Method for painting on parts of furniture

A technology for parts and furniture, which is applied in the field of furniture surface painting, can solve the problems of difficult surface thickness uniformity, many times of painting, and slow painting speed, so as to save raw materials, fast painting speed, and improve painting speed. speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Paint the surface of furniture according to the present invention, especially a part of a chair with a curved shape, the specific implementation method is as follows:

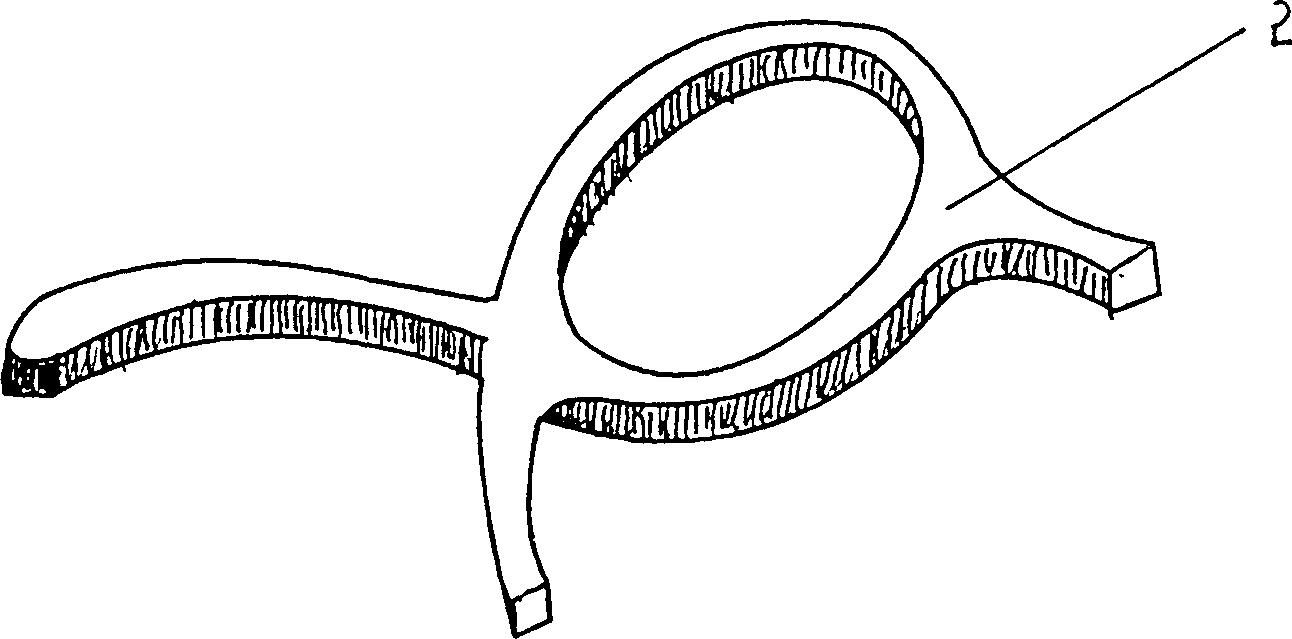

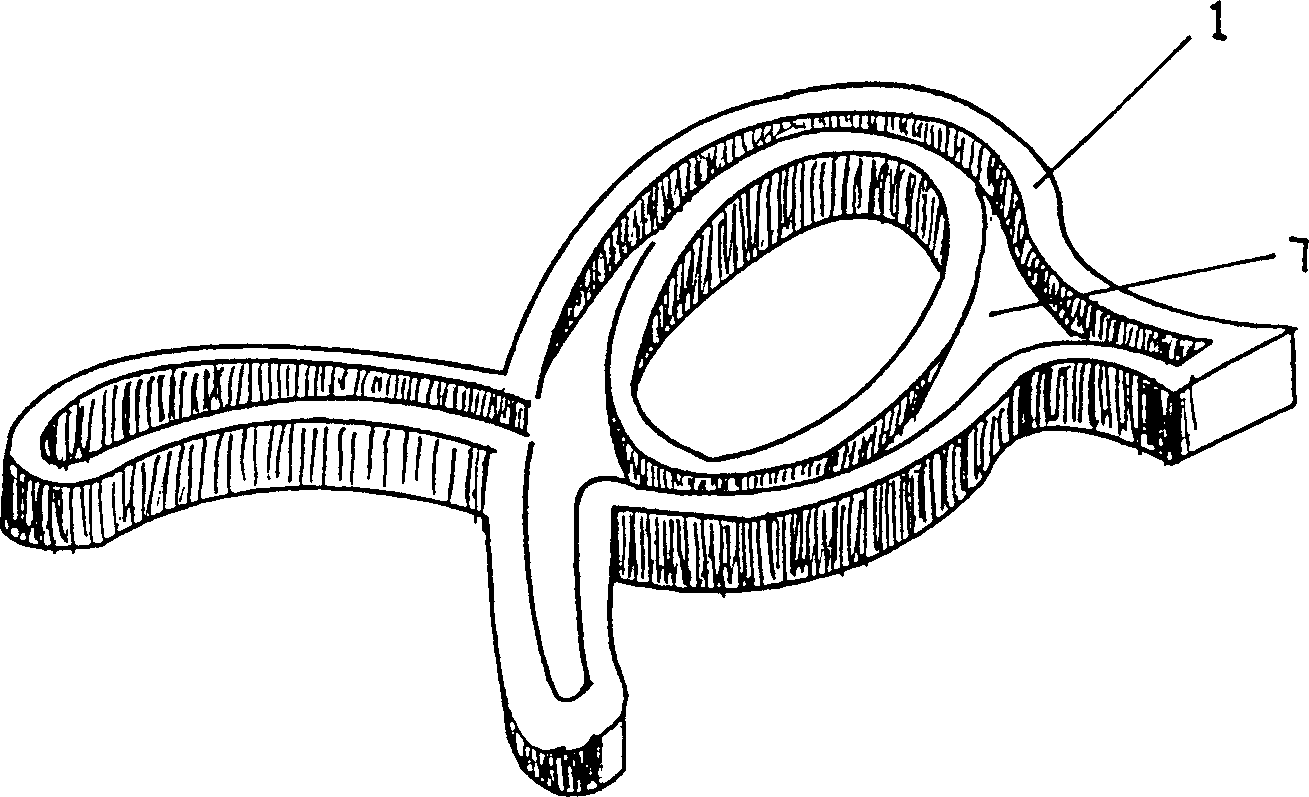

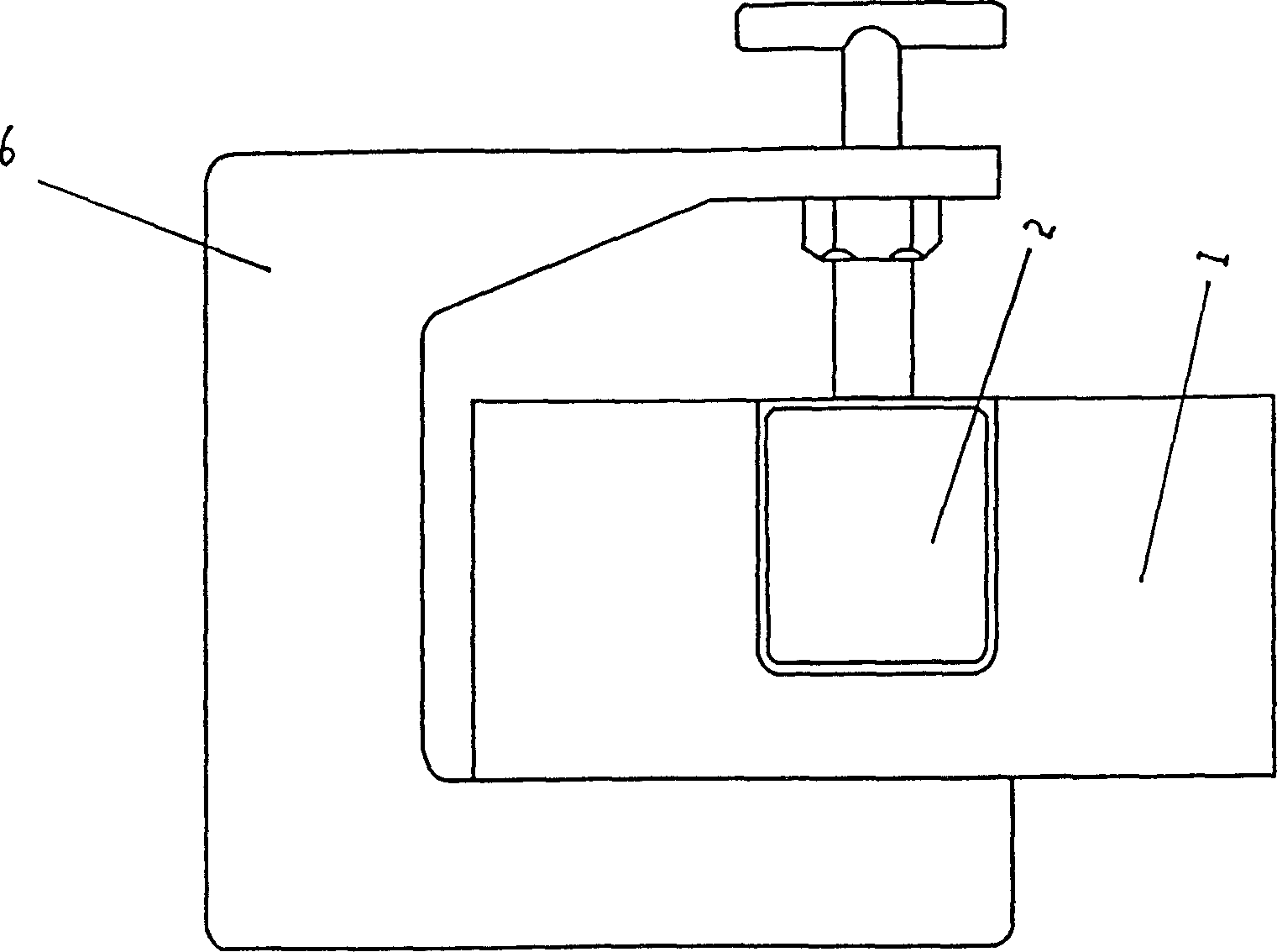

[0019] a. Make molds. As shown in Figure 1, a part 2 of furniture to be painted with a smooth and smooth surface after treatment, such as a curved chair foot, is used as a master mold to make the groove 7 of the mold 1 that meets the design requirements, and the groove 7 of the mold 1 The shape of the groove 7 is consistent with that of the furniture part 2 . Such as Figure 3A As shown, the bottom of the groove 7 is provided with at least one small hole 9, the diameter of the small hole 9 is slightly larger than the diameter of the screw rod 3, and the screw rod 3 protrudes from the bottom of the mold 1 through the small hole 9. Nut 8 is screwed on the screw rod 3, and it is fixed in the mold 1 and below the aperture 9. It divides the screw rod 3 into two parts, and the screw rod part above the nut 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com