Horizontal casting equipment for aluminium alloy flat ingot

A technology for hot top casting and flat ingot casting, which is applied in the field of hot top casting devices, can solve problems such as cracking, ingot surface pulling marks, aggravating the depth of ingot surface deflection, etc., and achieves hard cracks and good liquid cavity shape. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

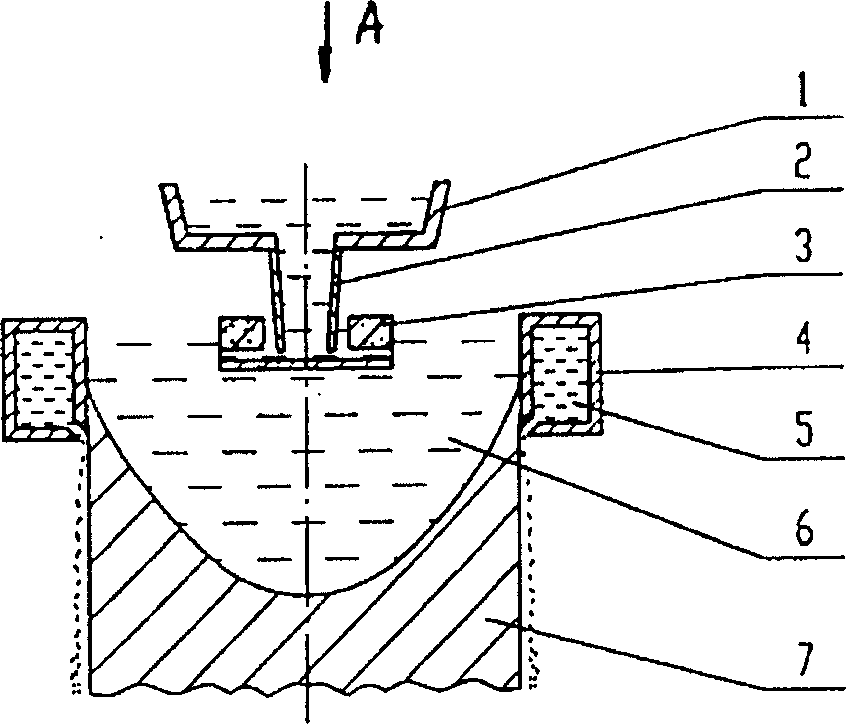

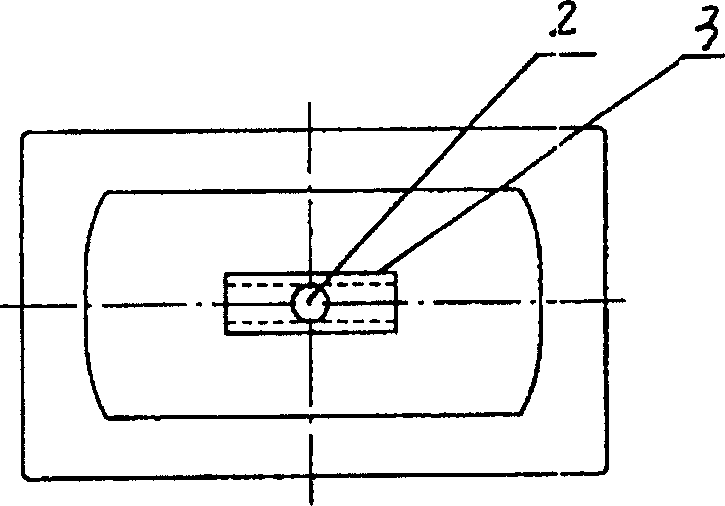

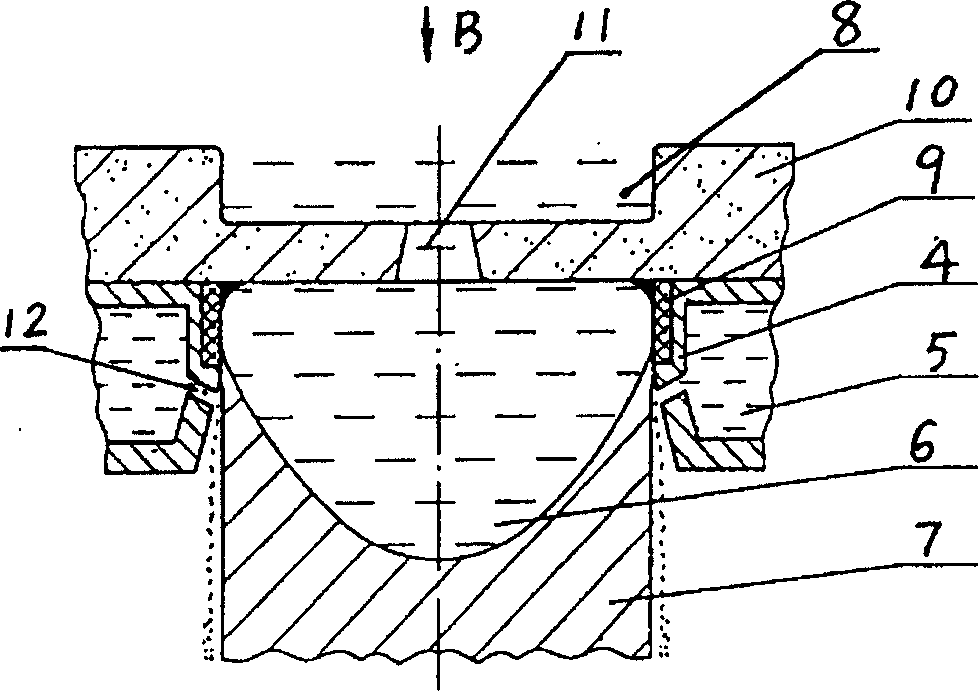

[0016] In this example, 12 crystallizers are arranged on the same mold platform, and each crystallizer is provided with a dummy head installed on the dummy seat corresponding to each crystallizer under the mold platform. The hot top 10 with a concave splitter plate 8, the cross section of the crystallizer is flat, and the bottom of the hot top splitter plate is evenly provided with two split holes 11 corresponding to the longitudinal length of each flat crystallizer, and the split holes are upper and lower. Large trumpet shape, this shape is more conducive to diversion.

[0017] The cooling water slot 12 on the flat crystallizer of this example is that the longitudinal cooling water slot width is greater than the transverse cooling water slot width, and its width ratio is 4 / 3: 1. This is because the longitudinal side wall of the flat ingot is longer than the horizontal side wall. If the width of the transverse cooling water gap is the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com