Plasma display and method of operation with high efficiency

A technology of plasma, method of operation, applied in the field of plasma display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

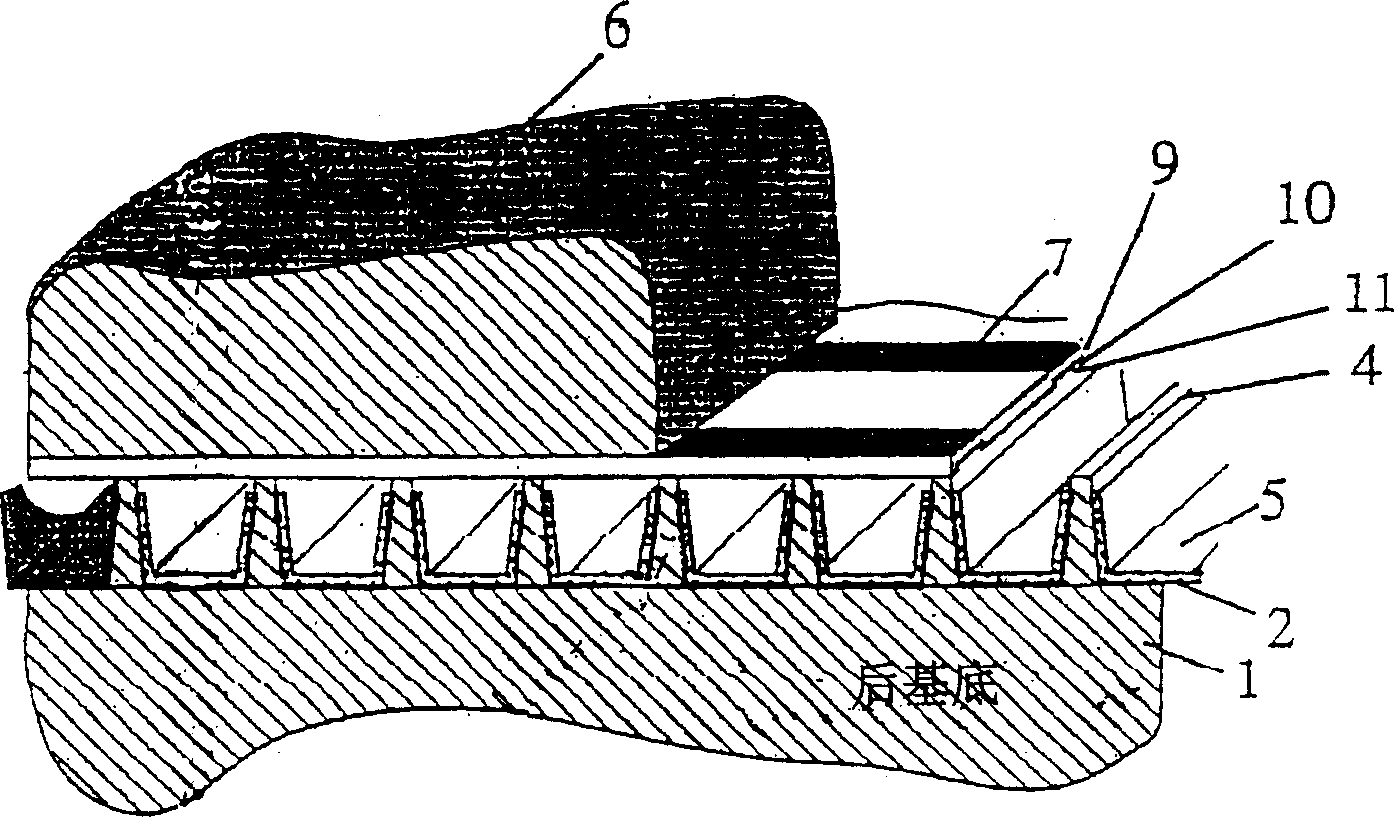

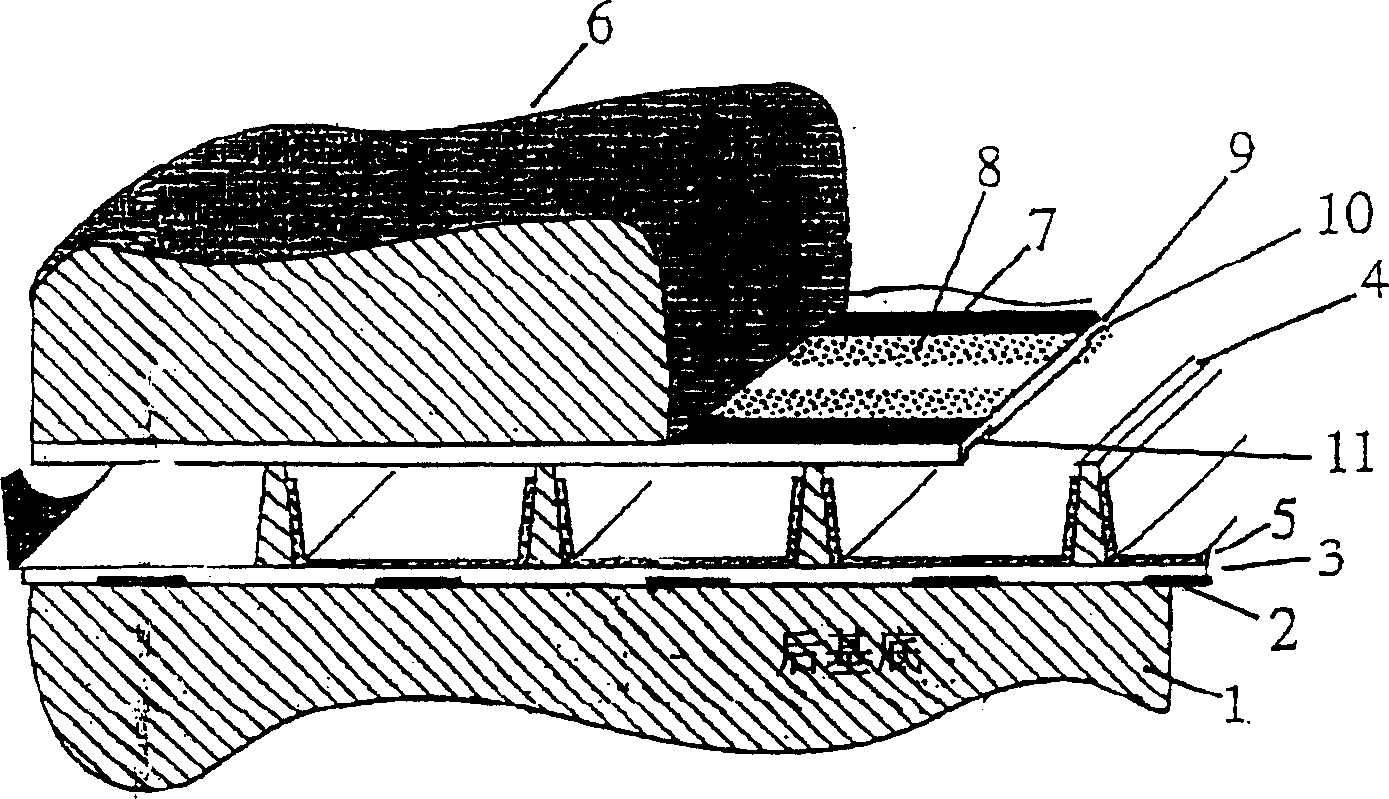

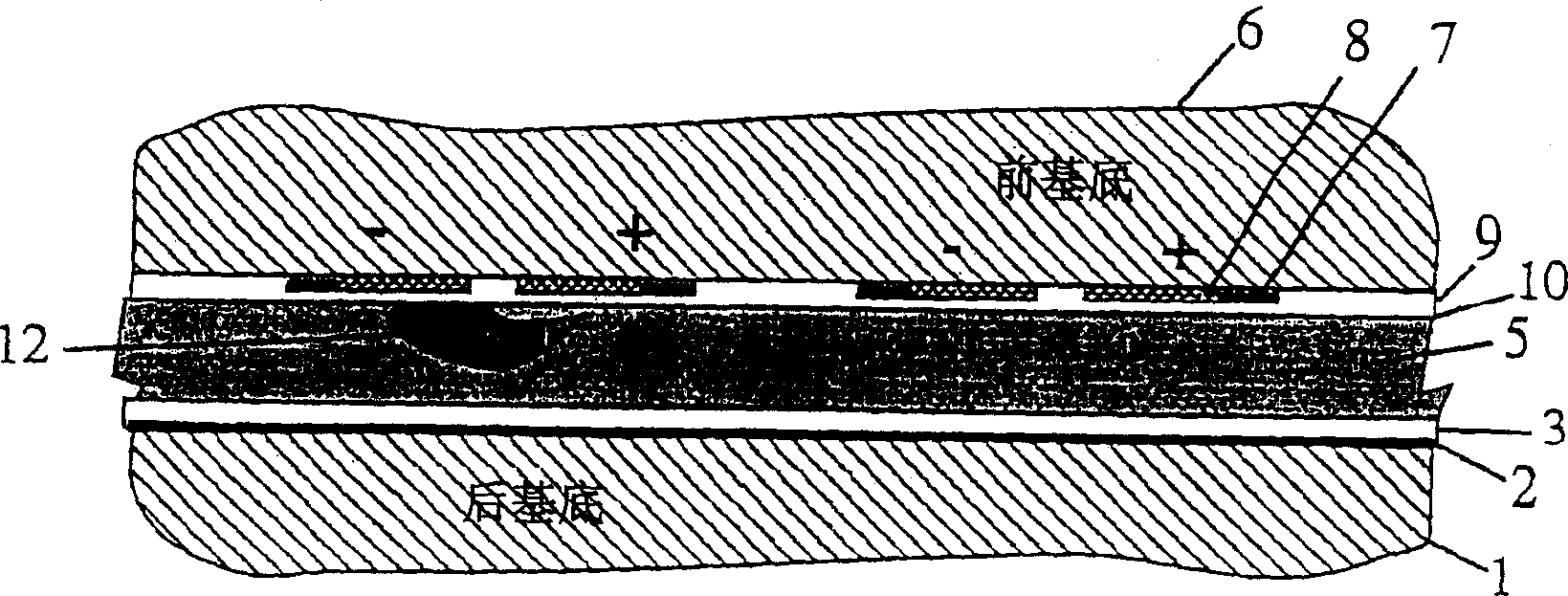

[0046] Referring to the drawings, wherein like numerals represent like elements, figure 1 A partial cross-sectional view of an example full-color display is shown in . The front or top substrate has on its inner surface a display electrode 7 which may be combined with a transparent extension 8 covered with a dielectric material 9 whose surface is covered with a photoemissive layer 10 . In this surface are formed microchannels 11 parallel to the display electrodes. The front substrate is sealed in contact with the rear substrate 1, which contains light-emitting regions 5 on the surface of microgrooves separated by a thin barrier layer 4 and forming gas-filled channels in said microgrooves. A fluorescent material is deposited on the region 5 where it coincides with the electrode 2 covering the inner surface of the microgroove. Each adjacent light-emitting area may contain three different fluorescent colors, such as red (R), green (G), and blue (B), in a repeating manner. A pi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap