the exemplary embodiments of the present application will be described in further detail below with reference to the accompanying drawings. Obviously, the described embodiments are only a part of the embodiments of the present application, and Not all embodiments are exhaustive. It should be noted that the embodiments in the present application and the features of the embodiments may be combined with each other in the case of no conflict.

[0019] In the process of realizing this application, the inventor found that the following defects exist in the prior art:

[0020] (1) The identification speed of the fire source is slow, the accuracy and intelligence are low, and there are false alarms and omissions. At present, the identification of fire source points usually adopts dual-wavelength fire detectors or temperature-sensing optical fibers. The dual-wavele...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap