Glittering cube-corner retroreflective sheeting

A retro-reflective, cube-based technology, used in optics, optical components, thin material processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1a-1e

[0162] Examples 1a-1ee... Batch Production of Glitter Articles

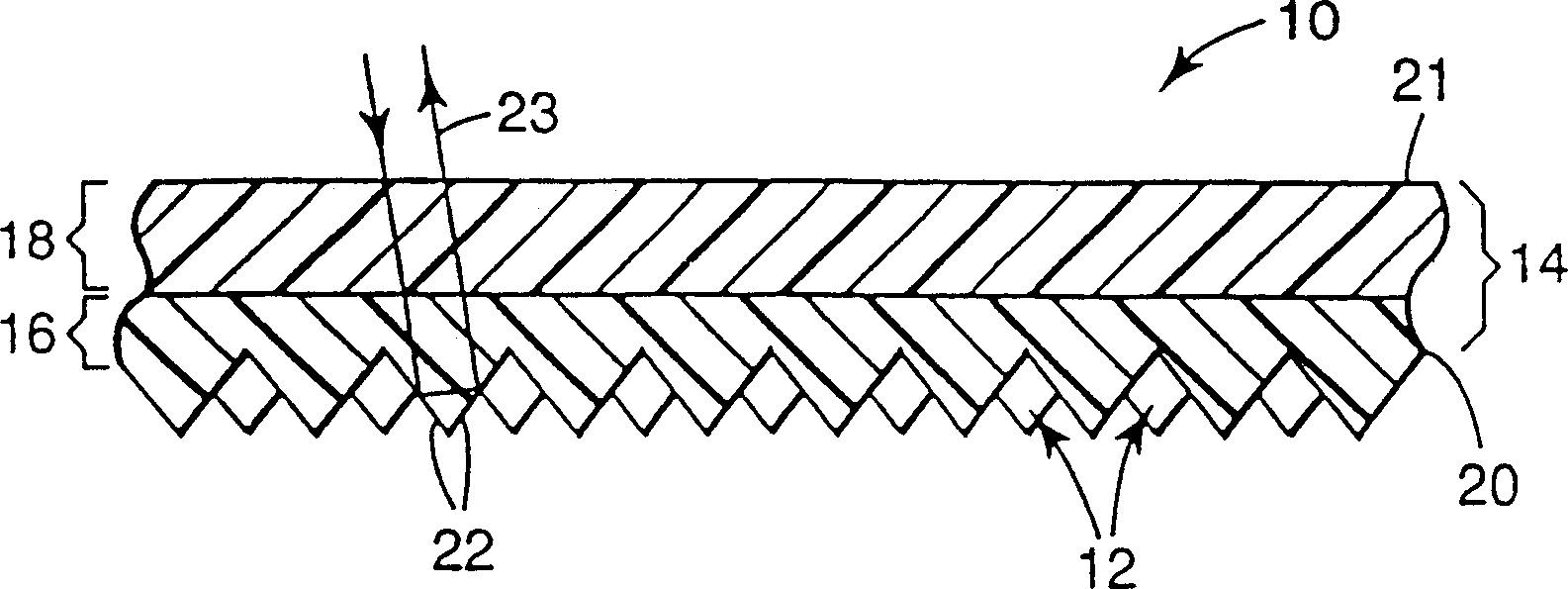

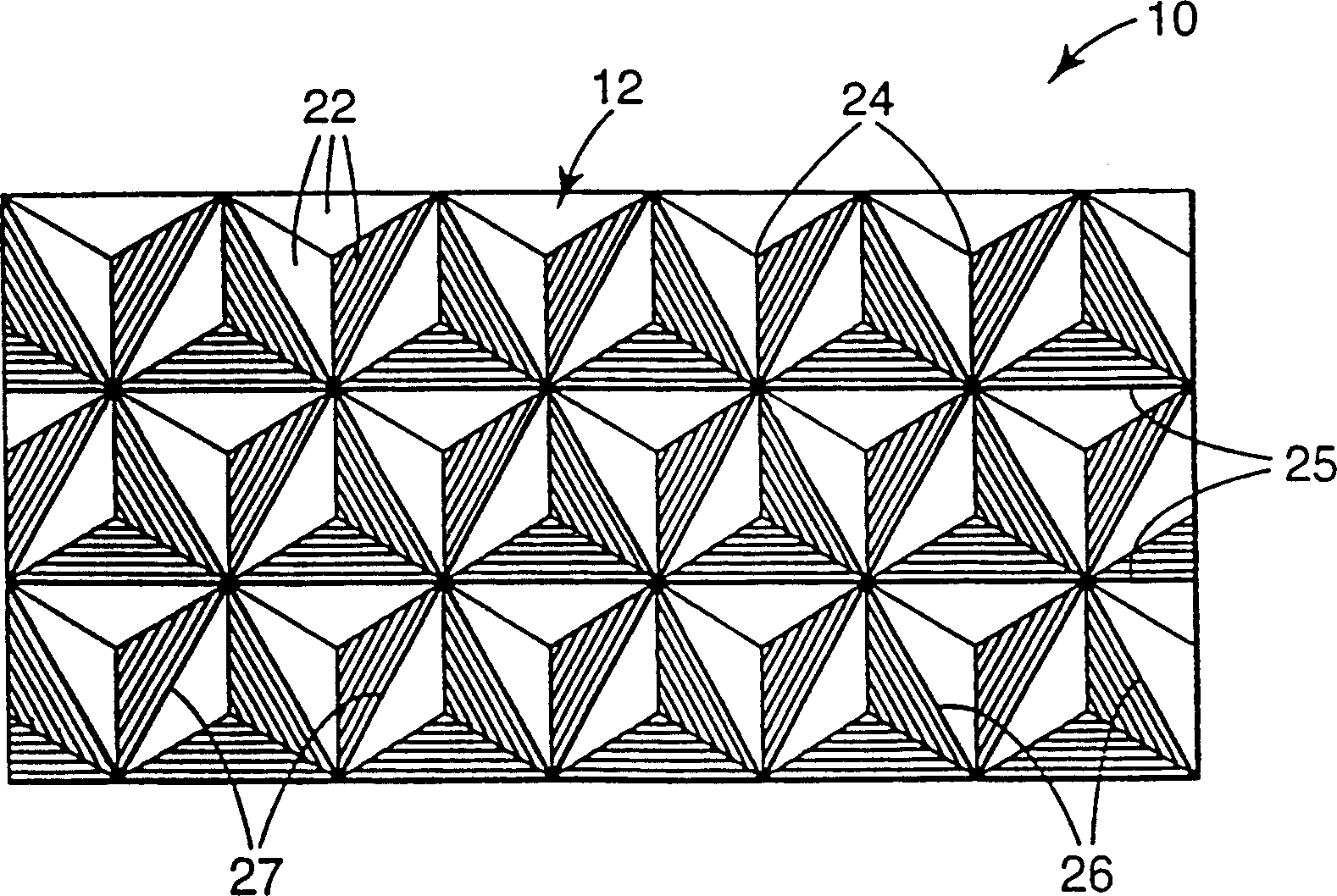

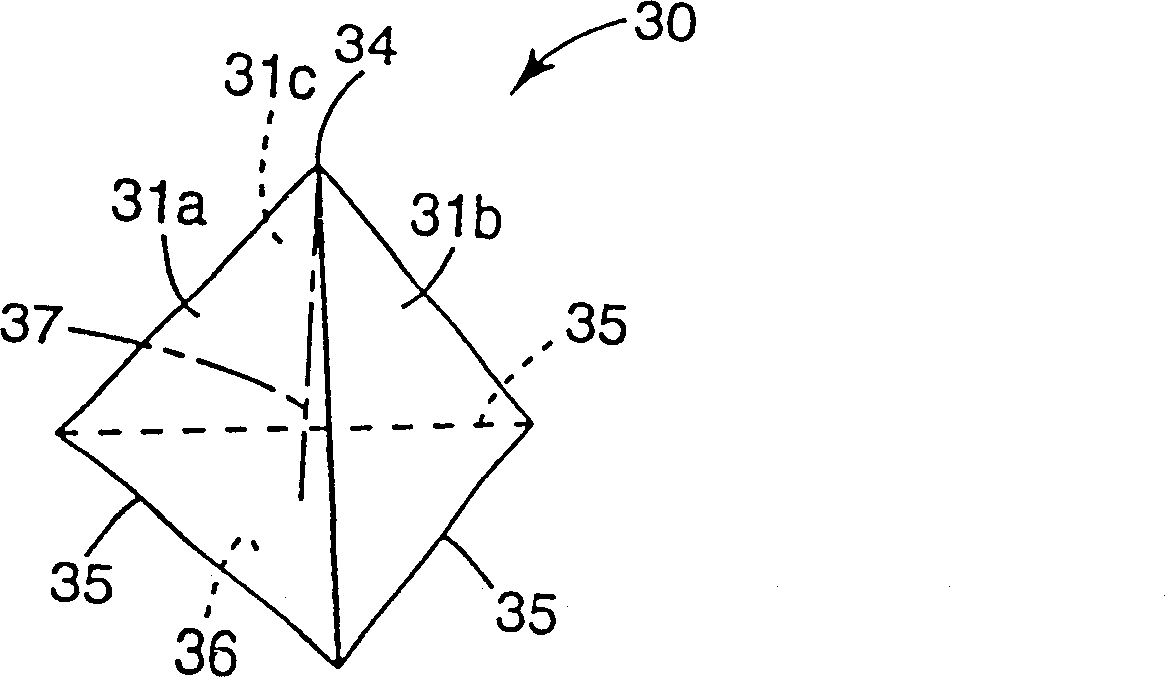

[0163] Ordered cube-corner retroreflective sheeting was prepared as described in Example 1 of US Patent Application Serial No. 08 / 472,444, filed June 7,1995. The retroreflective sheeting comprises cube-corner retroreflective elements, a 0.01 inch (250 micron) thick colorless, transparent, flexible body layer and a 0.002 inch (50 micron) thick polyethylene terephthalate carrier film, wherein the The cube-corner elements are approximately 0.0035 inches (90 microns) from apex to base and are made of 1,6-hexanediol diacrylate, trimethylolpropane triacrylate, and bisphenol A epoxy diacrylate at 25: 50:25 weight ratio and using 1% resin weight Darocur TM 4265 as a photoinitiator. The resin was cured through the film using a FUSION H lamp (available from Fusion UV Curing systems, Inc. (Gaithersburg, Maryland)) at 235 W / cm, 25 ft / min (7.6 m / min) Post-curing was accomplished from the backside of the cube-corner elem...

Embodiment 1

[0164] Example 1s was used to test lightness, and this sample exhibited an LFY value of 37.73.

[0165] serial number

Embodiment 2a-2

[0166] Examples 2a-2m...Imaged Glittering Articles Formed Using Flexographic Printing Plates

[0167] Ordered cube-corner retroreflective sheeting as described in Examples 1a through 1ee was used. Place a sheet of Kraft release paper on the rubber mat of a Hix Model N800 thermal laminator. There will be raised images ( Figure 16a ) is placed on top of the paper with the image of the letters "JPJ" surrounded by a circle. An ordered cube-corner retroreflective sheeting with a polyester carrier on top of the body layer was placed on top of the flexographic printing plate such that the backside of the cube-corner elements contacted the raised image elements on the printing plate. Place a second sheet of Kraft release paper on top of the cube-corner sheet. This arrangement is equivalent to Figure 11 , where the flexographic printing plate is represented by 104. Heat this assembly to 350°F (175°C). The air line pressure (psi) and heating time are listed in Table 2. At the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com