Built-in fixing method for SCR (Selective Catalytic Reduction) area type smoke mixer

A fixed method and built-in technology, applied in the direction of combustion method, waste gas exhaust device, indirect carbon dioxide emission reduction, etc., can solve the problems of inapplicability, high construction difficulty, heavy construction workload, etc., and achieve stable installation and economical construction And the effect of excellent safety and small construction workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

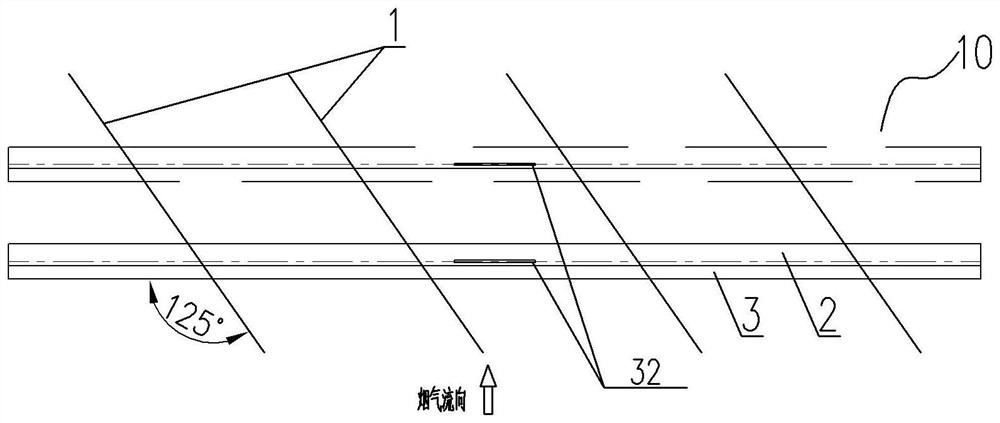

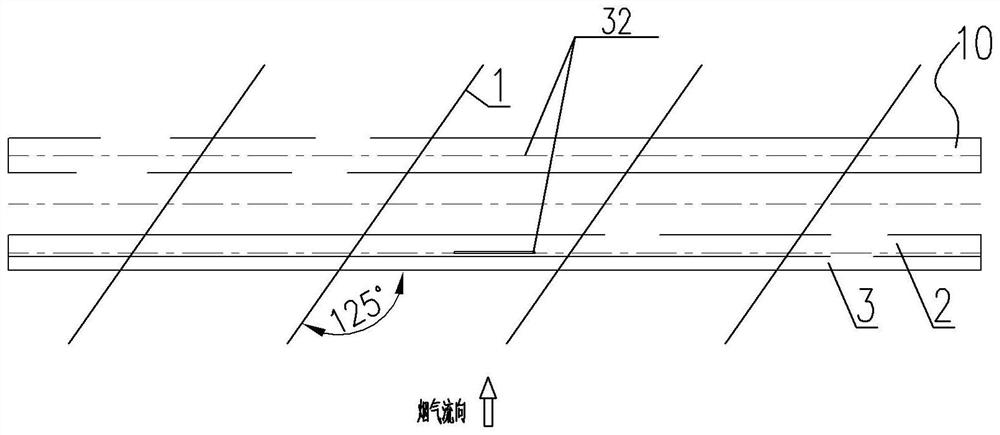

[0025] A built-in fixing method for SCR regional smoke mixer, see Figure 1-Figure 6 .It includes the following steps:

[0026] One of the cross sections of the flue that is perpendicular to the flow direction of the flue gas is set in advance, and the SCR area type smoke mixer is set, the depth of the cross section is A, the width is B, and B is greater than A;

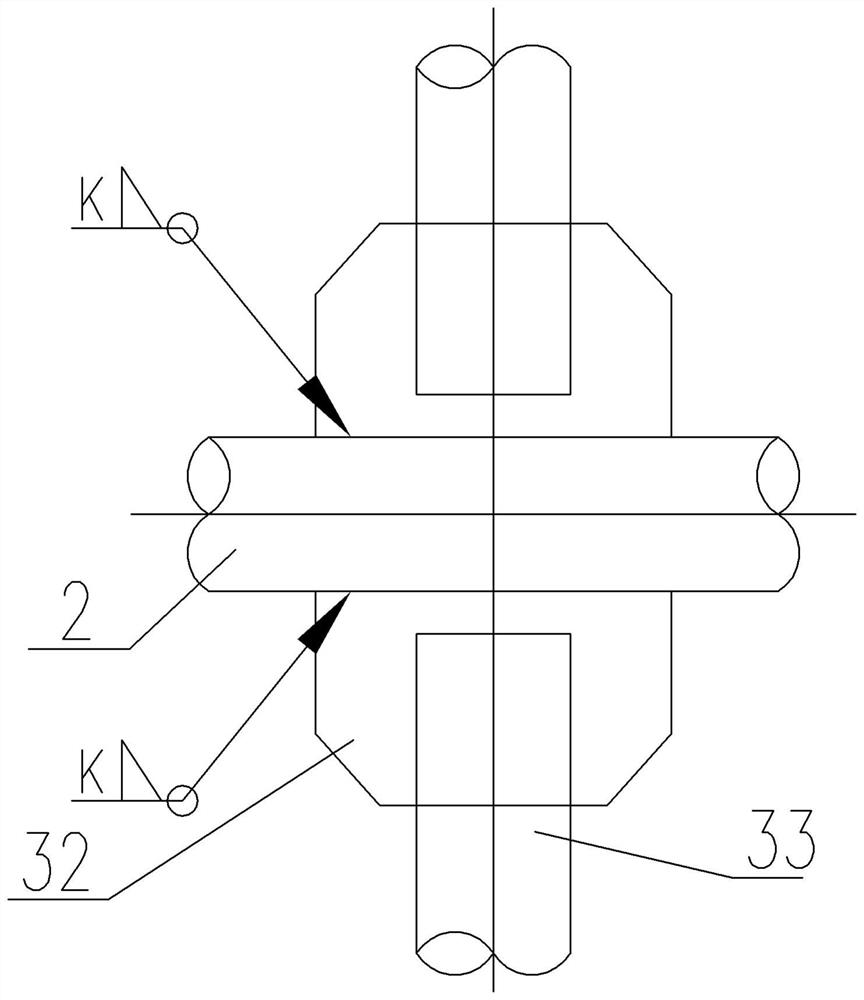

[0027] a Several mixer bodies 1 are fixed in series by two upper and lower inner struts 2, and the windward surface of each inner strut is provided with anti-wear angle steel 3 to form several groups of regional flue gas mixer assemblies 10, with 3 packs of anti-wear angle steel Cover the windward area of the inner strut 2;

[0028] b. The flue reinforced steel plates 20 are respectively welded and arranged on the inner wall surfaces on both sides in the depth direction, and the flue reinforced steel plates 20 on both sides are respectively arranged in a one-to-one correspondence. The ends are respectively welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com