Monitor system with internal power supply

A monitoring system and monitored technology, applied in the field of monitoring systems, can solve the problems of reduced electromotive force, insufficient electromotive force for photocells, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

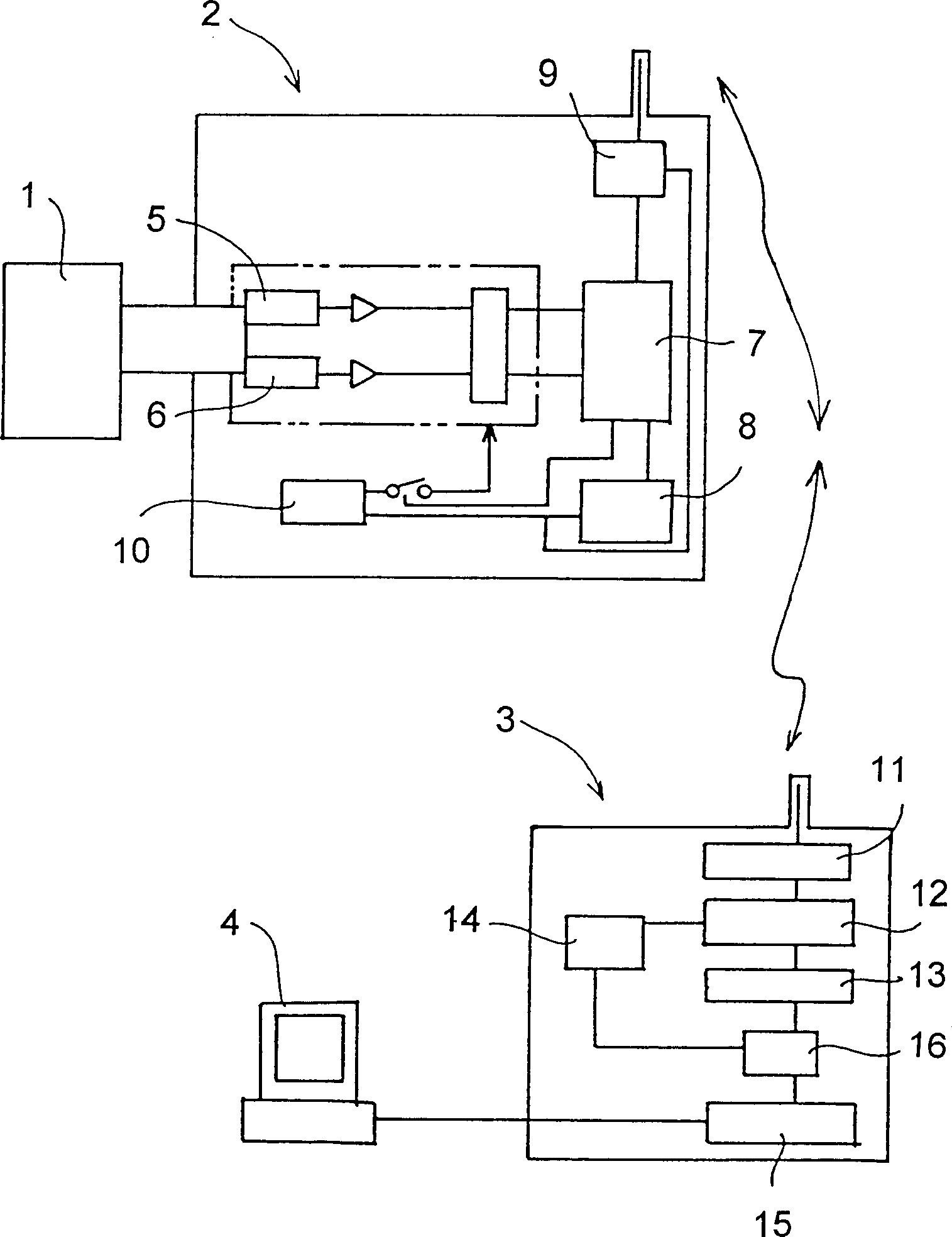

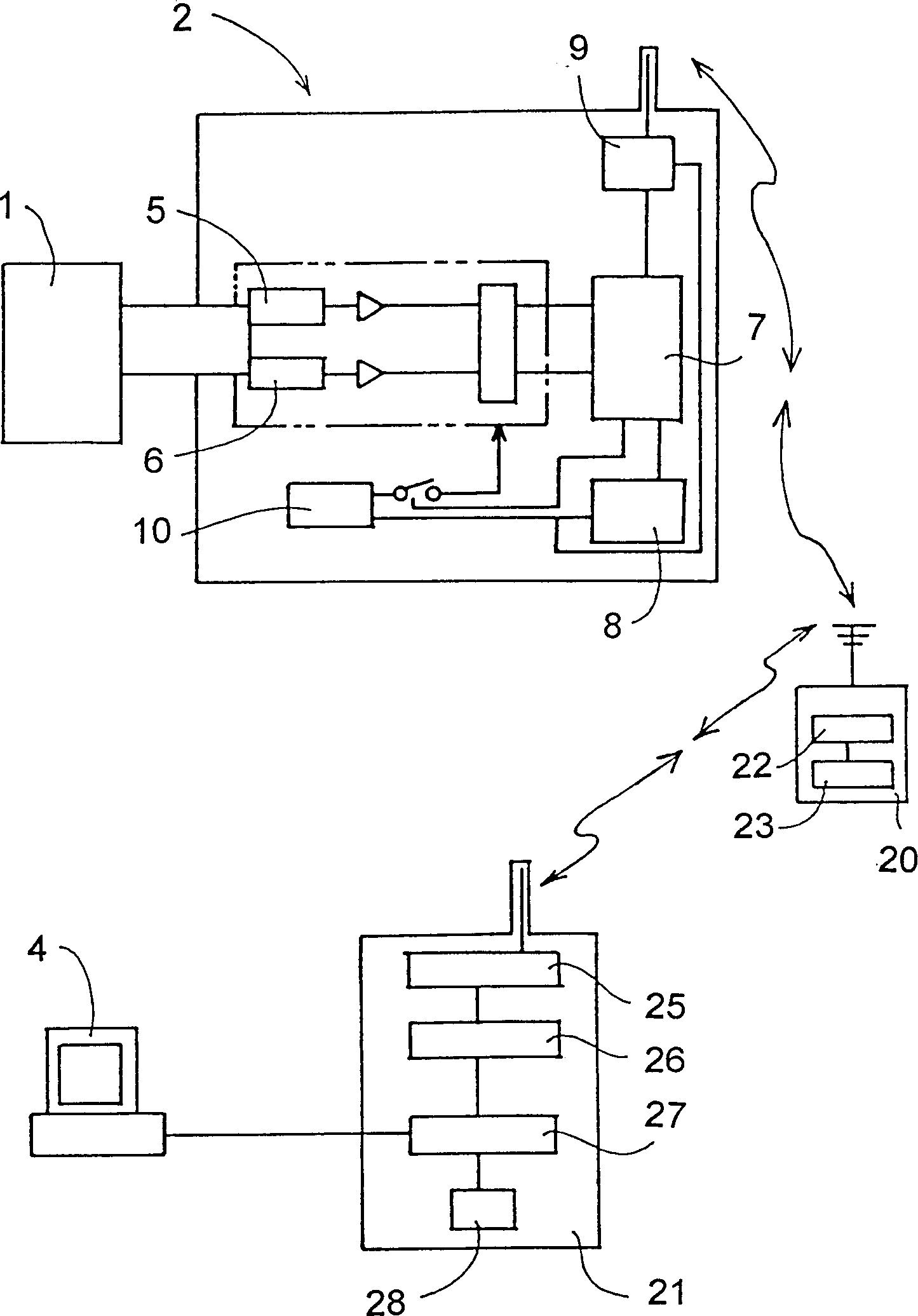

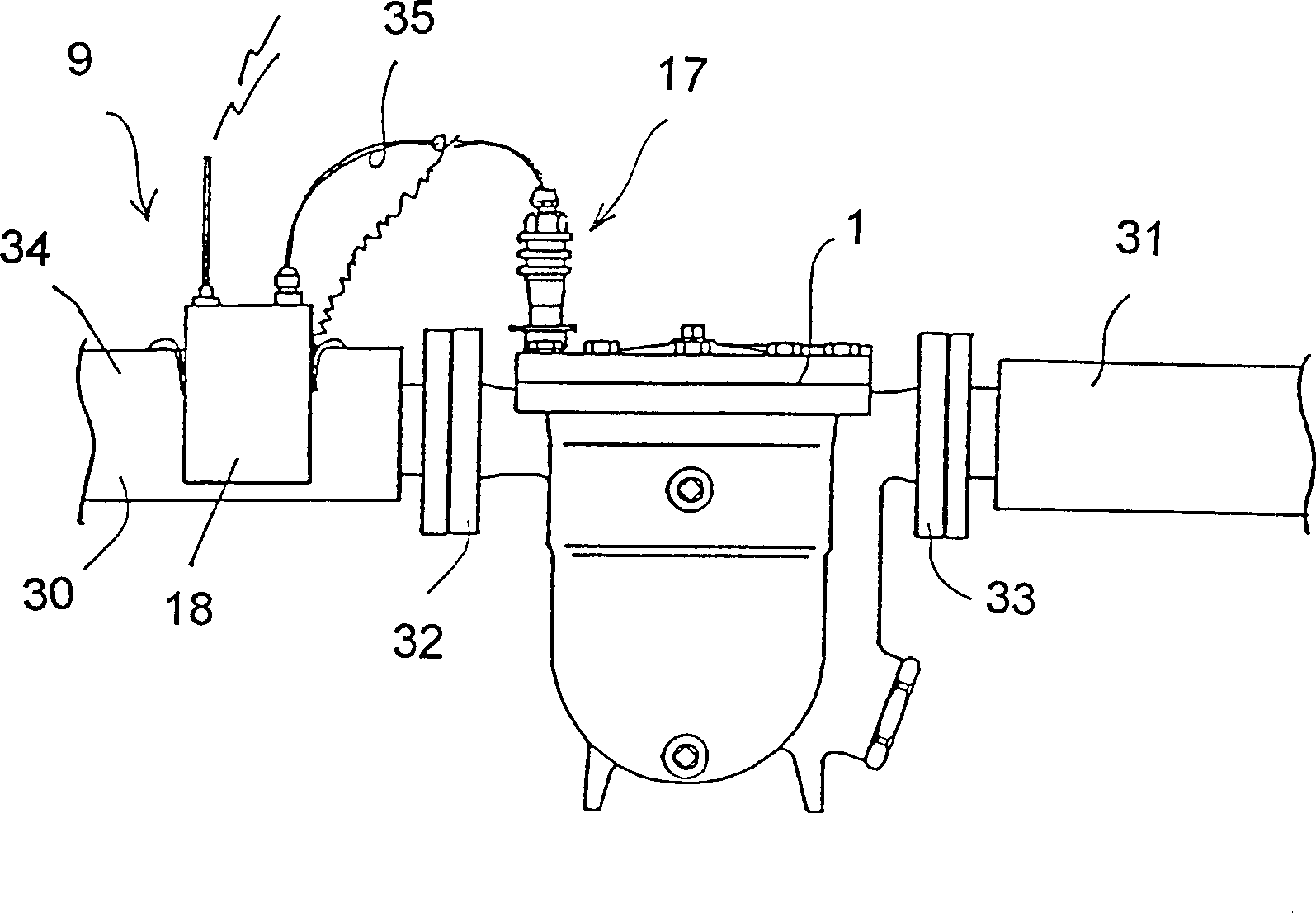

[0014] figure 1 The monitoring system shown, wherein the sensor unit 2 is directly connected to the monitored valve, separator (trap) 1, or similar parts, monitoring information is collected by a remote portable data recorder 3, detailed analysis of data, calculation operations and Display and storage etc. are performed by the computer 4 .

[0015] The installation method of the sensor unit 2 and the valve may be a fast connection, such as a screw connection, or a detachable connection through a joint. When the sensor unit 2 cannot be directly connected to the object to be monitored, the sensor unit 2 can be placed near the object to be monitored through a conversion component having a physical quantity corresponding to the object to be monitored. Of course, the sensor unit 2 can also be placed in the object to be monitored, such as a valve, separator 1 and so on.

[0016] Such as figure 1 The shown sensor unit 2 includes sensors 5 and 6 that can detect physical quantities,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com