Valve with anti-freezing function

A valve and functional technology, applied in the field of valves with antifreeze function, can solve problems such as backflow, liquid retention, volume increase, etc., and achieve the effect of ensuring normal transmission and avoiding backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

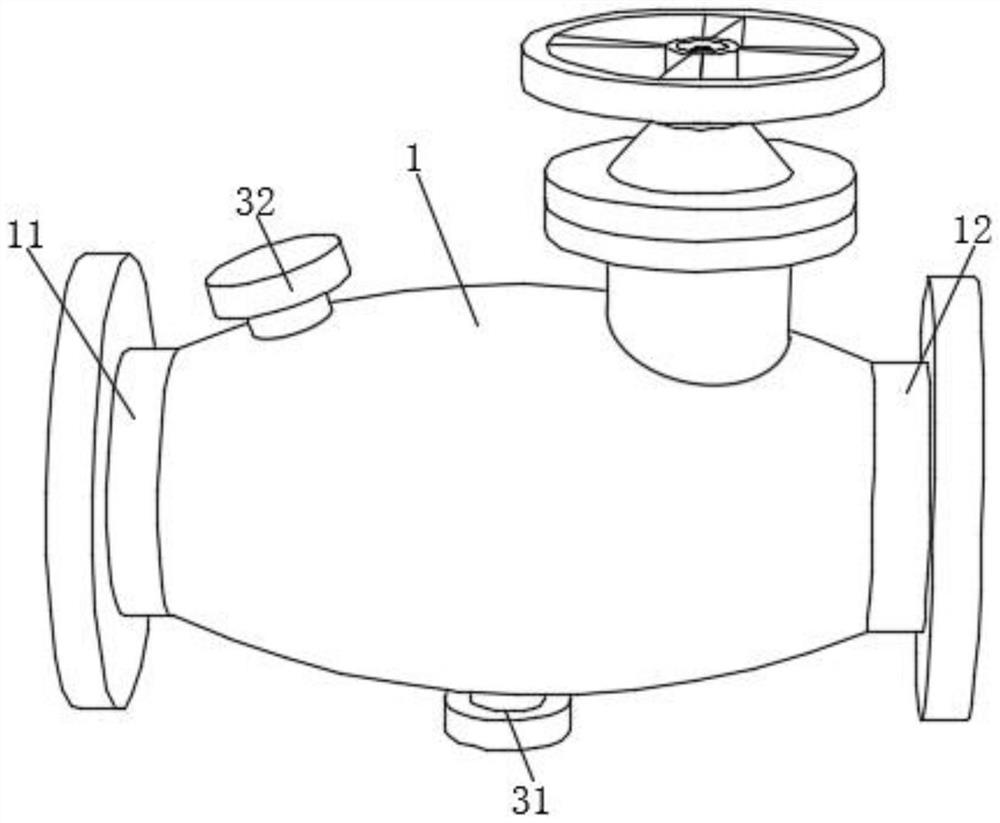

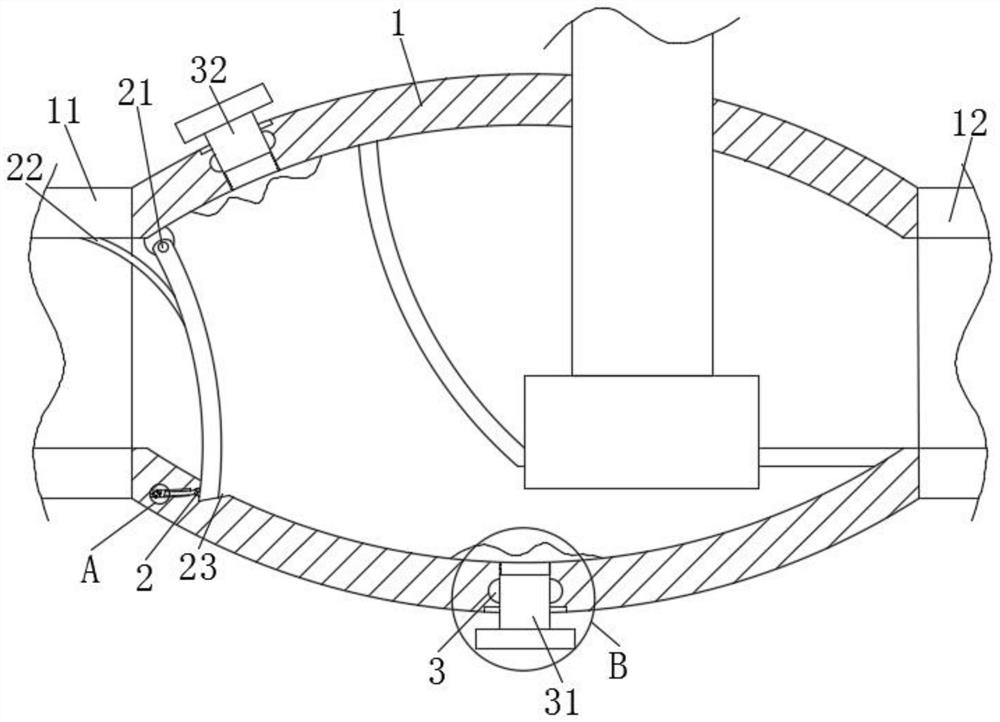

[0031] like Figure 1-6As shown, the present invention provides a valve with antifreeze function, comprising a valve body 1, two ends of the valve body 1 are respectively provided with a water inlet pipe 11 and a water outlet pipe 12, the inner side of the valve body 1 is provided with a backflow prevention mechanism 2 and an antifreeze mechanism Mechanism 3, the backflow prevention mechanism 2 includes a backflow prevention movable plate 21, one end of the backflow prevention movable plate 21 is movably connected to the inner wall of the valve body 1, and the valve body 1 is provided with a sealing groove 23, a soft connection push rod 24, The chute 25 and the elastic backflow prevention component 26, the antifreeze mechanism 3 includes a bottom piston 31 and an air pressure balance piston 32. A sealing assembly 33 is provided between the outer surface of the bottom piston 31, the inner wall of the valve body 1 and the outer surface of the air pressure balance piston 32, and ...

Embodiment 2

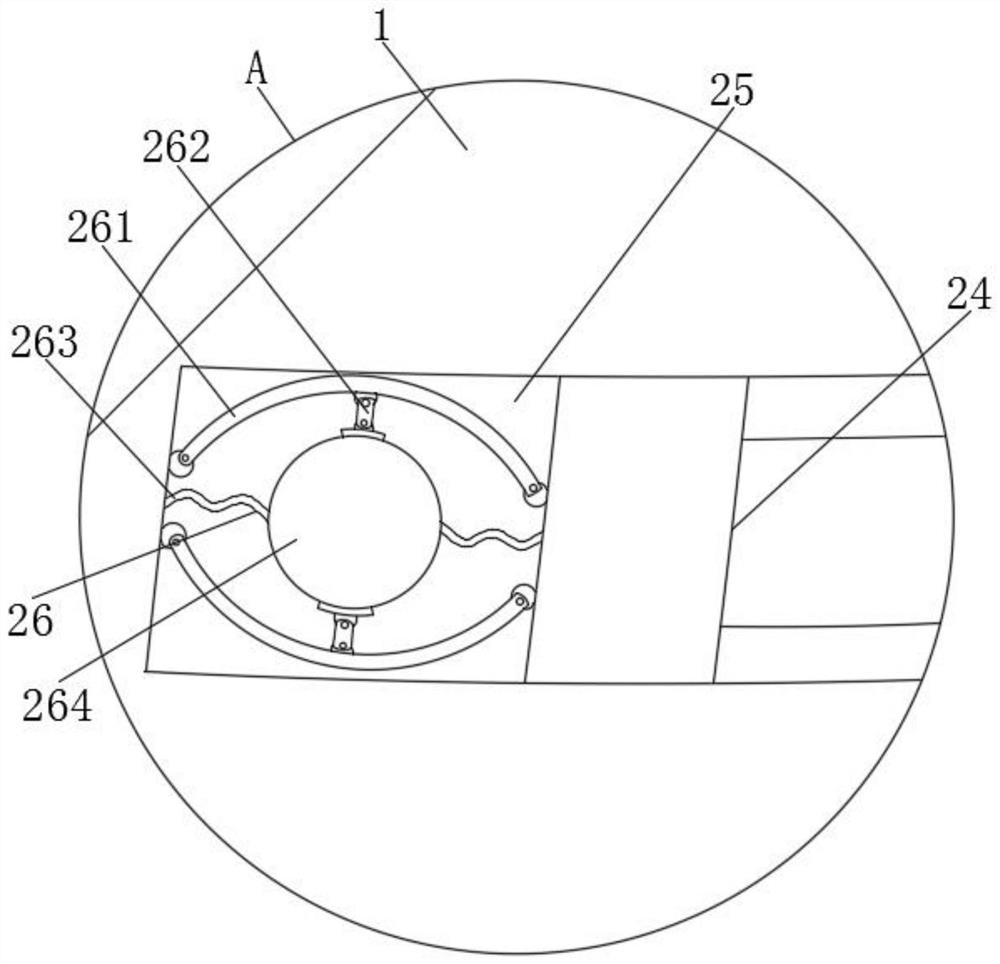

[0034] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the elastic backflow prevention component 26 includes an elastic sheet 261, and both ends of the elastic sheet 261 are respectively connected with the inner wall and soft connection of the chute 25. One side of the push rod 24 is movably connected, the inner side of the elastic sheet 261 is movably connected with a connecting rod 262, the outer surface of the connecting rod 262 is fixedly connected with a soft rebound ball shell 264, and the outer surface of the soft rebound ball shell 264 is connected The elastic pull rope 263 is fixedly connected, one end of the elastic pull rope 263 is fixedly connected with the inner wall of the chute 25 and one side of the soft connection push rod 24, and the inner wall of the soft rebound ball shell 264 is fixedly connected with a connecting curved plate 2641, both ends of the connecting curved plate 2641 are m...

Embodiment 3

[0037] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the sealing assembly 33 includes a soft sealing sheet 331, the outer surface of the soft sealing sheet 331 is connected with the bottom piston 31 and the air pressure balance piston 32 The outer surface of one end of the valve body is fixedly connected, the outer surface of the soft sealing sheet 331 is movably connected to the inner wall of the valve body 1, and the outer surfaces of the bottom piston 31 and the air pressure balance piston 32 are fixedly connected with a soft sealing ring 332 and a sealing block 333. The outer surfaces of the soft sealing ring 332 and the sealing block 333 are movably connected with the inner wall of the valve body 1 .

[0038] In this embodiment, when the pressure of the inlet water at the inlet pipe 11 is reduced and the valve body 1 is closed, there will be a lot of water remaining inside, and when the weather te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com