Microwave oven

A microwave and microwave technology, applied in the field of microwave ovens, can solve the problems of low temperature, uneven heat distribution, and inability to transmit heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

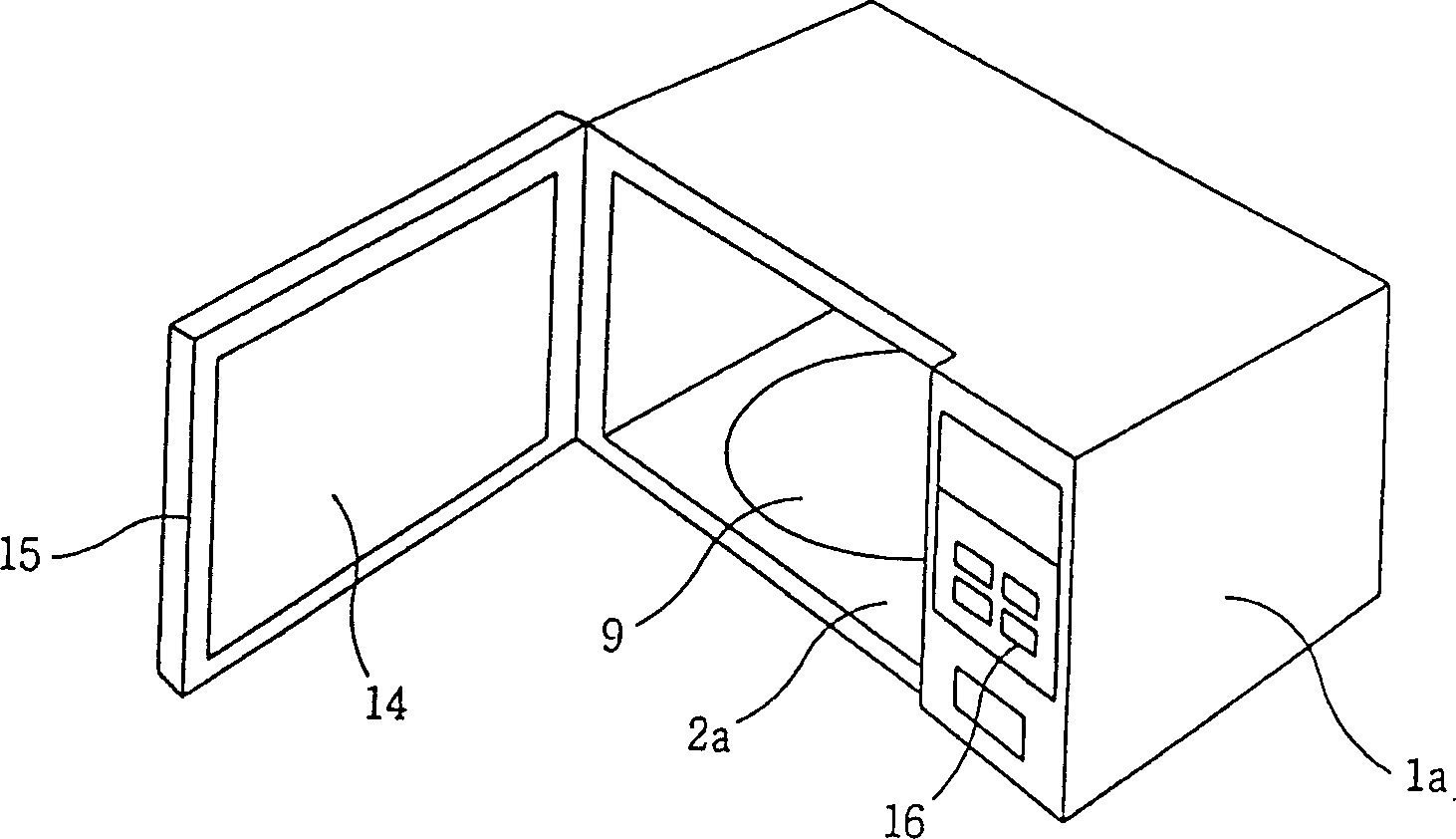

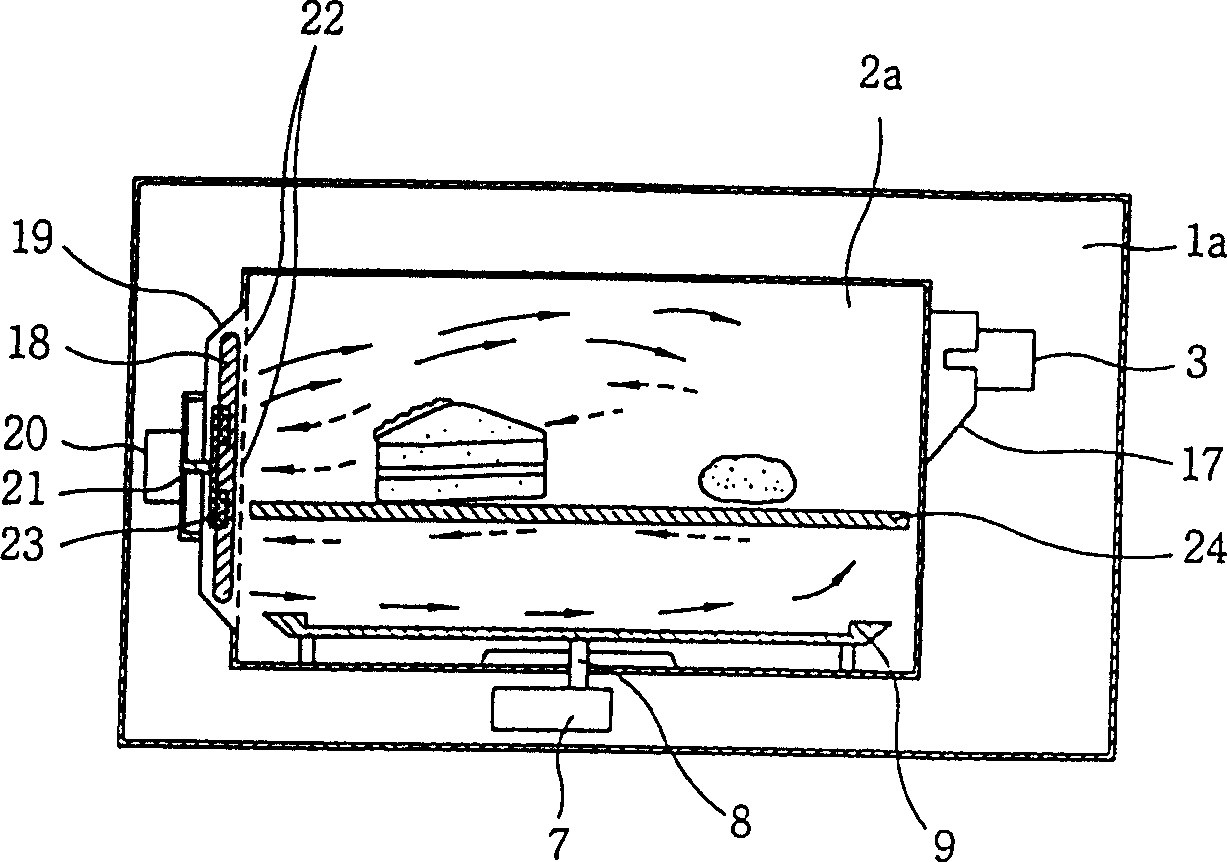

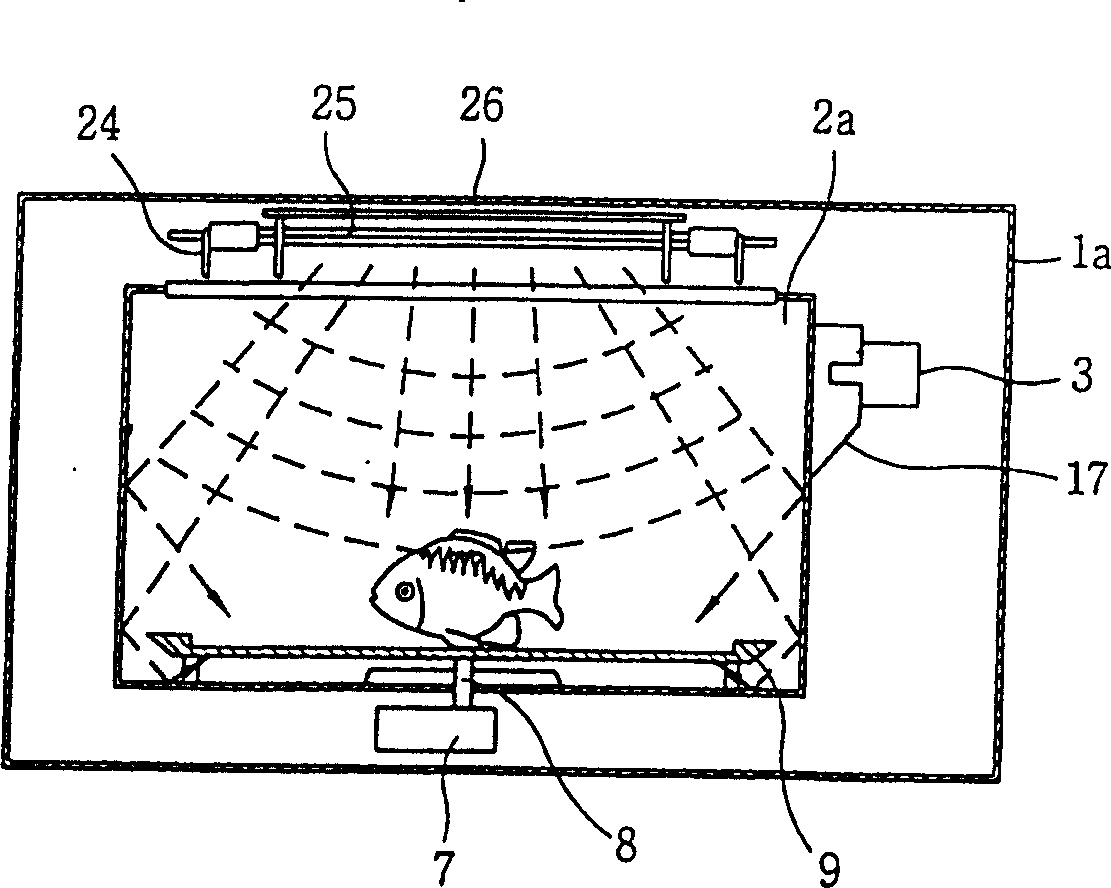

[0031] Preferred embodiments of the present invention are described in detail with reference to the accompanying drawings.

[0032] Such as Figure 4 with 7 As shown, the microwave oven of the present invention includes a cooking chamber 2 with a specific area for cooking food, a magnetron 3 installed outside the cooking chamber 2, a waveguide 4 with two-way flow channels 4a, 4b installed inside the waveguide 4 The microwave guide plate 5, and the plasma lamp 13 installed adjacent to the side of the flow channel of the waveguide 4.

[0033] A waveguide 4 having a rectangular or tubular shape is mounted on the side of the magnetron 3 to guide microwaves inside the cooking chamber 2, and has two-way flow passages 4a and 4b whose ends face the inner bottom surface of the cooking chamber 2 The other end of the circulation passage faces the plasma lamp installed on the inner top surface of the cooking chamber 2.

[0034] A baffle-shaped microwave guide plate 5 is hinged to the b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap