Double-system temperature controlled acoustochemical reactor

A chemical reactor, dual-system technology, applied in the field of dual-system temperature-controlled sonochemical reactors, can solve problems such as undetermined influence and temperature rise, and achieve the effect of increasing chemical reaction speed and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below with reference to the drawings and embodiments, but the present invention is not limited to these embodiments.

[0013] The inventor gave the first embodiment of the present invention.

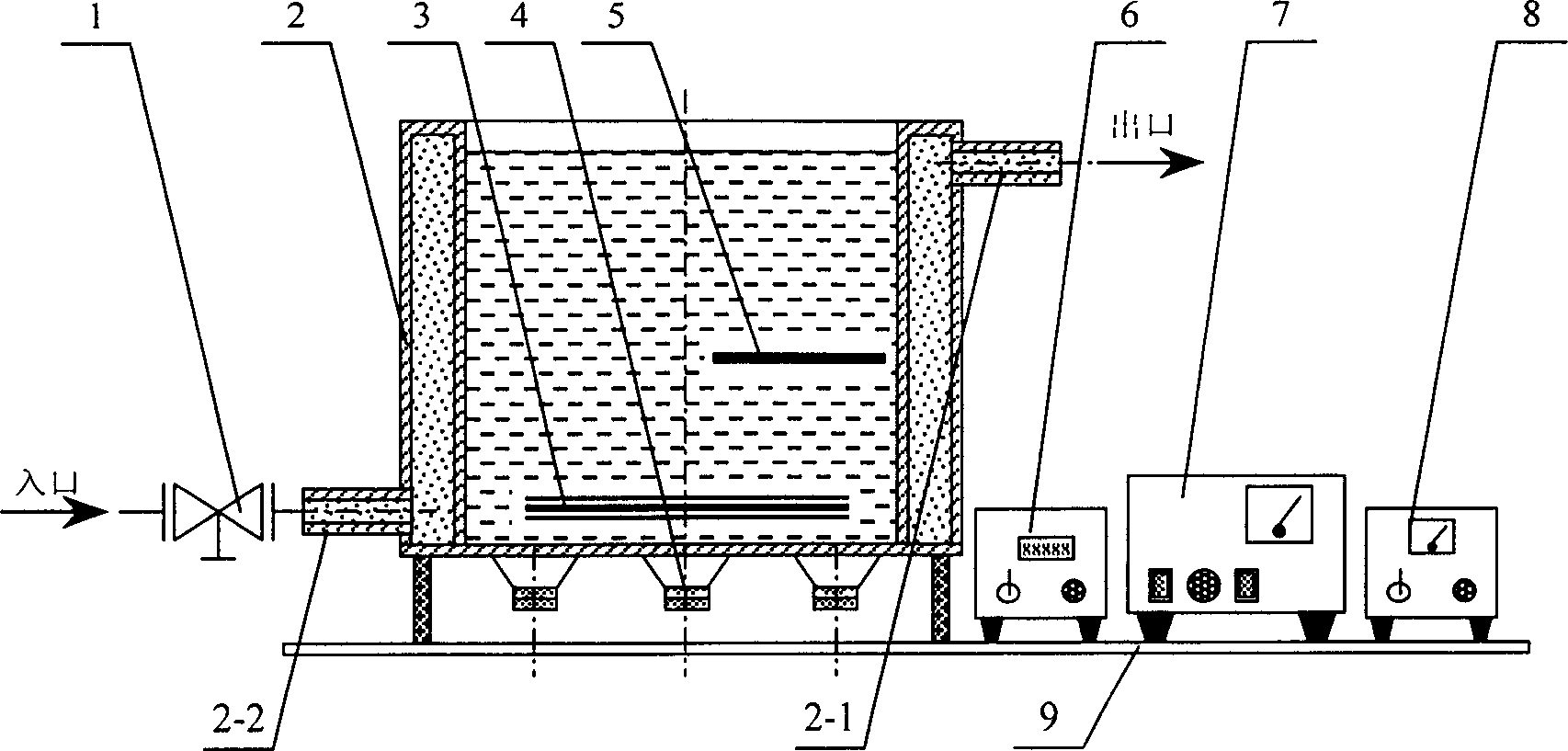

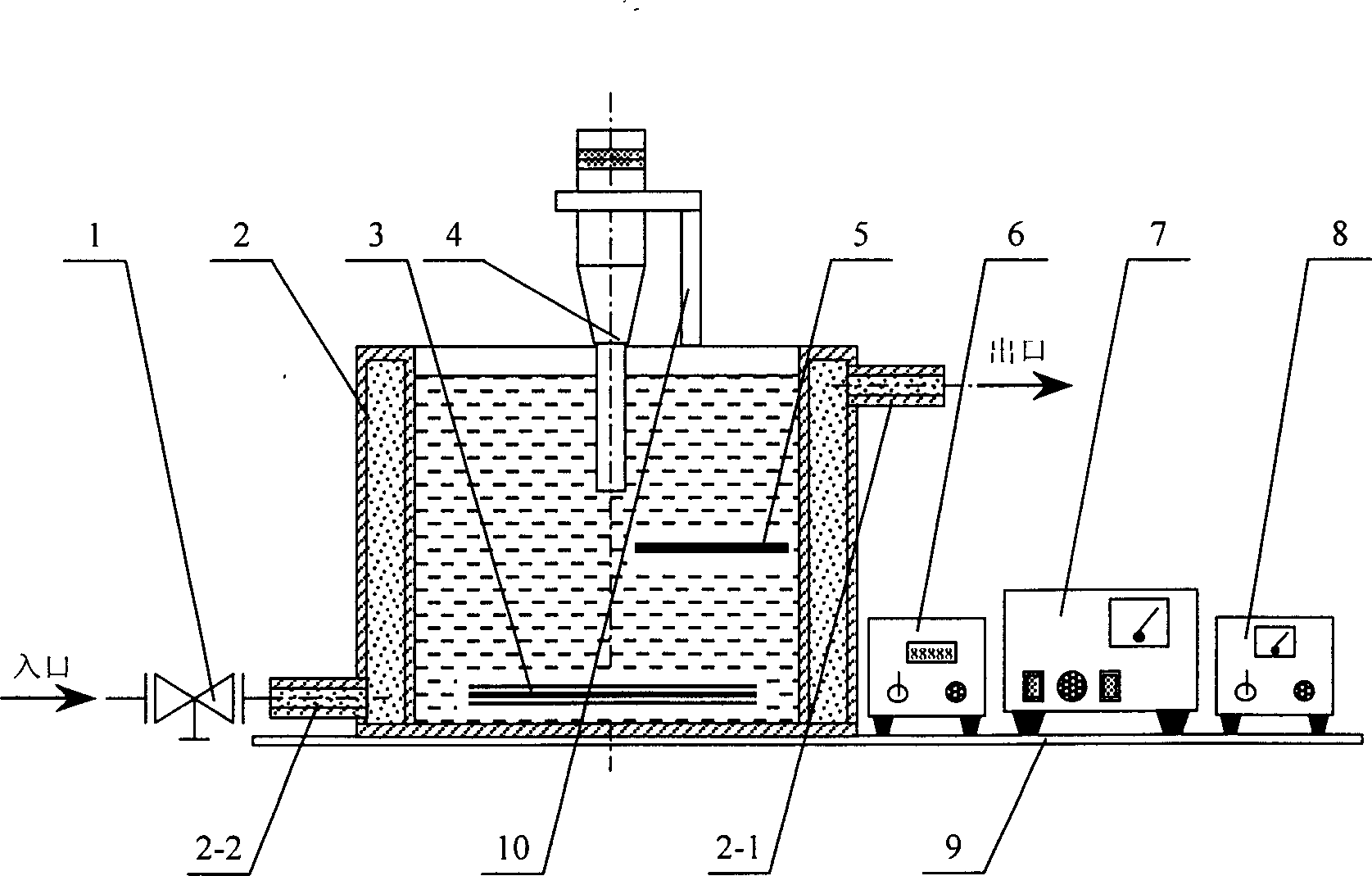

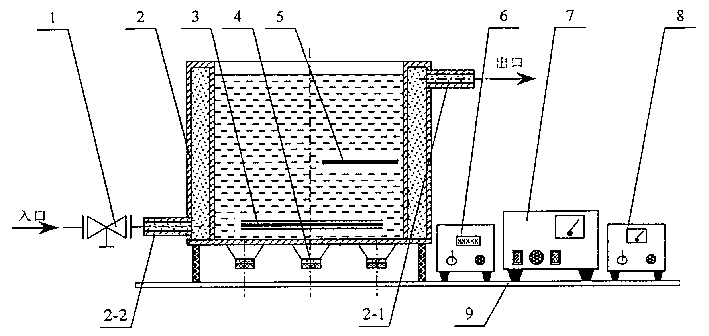

[0014] in figure 1 In this embodiment, the dual-system temperature-controlled acoustic chemical reactor is composed of a proportional solenoid valve 1, a double-walled reaction liquid tank 2, a heater 3, an ultrasonic transducer 4, a temperature sensor 5, a temperature controller 6, and an ultrasonic generator. The device 7, the heating controller 8, and the mounting plate 9 are connected together. Among them, the proportional solenoid valve 1, the heater 3, the temperature sensor 5, the temperature controller 6, and the heating controller 8 are connected to form a temperature control mechanism.

[0015] The double-walled reaction liquid tank 2 is fixedly connected to the upper surface of the mounting plate 9 with screw fasten...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap